Energy-converting attraction-type power system

A technology of power plant and powdery materials, applied in the directions of transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problems of low mixing ratio m, short conveying distance, low fan exhaust pressure, etc., to achieve convenient operation and maintenance, The effect of improved efficiency and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in more detail below in conjunction with the accompanying drawings and a preferred embodiment.

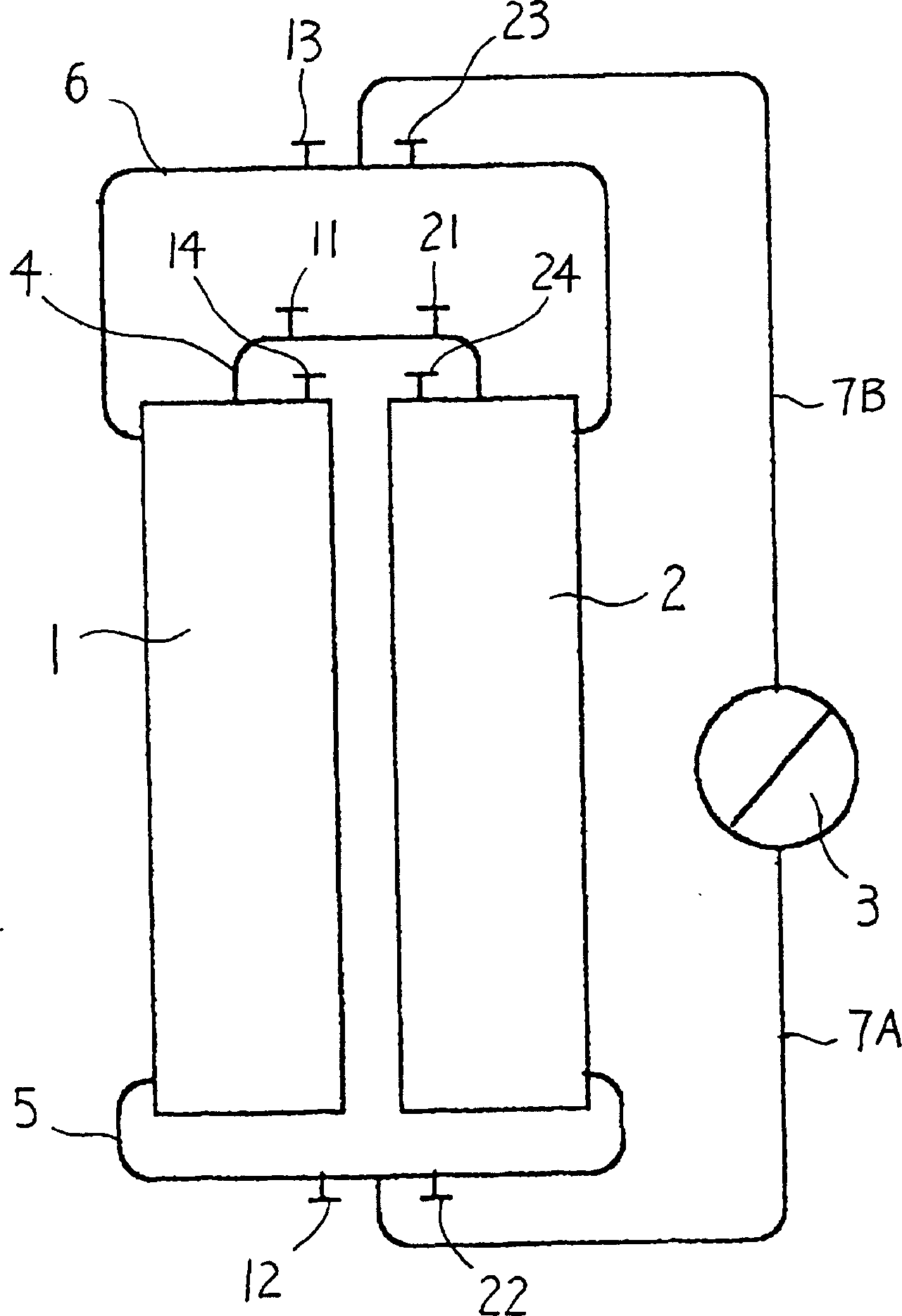

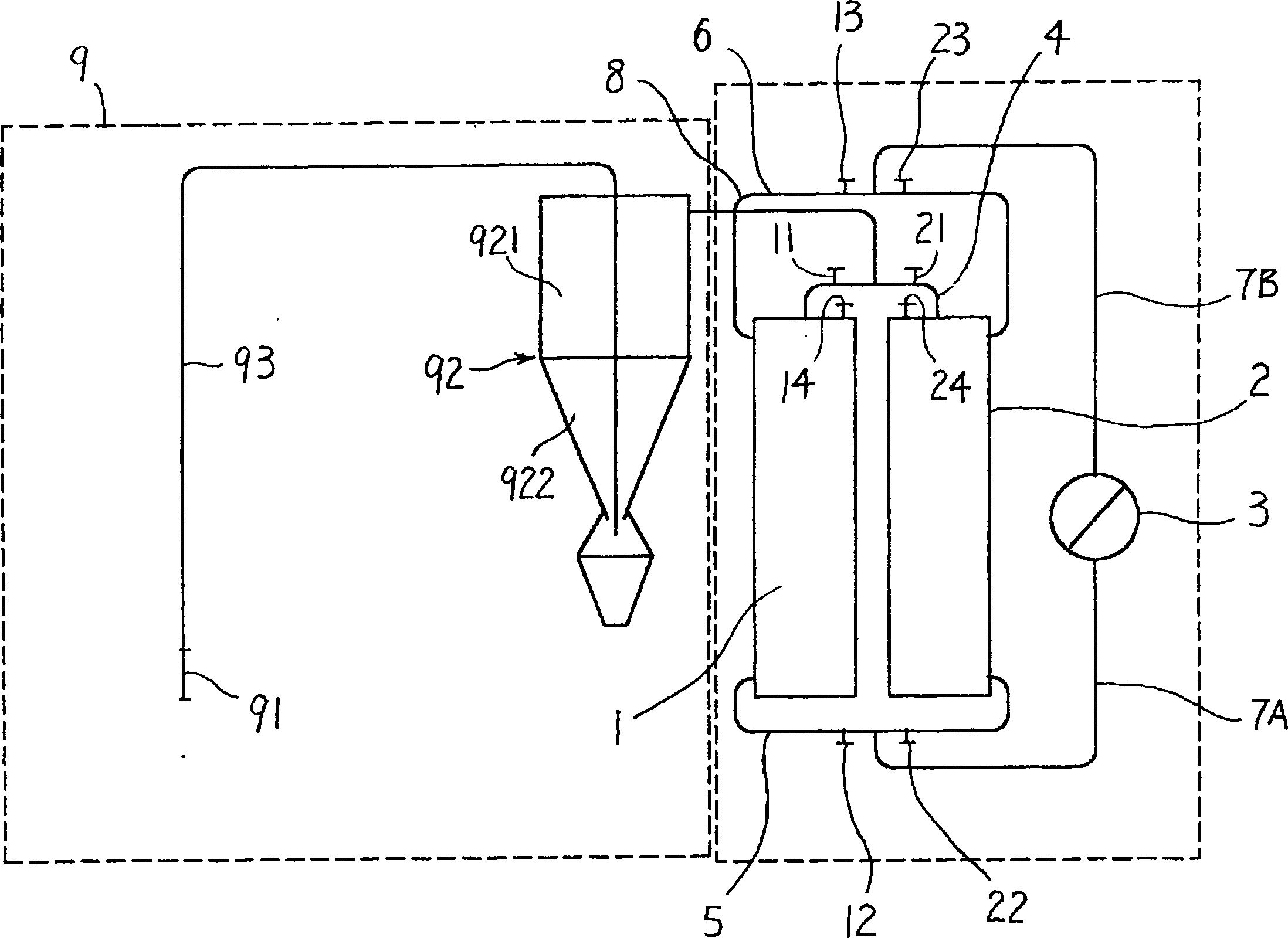

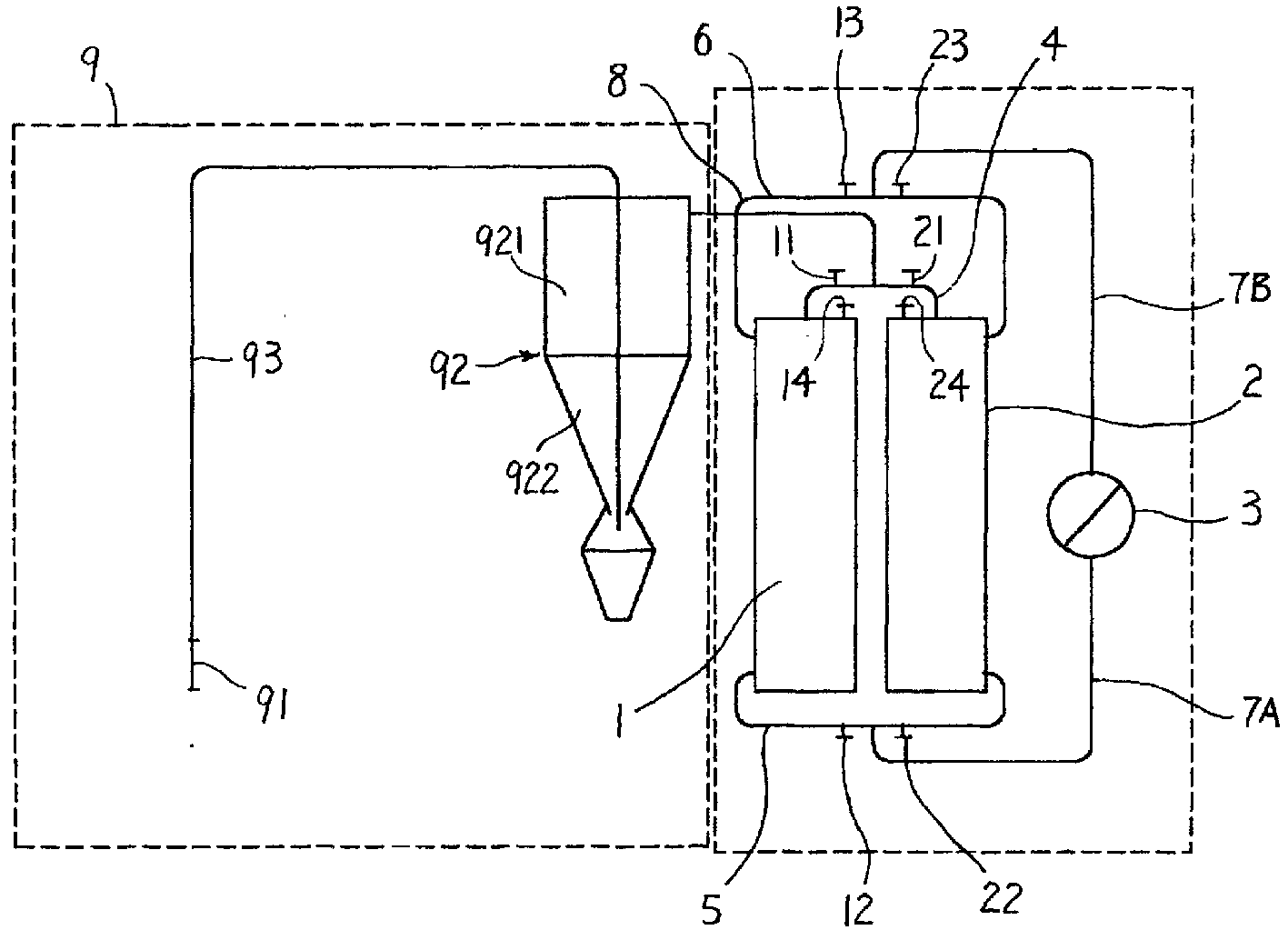

[0018] figure 1 Shows the basic structure of the energy-transfer suction power device of the present invention, as shown in the figure, the present invention is a kind of conversion of the liquid level energy by the work done by the liquid pump through the transduction tank without interruption, through this conversion to generate The negative pressure suction device required for conveying materials, the device includes two transduction tanks 1, 2 and a liquid pump 3, the two transduction tanks are closed cylinders made of metal, and the two transduction tanks pass through The pipelines 4, 5 and 6 are connected, and the liquid pump is connected with the two transducing tanks through the liquid inlet pipe 7A and the liquid outlet pipe 7B. Control valves 11 and 21 are installed on the connecting pipeline 4 of the two energy-transforming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com