B column on vehicle and manufacturing method

A manufacturing method and B-pillar technology, applied to vehicle components, upper structure, upper structure sub-assembly, etc., can solve the problems of unsuitable control of welding quality, large number of welding fixtures, and inconformity with the trend of lightweight, etc., to achieve The effect of light weight, uniform load, and easy springback of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings.

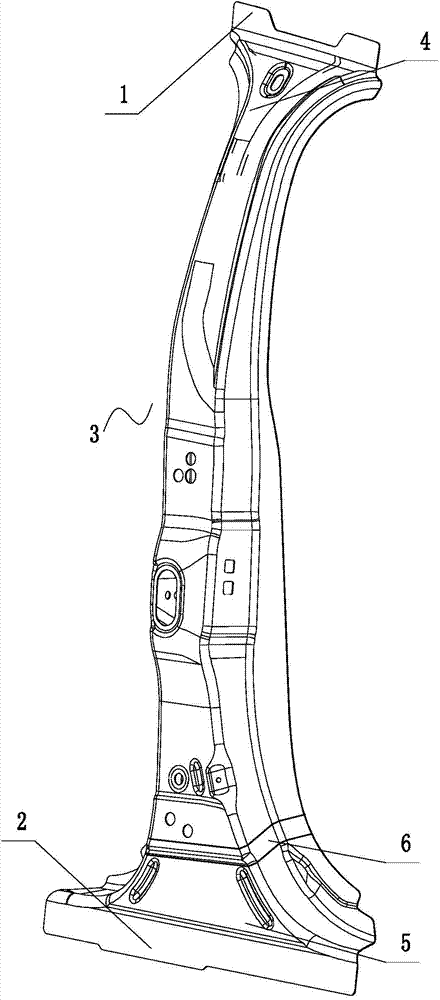

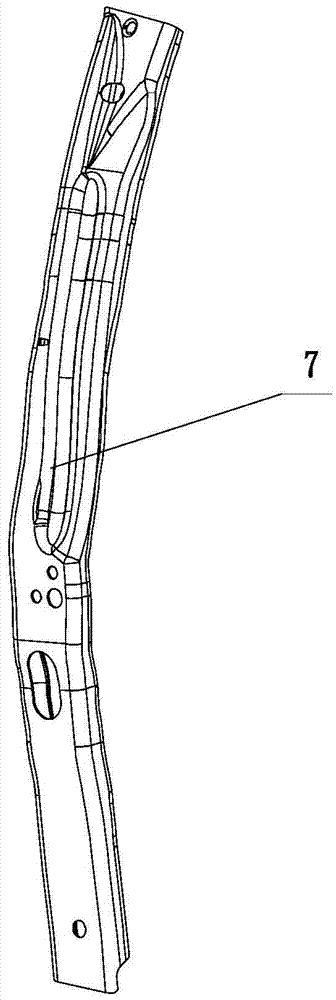

[0019] Such as Figure 1 ~ Figure 2 As shown: the B-pillar on the vehicle includes an upper fixing part 1, a lower fixing part 2, a B-pillar main body 3, a hard area part 4, a soft area part 5, a transition area 6, a reinforcing pipe 7 and the like.

[0020] Such as figure 1 , figure 2 As shown, the present invention includes a B-pillar main body 3, the top of the B-pillar main body 3 is an upper fixing part 1 fixed to the roof, and the bottom of the B-pillar main body 3 is a lower fixing part 2 fixed to the door sill; the upper part of the B-pillar main body 3 It is the hard zone part 4, the lower part is the soft zone part 5, the transition zone 6 is between the hard zone part 4 and the soft zone part 5, and the reinforcing pipe 7 is set in the hard zone part 4; the hard zone part 4 is made of ultra-high strength steel The martensitic structure with a strength of 1300-15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com