Polyester-resin-based cement material

A technology of polyester resin and cement materials, which is applied in the field of building materials, can solve problems such as poor mechanical properties, and achieve the effects of good steric hindrance effect, reduced force, and increased ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

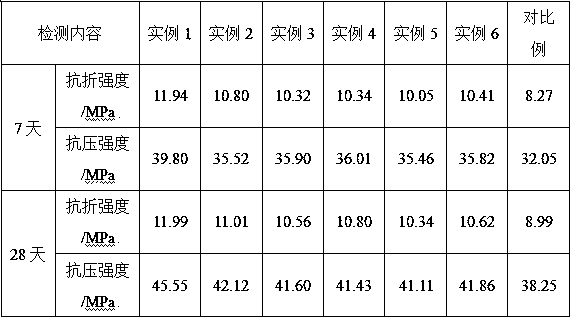

Examples

example 1

[0034] In parts by weight, 120 parts of polyethylene terephthalate, 5 parts of acetic anhydride, and 6 parts of pyridine were sequentially added to the No. 1 three-necked flask, and nitrogen was introduced into the three-necked flask at a rate of 10 mL / min. Under nitrogen protection, at a temperature of 205°C and a speed of 500r / min, the reaction was heated and stirred for 7h to obtain the alcoholysis product, and then the alcoholysis product, maleic acid was obtained in a mass ratio of 10:3:1:1 The acid anhydride, cottonseed oil and linoleic acid were put into a No. 2 three-necked flask, heated and stirred for 6 hours at a temperature of 210°C and a speed of 400r / min, and discharged to obtain an unsaturated polyester resin; in parts by weight, Take 50 parts of unsaturated polyester resin, 30 parts of styrene, 6 parts of emulsifier, 25 parts of water, 80 parts of cement, 200 parts of aggregate, 4 parts of water reducing agent, 15 parts of caprolactam, 10 parts of polyacrylamide,...

example 2

[0036] In parts by weight, 120 parts of polyethylene terephthalate, 5 parts of acetic anhydride, and 6 parts of pyridine were sequentially added to the No. 1 three-necked flask, and nitrogen was introduced into the three-necked flask at a rate of 10 mL / min. Under nitrogen protection, at a temperature of 205°C and a rotation speed of 500r / min, the reaction was heated and stirred for 7 hours to obtain the alcoholysis product, and then the alcoholysis product and maleic anhydride were added to No. 2 in a mass ratio of 10:3 In a three-necked flask, under the conditions of a temperature of 210°C and a rotation speed of 400r / min, the reaction was heated and stirred for 6h, and the material was discharged to obtain an unsaturated polyester resin; in parts by weight, take 50 parts of the unsaturated polyester resin, 30 Parts of styrene, 6 parts of emulsifier, 25 parts of water, 80 parts of cement, 200 parts of aggregate, 4 parts of water reducing agent, 15 parts of caprolactam, 10 parts...

example 3

[0038] In parts by weight, 120 parts of polyethylene terephthalate, 5 parts of acetic anhydride, and 6 parts of pyridine were sequentially added to the No. 1 three-necked flask, and nitrogen was introduced into the three-necked flask at a rate of 10 mL / min. Under nitrogen protection, at a temperature of 205°C and a rotation speed of 500r / min, the reaction was heated and stirred for 7 hours to obtain the alcoholysis product, and then the alcoholysis product, maleic anhydride, was obtained in a mass ratio of 10:3:1. The cottonseed oil was added to the No. 2 three-necked flask, heated and stirred for 6 hours at a temperature of 210°C and a rotating speed of 400r / min, and discharged to obtain an unsaturated polyester resin; in parts by weight, take 50 parts of unsaturated polyester resin in turn. Polyester resin, 30 parts styrene, 6 parts emulsifier, 25 parts water, 80 parts cement, 200 parts aggregate, 4 parts water reducing agent, 15 parts caprolactam, 10 parts polyacrylamide, 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com