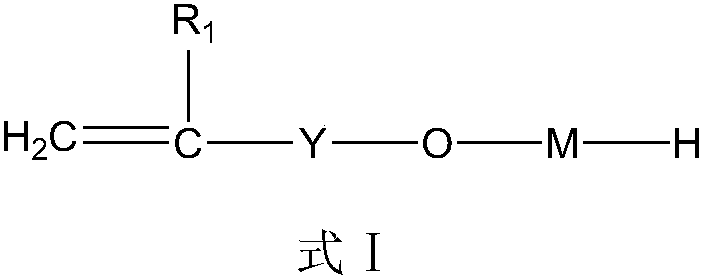

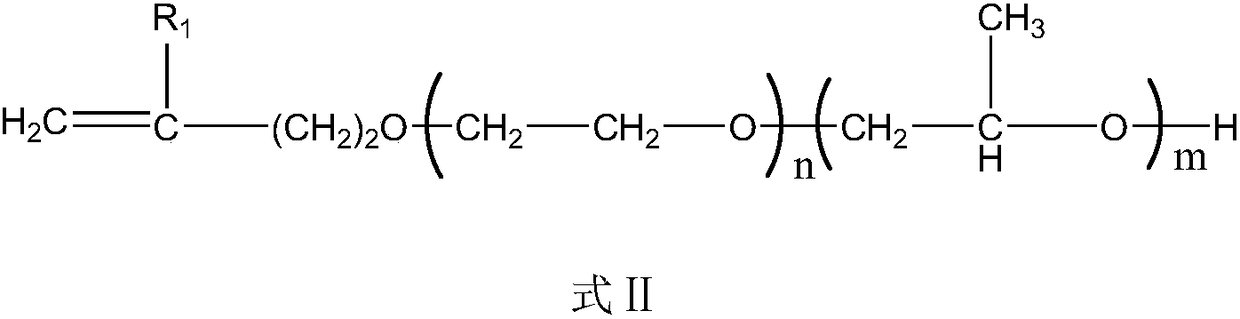

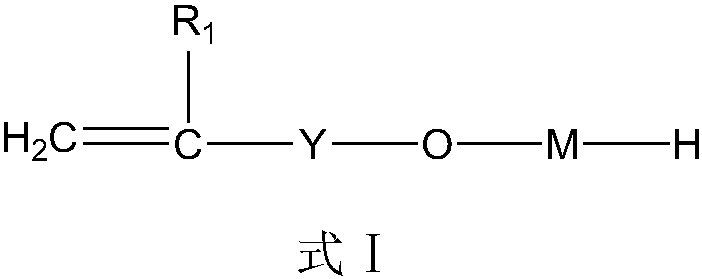

Viscosity reduction polycarboxylic acid water reducer and preparation method thereof

A technology of viscous polycarboxylic acid and water reducing agent, applied in the field of water reducing agent, can solve the problems of unsatisfactory effect, difficult to guarantee product stability, high energy consumption in the production process, and achieve significant steric stabilization effect and good steric hindrance. effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the present invention carries out the copolymerization reaction in the aqueous solution system, and temperature is the key condition of the polymerization reaction, and the formation of the reaction product can be better controlled within the reaction temperature range, so that the polymerization reaction can be carried out quickly and smoothly, and it is not easy to produce side effects. reaction, thereby simplifying the preparation process and reducing the preparation cost.

[0042] In one embodiment of the preparation method according to the present invention, the initiator used can be a common initiator in the field of polycarboxylate superplasticizer preparation, including but not limited to redox system, ammonium persulfate system, azobisiso Butyamidine hydrochloride and the like can be used in an amount of 0.3% to 2.8% of the total mass of the monomers.

[0043] In one embodiment of the preparation method according to the present inventi...

preparation example

[0060] c-1:

[0061] Weigh 230.0g of phenol and add it to a three-necked flask equipped with a condenser, a stirrer, and a thermometer, add 26.03g of modifier polyvinyl alcohol and 153.3g of distilled water, stir, add 2.28g of KOH, keep the temperature at 40°C, and stir to react 20min, add 66.5g formaldehyde, heat up, continue stirring for 40min, then add 0.98g KOH, raise the temperature to 70°C, keep stirring at constant temperature for 20min, finally add 146.8g formaldehyde, raise the reaction temperature to 90°C, and keep stirring at constant temperature After reacting for 20 minutes, the obtained product is water-soluble phenolic resin, then add 104g of 30% NaOH lye, and stir fully at 40°C for 1h; cool to room temperature, slowly add 65g of allyl chloride dropwise, after dropping, heat up to 70°C, and react 3h time; when a large amount of precipitates appear in the reaction system, the reaction is stopped, and the material is cooled and discharged; the product obtains c-1 ...

Embodiment 1

[0069] Add 173.3g of deionized water into a 500ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, stir and heat up to 50°C, add 223.6g of monomer (b-2), 10.4g of monomer (c-1 ), add 26g monomer (a-1) after the above-mentioned monomer dissolves, then add dropwise initiator (1.3g ammonium persulfate and 30g water mixture), chain transfer agent (0.52g mercaptoacetic acid and 40g water mixture) , respectively dropwise at a constant speed for 2 hours and react, the aging time is 1 hour, after the reaction, the temperature of the system is down to normal temperature, and the pH value of the reaction mixture is adjusted to neutrality with a NaOH aqueous solution with a mass concentration of 30%, and the material is discharged, i.e. The high-performance polycarboxylate water reducer product JN-1 was obtained, the solid content of the product was 40%, and the weight average molecular weight of the obtained polymer was 32400.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com