Anaerobic treatment method of kitchen garbage

A kitchen waste and anaerobic treatment technology, applied in the direction of waste fuel, fermentation, etc., can solve the problems of complex sorting system, high energy consumption, large water consumption, etc., and achieve wide adaptability of project scale, unit equipment modules, The effect of short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1, anaerobic treatment of kitchen waste

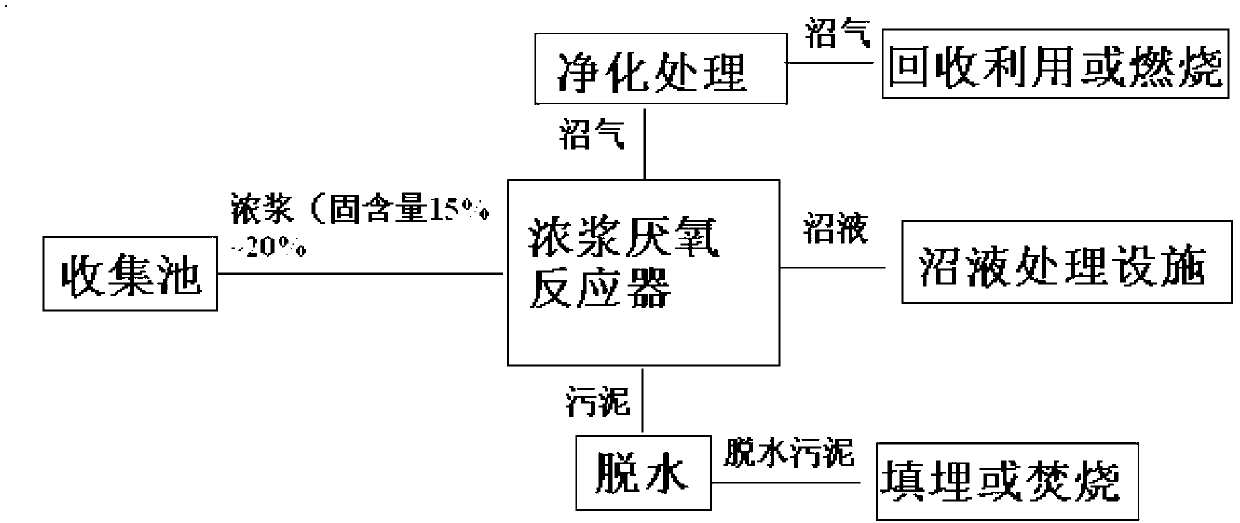

[0018] according to figure 1 Process shown in the flow chart.

[0019] (1) Adjust the water quality and quantity of the collected kitchen waste in the collection tank to obtain a thick slurry with a total solid content of 15%.

[0020] (2) Pump the thick slurry into the anaerobic reactor for anaerobic treatment. The temperature of the anaerobic treatment is controlled at 35°C for 20 days. This anaerobic treatment removes 79% of the organic matter in the thick slurry. Measure the change of COD before and after thick slurry treatment to detect its removal effect.

[0021] (3) Purify the biogas obtained from the anaerobic treatment in the previous step. The specific steps are to introduce the biogas into the dehydration and desulfurization device for purification treatment, and then it can be recycled or burned; the sludge obtained in the previous step is dehydrated. The specific steps are: In order to process the slu...

Embodiment 2

[0023] Embodiment 2, anaerobic treatment of kitchen waste

[0024] according to figure 1 Process shown in the flow chart.

[0025] (1) Adjust the water quality and quantity of the collected kitchen waste in the collection tank to obtain a thick slurry with a total solid content of 20%.

[0026] (2) Pump the thick slurry into the anaerobic reactor for anaerobic treatment. The temperature of the anaerobic treatment is controlled at 60°C for 15 days. This anaerobic treatment removes 82% of the organic matter in the thick slurry. Measure the change of COD before and after thick slurry treatment to detect its removal effect.

[0027] (3) Purify the biogas obtained from the anaerobic treatment in the previous step. The specific steps are to introduce the biogas into the dehydration and desulfurization device for purification treatment, and then it can be recycled or burned; the sludge obtained in the previous step is dehydrated. The specific steps are: In order to process the slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com