Polyacrylamide/microsphere composite gel and preparation method thereof

A technology of polyacrylamide and composite gel, which is applied in the field of polyacrylamide/microsphere composite gel and its preparation, and can solve the problems of reservoir damage and expensive construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, the preparation of acrylamide / hydroxyethyl methacrylate composite microspheres (AM\HEMA composite microspheres)

[0041] AM\HEMA composite microspheres were synthesized by low temperature inverse microemulsion method.

[0042] First prepare the oil phase, weigh a certain amount of span80, tween60 and No. 10 white oil in a three-necked flask, stir in a water bath at 50 ° C for 0.5 h at a constant temperature, and the rotation speed is 350 r / min. In the oil phase, the mass fraction of span80 is 22.09 %, the mass fraction of tween60 is 12.47%; then the water phase is prepared, and a certain amount of AM, HEMA, MBA, KPS, deionized water is weighed in a beaker, and stirred at room temperature until completely dissolved; then at 20°C, the The water phase is added dropwise to the oil phase at a rate of 2-3 drops / s. At this time, the stirring rate is 350r / min. After emulsification for 0.5h, cool down to 18°C, observe the heating process, record the highest tempera...

Embodiment 2

[0046] Embodiment 2, the preparation of polyacrylamide / microsphere composite gel

[0047]Add 2 g of 10% thiourea solution to the deionized water solution, and slowly add the acrylamide / hydroxyethyl methacrylate composite microspheres prepared in Example 1 under stirring conditions, ultrasonically oscillate for 20 minutes and then stir for 30 minutes to make the solution as uniform as possible. Afterwards, 2 g of HPAM powder was added to the above suspension and continued to stir for 4 h, and then 2 g of chromium acetate aqueous solution with a mass concentration of 10% was added to the above mixture and continued to stir for 30 min. The cross-linking system was gelled at a constant temperature of 70° C. for 3 hours to obtain a polymer composite gel.

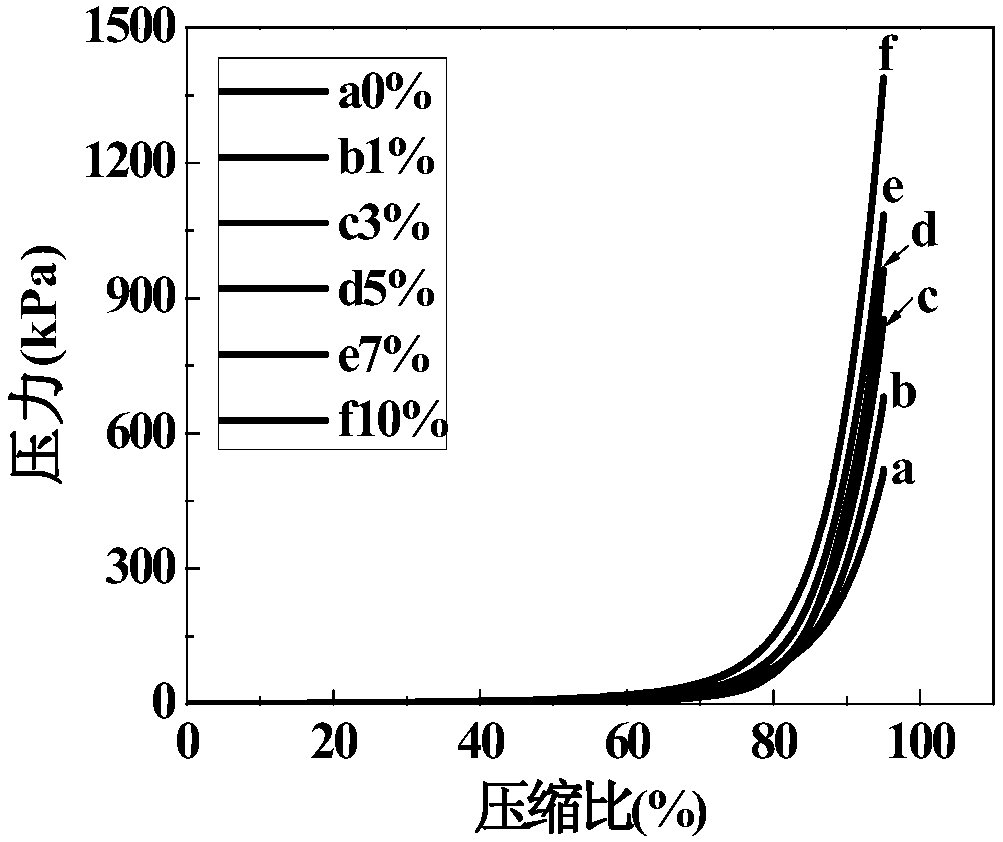

[0048] According to the above steps, keep the mass fraction of HPAM and chromium acetate constant, and change the concentration of acrylamide / hydroxyethyl methacrylate composite microspheres from 0% to 10%, to investigate the inf...

Embodiment 3

[0053] Embodiment 3, the mechanical performance test of polyacrylamide / microsphere composite gel

[0054] 1. Scanning electron microscope

[0055] Use the scanning electron microscope (SEM) mode of the Quanta 200F environmental scanning electron microscope to observe the cross-sectional structure of the gel sample, freeze the sample with liquid nitrogen, dry it, spray gold, and then observe.

[0056] The microscopic morphology of acrylamide / hydroxyethyl methacrylate composite microspheres and microspheres / polyacrylamide composite gel was observed by scanning electron microscopy, as shown in figure 1 (A) and figure 1 (B) shown.

[0057] The morphology of acrylamide / hydroxyethyl methacrylate composite microspheres is shown. The size of acrylamide / hydroxyethyl methacrylate composite microspheres is different, and the particle size ranges from hundreds of nanometers to tens of microns. Shape and smooth surface without impurities, good dispersion, no particle aggregation, the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive stress | aaaaa | aaaaa |

| Compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com