Flotation reagent for high-calcium-magnesium vanadium titano-magnetite and method for preparing chlorinated titanium-rich material from high-calcium-magnesium vanadium titano-magnetite

A flotation agent, magnesium vanadium titanium technology, applied in flotation, process efficiency improvement, grain treatment, etc., can solve the problems of limited quantity of chlorinated titanium-rich materials, difficult to handle by-product mother liquor, long process route, etc., to achieve Ease of industrialization, strong adaptability of raw materials, and the effect of improving comprehensive yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

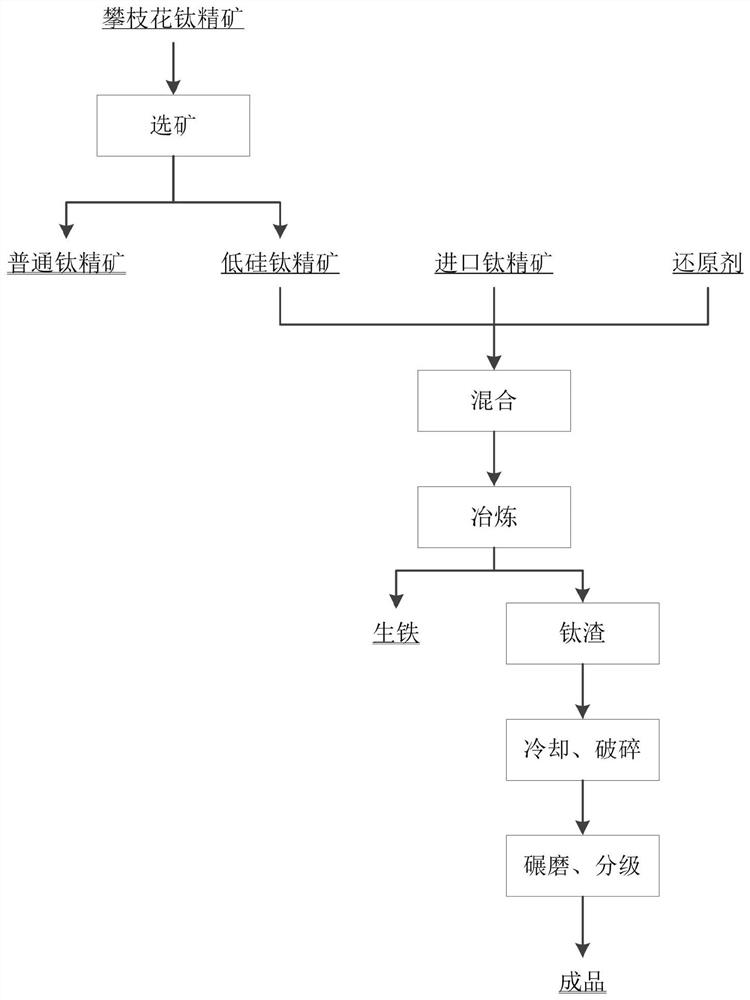

Image

Examples

Embodiment 1

[0039] Producing titanium chloride rich material according to the following method:

[0040] (1) For a Panxi high silicon calcium magnesium titanium concentrate (TiO 2 : 46.51%, SiO 2 : 2.58%, CaO: 2.27%, MgO: 3.75%) for ball milling to fully dissociate ilmenite and gangue, and then adjust the pulp concentration after grinding according to the ratio of mineral water mass ratio to 1:6;

[0041] (2) Adding high-calcium magnesium vanadium-titanium magnetite flotation agent to the ore pulp and carrying out flotation for 4 times to obtain titanium concentrate; 2 SO 4 , the inhibitor is composed according to the mass ratio of 10:30:3:12, wherein the compound agent is composed of synthetic dodecylamine, taric acid, and mixed amines according to the mass ratio of 80:10:10; the inhibitor is composed of water Glass and malonic acid are composed according to the mass ratio of 1:1. Titanium concentrate (TiO 2 : 48.19%, SiO 2 : 0.66%, CaO: 0.23%, MgO: 1.75%) yield rate is 43.5%, and ...

Embodiment 2

[0048]Producing titanium chloride rich material according to the following method:

[0049] (1) For a Panxi high silicon calcium magnesium titanium concentrate (TiO 2 : 46.51%, SiO 2 : 2.58%, CaO: 2.27%, MgO: 3.75%) for ball milling to fully dissociate ilmenite and gangue, and then adjust the pulp concentration after grinding according to the ratio of mineral water mass ratio to 1:6;

[0050] (2) Adding high-calcium magnesium vanadium-titanium magnetite flotation agent to the ore pulp and carrying out flotation for 4 times to obtain titanium concentrate; 2 SO 4 , the inhibitor is composed according to the mass ratio of 10:20:5:13, wherein the composite agent is composed of synthetic dodecylamine, taric acid, and mixed amines according to the mass ratio of 80:10:10; the inhibitor is composed of water Glass and malonic acid are composed according to the mass ratio of 1:2. Titanium concentrate (TiO 2 : 48.19%, SiO 2 : 0.66%, CaO: 0.23%, MgO: 1.75%) yield rate is 43.5%, and ...

Embodiment 3

[0057] Producing titanium chloride rich material according to the following method:

[0058] (1) For a Panxi high silicon calcium magnesium titanium concentrate (TiO 2 : 46.51%, SiO 2 : 2.58%, CaO: 2.27%, MgO: 3.75%) for ball milling to fully dissociate ilmenite and gangue, and then adjust the pulp concentration after grinding according to the ratio of mineral water mass ratio to 1:6;

[0059] (2) Adding high-calcium magnesium vanadium-titanium magnetite flotation agent to the ore pulp and carrying out flotation for 4 times to obtain titanium concentrate; 2 SO 4 , the inhibitor is composed according to the mass ratio of 10:16:3:10, wherein the compound agent is composed of synthetic dodecylamine, taric acid, and mixed amines according to the mass ratio of 80:10:10; the inhibitor is composed of water Glass and malonic acid are composed according to the mass ratio of 1:1.3. Titanium concentrate (TiO 2 : 48.19%, SiO 2 : 0.66%, CaO: 0.23%, MgO: 1.75%) yield rate is 43.5%, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com