Construction method of fabricated light steel structure composite outer wall plate

A technology of composite exterior wall panels and light steel structures, applied to walls, building components, building structures, etc., can solve problems such as heavy weight and inconvenient hoisting construction, increase strength and shear resistance, increase support capacity, and structure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: A construction method for an assembled light steel structure composite exterior wall panel, comprising the following steps:

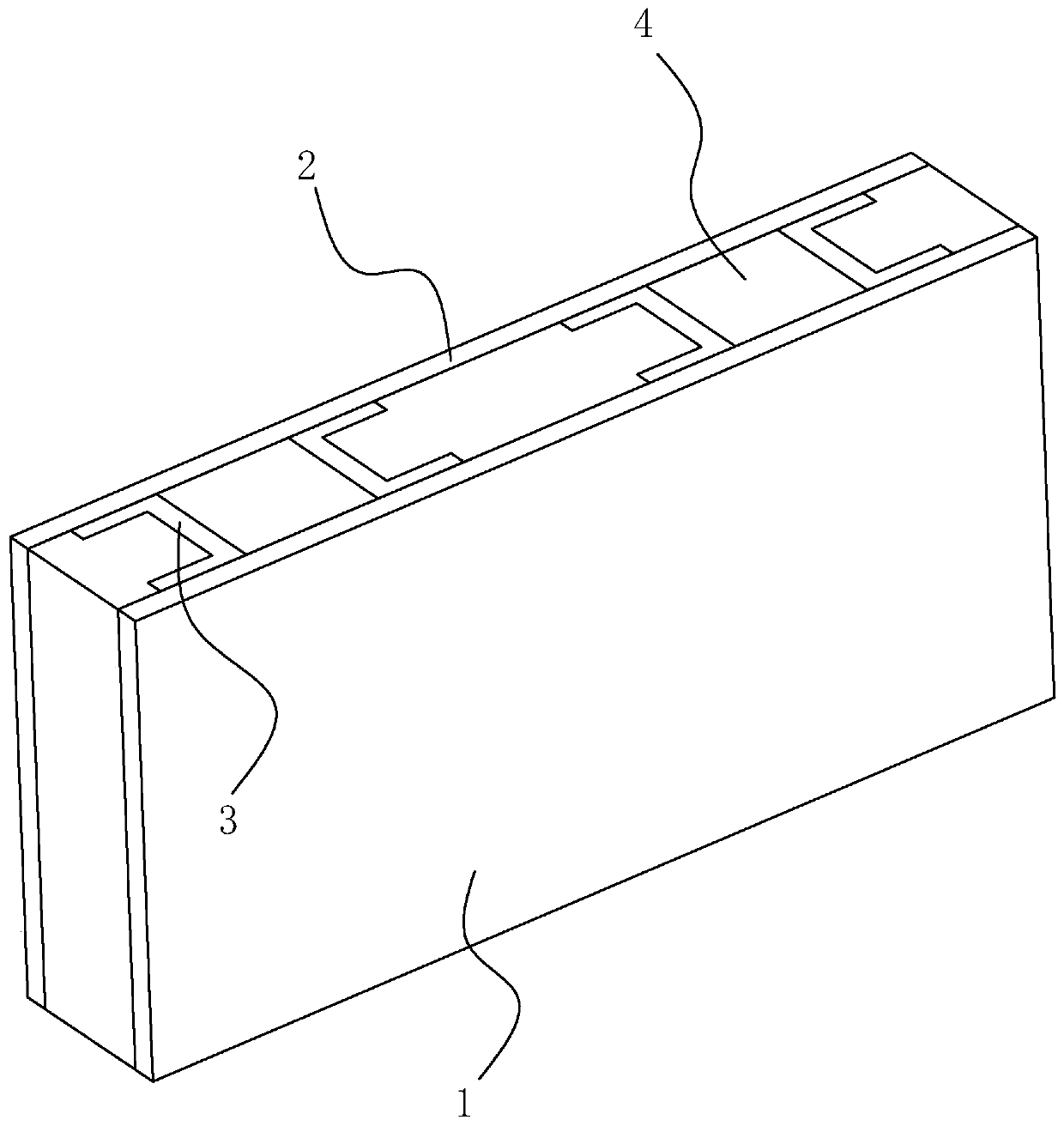

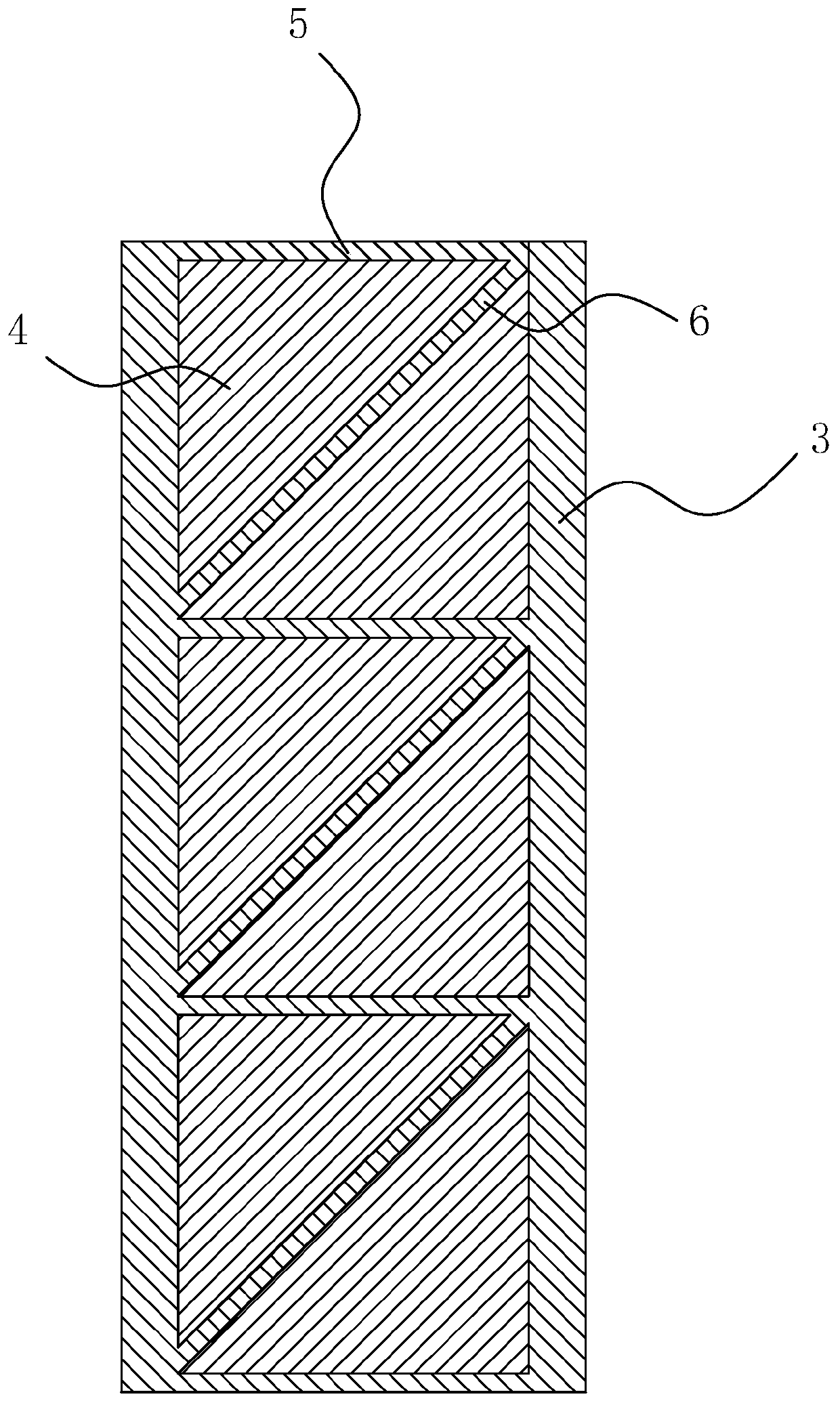

[0035] a. Wall structure design: for wall structure design, see attached figure 1 And attached figure 2 , the wall structure includes an outer leaf wall 1, an inner leaf wall 2, several C-shaped steels 3 arranged between the outer leaf wall 1 and the inner leaf wall 2, and an insulation layer 4 filled between the outer leaf wall 1 and the inner leaf wall 2; The outer leaf wall 1 is a reinforced concrete structure and the side of the outer leaf wall 1 facing away from the inner leaf wall 2 is provided with an interior decoration layer. In this embodiment, the interior decoration layer adopts facing bricks; the inner leaf wall 2 adopts high-strength gypsum board; C-shaped steel 3 points There are several groups, each group includes two C-shaped steels 3, the openings of the two C-shaped steels 3 in the same group are facing away fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com