Method for lowering consumption of tundish covering agent

A covering agent and tundish technology, applied in the field of metallurgy, can solve the problems of large consumption of covering agent, high manufacturing cost, crusting, etc., and achieve the effect of avoiding the problem of slag inclusion in billets, preventing crusting, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

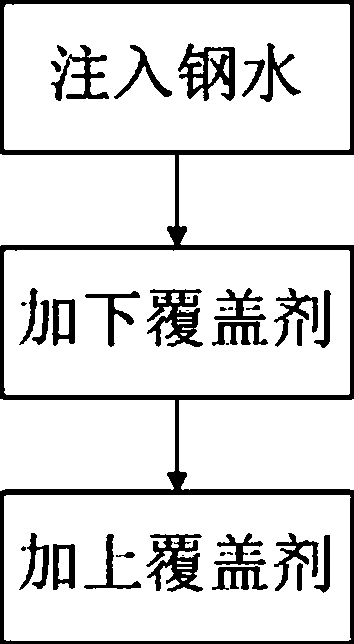

Image

Examples

Embodiment 1

[0037] Embodiment 1: Inject molten steel into the tundish. After the liquid level of the molten steel is greater than 400 mm, add the lower covering agent to the tundish for the first time, and the addition amount is 250 kg; Add the lower covering agent in an amount of 100kg, so that the lower covering agent is evenly dispersed on the molten steel surface; add carbonized rice husks on the surface of the lower covering agent, the addition amount is 120kg, and the carbonized rice husks are evenly dispersed on the surface of the lower covering agent. The amount of carbonized rice husk added is 25% of the total covering agent. Comparing the control elements in the refined outbound molten steel and the molten steel after continuous casting, as shown in Table 2, the control amounts of carbon and silicon meet the standards of H08A steel, and the amount of carbon added is less than 0.01%. Crusts appeared around the rod. The lower covering agent effectively prevents the carbonized ric...

Embodiment 2

[0040]Embodiment 2: Inject molten steel into the tundish. After the liquid level of the molten steel is greater than 400mm, add the lower covering agent to the tundish for the first time, and the addition amount is 270kg; Add the lower covering agent in an amount of 120kg, so that the lower covering agent is evenly dispersed on the molten steel surface; add carbonized rice husks on the surface of the lower covering agent, the addition amount is 170kg, and the carbonized rice husk is evenly dispersed on the surface of the lower covering agent. The amount of carbonized rice husk added is 30% of the total covering agent. Comparing the control elements in the refined outbound molten steel and the continuous casting molten steel, as shown in Table 3, the control amounts of carbon and silicon are in line with the standard of H08A steel, and the amount of carbon added is less than 0.01%. There is no encrustation phenomenon around. The lower covering agent effectively prevents the ca...

Embodiment 3

[0043] Embodiment 3: Inject molten steel into the tundish. After the liquid level of the molten steel is greater than 400 mm, add the lower covering agent to the tundish for the first time, and the addition amount is 290 kg; Add the lower covering agent in an amount of 140kg, so that the lower covering agent is evenly dispersed on the molten steel surface; add carbonized rice husks on the surface of the lower covering agent, the addition amount is 190kg, and the carbonized rice husks are evenly dispersed on the surface of the lower covering agent. The amount of carbonized rice husk added is 30% of the total covering agent. Comparing the control elements in the refined outbound molten steel and the molten steel after continuous casting, as shown in Table 4, the controlled amounts of carbon and silicon meet the standards of H08A steel, and the amount of carbon added is less than 0.01%. There is no encrustation phenomenon around. The lower covering agent effectively prevents the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com