Acrylamide/nano cellulose composite gel and preparation method thereof

A technology of nanocellulose and acrylamide, applied in the field of acrylamide/nanocellulose composite gel and its preparation, can solve the problems of reservoir damage, high construction cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1, the preparation of acrylamide / nanocellulose composite gel

[0043] Due to the low solid content of nanocellulose, the nanocellulose is first processed by a high-speed centrifuge to increase its solid content to 6%, and then the treated nanocellulose is mixed with deionized water evenly, and then ultrasonically oscillated for 20 minutes , then add acrylamide to the above suspension and continue stirring for 2h, then add 0.5% (mass fraction) of N,N-methylenebisacrylamide and 0.5% (mass fraction) of potassium persulfate to the previous solution in sequence Stirring was continued for 30 min. The cross-linking system was gelled at a constant temperature of 70° C. for 3 hours to obtain a polymer composite gel.

[0044] The specific formulation of the prepared composite gel is shown in Table 2.

[0045] Table 2 Acrylamide / nanocellulose composite gel formula

[0046]

Embodiment 2

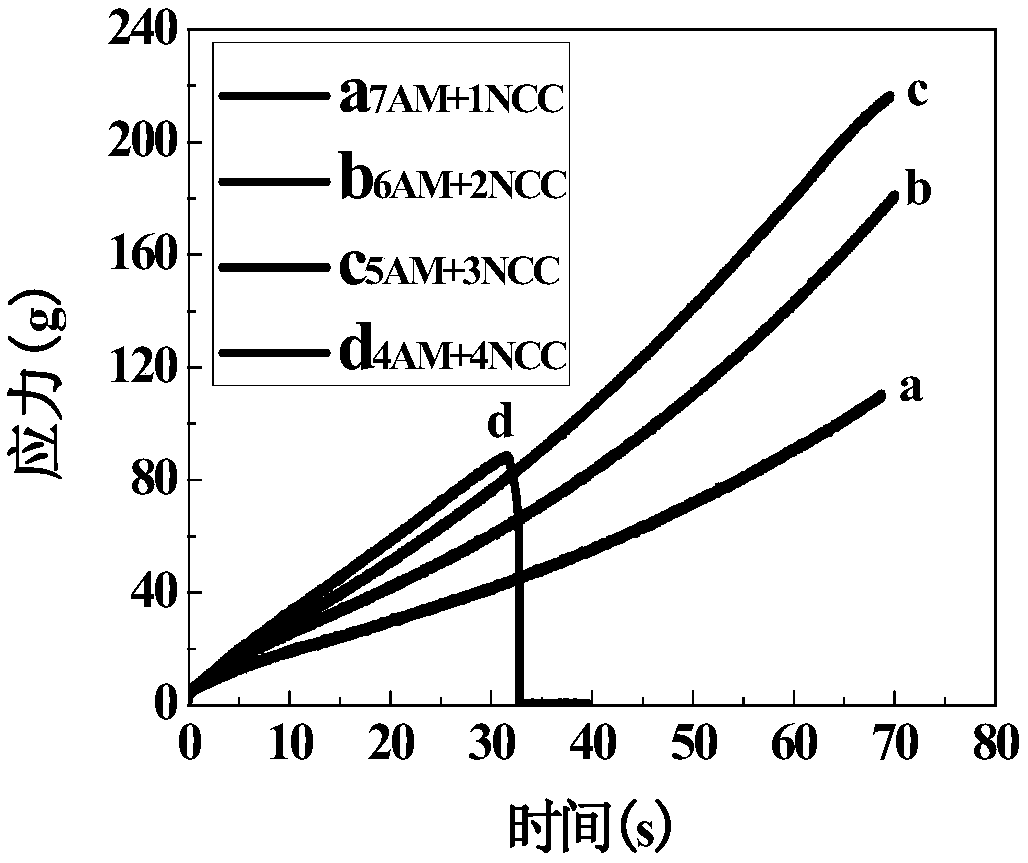

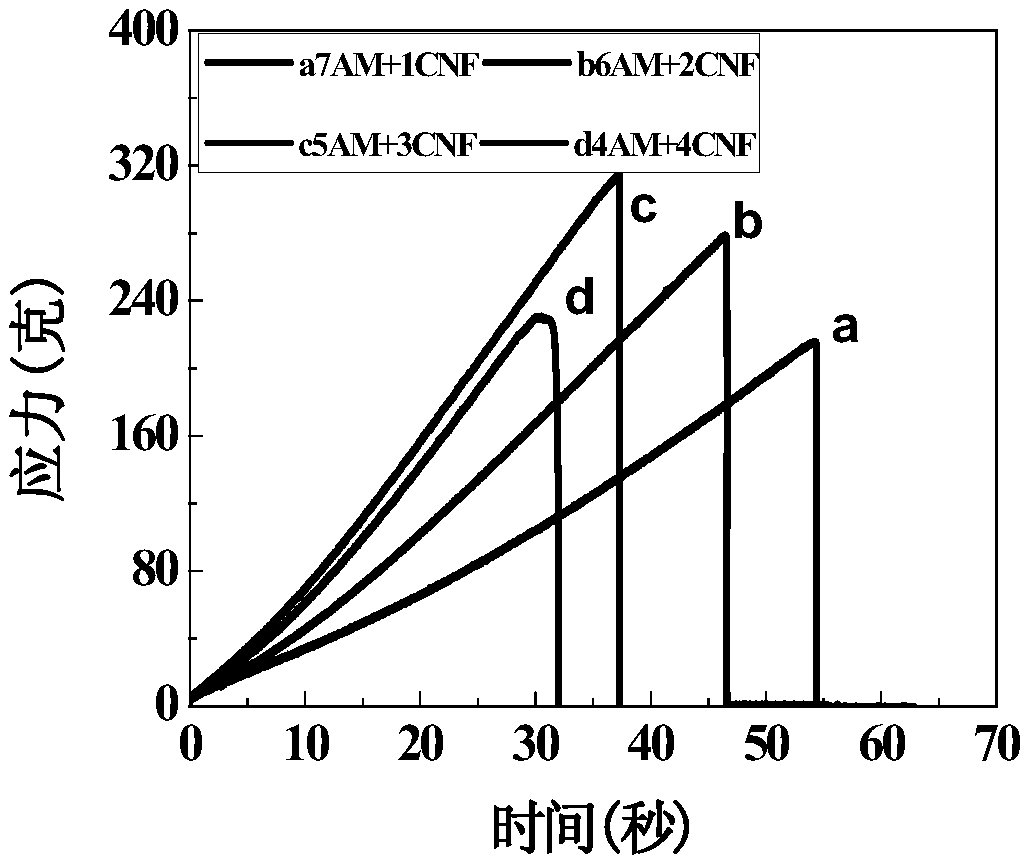

[0047] Embodiment 2, the mechanical performance test of acrylamide / nanocellulose composite gel

[0048] 1. Scanning electron microscope

[0049]Use the scanning electron microscope (SEM) mode of the Quanta 200F environmental scanning electron microscope to observe the cross-sectional structure of the gel sample, freeze the sample with liquid nitrogen, dry it, spray gold, and then observe.

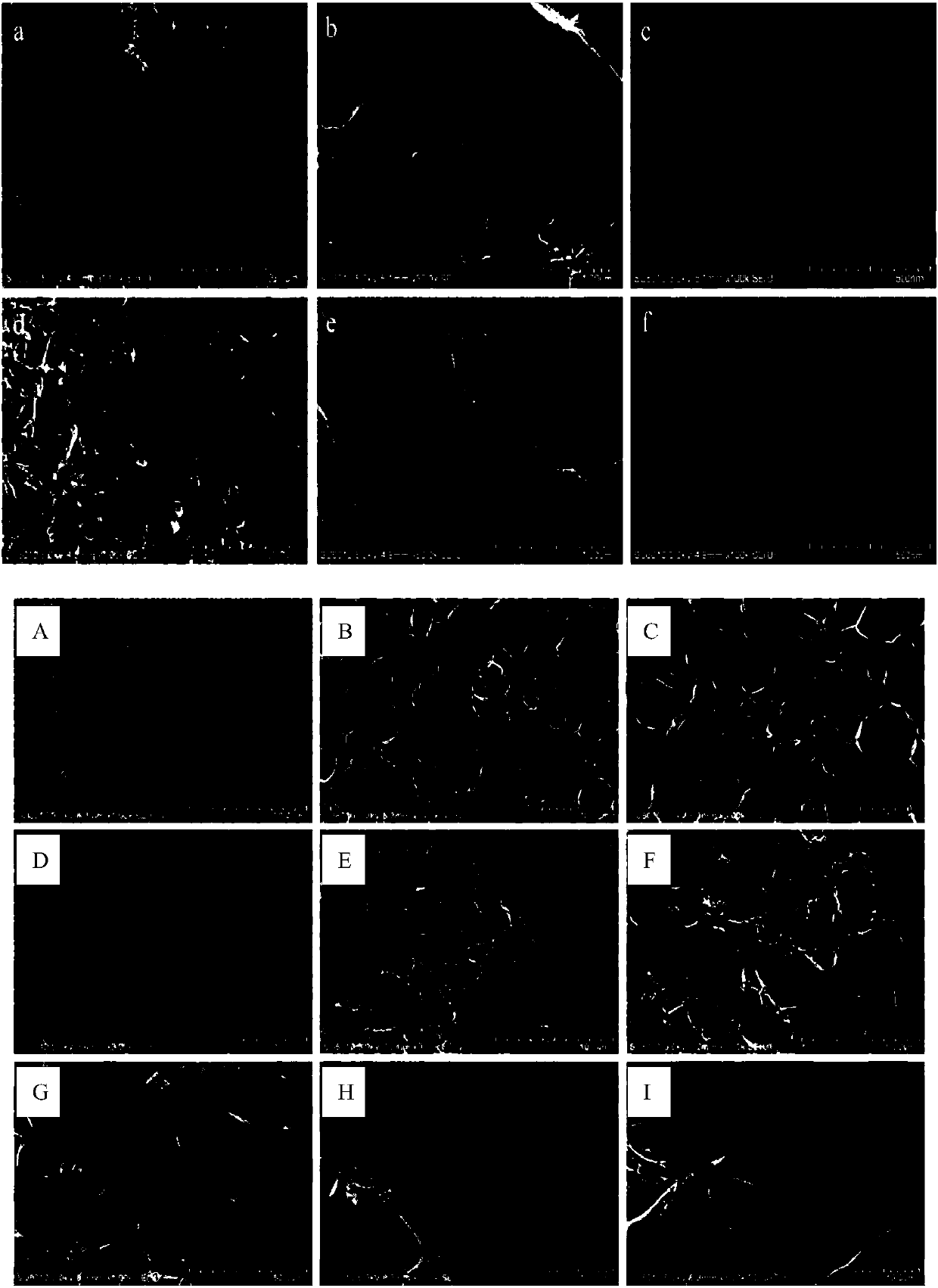

[0050] Observation of two specifications of nanocellulose by SEM, such as figure 1 shown, where figure 1 (a), figure 1 (b) and figure 1 (c) is the SEM photo of NCC, figure 1 (d), figure 1 (e) and figure 1 (f) is the SEM photo of CNF. It can be seen from the figure that the two specifications of nanocellulose are gathered together in irregular shapes. After zooming in, it can be found that the two kinds of cellulose are still filamentous, and CNF longer than NCC. Different lengths have different reinforcing effects on the composite gel.

[0051] figure 1 At the same time, a blank a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com