Recovery processing device of scrap disposable drug sundries and processing method

A sanitary product, recycling technology, applied in the field of renewable resource recycling, can solve the problems of material waste, environmental pollution, low recycling rate, etc., and achieve the effects of reducing consumption and pollution, strong controllability and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

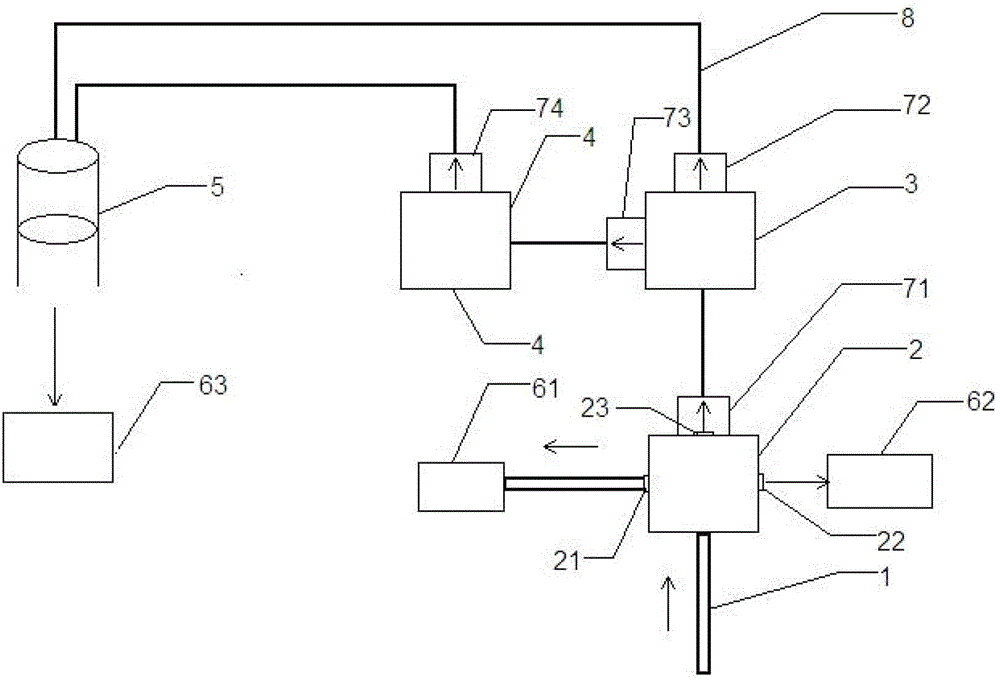

[0035] A recycling and processing device for discarded disposable sanitary products, including a crushing and separating machine, the crushing and separating machine includes a crushing mechanism and a separating mechanism, wherein:

[0036] The crushing mechanism includes a cylinder body, a main shaft connected to a power device located in the cylinder, and a blade connected to the main shaft; at least one of the cylinder body and the main shaft can rotate;

[0037] The separation mechanism includes a first-level screen and a second-level screen. The separation mechanism is provided with a first outlet and a second outlet. The first-level screen is located above the second-level screen, and the first outlet is located above the first-level screen. , the second outlet is located below the second-stage screen.

[0038] The device further includes at least one packing machine, which is used for packing the materials sent out from the first outlet and / or the second outlet of the ...

Embodiment 2

[0045] A recycling and processing device for discarded disposable sanitary products, including a crushing and separating machine, the crushing and separating machine includes a crushing mechanism and a separating mechanism, wherein:

[0046] The crushing mechanism includes a cylinder body, a main shaft connected to a power device located in the cylinder, and a blade connected to the main shaft; at least one of the cylinder body and the main shaft can rotate;

[0047] The separation mechanism includes a first-level screen and a second-level screen. The separation mechanism is provided with a first outlet and a second outlet. The first-level screen is located above the second-level screen, and the first outlet is located above the first-level screen. , the second outlet is located below the second-stage screen.

[0048] The device further includes at least one packing machine, which is used for packing the materials sent out from the first outlet and / or the second outlet of the ...

Embodiment 3

[0059] A recycling and processing device for discarded disposable sanitary products, including a crushing and separating machine, the crushing and separating machine includes a crushing mechanism and a separating mechanism, wherein:

[0060] The crushing mechanism includes a cylinder body, a main shaft connected to a power device located in the cylinder, and a blade connected to the main shaft; at least one of the cylinder body and the main shaft can rotate;

[0061] The separation mechanism includes a first-level screen and a second-level screen, and the separation mechanism is also provided with a first outlet 21, a second outlet 22, and a third outlet 23;

[0062] The first stage screen is located at the top of the second stage screen, the first outlet 21 is located above the first stage screen, the second outlet 22 is located below the second stage screen, and the third outlet 23 is located between the first stage screen and the second stage. between grade screens;

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com