Solid polycarboxylate superplasticizer and preparation method thereof

A technology of polycarboxylic acid and water reducing agent, which is applied in the field of building materials, can solve problems such as difficulty in ensuring product stability, high cost of long-distance transportation, and unsatisfactory use effects, etc., and achieves significant dimensional stability effects, good industrialization prospects, and improved Effect of Adsorption Efficiency and Adsorption Layer Thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention provides a kind of preparation method of solid polycarboxylate water reducer, comprising:

[0032] Mix unsaturated polyoxyethylene polyoxypropylene ether and silane coupling agent and heat up (40-55°C) to melt to obtain the primer;

[0033] Add unsaturated carboxylic acid and / or unsaturated carboxylic acid ester to the base material, then add initiator and chain transfer agent dropwise in sequence and keep stirring to carry out polymerization reaction;

[0034] Aging treatment is carried out after the polymerization reaction to obtain a solid material, and the solid polycarboxylate water reducer is obtained. The aging treatment includes keeping the temperature of the polymerization reaction constant and stirring continuously.

[0035] In some embodiments, the weight average molecular weight of the solid polycarboxylate water reducer is 10,000-30,000, further, it may be 10,000-25,000.

[0036] Taking the mass sum of the unsaturated polyoxyethylene...

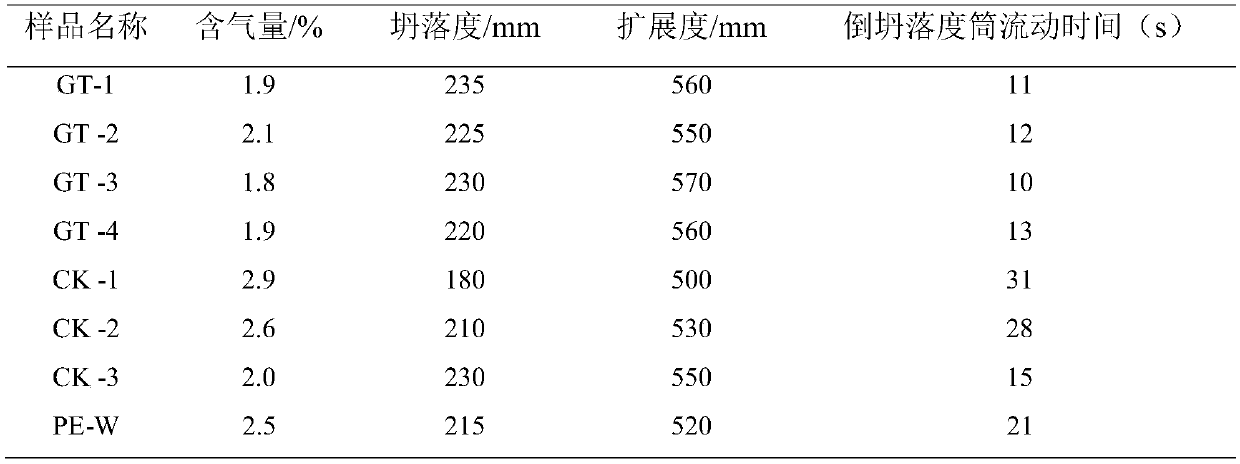

Embodiment 1

[0061] Add 258 grams of monomer (b-2) and 10 grams of monomer (c-1) into a 500ml four-neck flask equipped with a stirrer, a thermometer, and a dropping device, and add 30 grams of monomer after the temperature is raised to 50 ° C. Monomer (a-1), then drip initiator dimethyl azobisisobutyrate 1.5 grams, chain transfer agent mercaptoacetic acid 0.6 grams, add dropwise at a constant speed for 2 hours respectively, aging time is 1 hour, after the reaction finishes Material, obtains polycarboxylate superplasticizer product GT-1, and its weight-average molecular weight is 13300.

Embodiment 2

[0063] Add 255 grams of monomer (b-1) and 15 grams of monomer (c-2) into a 500ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, and add 20 grams of monomer after the temperature is raised to 50 ° C. Monomer (a-1) and 4 grams of monomer (a-3), then dropwise add 3.6 grams of initiator azobisisobutyronitrile, 2.4 grams of chain transfer agent thioglycolic acid, add dropwise at a uniform speed for 2 hours respectively, and the aging time is After 1 hour, the material was discharged after the reaction, and the polycarboxylate superplasticizer product GT-2 was obtained, and its weight-average molecular weight was 10600.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com