Gas powered gun and a pressure tube for a gas powered gun

a gas powered gun and pressure tube technology, applied in the field of gas powered guns, can solve the problems of time-consuming, and achieve the effect of weak biasing of the member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057]Embodiments of the present disclosure will be described in more detail in the following with reference to the accompanying drawings.

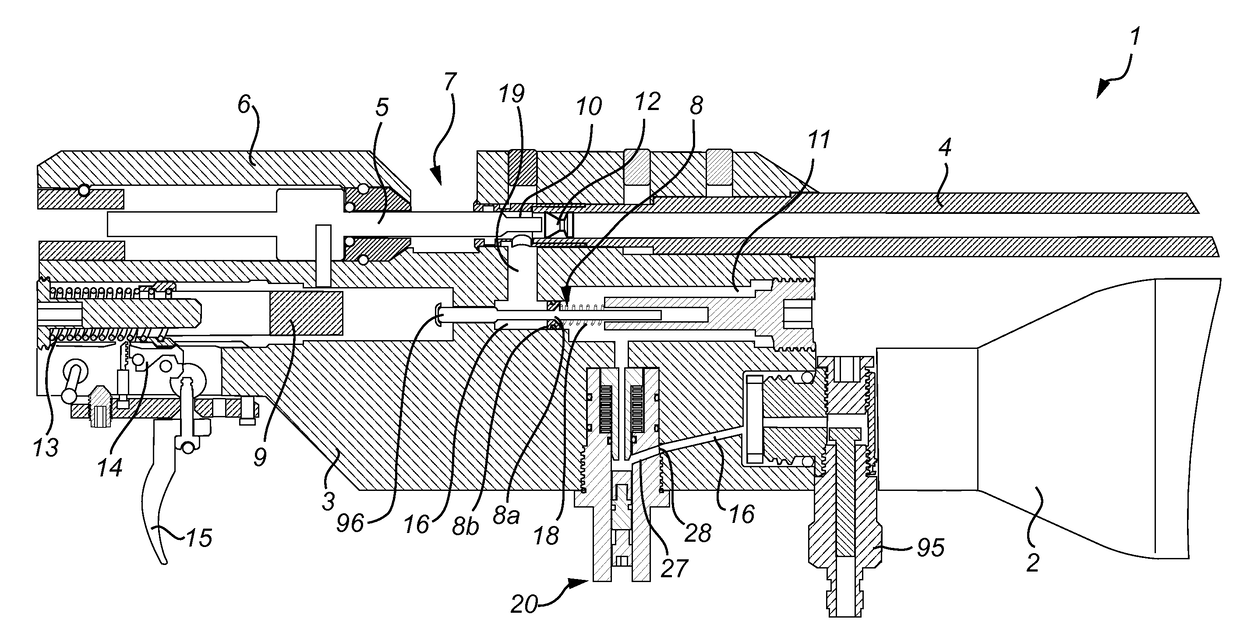

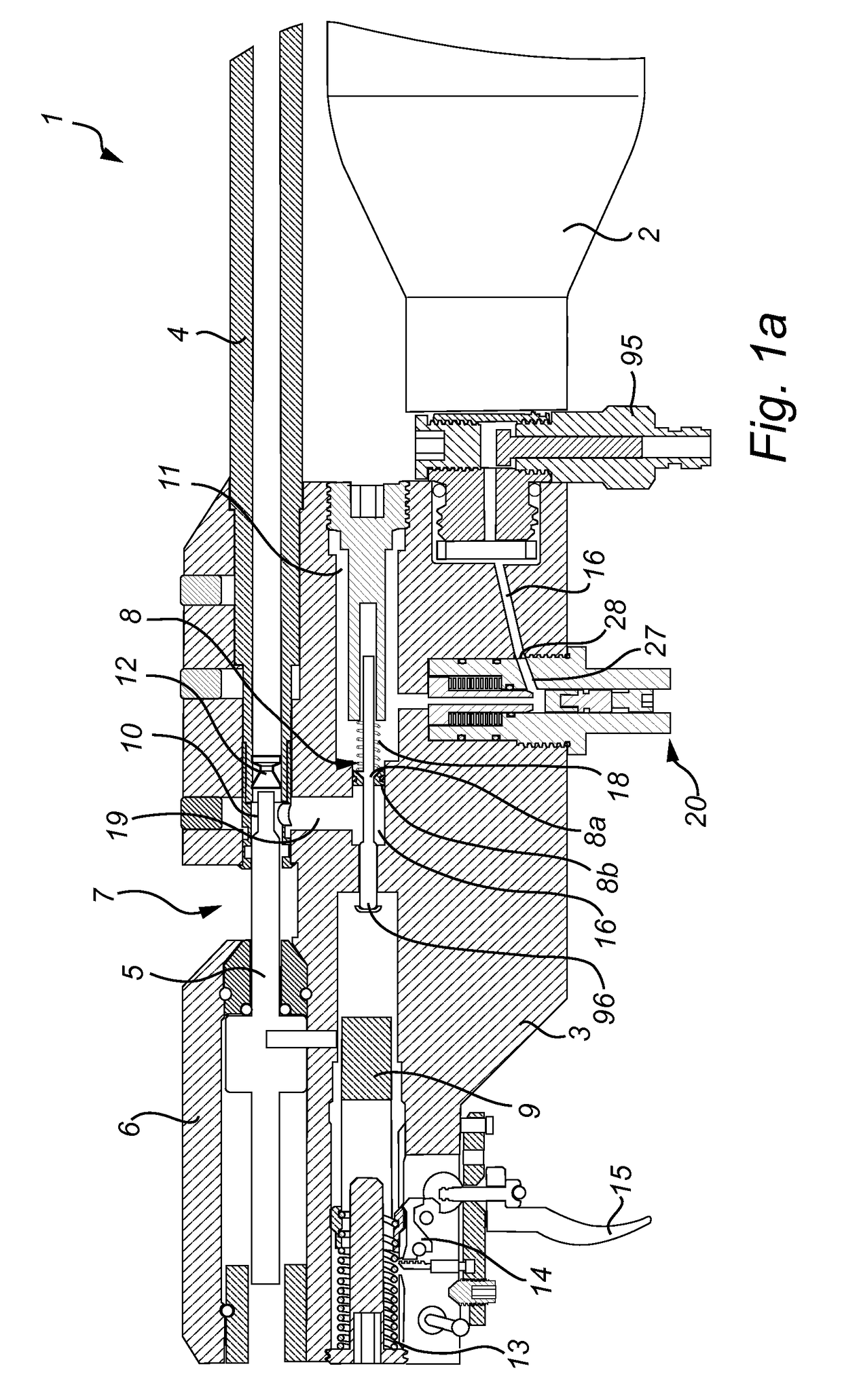

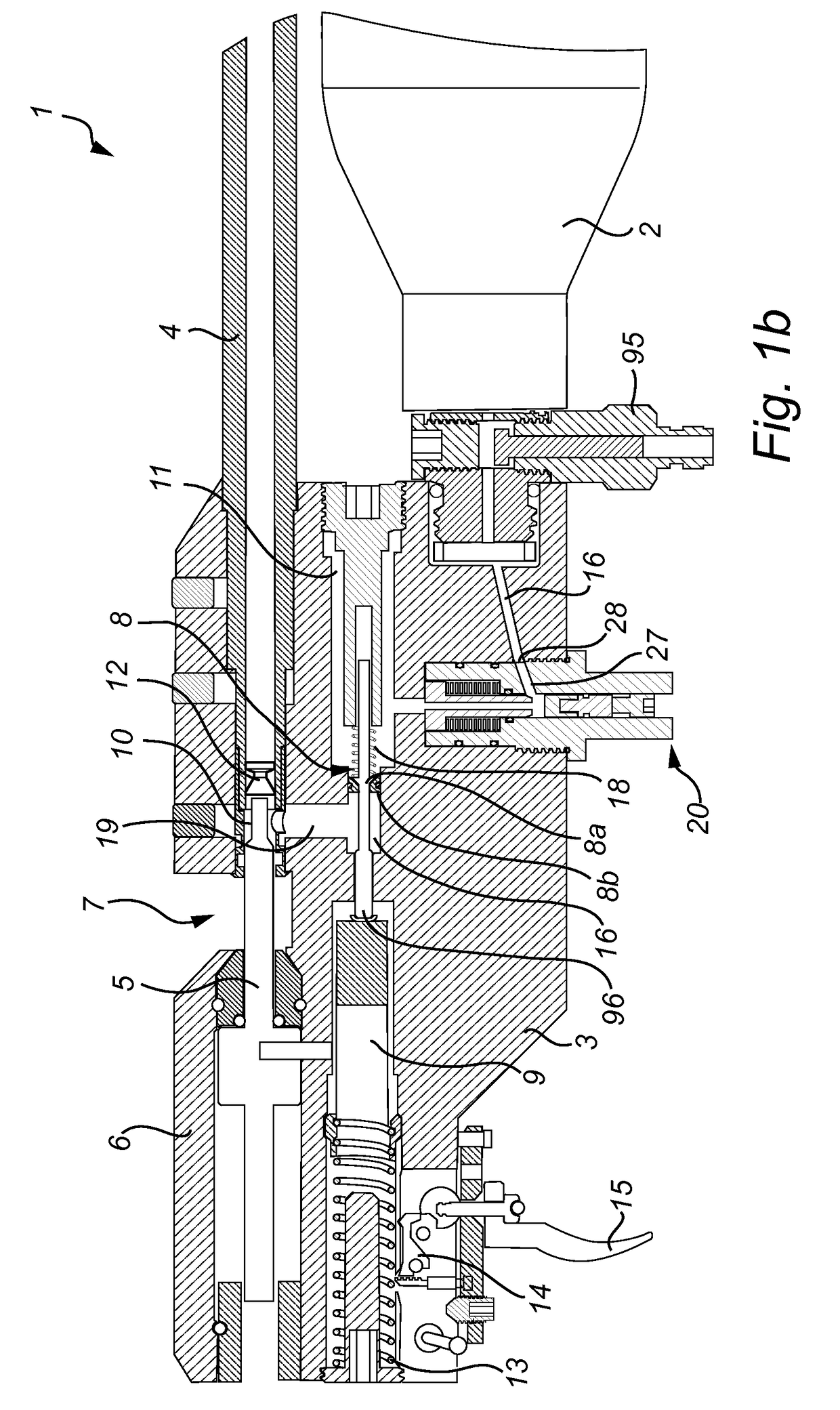

[0058]FIGS. 1a and 1b shows a gas powered gun 1. The gun 1 is of the kind where a bottle 2 of compressed air or other gas is fitted to the body 3 of the gun 1. The compressed gas is fed to a pressure chamber 11 and when the trigger 15 of the gun 1 is pulled, the compressed air is forwarded to a space 10 behind a bullet 12 which fires the bullet 12. In more detail, the bottle 2 is connected to the gun 1 at the front. A connector 95 is arranged between the bottle 2 and the gun 1 and it is used to fill the bottle 2 with gas. The gun 1 also comprises a gas regulator 20. A passage 16 in the gun body 3 forwards the gas from the bottle 2 into the regulator 20, which regulates the gas pressure in the pressure chamber 11. The gun 1 further comprises a barrel 4, and a feeder pin 5 slidably arranged in a housing 6 behind the barrel 4. In a space between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com