Waterproof, acid-resistant and alkaline-resistant fluorescent water-based ink universally used on paper and plastics and preparation method of ink

A water-based ink, acid and alkali resistant technology, applied in the field of ink, can solve the problems of easy volatilization, poor gloss, poor water resistance, etc., achieve high adhesion, improve gloss and color vividness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

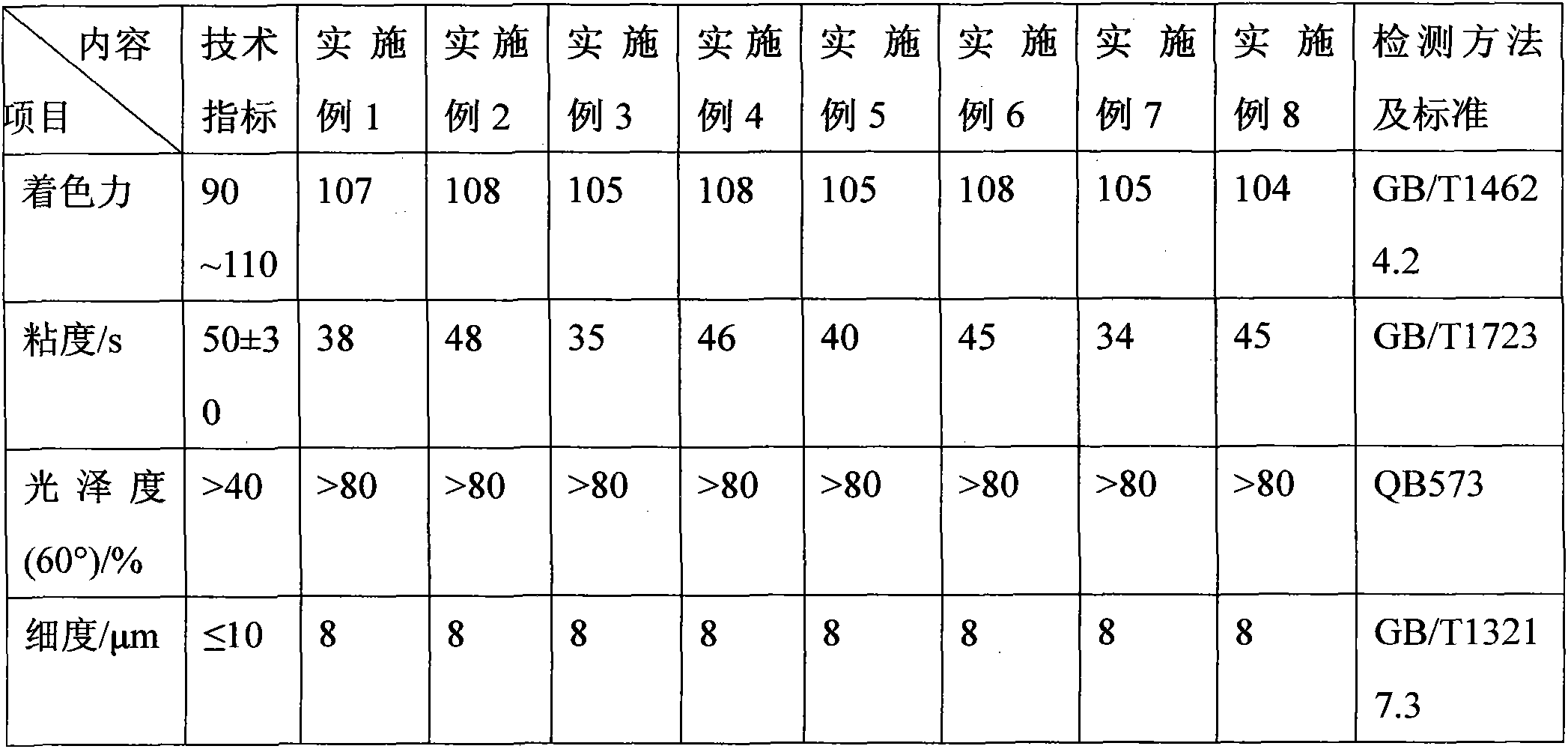

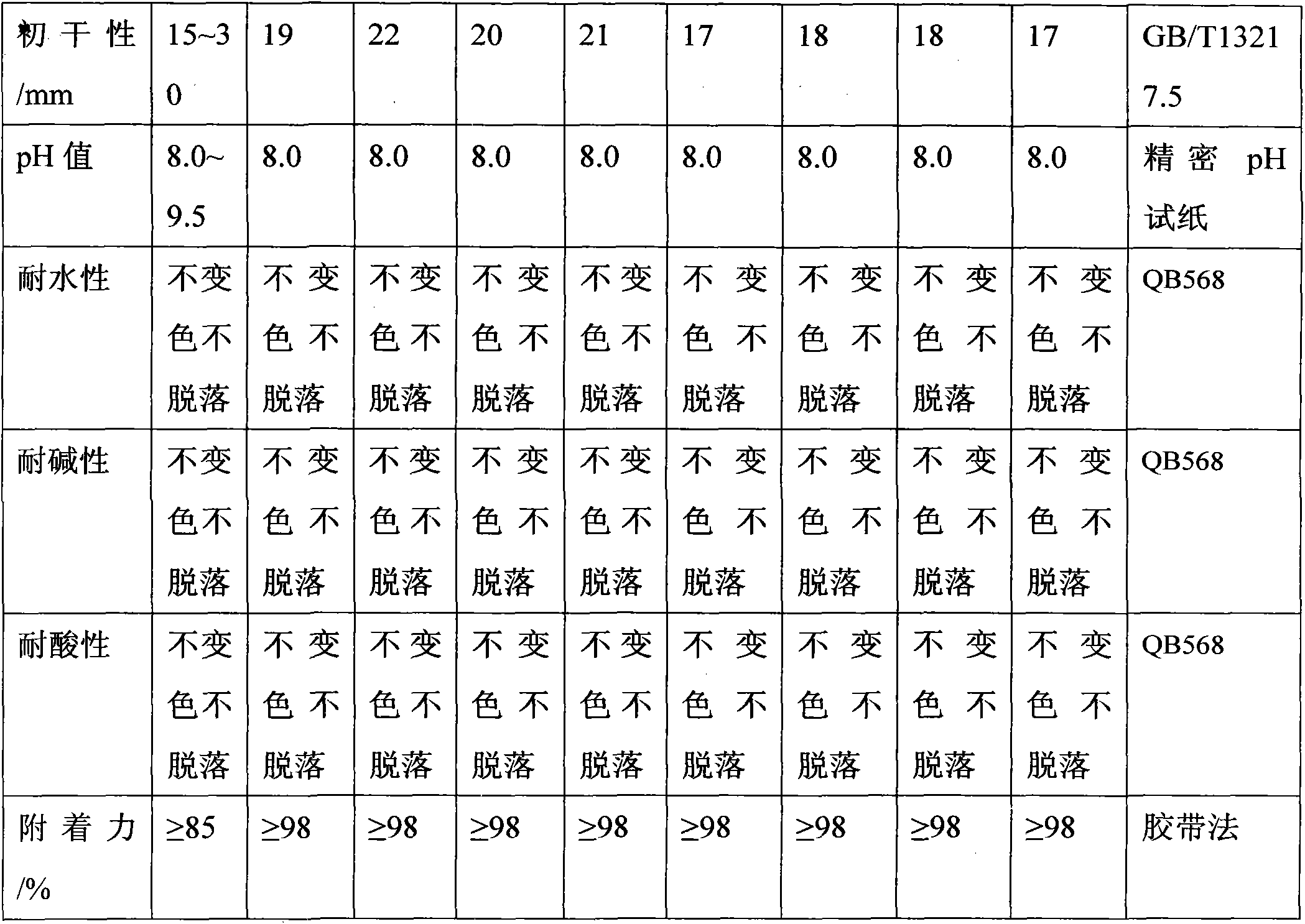

Examples

Embodiment 1

[0035] Weigh 20 parts of deionized water, 40 parts of self-crosslinking acrylate emulsion with number average molecular weight greater than 200,000, glass transition temperature lower than -20°C, solid content of 30%, pH=8, number average molecular weight of 10000, with Add 4 parts of super water-based dispersant with block structure, 4 parts of isopropanol and 0.25 parts of alkylphenol polyoxyethylene ether into the container and stir evenly at a speed of 400 rpm for 60 minutes, then mix 20 parts of permanent red, Add 2 parts of the rare earth metal colorless fluorescent red pigment into the container and stir evenly for 180 minutes at a speed of 800 rpm; add the fully dispersed pigment in the container to a sand mill for sand grinding, and the sand grinding temperature is 50 ° C. 20 parts of self-crosslinking acrylic emulsion with a number average molecular weight greater than 200,000, glass transition temperature lower than -20°C, solid content of 48%, pH=8, and 0.25 parts o...

Embodiment 2

[0037] Weigh 50 parts of deionized water, 65 parts of self-crosslinking acrylate emulsion with number average molecular weight greater than 200,000, glass transition temperature lower than -30°C, solid content of 48%, pH=8, number average molecular weight of 50,000, with Add 10 parts of super water-based dispersant with block structure, 5.5 parts of n-propanol and 0.95 parts of emulsified silicone oil into the container and stir evenly at a speed of 300 rpm for 60 minutes, then add 30 parts of permanent blue, rare earth metal colorless fluorescent Add 10 parts of blue pigment into the container and stir evenly at a speed of 1000 rpm for 180 minutes; add the fully dispersed color material in the container to a sand mill for sanding, the sanding temperature is 50°C, and cycle sanding 5 times Finally, 35 parts of a self-crosslinking acrylic emulsion with a number average molecular weight of more than 200,000, a glass transition temperature of less than -30°C, a solid content of 48...

Embodiment 3

[0039] Weigh 30 parts of deionized water, 60 parts of self-crosslinking acrylate emulsion with number average molecular weight greater than 200,000, glass transition temperature lower than -10°C, solid content of 40%, pH=8, number average molecular weight of 5000, with 8 parts of super water-based dispersant with block structure, 4.5 parts of ethanol and 0.75 parts of polyoxyethylene polyoxypropylene amine ether were added to the container and stirred evenly at a speed of 300 rpm for 60 minutes, and then 20 parts of benzidine yellow, rare earth Put 2 parts of metallic colorless fluorescent yellow pigment into the container and stir evenly for 180 minutes at a speed of 1000 rpm; put the fully dispersed pigment in the container into a sand mill for sanding, the sanding temperature is 50°C, and circulate After sanding 5 times, the number average molecular weight is greater than 200,000, the glass transition temperature is lower than -10°C, the solid content is 40%, 30 parts of sel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com