Patents

Literature

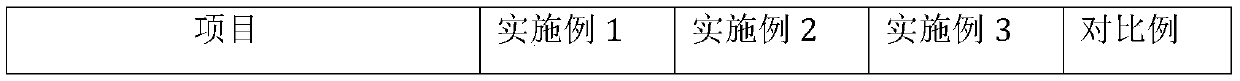

88results about How to "Controllable reaction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing viscosity-reducing polycarboxylate superplasticizer

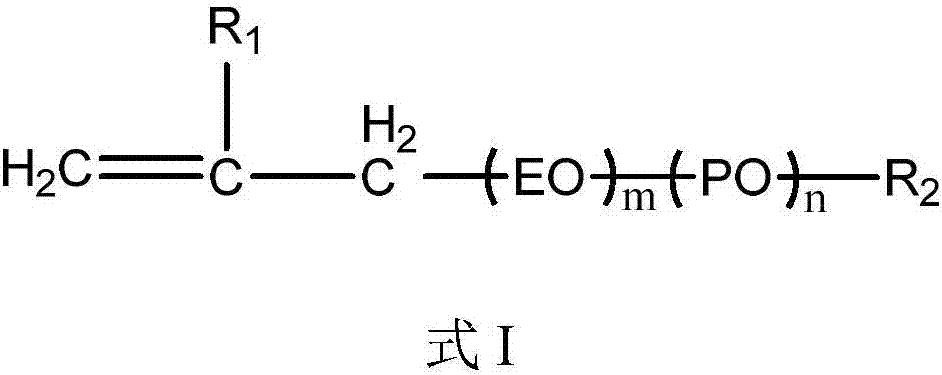

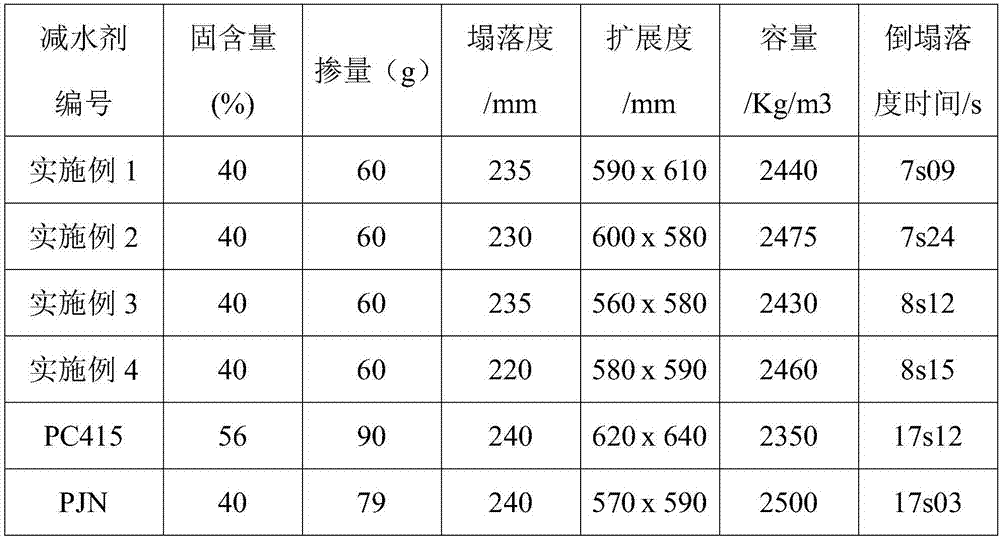

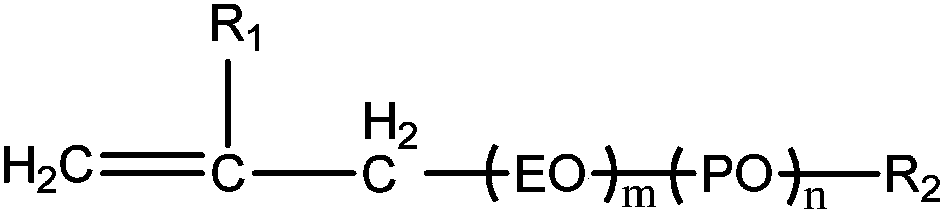

The invention provides a method for preparing viscosity-reducing polycarboxylate superplasticizer. The viscosity-reducing polycarboxylate superplasticizer is prepared through a bulk polymerization reaction, and the method comprises the following steps of: (1) mixing polyoxyethylene polyoxypropylene ether and polyoxyethylene ether, controlling the temperature at 40-60 DEG C, stirring the mixture evenly, and then adding an initiator and a mixture of unsaturated carboxylic acids, hydroxyalkyl unsaturated carboxylate and a chain transfer agent; and (2) performing aging for 1-1.5 hours after the step (1) is completed, and reducing the temperature to obtain the viscosity-reducing polycarboxylate superplasticizer. Since the bulk polymerization reaction is carried out at a low temperature, the method has strong operability, mild conditions and low energy consumption; the viscosity-reducing polycarboxylate superplasticizer prepared by using the method is at a liquid state at room temperature, has effective concentration of 100% and stable storage performance, and is suitable for long-distance transportation and use; meanwhile, the viscosity of a concrete mixture can be reduced effectively through the superplasticizer so that stirring, transportation and pumping of concrete can be facilitated, and the superplasticizer is suitable for the promotion and application of high-rise engineeringand high-performance concrete.

Owner:JIAHUA CHEM MAOMING

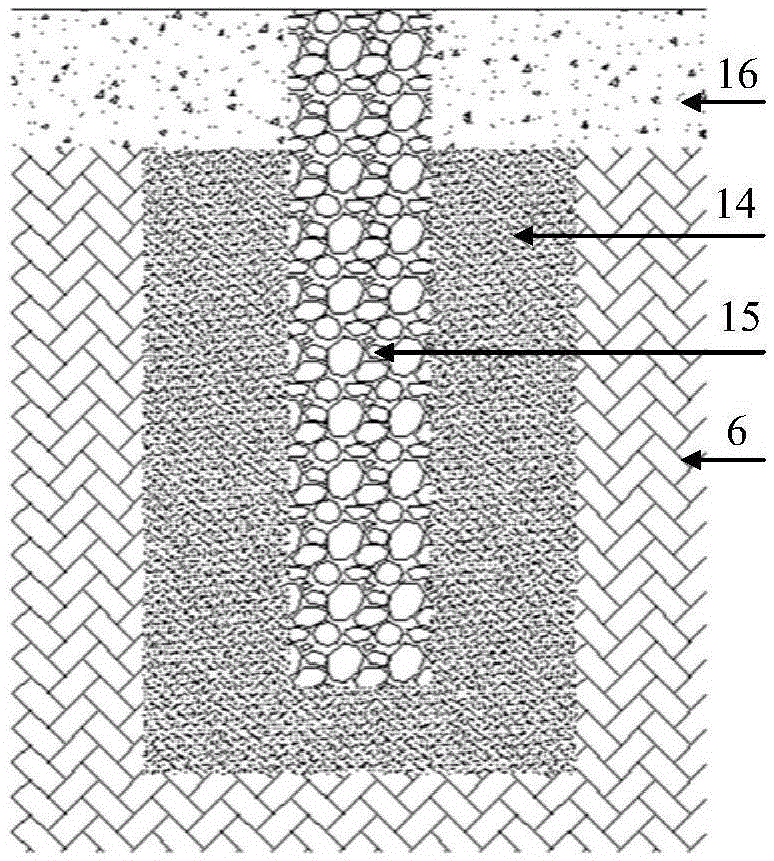

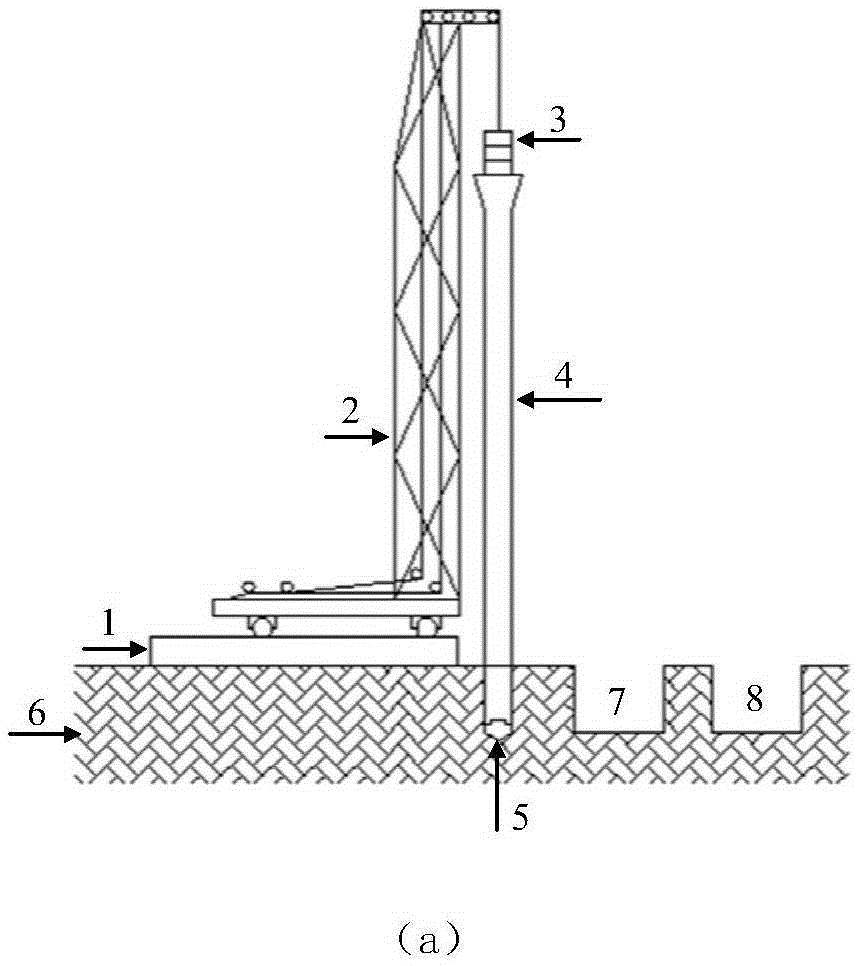

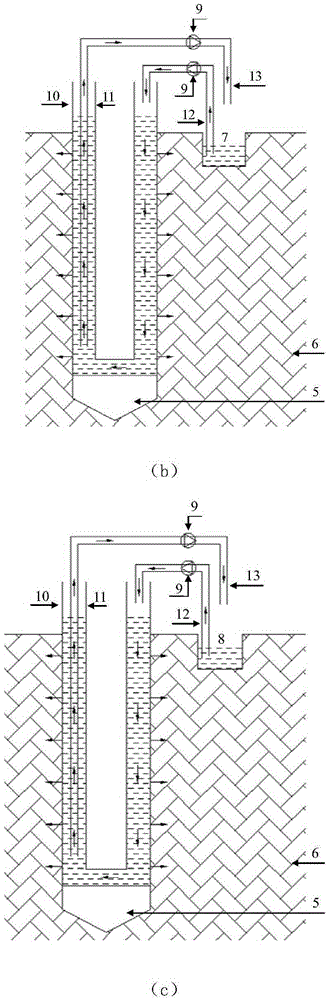

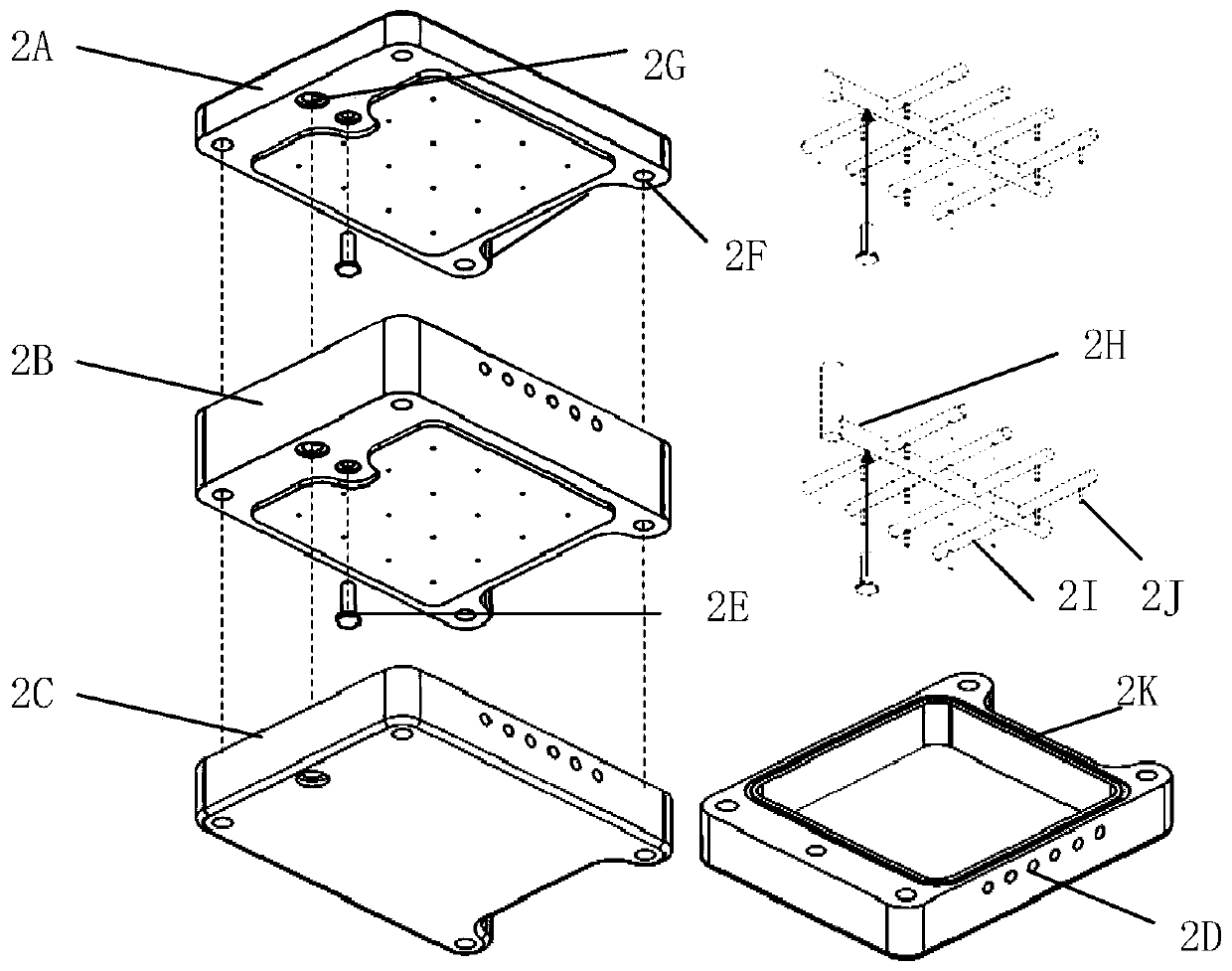

Composite foundation with discrete material pile restrained through microorganism soil solidification and construction method

ActiveCN105386436AImprove bearing capacityIncrease profitBuilding constructionsOrganic fertilisersMicroorganismSoil science

The invention relates to a composite foundation with a discrete material pile restrained through microorganism soil solidification and a construction method. The construction method includes the steps that a, a pile pipe is pressed into a foundation body; b, meanwhile, microorganism bacterium liquid is injected into a gap between an inner steel sleeve and an outer steel sleeve and diffused into the foundation body around the pile; c, the microorganism bacterium liquid is pumped out, a cementing solution is injected and diffused into the foundation body around the pile and reacts with the microorganism bacterium liquid to generate calcium carbonate crystals, and loose sandy soil or floury soil is cemented; d, the step b and the step c are repeated until the soil around the pile meets reinforcement requirements; e, discrete materials are poured into a hole of the inner steel sleeve; and f, a bed course is laid, so that the composite foundation is formed. According to the composite foundation with the discrete material pile restrained through microorganism soil solidification, the microorganism bacterium liquid and the cementing solution react to generate calcium carbonate so as to solidify the soil around the pile, so that the strength of the soil around the pile is improved, and the discrete material pile is protected against the problems of different pile diameters, bulging damage, pile hole caving and the like; the microorganism solidified soil and the pile can be combined to bear loads, and thus the bearing capacity of the single pile is improved.

Owner:NANJING FORESTRY UNIV

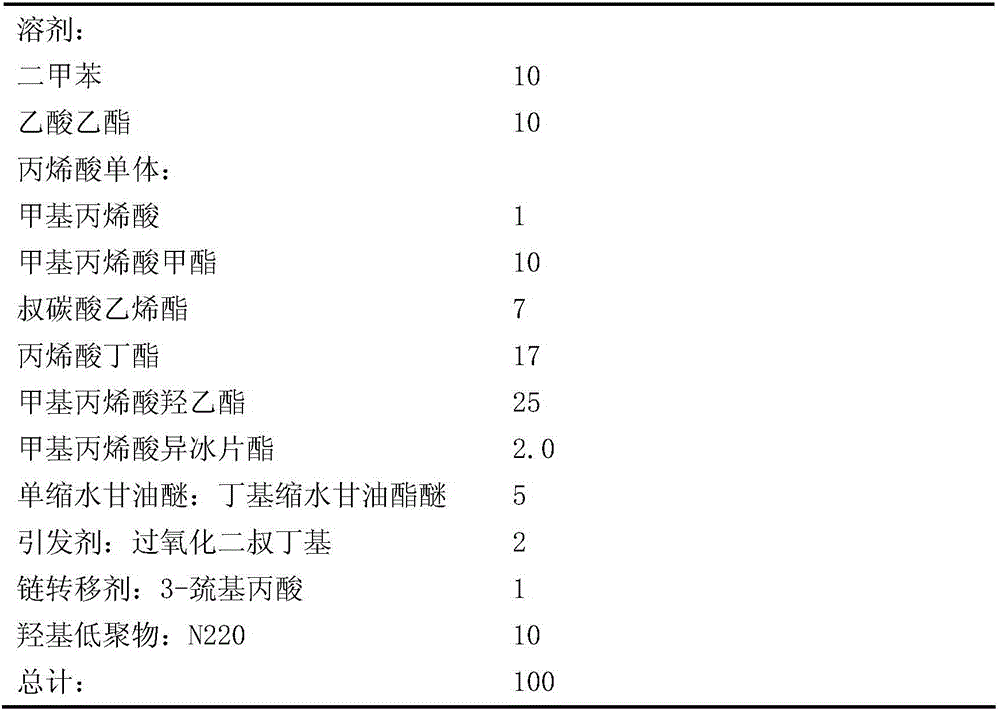

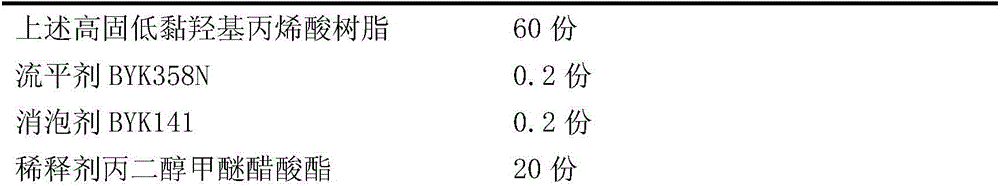

High-solid low-viscosity hydroxy acrylic resin as well as preparation method and application thereof

ActiveCN106009454ALow viscosityHigh cost performancePolyurea/polyurethane coatingsPolymer scienceOligomer

The invention discloses high-solid low-viscosity hydroxy acrylic resin as well as a preparation method and application thereof. During preparation, a first part of solvent and mono-glycidyl ether are added into a reaction kettle, stirred and heated to 140-180 DEG C; a first part of initiator and a chain transfer agent are added into an acrylic monomer mixture, the obtained mixture is dropwise added into a reaction kettle within 3-6 h, and the temperature is kept for 0.5-1h after dropwise addition; the residual initiator and the residual solvent are mixed uniformly and added into the reaction kettle within 20-40 min, the temperature is kept for 1-2 h after the addition is completed, a hydroxyl oligomer is added, stirring is performed for 30-60 min, the temperature is lowered for material discharge, and the high-solid low-viscosity hydroxy acrylic resin is obtained. The resin solid accounts for 70% or higher, the viscosity is as low as 300mPa*s. The technology for preparing the hydroxy acrylic resin is simple, the cost is low, and a bi-component polyurethane coating film has excellent water resistance, acid and alkali resistance and mechanical properties.

Owner:英德市佐桐化学品有限公司

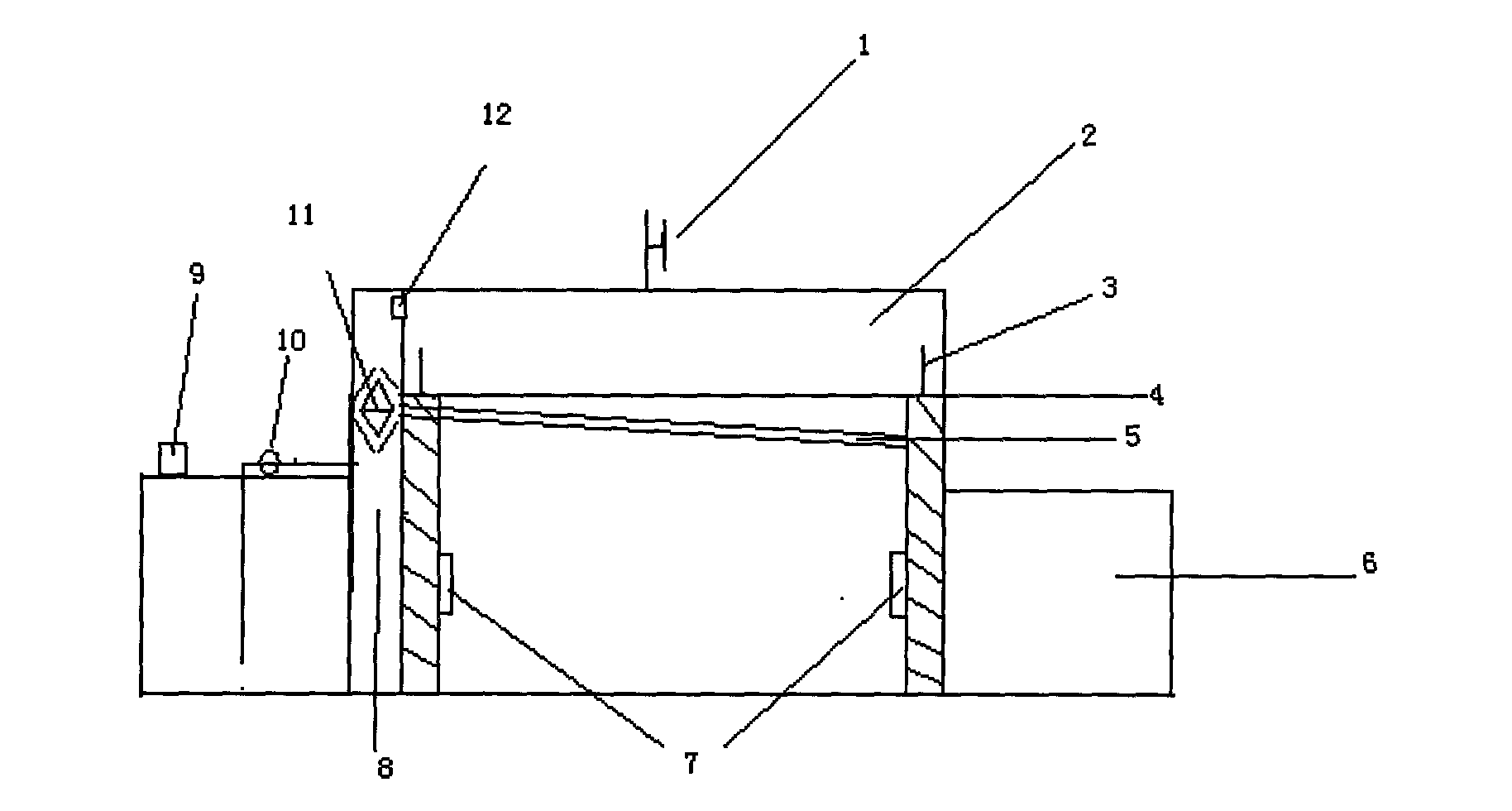

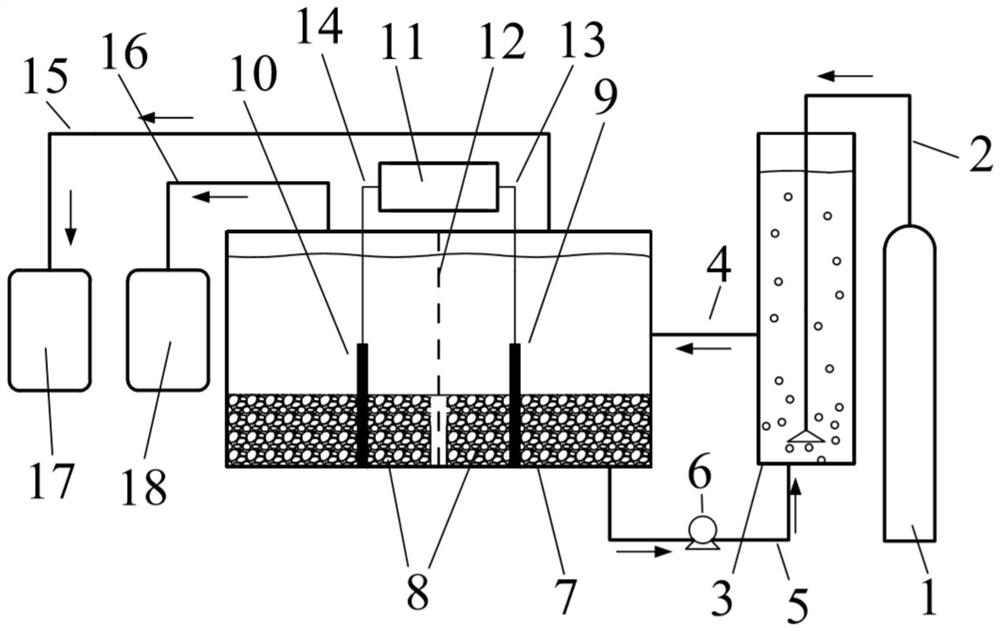

Aluminum alloy/hydroboron hydrolysis reaction-based miniature hydrogen production system and hydrogen production method

The invention relates to an aluminum alloy / hydroboron hydrolysis reaction-based miniature hydrogen production system and a hydrogen production method thereof, belonging to the field of hydrogen preparation technique. The aluminum alloy / hydroboron hydrolysis reaction-based miniature hydrogen production system comprises a hydrogen production generator and a liquid storage tank, wherein the hydrogen production generator is coated by the liquid storage tank; an outlet at the bottom end of the liquid storage tank is connected with a hydrogen production generator liquid delivery pipe, a liquid delivery control valve, a stainless steel pipe and a reaction region; the top end of the liquid delivery pipe is connected with a hydrogen storage chamber; the hydrogen production generator is divided into a reaction chamber and the hydrogen storage chamber by a separation film; and two symmetrical circular truncated cones are arranged at the bottom of the reaction region. The hydrogen production method of the aluminum alloy / hydroboron hydrolysis reaction-based miniature hydrogen production system is characterized in that the hydroboron solution input velocity of the liquid delivery control valve is regulated to realize the start / stop of the hydrolysis reaction of the hydrogen production system, so as to stabilize the hydrogen pressure of the hydrogen production system. The aluminum alloy / hydroboron hydrolysis reaction-based miniature hydrogen production system and the hydrogen production method have the characteristics of being simple in structure, and safe and reliable, and suitable for supplying hydrogen for portable fuel cells or internal combustion engines.

Owner:CHINA JILIANG UNIV

Method for preparing nickel-plated copper powder

ActiveCN101733401AGuaranteed uniformitySimple processLiquid/solution decomposition chemical coatingOrganic acidPhysical chemistry

The invention provides a method for preparing nickel-plated copper powder. The method comprises the following steps: (a) putting copper powder with the granularity between 200 and 800 meshes in 15 to 75 weight percent of hydrochloric acid solution for activation for 20 to 80min, and then carrying out water washing till the solution is neutral; (b) putting the copper powder activated in step (a) in 5 to 10 weight percent of the hydrochloric acid solution for acid washing for 5 to 15min, carrying out water washing till the solution is neutral, and then filtrating the solution for later use; (c) putting the copper powder subjected to acid washing in step (b) in nickel-plated solution for chemical plating and then carrying out cleaning and centrifugal filtration on the copper powder subjected to chemical plating to obtain the nickel-plated copper powder; and (d) soaking the nickel-plated copper powder obtained in step (c) in organic acid ester mixed solution for 0.5 to 3 hours and then filtering and drying the mixed solution to obtain the product.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

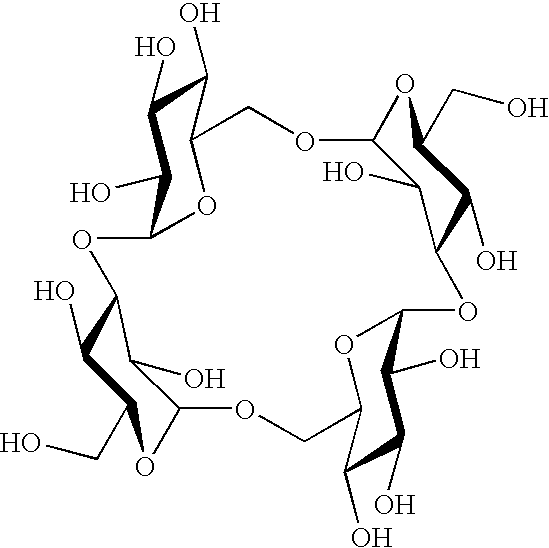

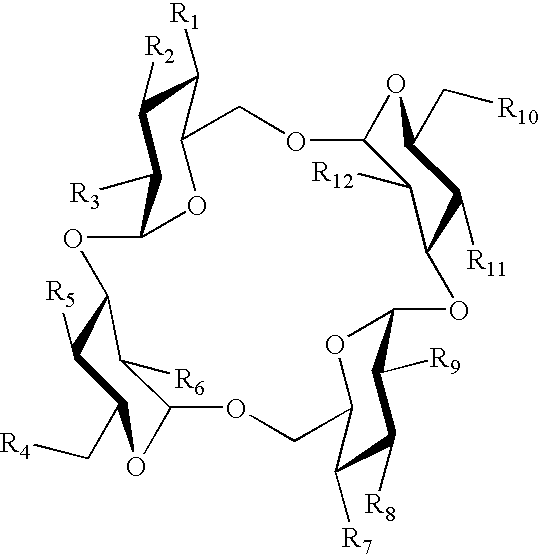

Sugar derivative

ActiveUS20040254367A1Improve bindingLess fermentabilityEsterified saccharide compoundsBiocideTM compoundSugar derivatives

For extending the uses of a compound represented by, Chemical formula 1, the object of the present invention is to provide a derivative of cyclic tetrasaccharide whose physicochemical properties are changed from those of cyclic tetrasaccaride, a composition comprising the same, and a process for producing the same. The present invention solves the above object by providing a derivative of cyclic tetrasaccharide, which is produced by the steps of reacting a compound represented by Chemical formula 1 with a reactive reagent and substituting one ore more hydroxyl groups with substituents except hydroxyl group and O-glycosyl group; a composition comprising the same; and a process for producing the derivative of cyclic tetrasaccharide. Chemical formula 1

Owner:HAYASHIBARA CO LTD

Alumina-based insulator and low-temperature sintering method thereof

InactiveCN106495675AUniform particle sizeImprove controllabilityNanotechnologyAluminium oxides/hydroxidesNano al2o3Young's modulus

The invention discloses an alumina-based insulator and a low-temperature sintering method thereof. The sintering temperature of the alumina-based insulator is lower than 1100 DEG C, the volume resistivity is not lower than 5*10<13> ohm cm, the dielectric strength is not lower than 500 kV / cm, the heat conductivity is not less than 30 W / m K, the bending strength is not lower than 400 Mpa, the Young's modulus is not lower than 300 Gpa, and the fracture toughness is not lower than 10 Mpa. The alumina-based insulator is prepared through the following steps: preparing nano alumina powder through a specific sol-gel technology and then adding various functional agents and sintering aids for high-pressure low-temperature sintering. According to the alumina-based insulator disclosed by the invention, the preparation temperature is low, the mechanical performance and the electric performance are excellent, the economical performance is good, the structure is dense, and the alumina-based insulator is suitable for large-scale industrial production.

Owner:郑平珍

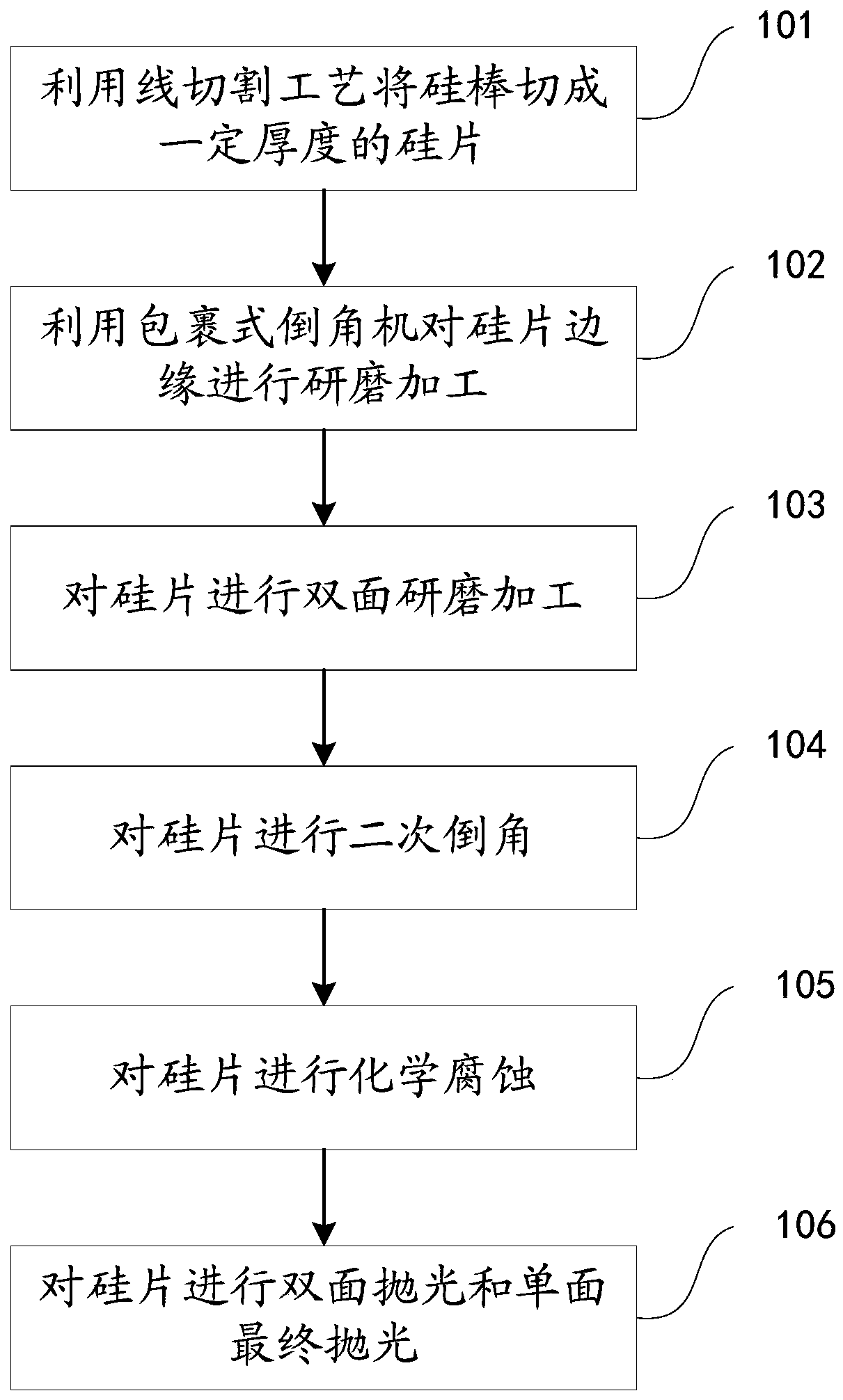

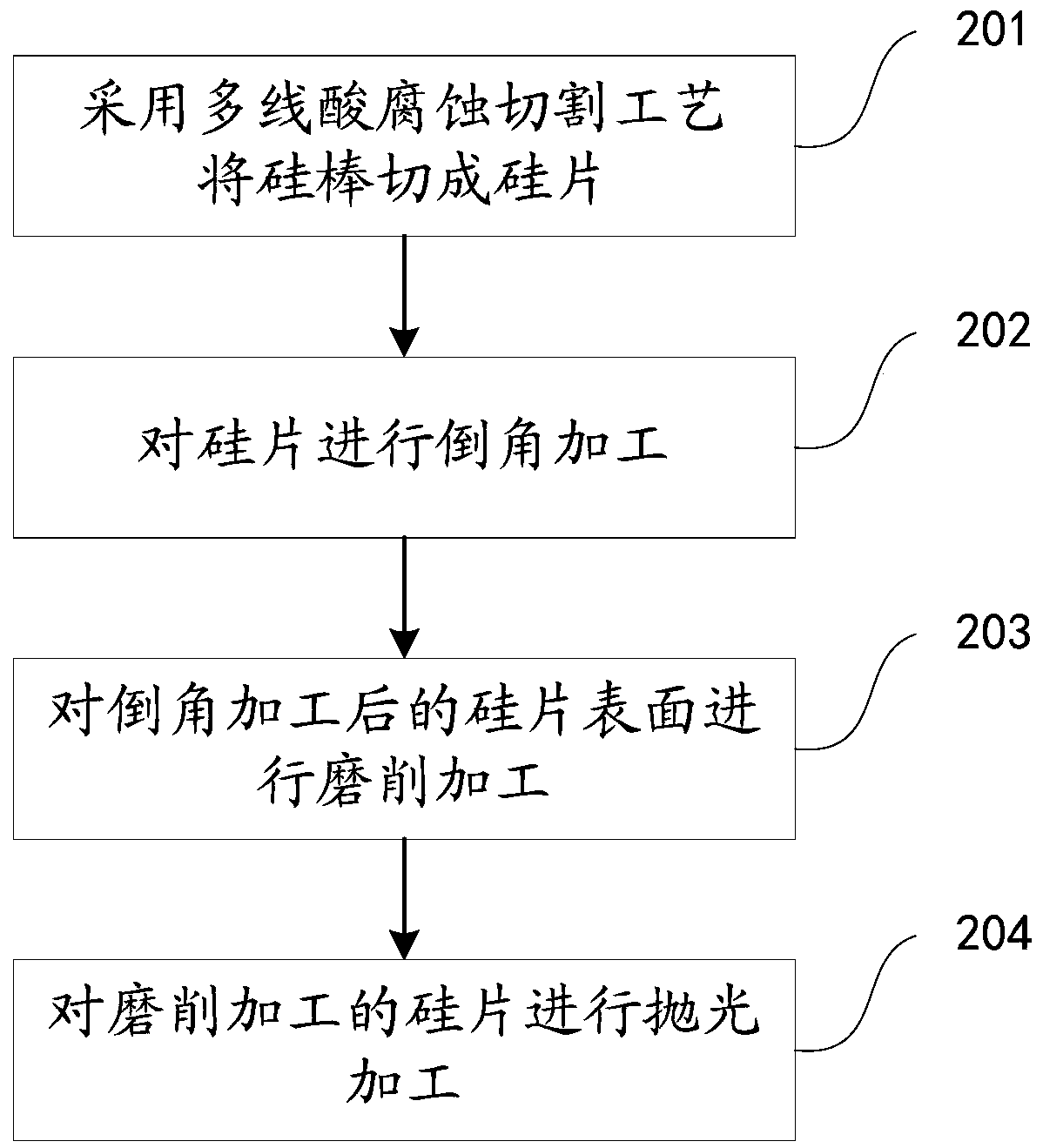

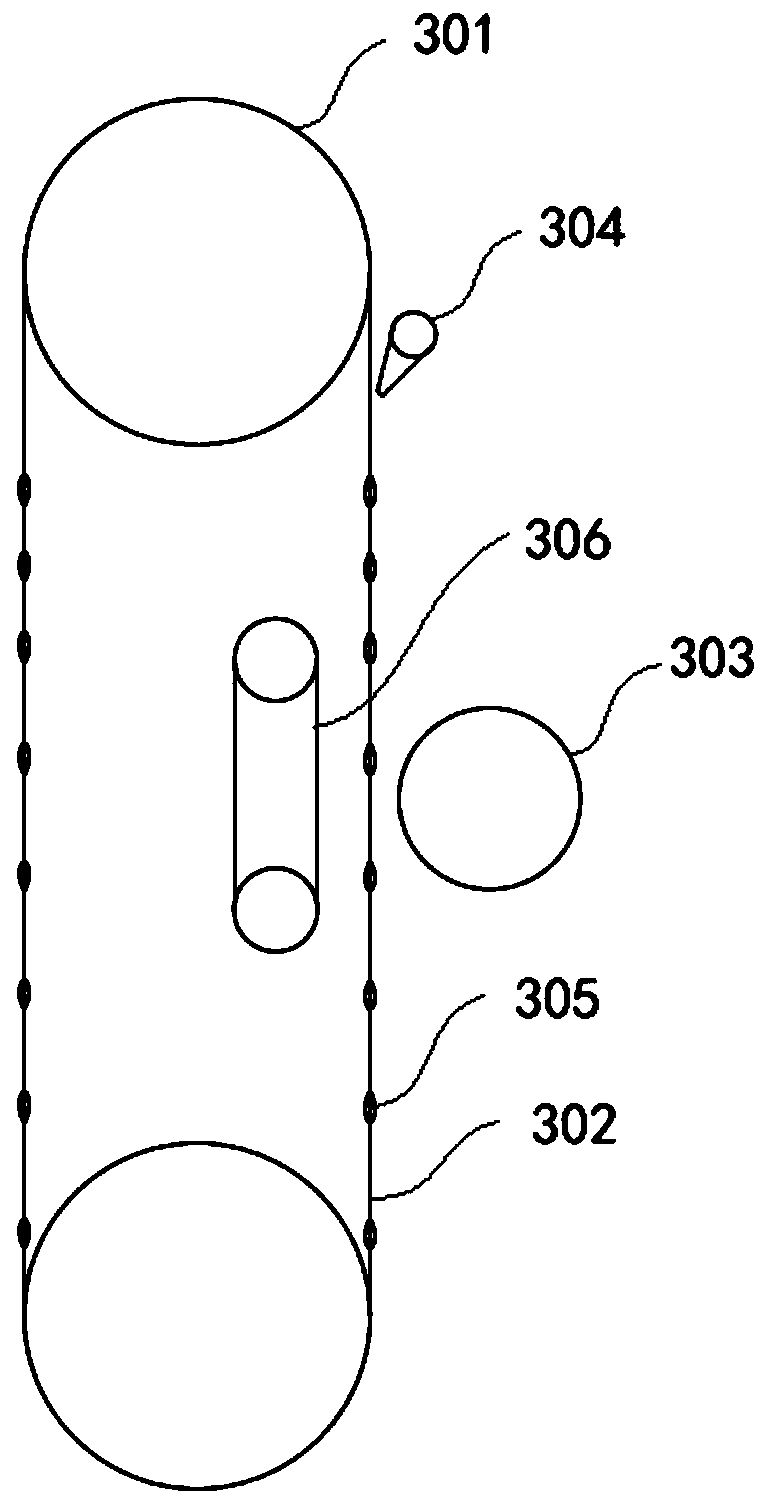

Silicon wafer molding processing method

InactiveCN110625835AAvoid long cuttingAvoid noiseEdge grinding machinesSemiconductor/solid-state device manufacturingReaction rateAcid corrosion

The invention provides a silicon wafer molding processing method. The silicon wafer molding processing method comprises the following steps of cutting a silicon rod into a silicon wafer by adopting amulti-line acid corrosion cutting process; chamfering the silicon wafer; grinding the surface of the silicon wafer after chamfering; and polishing the ground silicon wafer after grinding. According tothe silicon wafer forming processing method, the silicon rod is cut by adopting a multi-line acid corrosion cutting process, the ultrathin silicon wafer can be obtained, the processing efficiency ishigh, the quality is good, the various reaction rates are controllable, the problems that the silicon wafer is long in cutting time and large in noise in the traditional silicon wafer forming processing process, and the quality of the silicon wafer obtained by cutting cannot meet the requirements are solved.

Owner:XIAN ESWIN MATERIAL TECH CO LTD +1

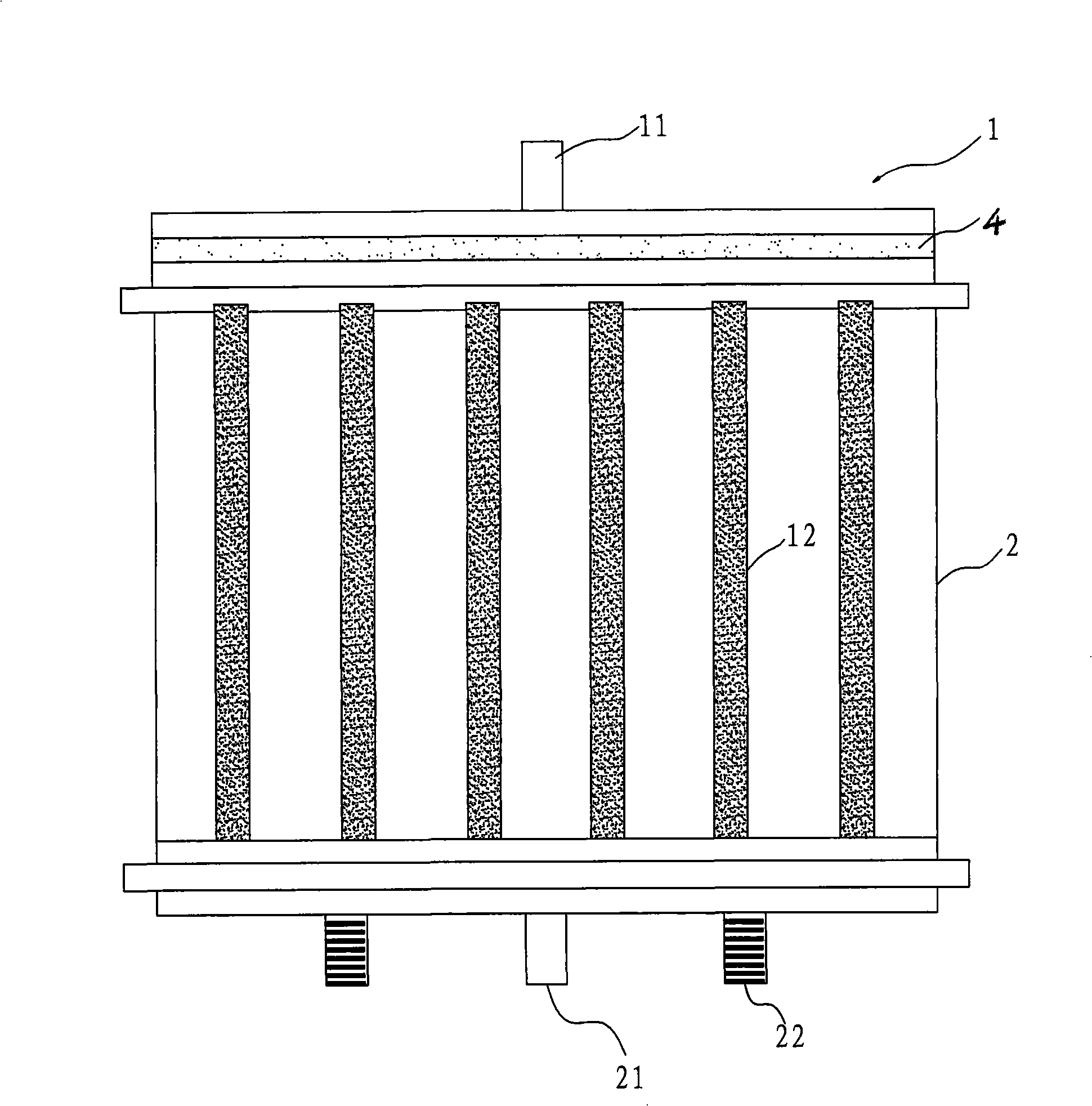

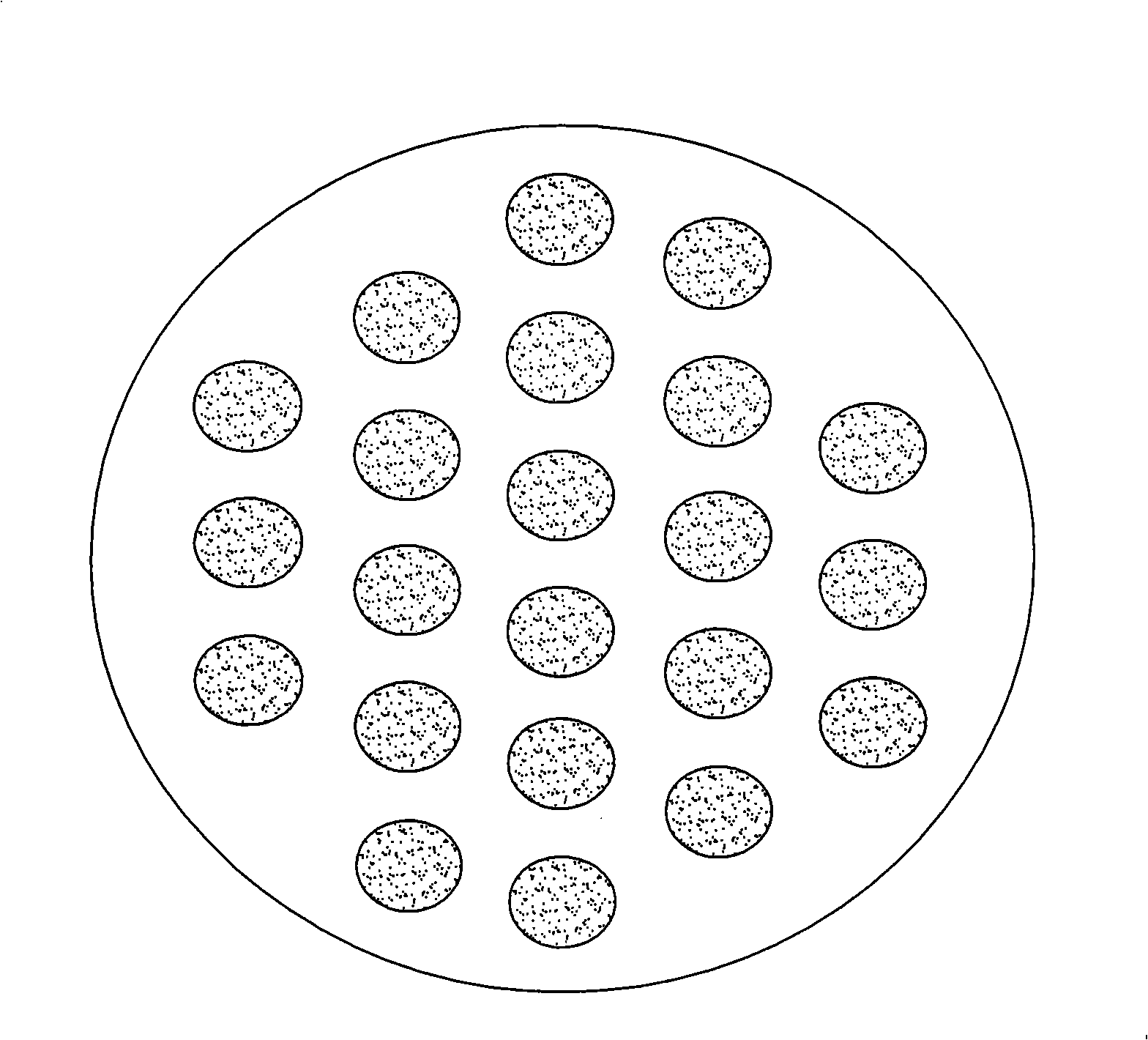

Method for preparing epoxy resin base polyalcohol integral pole and special mold thereof

InactiveCN101293148AEasy to manufactureMild reaction conditionsOther chemical processesSolid sorbent liquid separationChemical structureFirming agent

The invention relates to a preparation method of epoxy resin-based polymer monolithic column; a given quantity of the epoxy resin and firming agents and a low molecular weight polymer mixture with a good compatibility used as pore-forming agents are added in an empty tube column; solidification temperature is controlled so as to regulate the speed of polymerization reaction; after the solidification is finished, the pore-forming agents are removed by washing so as to get the polymer monolithic column. The preparation process of the invention is simple and environmental friendly. The invention also discloses a dedicated mould. The monolithic column can be made into various specifications and forms as required and has the advantages of evenly distributed aperture, adjustable size, strong hydrophilic property, acid and alkali resistance, solvent resistance and good thermostabilization; and a large number of reactive functional groups are contained in the chemical constitution of the material of the monolithic column, which is suitable for performing a plurality of chemical modifications to an inner surface of a pore canal so as to further functionalize. The preparation method of the epoxy resin-based polymer monolithic column can be applied extensively to the fields such as the extraction and recovery of solid phase, the preparation of chromatogram, the separation of biological medicines, the environmental protection and the catalysis etc.

Owner:NINGBO UNIV

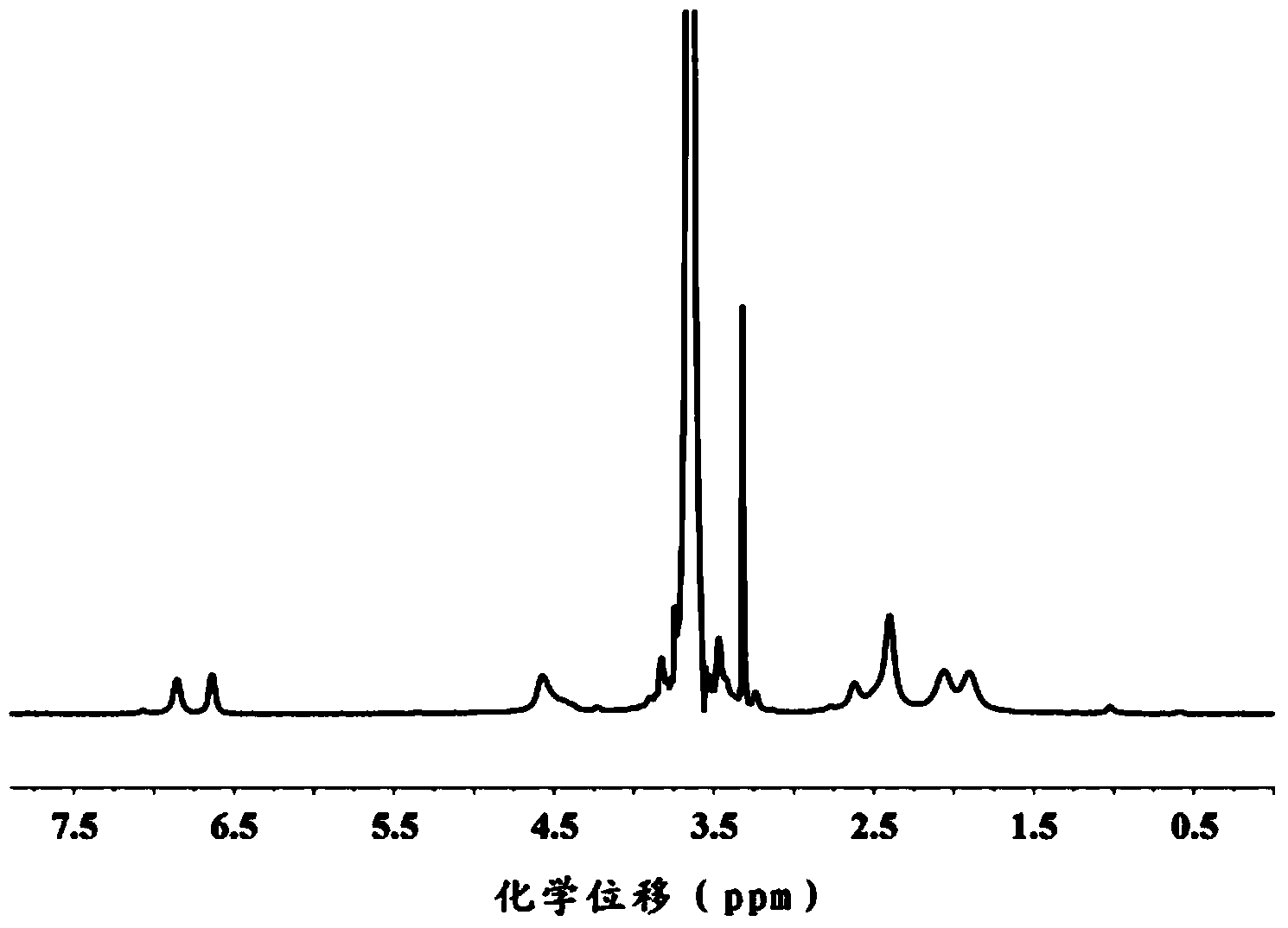

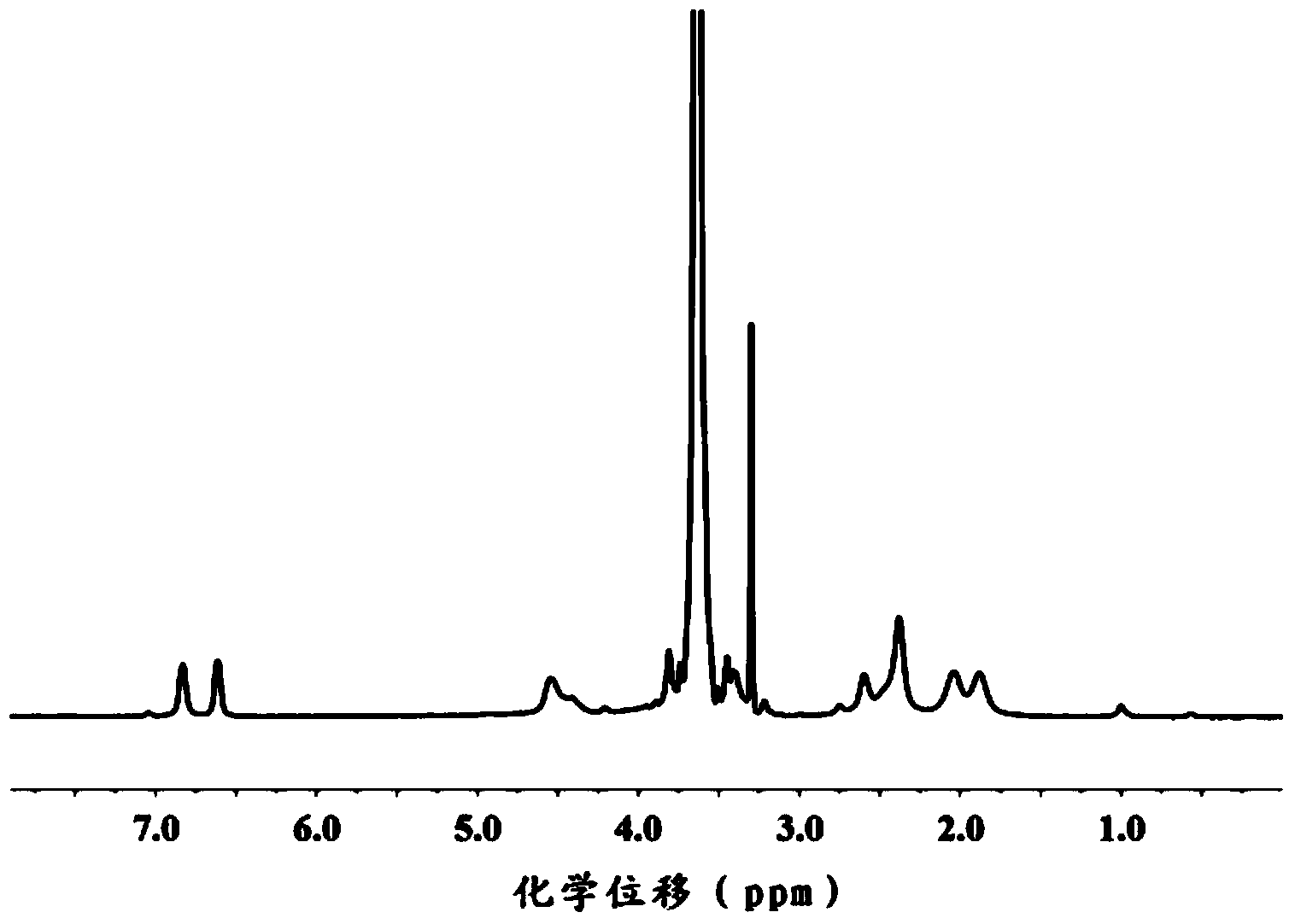

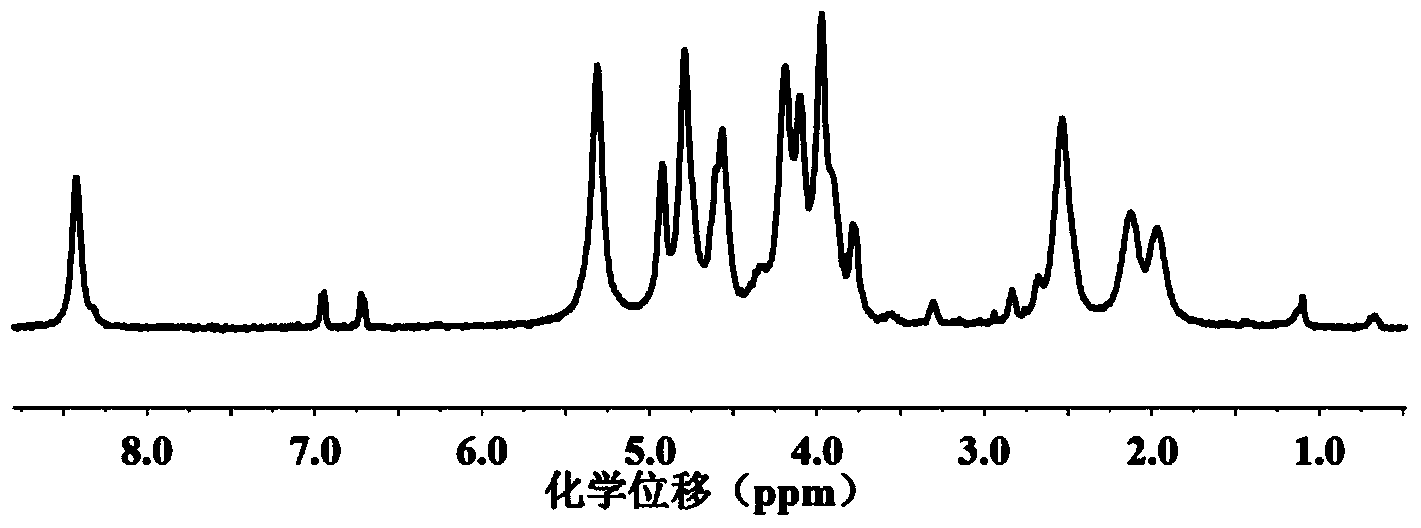

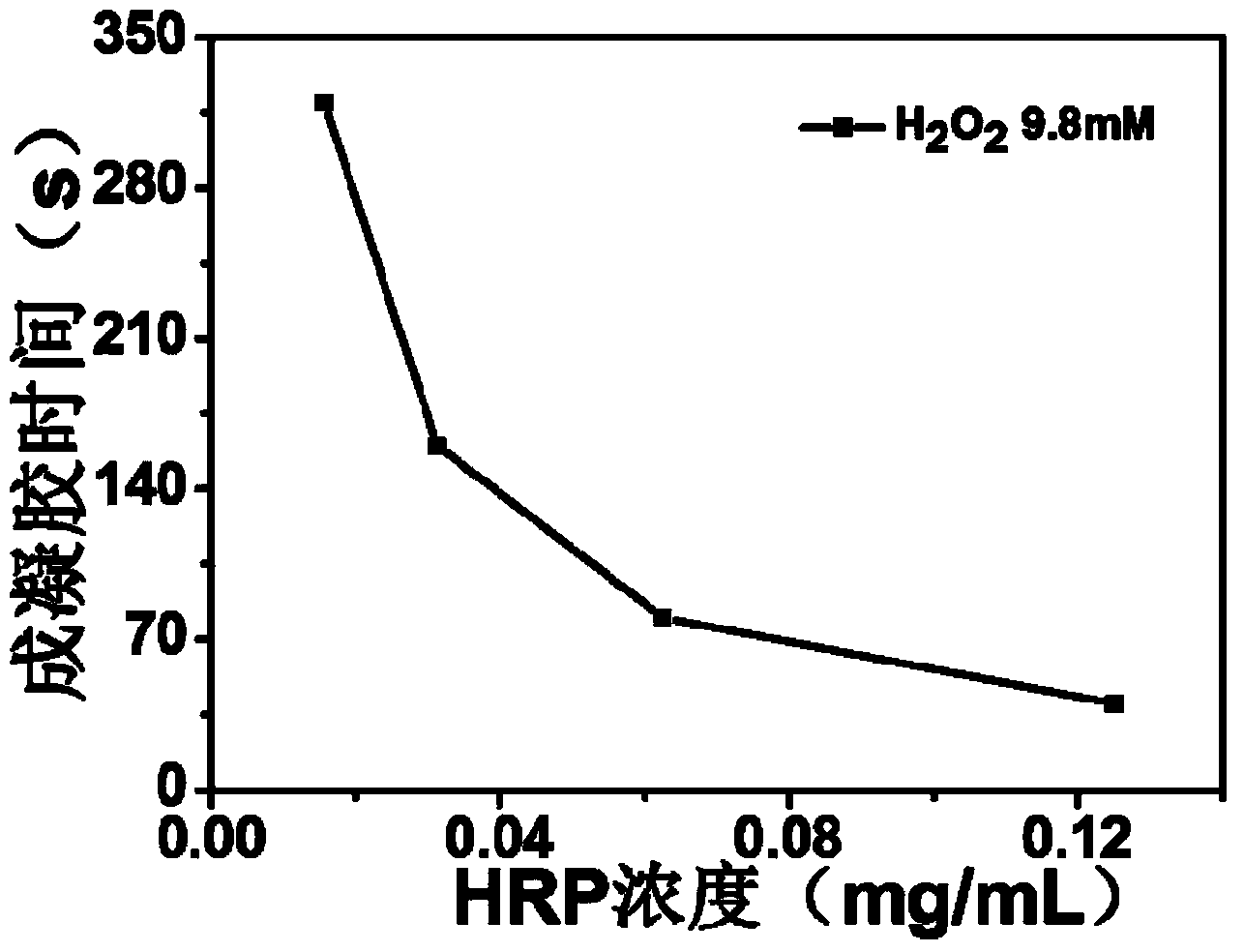

Polyamino acid graft copolymer, preparation method thereof and injectable hydrogel

ActiveCN103524748AHigh mechanical strengthGood water solubilityAerosol deliveryOintment deliverySolubilityReaction rate

The invention provides a polyamino acid graft copolymer, a preparation method thereof and an injectable hydrogel. The polyamino acid graft copolymer is shown in a formula (I). Compared with a natural polymer, the polyamino acid graft copolymer takes poly (L-glutamic acid) with a formula (V) structure as a main chain, natural protein and polypeptide can be simulated in a certain extent, and the polyamino acid graft copolymer has excellent biocompatibility and degradability; the graft polymer is provided with a branch chain with a formula (II) structure and comprises a phenol structure, different grafting ratios can be adjusted, cross-linking can happen under the action of HRP (horse radish peroxidase) and hydrogen peroxide, the formation condition is mild, and the reaction rate is easy to control, so that the injectable hydrogel with higher mechanical strength can be prepared; and the graft copolymer further comprises a branch chain with a formula (III) structure, and the different grafting ratios can be adjusted, so that the polyamino acid graft copolymer shown as the formula (1) has excellent water solubility.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

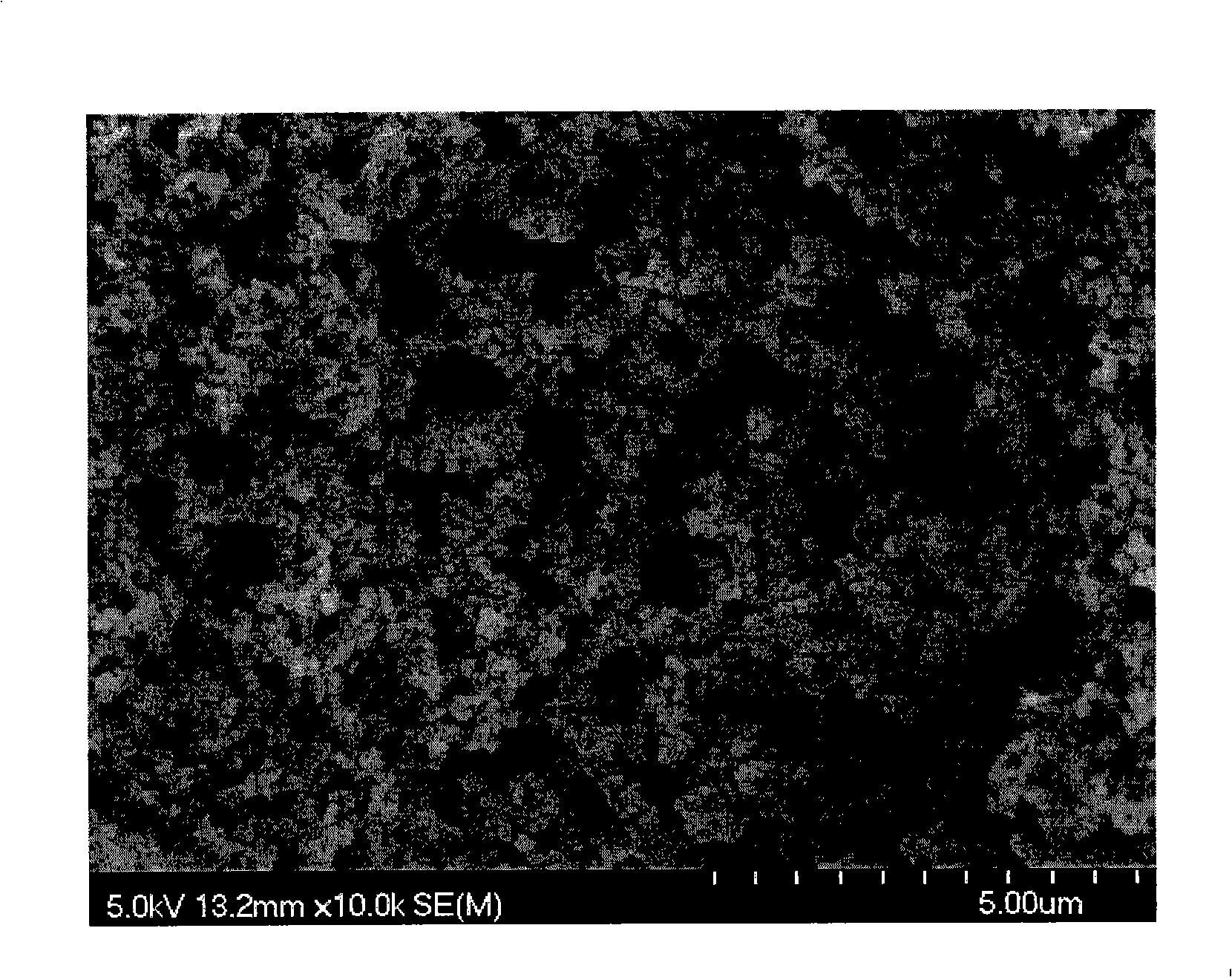

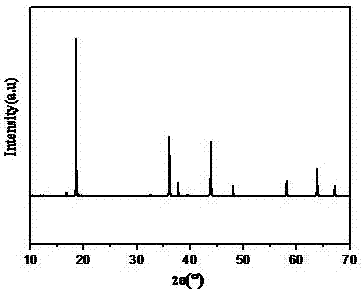

Preparation method for nano-scale spinel nickel-doped lithium manganate material

ActiveCN106981653APromote circulationUniform size distributionCell electrodesSecondary cellsAir atmosphereNickel salt

The invention discloses a preparation method for a nano-scale spinel nickel-doped lithium manganate material. The method comprises the following steps: accurately weighing lithium salt, manganese salt and nickel salt in a mole ratio of lithium ion to manganese ion to nickel ion of 1:1.92:0.08 in a molecular formula of LiNi0.08Mn1.82O4 and placing into a beaker; stirring and dissolving in a defined amount of distilled water at 50 DEG C and forming a uniform mixed solution, and then dropwise adding an oxidizing agent while stirring and keeping the temperature for 5-15min; heating under a constant temperature at 100 DEG C, evaporating a certain volume of water in the solution and then transferring into a porcelain crucible; placing the porcelain crucible filled with the solution into a temperature programming box type resistance furnace at 150 DEG C, keeping the temperature and heating for 5min, performing combustion reaction for 30-60 min under 400 DEG C air atmosphere, keeping the temperature at 500 DEG C for 1-2h, cooling and then grinding; secondarily roasting the ground powder at 600-700 DEG C, keeping the temperature for 3-6h and grinding again, thereby acquiring the final product. An anode material prepared according to the invention has excellent circulating stability.

Owner:YUNNAN MINZU UNIV

Diaper with good absorbing, water-locking and antibacterial properties and processing technique thereof

ActiveCN110123528AGood drainage and absorption performanceIncrease the areaAbsorbent padsBaby linensHigh absorptionResin microsphere

The invention relates to a processing technique of a diaper. A diaper body is included and is provided with a surface layer, a flow guide layer, an absorbing core layer and a bottom membrane layer sequentially from top to bottom; the absorbing core layer comprises a dust-free paper layer and a high-absorption material layer sequentially from bottom to top; the high-absorption material layer is made by mixing antibacterial high-absorption resin microspheres and fluff pulp in a mass ratio of (3-4):(7-6). A synthetic method of the antibacterial high-molecular water-absorbing resin microspheres applied in the diaper acts as a modification to a method of synthesizing high-molecular water-absorbing resin via a solution process; magnetic ordered mesoporous carbon nanospheres with multiple ducts,regular pore size and large specific surface area are used as a carrier; therefore, polymerization efficiency is improved, the finished high-molecular water-absorbing resin microspheres have uniform character, and the post-treatment procedures are simple.

Owner:HANGZHOU COCO HEALTHCARE PRODS +2

Synthesis method and application of superabsorbent resin microspheres with antibacterial properties

ActiveCN110272517AIncrease the areaImprove liquid storage capacityAbsorbent padsBandagesResin microsphereSynthesis methods

The invention relates to a synthesis method and application of superabsorbent resin microspheres with antibacterial properties. The synthesis method comprises the following steps: (1) adding a certain amount of magnetic ordered mesoporous carbon nanospheres and a polymer dispersing agent to a certain amount of water, performing full and even stirring, then performing vacuum and / or ultrasonic-assisted degassing treatment for 1-2 h, adding a certain amount of acrylic acid, performing even stirring, and controlling the temperature at 35-45 DEG C; (2) adding a certain amount of sodium hydroxide to the system obtained in the step (1) while stirring, and controlling the temperature at 65-75 DEG C in the reaction process; (3) adding a certain amount of a composite crosslinking agent and an initiator, and controlling the temperature at 80-90 DEG C for a reaction for 2-3 hours so as to form a semi-finished product superabsorbent resin colloid, wherein the composite crosslinking agent is a mixture of NMBA and PEGDA; and (4) putting the superabsorbent resin colloid obtained in the step (3) in a certain amount of a solvent, performing rinsing for 1-3 times, adding a certain amount of a nano-silver antibacterial agent, performing drying until the moisture content at less than 3%, performing pulverization to a certain particle size, and performing magnetic separation so as to obtain the superabsorbent resin finished product.

Owner:HANGZHOU COCO HEALTHCARE PRODS +2

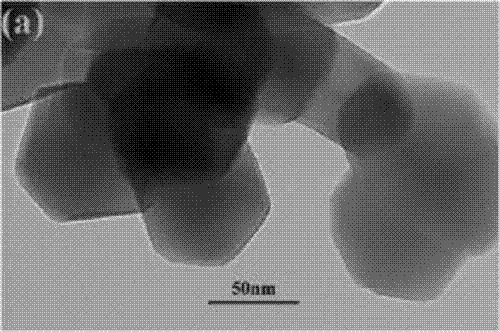

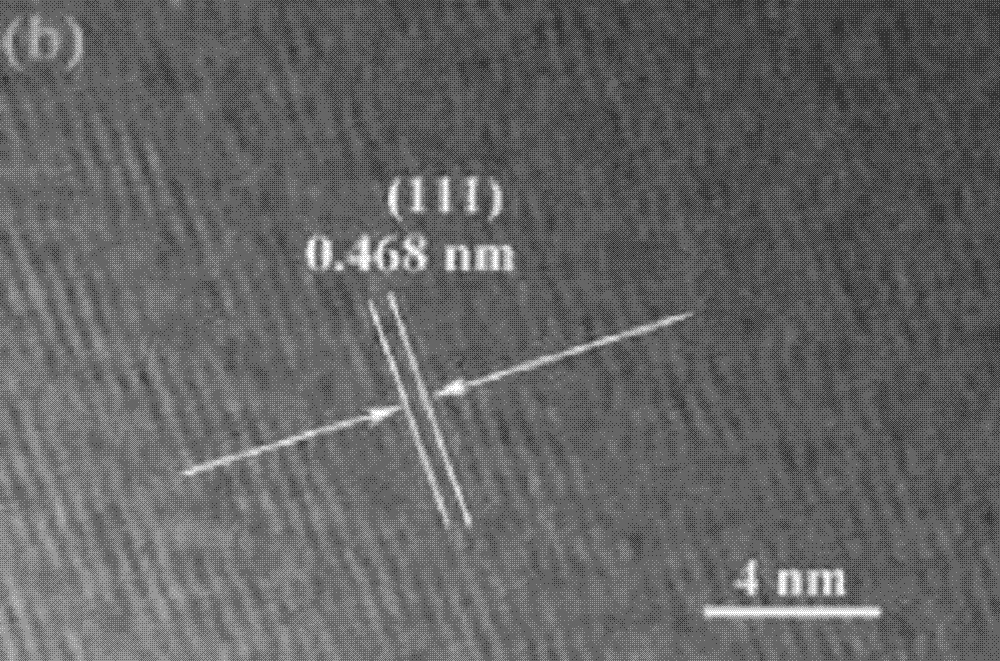

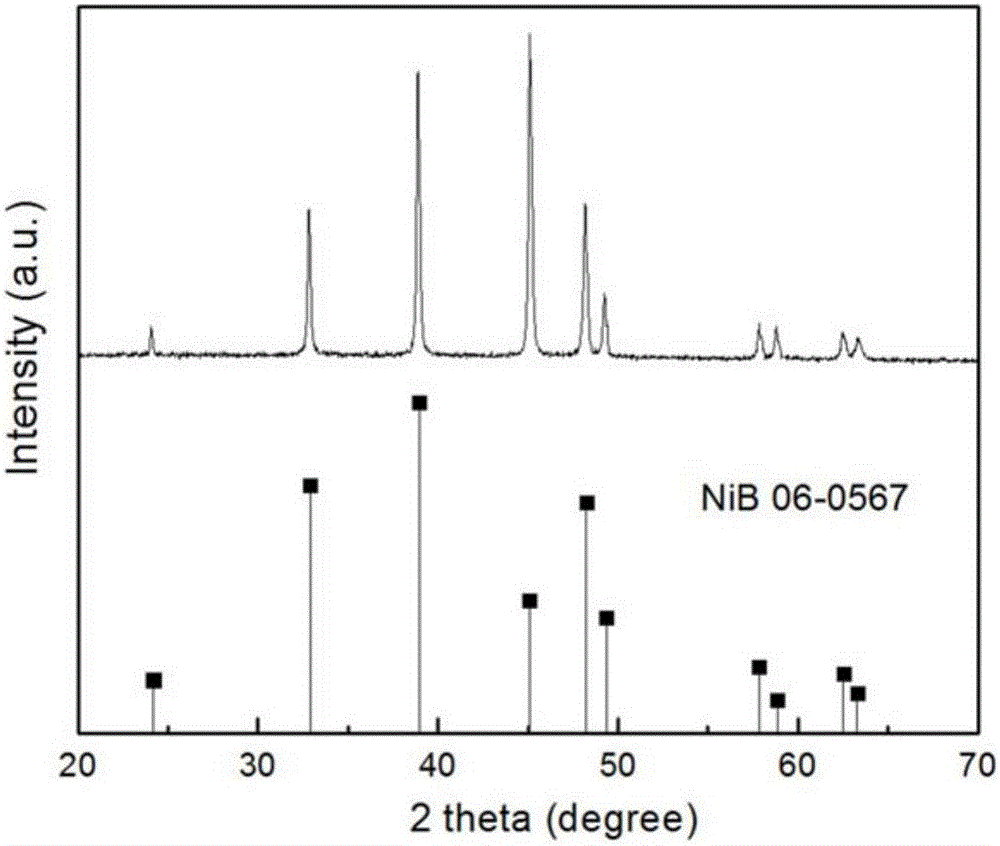

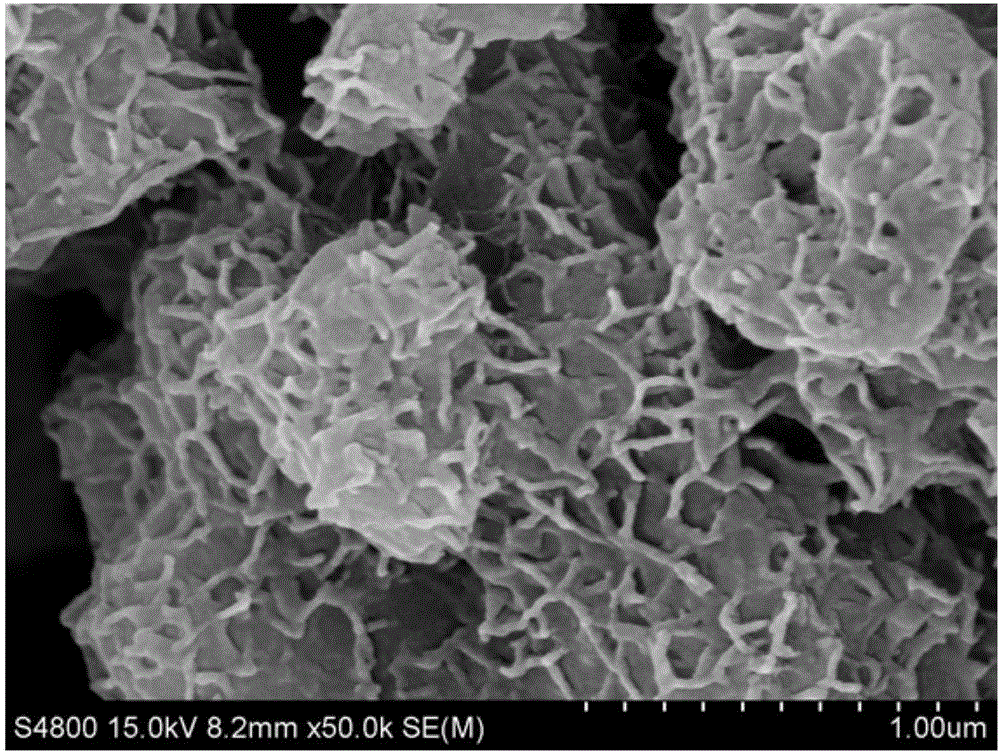

Flaky porous nickel boride powder and preparation method thereof

The invention discloses flaky porous nickel boride powder and a preparation method thereof and belongs to the technical field of inorganic powder preparation. The powder is crystalline-state NiB and is composed of nanosheets with the average thickness of 20 nm and the plane view size of 200-300 nm. The nanosheets are connected in a staggered mode to form an open porous structure. The powder is prepared through the steps that micron-order metallic nickel powder, amorphous boron powder and alkali chloride powder are mixed; the mixed powder is put in a corundum crucible and heated to 1,000 DEG C or above under argon protection, and natural cooling is carried out after heat preservation is carried out for 0.5-2 h; the obtained product is soaked with water for 1-3 h, filtered, washed multiple times with water and ethyl alcohol respectively and dried, and the flaky porous NiB powder is obtained. The obtained nickel boride powder is in a crystalline state, has a flaky porous structure, can serve as a catalyst carrier material and also is a potential inorganic functional material.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

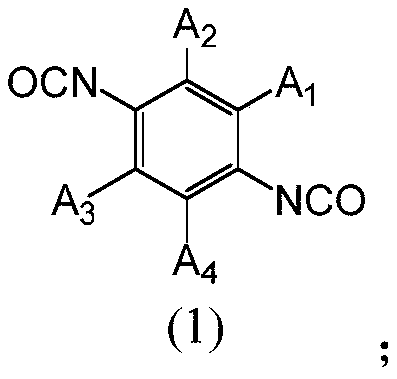

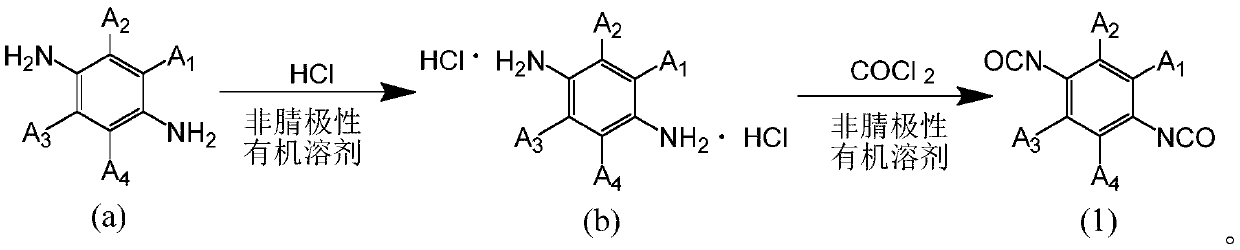

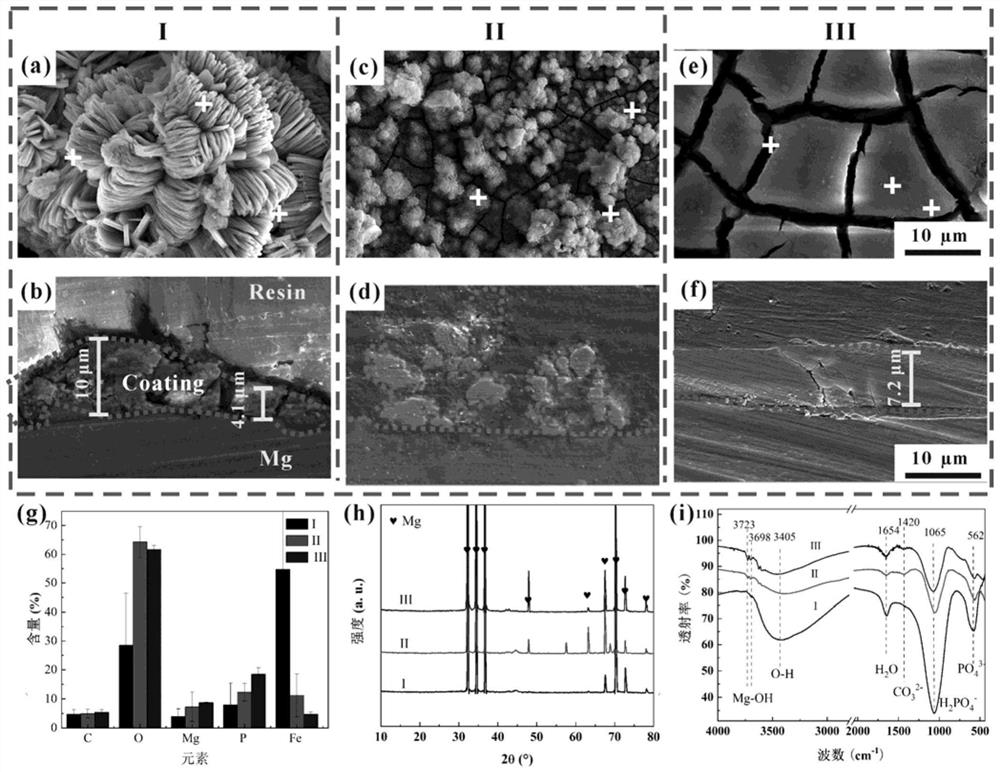

Preparation method of substituted 1,4-phenylene diisocyanate and application of non-nitrile polar organic solvent in preparation of substituted 1,4-phenylene diisocyanate

InactiveCN110183356ASimple reaction conditionsHigh purityOrganic compound preparationIsocyanic acid derivatives purification/separationFiltrationPhosgene

The invention belongs to the technical field of fine chemical engineering, and particularly relates to a preparation method of substituted 1,4-phenylene diisocyanate and an application of a non-nitrile polar organic solvent in preparation of the substituted 1,4-phenylene diisocyanate. The non-nitrile polar organic solvent provided by the invention is used as a reaction solvent for preparing the substituted 1,4-phenylene diisocyanate, and solid diamine (or hydrochloride thereof) continuously dissolves in the solvent system, the contact time and contact area of the diamine (or hydrochloride thereof) with phosgene are reduced, and gasification the solid diamine is not needed, so that the equipment structure is simplified, and production cost is reduced. Distribution of the dissolved diamine (or hydrochloride thereof) in the system is approximately equal to distribution of the residence time of the phosgene, and the process is controllable. According to the preparation method of the substituted 1,4-phenylene diisocyanate provided by the invention, the non-nitrile polar organic solvent system is adopted, so that generation of a large amount of wastewater is avoided, pollution to the environment is reduced, meanwhile, loss of substituted 1,4-phenylenediamine hydrochloride during filtration operation is reduced, and the yield is improved.

Owner:XINYI AGRI CHEM PLANT JIANGSU PROV

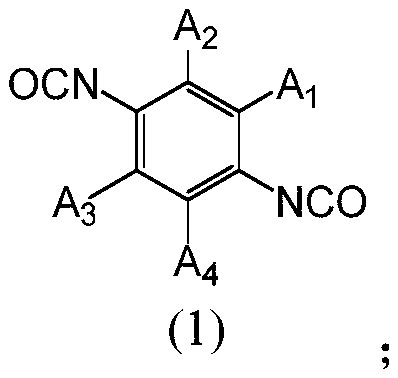

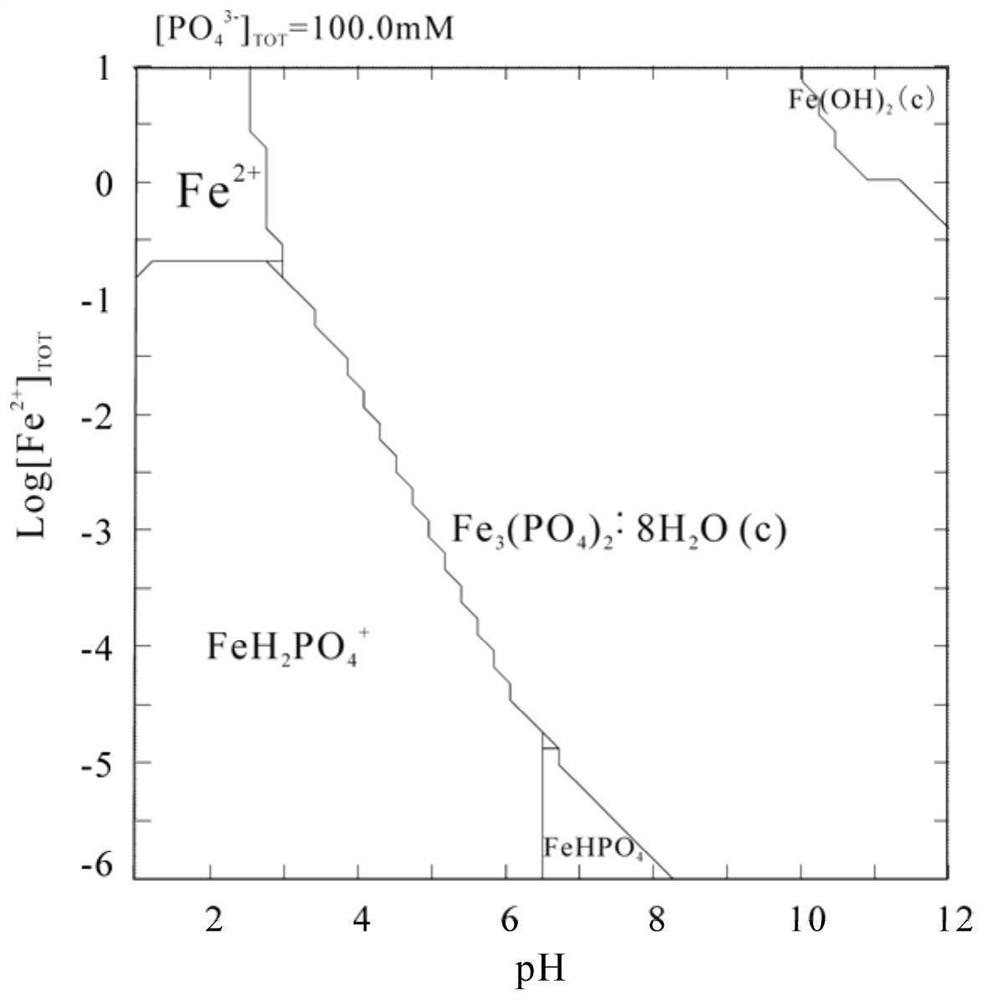

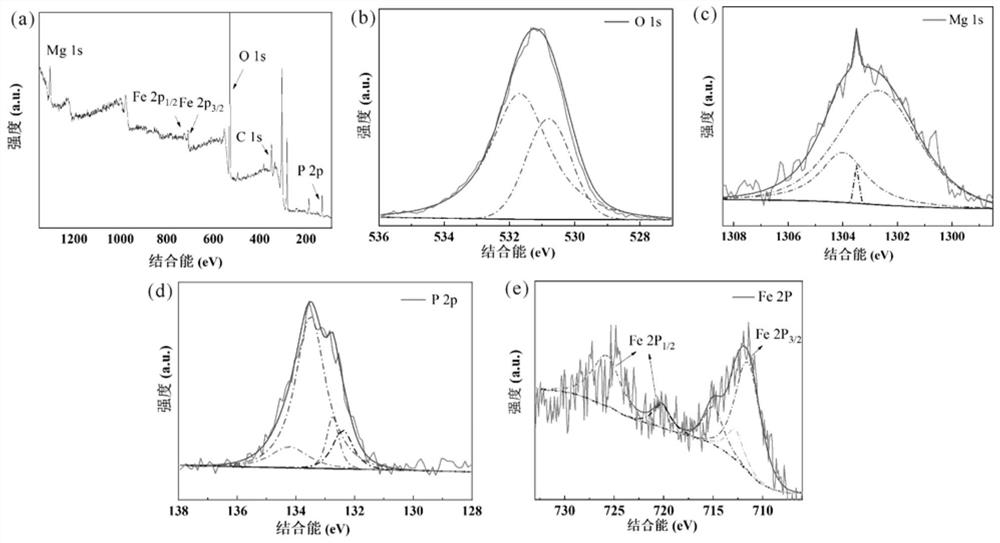

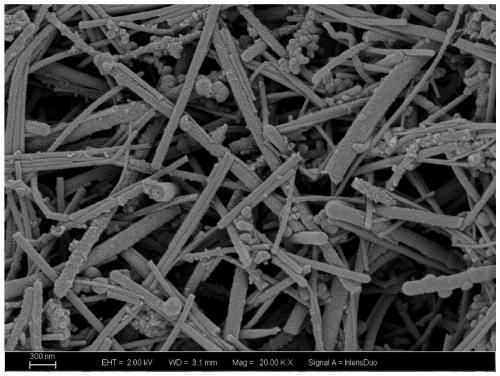

Magnesium or magnesium alloy surface autocatalytic degradation coating and preparation method thereof

ActiveCN111701606AHas a porous structureSelf-catalytic degradation is obviousCatalyst activation/preparationMetallic material coating processesPorous coatingMg alloys

The invention provides a magnesium or magnesium alloy surface autocatalytic degradation coating and a preparation method thereof. Phosphate and ferrite or ferric salt are used as raw materials, a chemical conversion method is adopted to prepare a coating capable of accelerating magnesium alloy degradation on the surface of a magnesium or magnesium alloy matrix, and the obtained coating is phosphate and hydroxide of iron and ferrous iron. The composite coating is a cathode type porous coating; since the open-circuit potential is higher than that of a magnesium alloy matrix, and meanwhile, elementary iron generated by reduction of iron or ferrous ions can form galvanic corrosion with the magnesium alloy, so that the effect of accelerating corrosion of the magnesium alloy is achieved, and further, autocatalytic degradation of the magnesium alloy is realized. A new way of thinking is created in the invention. Compared with the prior art, the method disclosed by the invention has the characteristics of environment-friendly and simple process, short reaction time, low production cost, no damage to a matrix structure and mechanical properties and the like. The obtained magnesium alloy surface coating has the advantages of being porous in structure, good in biodegradability and biocompatibility and the like, and therefore the magnesium alloy surface coating can be used as a structuralmaterial and can also be used as a degradable biomedical material.

Owner:SHANDONG UNIV OF SCI & TECH

Preparation and application of silicon nitride coated carbon nano tube

ActiveCN110342494AControllable reaction rateSimple processMaterial nanotechnologyNitrogen compoundsSilane compoundsNitrogen

The invention provides preparation and application of a silicon nitride coated carbon nano tube, and belongs to the technical field of functional materials. A preparation method of the silicon nitridecoated carbon nano tube comprises the following steps that S1, the carbon nano tube is loaded into a whole reaction kettle in a loosening mode and the whole reaction kettle is filled with the carbonnano tube, and then vacuumizing is carried out to 0.1-100Pa; then silicon tetrachloride gas is introduced into the reaction kettle to initial pressure in the reaction kettle being in a range of 1-2atm; then ammonia gas is introduced continuously and reacts with the silicon tetrachloride gas under -20-60 DEG C, and a nitrogenous silane compound generated by the silicon tetrachloride gas and the ammonia gas is deposited on the surface of the carbon nano tube; S2, at an ammonia gas atmosphere, the carbon nano tube attached with the nitrogenous silane compound on the surface in the S1 is heated to500-600 DEG C, and heat treatment is carried out for 1-2 hours; and S3, continuous heating is carried out to 650-1200 DEG C, heat treatment is carried out for 2-8 hours, so that the nitrogenous silane compound is decomposed into amorphous silicon nitride, and the amorphous silicon nitride is uniformly deposited on the surface of the carbon nano tube. According to the preparation and application of the silicon nitride coated carbon nano tube, industrial production requirement and application of the silicon nitride coated carbon nano tube can be realized.

Owner:SUZHOU FIRST ELEMENT NANO TECH

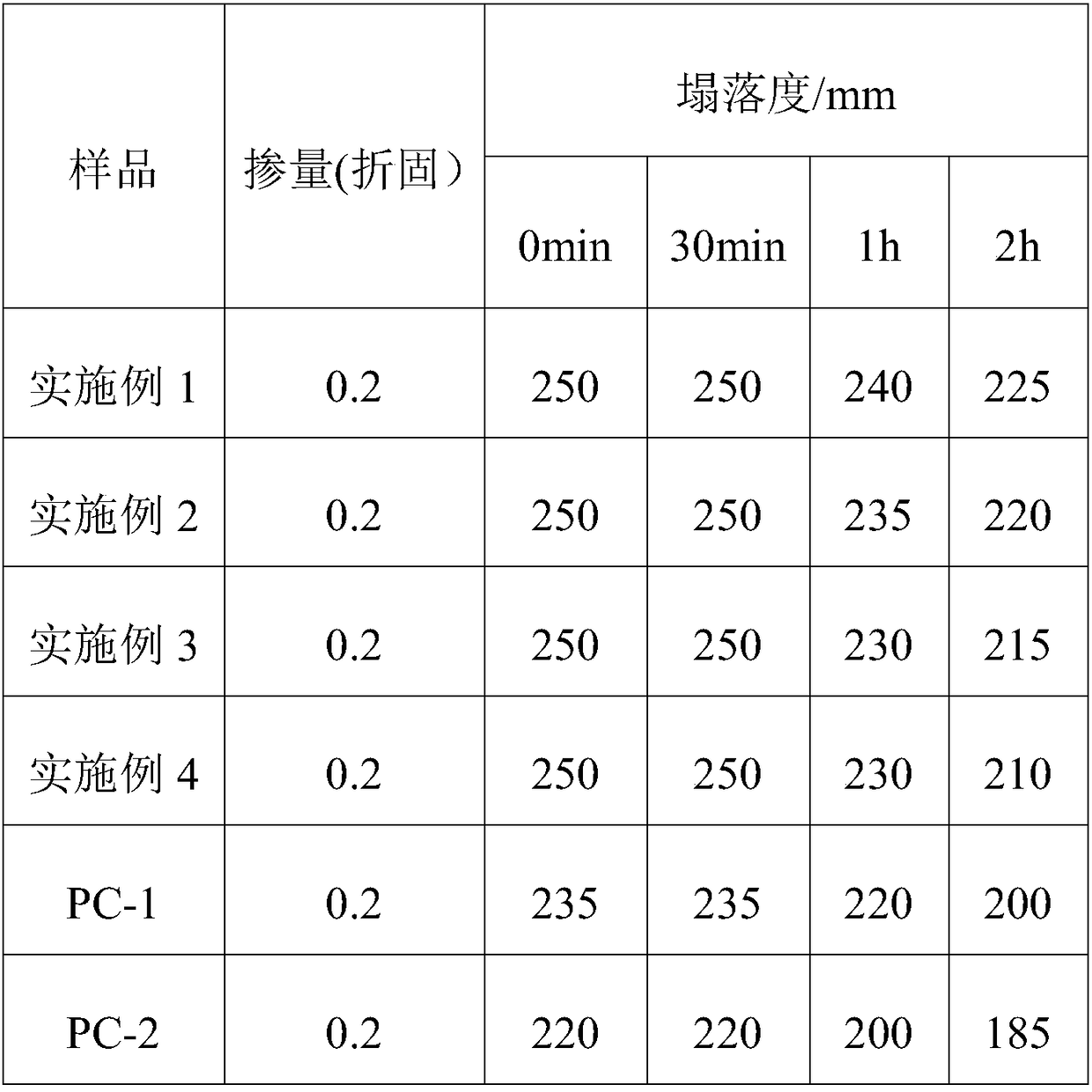

Preparation method of slump-proof polycarboxylate superplasticizer

ActiveCN108084358ALower melting temperatureLow reaction temperatureBulk polymerizationTransport time

The invention provides a preparation method of a slump-proof polycarboxylate superplasticizer. The slump-proof polycarboxylate superplasticizer is prepared by bulk polymerization. The preparation method comprises the steps of (1) mixing polyoxyethylene polyoxypropylene ether and polyoxyethylene ether, stirring well at controlled temperature of 40-60 DEG C, and adding an initiator and a mixture ofunsaturated carboxylic acid, unsaturated carboxylates and a chain transfer agent; (2) curing for 0.5-1 hour after completion of step (1), and cooling to obtain the slump-proof polycarboxylate superplasticizer. The bulk polymerization is performed at relatively low temperature, the conditions are mild, operability is high, and the synthesized polycarboxylate superplasticizer has high water-reducingproperty. The polycarboxylate superplasticizer prepared herein is in liquid state at normal temperature, having an effective concentration of 100% and good stability of storage performance; the polycarboxylate superplasticizer is applicable to long-range transport and use; the polycarboxylate superplasticizer has excellent slump-proof performance; the problem can be solved that concrete slumps due to high temperature and long transport time; the polycarboxylate superplasticizer has a promising industrial application prospect.

Owner:JIAHUA CHEM MAOMING

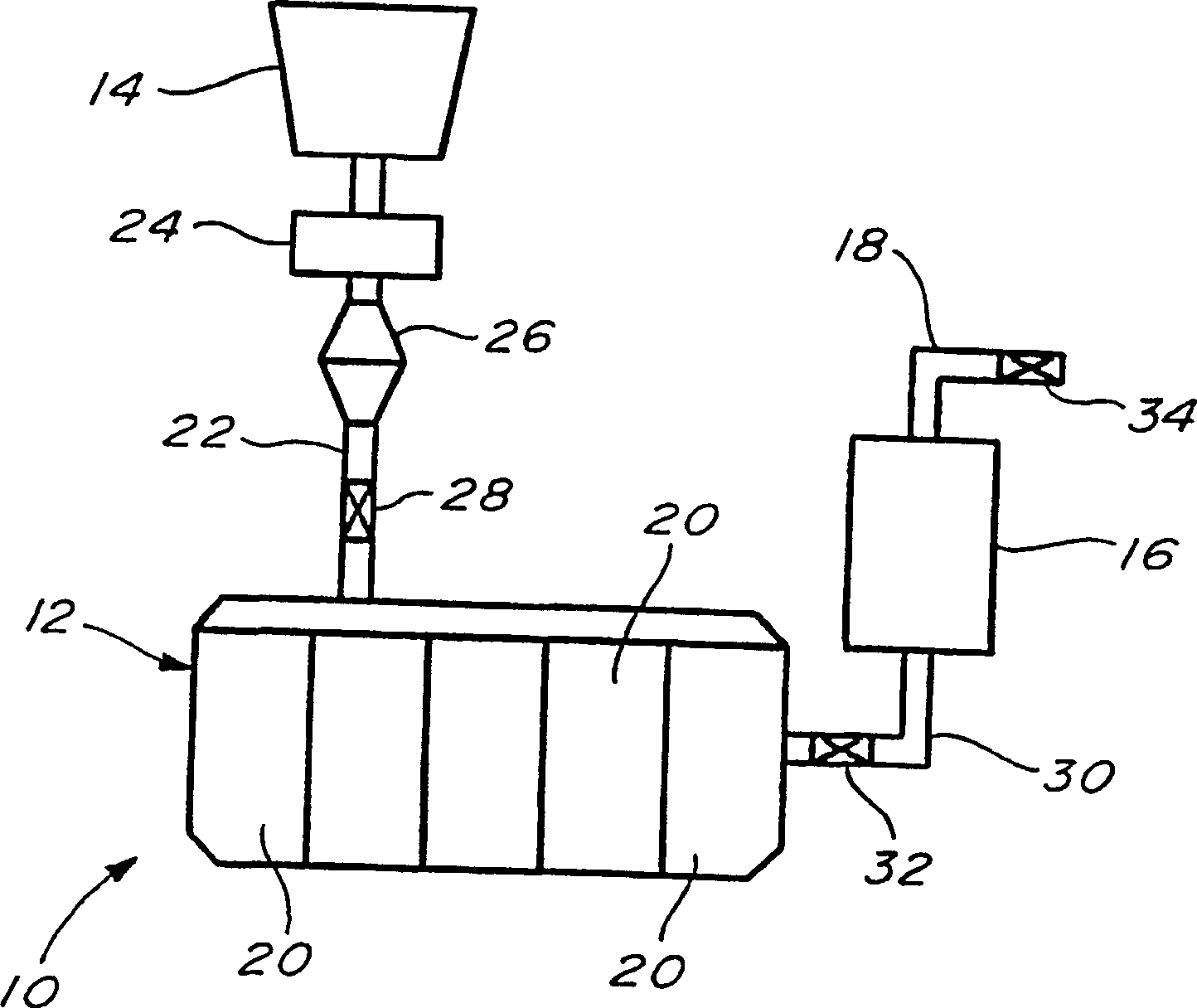

Method of hydrogen generation for fuel cell applications and a hydrogen-generating system

InactiveCN1438968AHigh total hydrogen capacityImprove response characteristicsGroup 4/14 organic compounds without C-metal linkagesHydrogen productionChemical reactionElectrical battery

Fuel cell (FC) is one of chemical power sources and is characterized in that it is capable of converting chemical energy directly to electric energy by inputting negative active materials (fuels, to be oxidated) and positive active materials (oxidant, such as air or oxygen generally) deposited outside the cell into two poles of the cell, wherein the energy conversion is not limited by heat engine efficiency and can reach 100% in theory, and it is not necessary to charge the cell. If the fuel used is hydrogen, the exhaust gas discharged is water, without polluting the environment, therefore such a fuel cell is a perfect energy conversion device which can be used in a middle or mini type power station for replacing a heat engine and can be used as a power supply for an electromotion vehicle, space navigation or remote areas. Such a fuel cell is even used for generating electricity by utilizing some chemical reactions in chemical plants (such as that chloride and hydrogen react to synthesis hydrogen chloride in chlor-alkali industry to reclaim one part energy).

Owner:MCGILL UNIV

Copper-based nickel plating-gold plating layer waste plating piece metal gradient recovery method

ActiveCN109487088AHigh purityReduce pollutionProcess efficiency improvementRecovery methodSolution treatment

The invention belongs to the technical field of waste recycling and discloses a copper-based nickel plating-gold plating layer waste plating piece metal gradient recovery method. The method comprisesthe following steps of 1, putting plating pieces into ethyl alcohol to conduct cleaning to remove surface greasy dirt and then conducting cleaning through deionized water; 2, conducting gold solutiontreatment on the cleaned plating pieces; 3, conducting nickel solution treatment on the plating pieces subjected to gold solution treatment; 3.1, washing the surfaces of the plating pieces subjected to gold solution treatment through deionized water. Through the copper-based nickel plating-gold plating layer waste plating piece metal gradient recovery method, reaction is controllable; a gold plating layer on the outermost side of a base body can be quickly and selectively removed in priority, corrosion dissolution to a metallic nickel layer under the gold plating layer is small, and the purpose of separating and recycling metallic gold is achieved; the metallic nickel layer on the surface of each degolded plating piece is selectively separated and recycled; and finally, selective separation and recycling of gold, nickel and copper in the plating pieces are realized.

Owner:NORTHEASTERN UNIV

Chemical nickel plating method and method for chemical plating copper-nickel conducting circuit

ActiveCN105386016ASimple processLow costLiquid/solution decomposition chemical coatingChemical platingCopper plating

The invention relates to the technical field of non-metal surface chemical plating, in particular to a chemical nickel plating method. The chemical nickel plating method is mainly applied to a non-metal surface chemical plating copper-nickel conducting circuit. The chemical nickel plating method comprises the following steps that firstly, acid pickling is used for nickel activating, and a non-metal part obtained after copper plating is put into an acid pickling solution to be soaked for 5-30 min; secondly, chemical nickel plating is conducted, the non-metal part obtained after acid pickling is soaked into a nickel plating solution to be soaked for 5-20 min; and finally the non-metal part plated with the copper-nickel conducting circuit is obtained, wherein the acid pickling solution includes, by weight, 10%-20% of concentrated hydrochloric acid and 2%-3% of nickel chloride. According to the chemical nickel plating method, acid pickling is directly used for nickel activating; compared with traditional activating conducted through precious metal, namely palladium, the technology is simple, cost is low, the activating effect is good, the reaction rate is easy to control, and it is ensured that a nickel plating layer on the copper circuit is uniform. The invention further relates to a method for the chemical plating copper-nickel conducting circuit.

Owner:东莞市发斯特精密科技股份有限公司

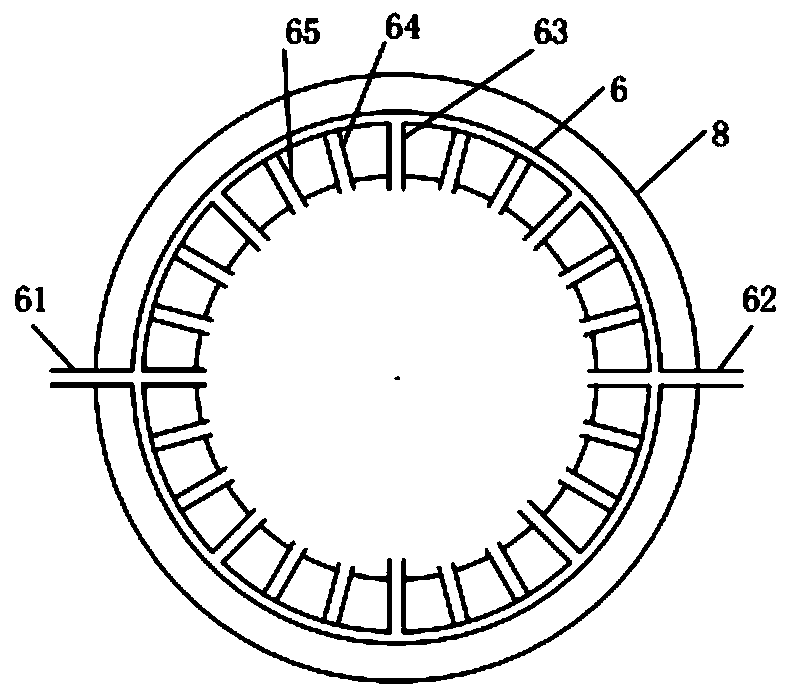

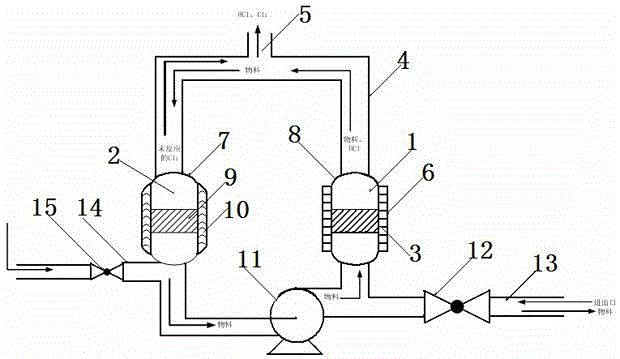

Preparation device of polysilazane and preparation method thereof

PendingCN109627446ATake advantage ofReduce wasteChemical/physical/physico-chemical stationary reactorsPolysilazaneFractionation

The invention belongs to the field of chemical engineering and particularly relates to a preparation device of polysilazane and a preparation method thereof. The preparation device comprises a double-layer tubular reactor, a raw material liquid supply device, a gas supply unit, a cooling device, a product separator, a byproduct collection device, a product fractionation device, a solvent collection device, and a polysilazane collection device. The crude product obtained after reaction is fed into the product separator through a lower end opening of the tubular reactor, and unreacted high-purity ammonia gas and the mixed liquid are delivered back to the reactor for circular reaction while the by-product is separated. Full utilization of the raw materials is achieved, raw material waste is greatly reduced, and the conversion rate is improved; the by-product in the preparing process can be effectively separated in time, the shortcoming is avoided that a large amount of by-products in a kettle-type reactor hinders the contact between ammonia gas and raw material liquid, the reaction time is shortened, and the production efficiency is improved.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

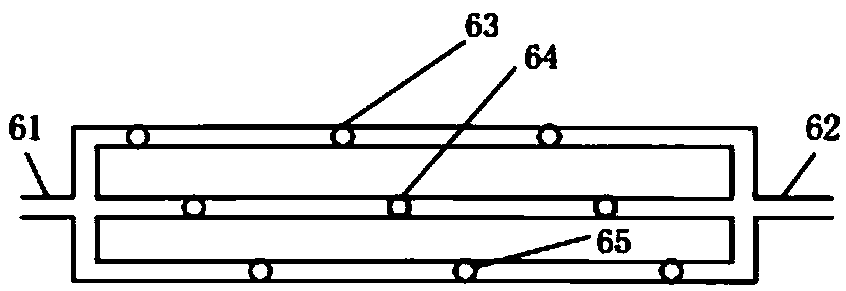

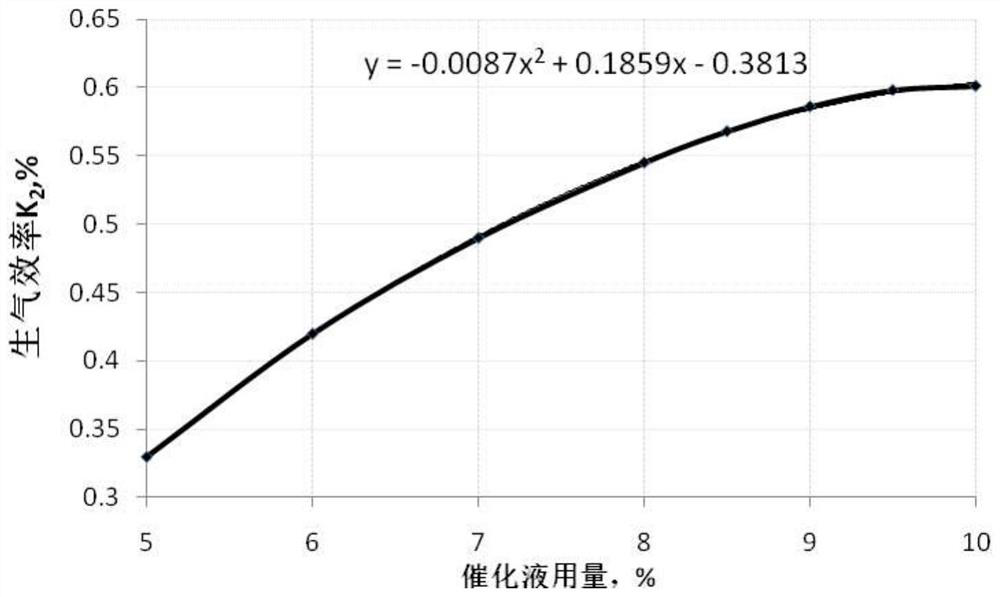

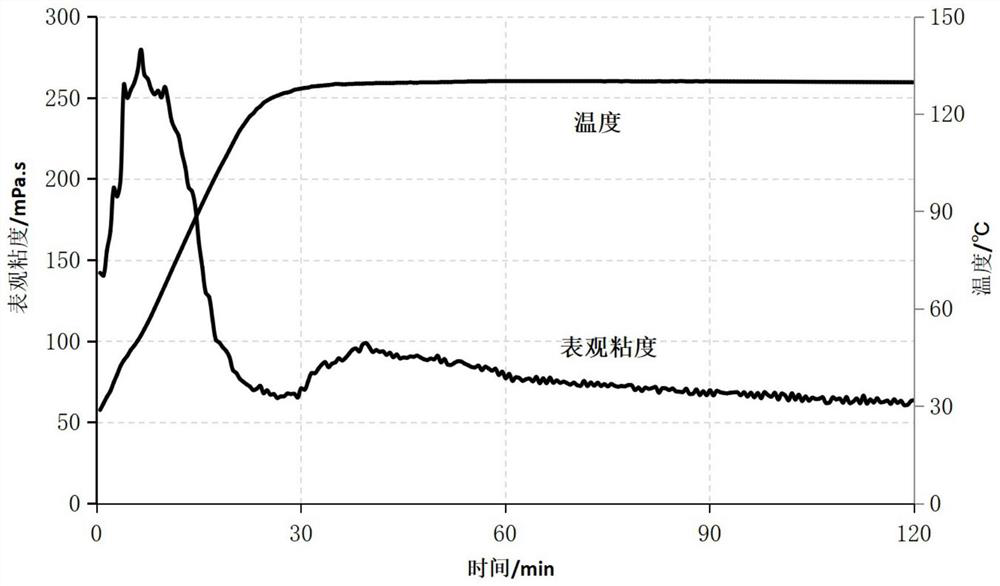

Self-heating composite foam fracturing fluid capable of being controlled in real time and on-site construction method

PendingCN114479820AControllable reaction rateAvoid generatingFluid removalDrilling compositionFoaming agentFracturing fluid

The invention relates to a self-heating composite foam fracturing fluid capable of being controlled in real time and an on-site construction method. The composite foam fracturing fluid comprises the following components in percentage by weight: 87.9-92.97% of base fluid, 6-10% of catalytic fluid, 1.0-1.8% of cross-linking fluid and 0.03-0.3% of gel breaker, wherein the base fluid is prepared from a composite thickening agent, a gas heat agent, a foaming agent, an acid stabilizer and liquid preparation water; the catalytic liquid consists of acid, a scale inhibitor and water, and is used when being prepared; the cross-linking liquid comprises a surfactant and a cross-linking agent. The on-site construction method comprises the following steps: respectively preparing a base solution and a catalytic solution according to a proportion before construction, sucking the base solution by a fracturing blender truck during construction, respectively adding a crosslinking solution and a gel breaker by a liquid adding pump and a dry adding system, pumping the catalytic solution from an outlet pipeline of a sand mixing tank by charging skid-mounted equipment, mixing the components, and then adding the crosslinking solution and the gel breaker into the sand mixing tank. The composite foam fracturing fluid which is resistant to high temperature and high salt, high in sand carrying performance, low in corrosion and low in damage is formed, the viscosity of crude oil can be effectively reduced, energy can be increased, discharge can be assisted, damage can be reduced, and productivity can be improved.

Owner:四川申和新材料科技有限公司

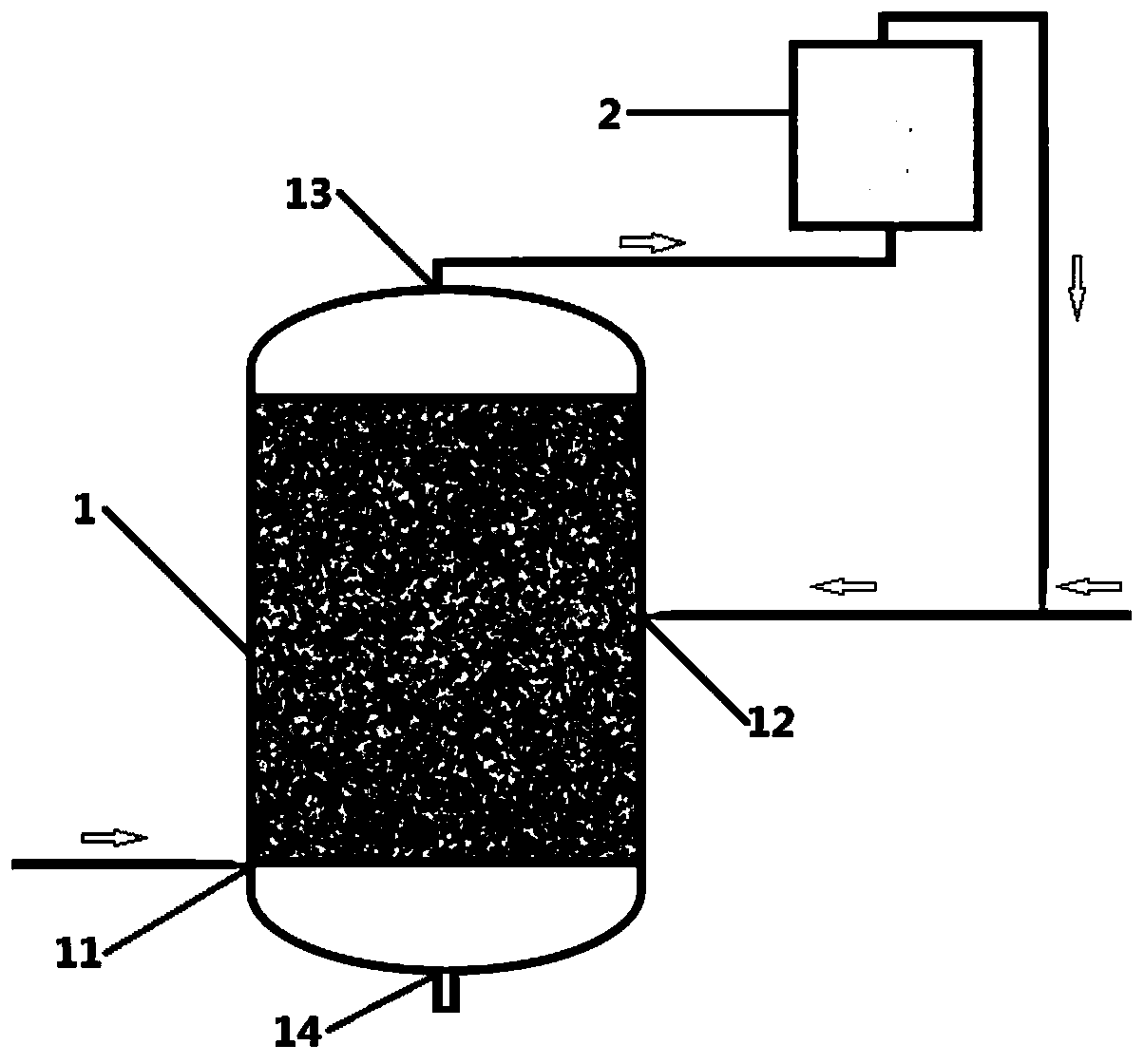

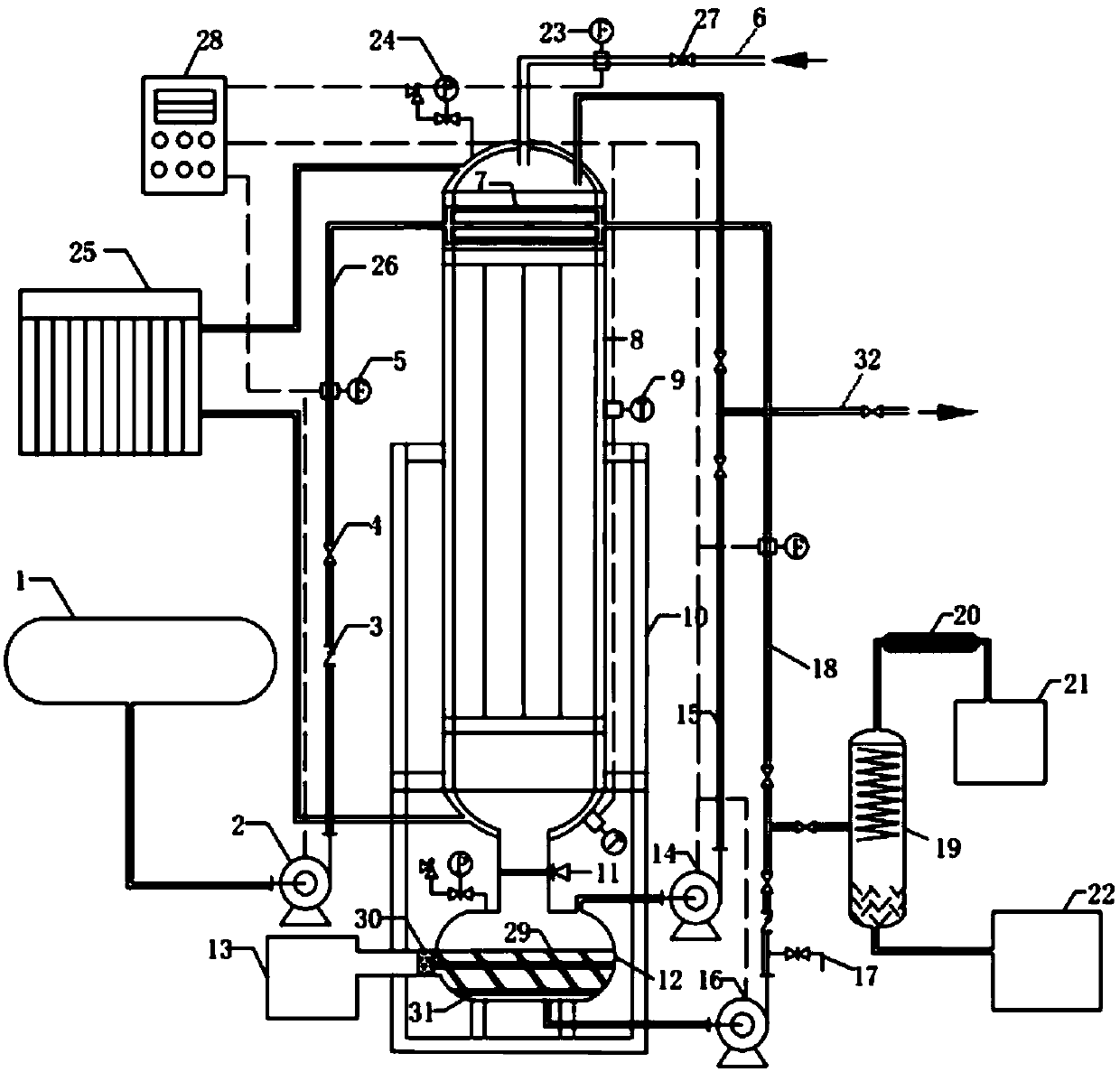

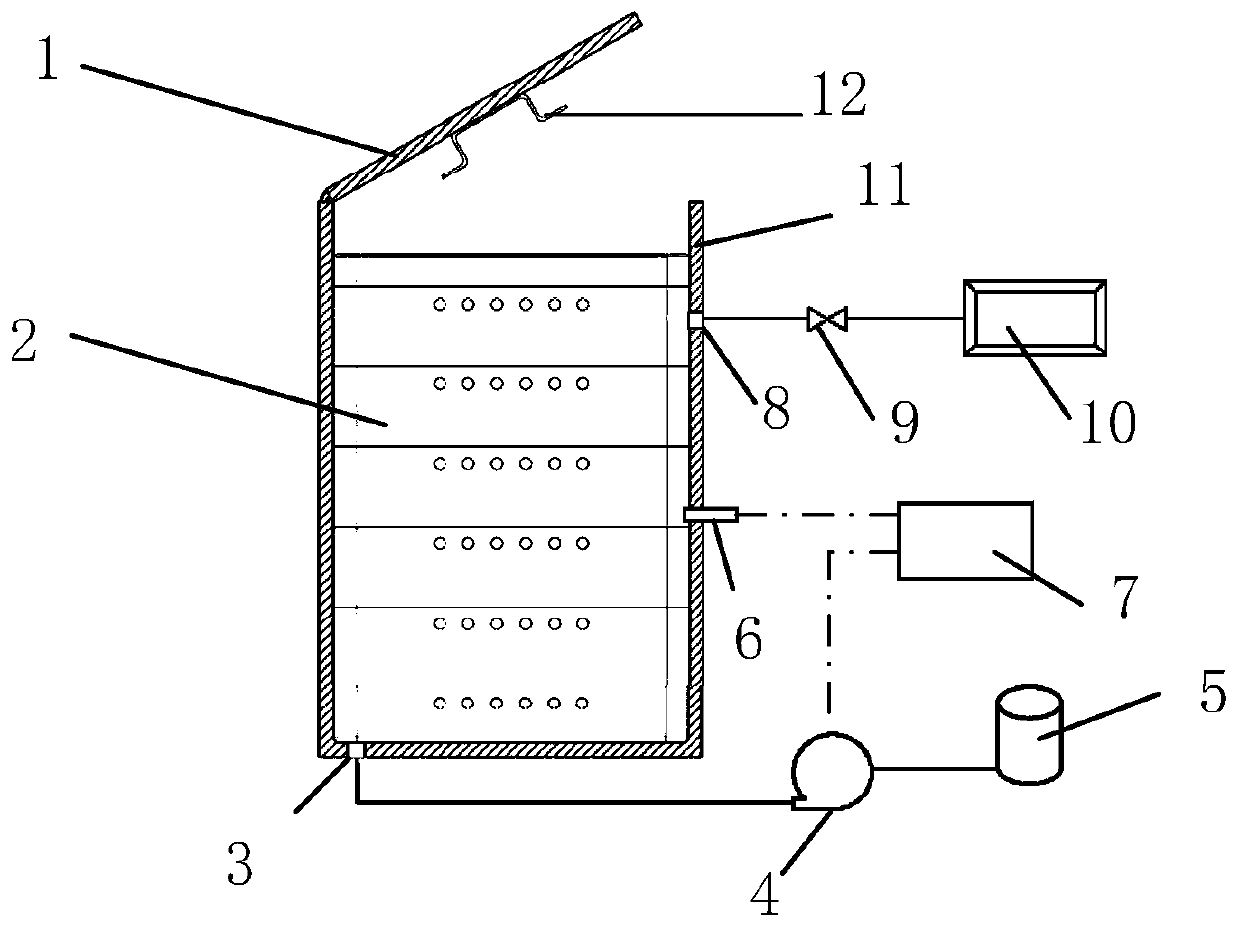

Hydrolysis hydrogen production device

ActiveCN111196595AControlling the rate of the hydrolysis reactionEasy to replaceHydrogen productionFuel cellsWater storage tankHydrogen pressure

The invention discloses a hydrolysis hydrogen production device, which comprises a hydrogen generator, a water storage tank, a water pump, a pressure sensor, a control valve and a controller, whereinthe hydrogen generator comprises an outer shell and a fuel box placed in the outer shell; a hydrogen generator cover plate is arranged at a top opening of the outer shell; an outlet of the water storage tank is communicated with a water inlet of the hydrogen generator through a water pump; the gas outlet in the outer shell is communicated with external hydrogen consumption equipment through a control valve; the pressure sensor is used for detecting the hydrogen pressure in the hydrogen generator, the output end of the pressure sensor is connected with the input end of the controller, and the output end of the controller is connected with the control end of the water pump. The device has the advantages of being convenient to replace fuel, safe to carry, easy to control the reaction rate andlow in cost.

Owner:西安迈进能源科技有限公司

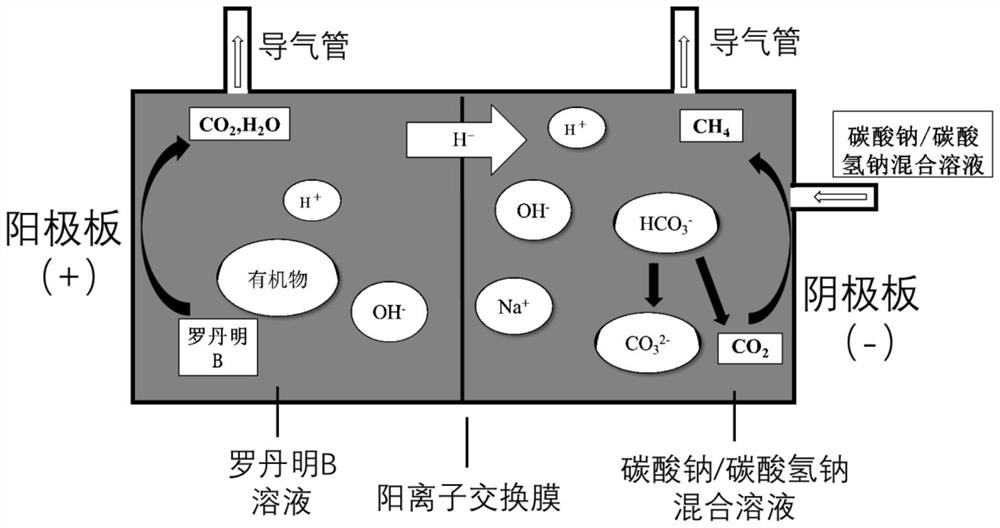

Device and method for producing methane by coupling printing and dyeing wastewater treatment with three-dimensional electrode

InactiveCN112320895AAchieve emission reductionRealize energy savingCellsWater contaminantsElectrolytic agentActivated carbon

The invention provides a device and method for producing methane by coupling printing and dyeing wastewater treated by a three-dimensional electrode, and belongs to the technical field of comprehensive utilization of wastewater. The device comprises a CO2 storage tank, an electrolyte generating tank, an electrolytic bath, activated carbon particles, a cathode electrode plate, an anode electrode plate, a direct-current stabilized power supply, a cation exchange membrane, a cathode product gas collecting device and an anode product gas collecting device. The cation exchange membrane is fixed between the two electrode plates and divides the internal space of the electrolytic cell into two electrode chambers, the electrolyte generating tank is connected with a cathode chamber of the electrolytic cell through two pipes to form electrolyte circulation, and the upper parts of the cathode and anode chambers are respectively communicated with respective product gas collecting devices through conduits. According to the device, carbon dioxide can be reduced by the cathode to generate methane while printing and dyeing wastewater is treated by the anode, gas products in the two chambers can becompletely separated by the ion exchange membrane, methane collection of the cathode is facilitated, and the aims of treatment of degradation-resistant wastewater and emission reduction of carbon dioxide are fulfilled.

Owner:UNIV OF SCI & TECH BEIJING

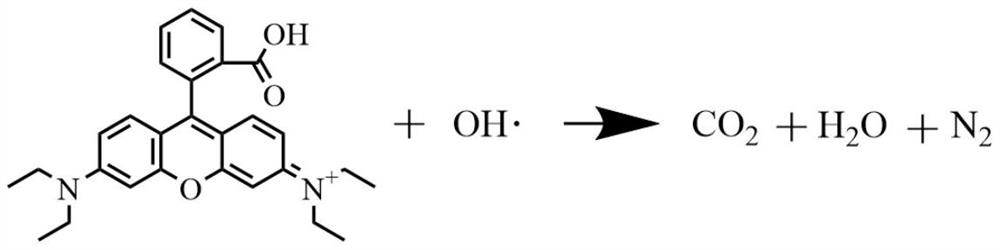

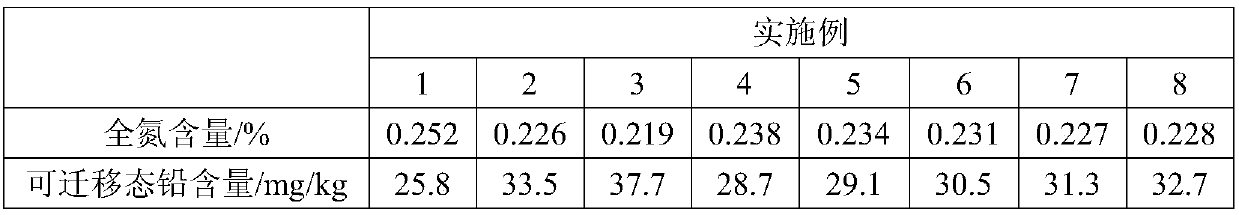

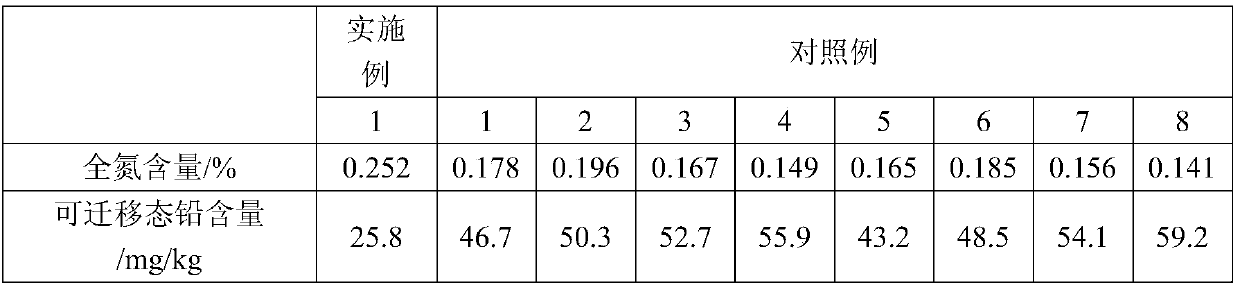

Lead ion repairing material for soil remediation and preparation method thereof

ActiveCN109517599APrevent implosionImproves soil nitrogen contentOrganic fertilisersSoil conditioning compositionsMaleic anhydrideUrea

The invention relates to a lead ion repairing material for soil remediation and a preparation method thereof. The lead ion repairing material for the soil remediation is composed of ammonium salt modified nano polylactic acid, an Sr-10 emulsifier, water, ethanol and urea modified polyacrylic acid; the ammonium salt modified nano polylactic acid is prepared by taking acid modified nano polylactic acid, ammonia water, amino acid, the ethanol and urea to react; the acid modified nano polylactic acid is prepared by taking modified nano polylactic acid, chlorosulfonic acid, acetic acid, oxalic acidand formic acid to react; the modified nano polylactic acid is prepared by taking polylactic acid, lignin, maleic anhydride, the ethanol, N,N-dimethylformamide, nanocellulose and the urea to react; and the urea modified polyacrylic acid is prepared by taking acrylic acid, isooctyl acrylate, the urea, the Sr-10 emulsifier, the water, the ethanol and ammonium persulfate to react. The lead ion repairing material for the soil remediation, provided by the invention, has excellent performance of removing migration-state lead ions of soil.

Owner:徐州中矿岩土技术股份有限公司

Chlorination reactor for preparing 1,1,1,2,3-pentachloropropane

InactiveCN103601612BEasy to separateReduce material requirementsPreparation by halogen additionChlorineExhaust gas

A chlorination reactor for preparing 1,1,1,2,3-pentachloropropane comprises a dechloridation reaction device and a chlorination reaction device; the dechlorination reaction device comprises a reaction barrel body A, the inner wall of the reaction barrel body A is provided with a heating layer and a catalyst layer, and the reaction barrel body A is also provided with a temperature measuring device; the chlorination reaction device comprises a reaction barrel body B, the reaction barrel body B is internally provided with a cooling layer, a catalyst filling layer and a temperature measuring device, and the bottom part of the reaction barrel body B is provided with a chlorine feeding port; the top parts of the dechlorination reaction device and the chlorination reaction device are communicated by a pipeline, the pipeline is provided with an exhaust gas discharge port, the bottom parts of the dechlorination reaction device and the chlorination reaction device are communicated by a circulating device, and the circulating device and the reaction barrel body A are respectively communicated with a material input and output port through a valve; chlorine enters from an chlorine inlet of the chlorination reaction device and is subjected to a reaction with chlorinated olefin in the chlorination reaction device to generate the target product, and the un-reacted chlorinated olefin material in the chlorination reaction device and the target product go into the dechlorination reaction device. The reaction is easy to control, and the production efficiency is greatly improved.

Owner:SHAANXI UNIV OF SCI & TECH

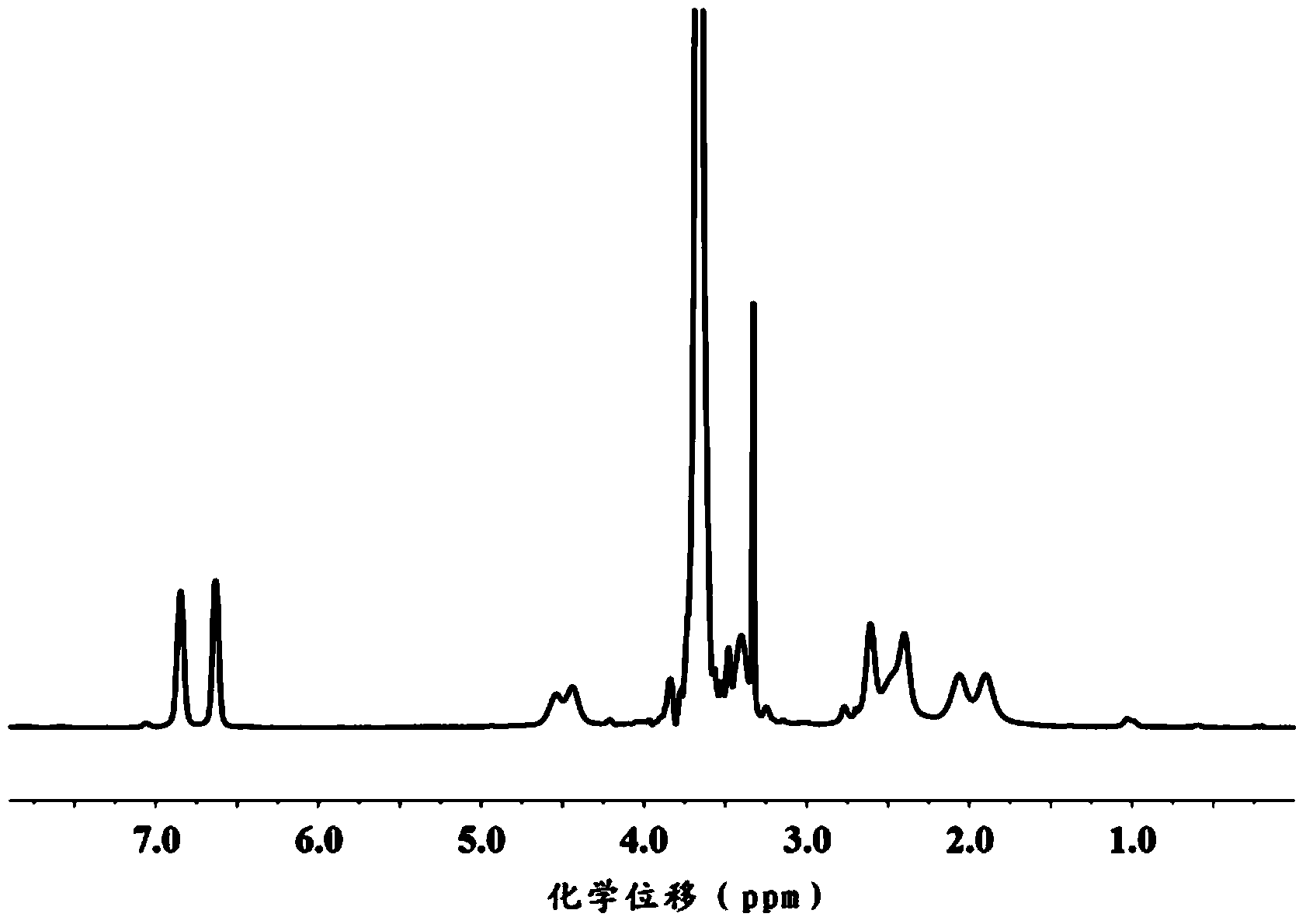

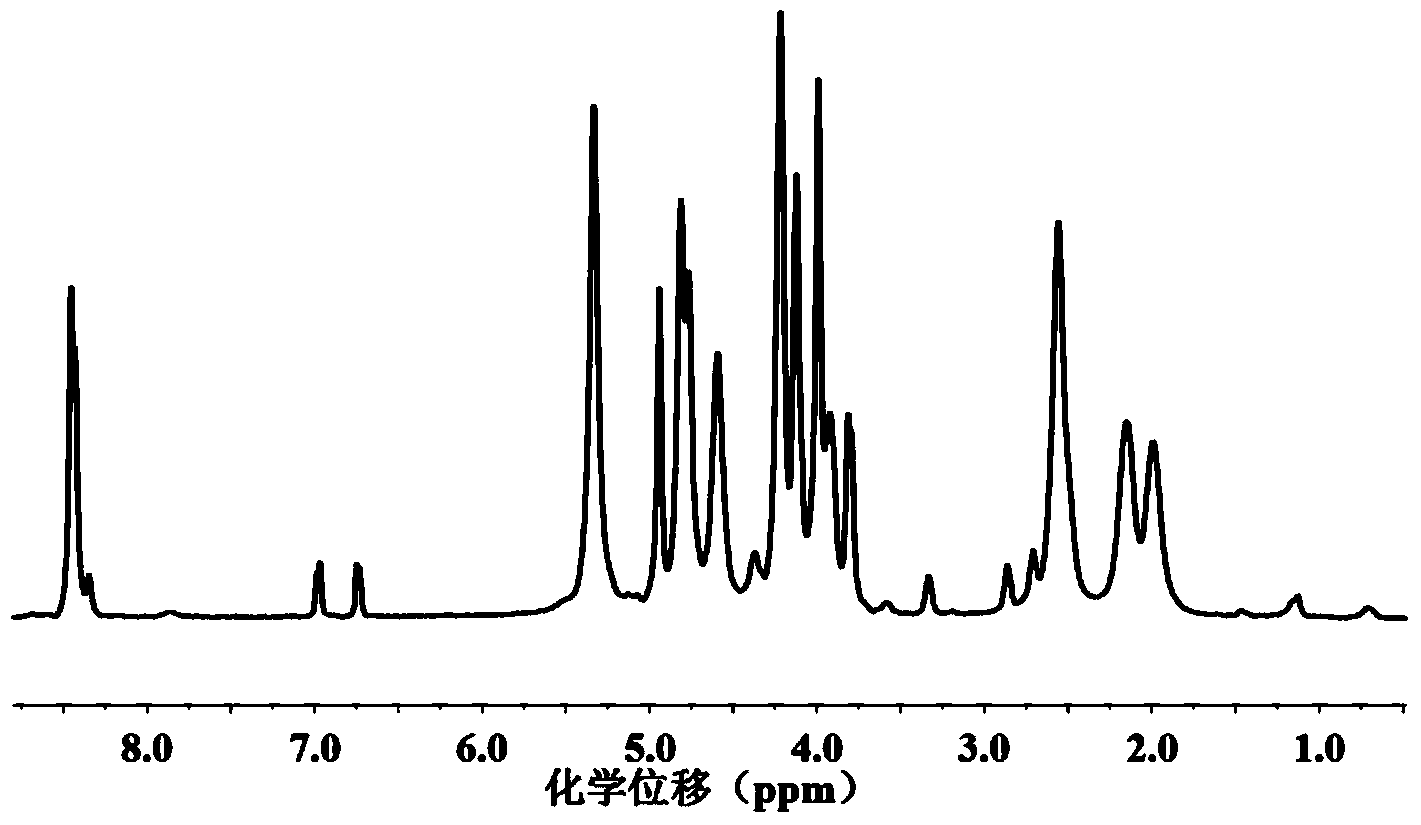

Glucose-like peptide and preparation method thereof as well as injectable hydrogel

ActiveCN103936981AHigh mechanical strengthGood biocompatibilityAerosol deliverySurgeryBiocompatibility TestingNative protein

The invention provides a glucose-like peptide and a preparation method thereof as well as injectable hydrogel. The preparation method comprises the following steps: mixing one or more compounds with the structures shown as formulas (V-1) to (V-3), a compound with the structure of a formula (IV), a compound with the structure of a formula (VI) and an organic solvent, and reacting in the presence of a catalyst to obtain the glucose-like peptide with the structure of the formula (I). Compared with an existing natural polymer, the glucose-like peptide has the advantages that the compound with the structure of the formula (IV) serves as a main chain, the glucose-like peptide has a secondary structure similar to that of natural proteins or polypeptides and also has high biocompatibility and biodegradability; the glucose-like peptide can simulate the structure of protein polysaccharides in an extracellular matrix; the glucose-like peptide contains a phenol structure, different grafting rates can be regulated, a cross-linked network can be formed under the effects of horse radish peroxidase and hydrogen peroxide, the reaction condition is mild, the reaction rate is easily controlled, and the hydrogel with controllable performance can be prepared.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

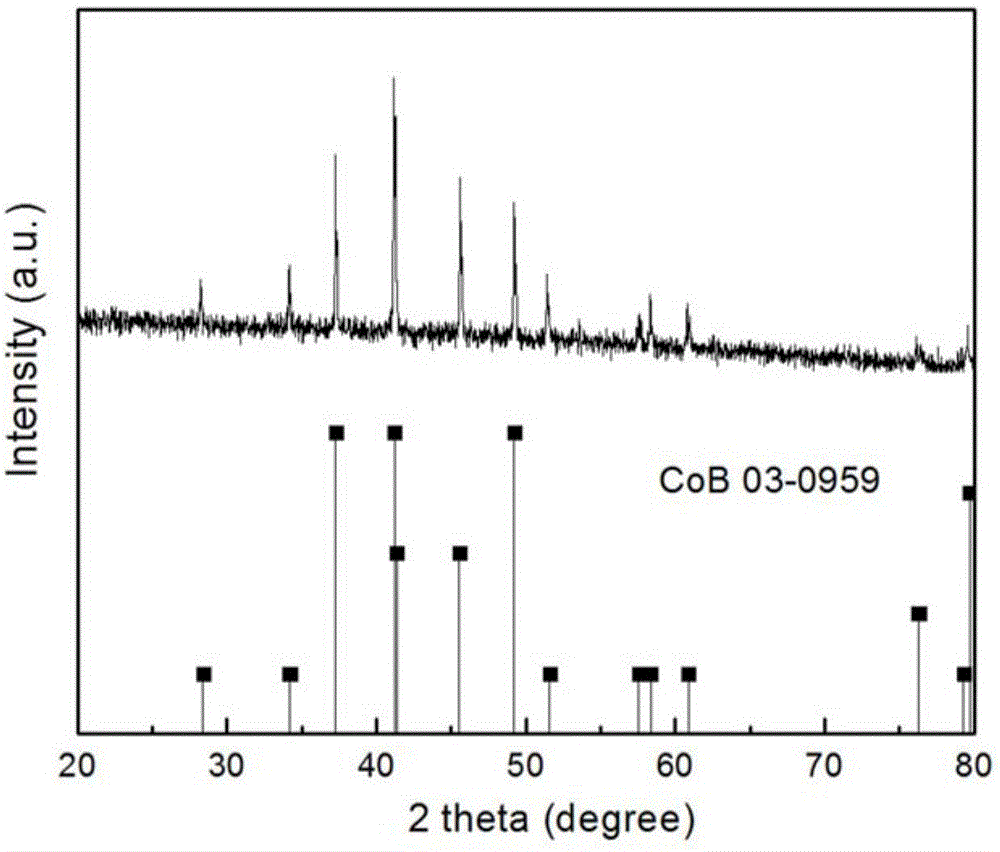

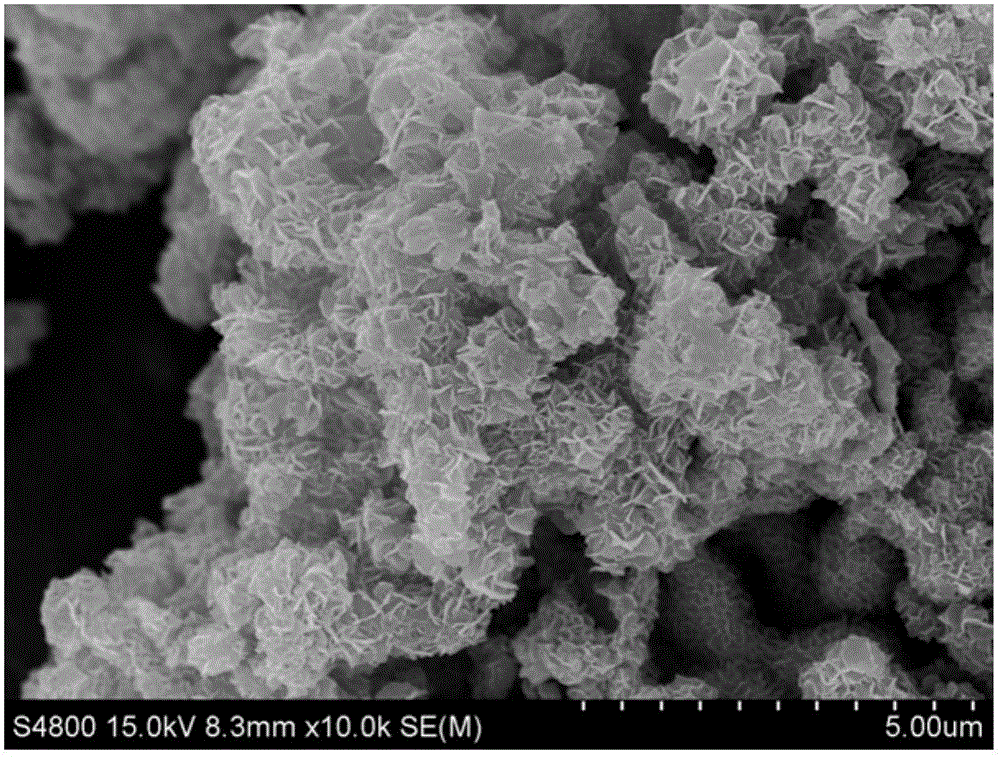

Sheet-like porous CoB powder and preparation method thereof

ActiveCN106276942AInhibition of violent reactionsFacilitated DiffusionMetal boridesAlkali metalChloride

The invention discloses sheet-like porous CoB powder and a preparation method thereof and belongs to the technical field of inorganic powder preparation. The powder is CoB in a crystalline state and consists of nanosheets with the average thickness being 20 nm and the plane size being 200-300 nm, and the nanosheets are connected in a staggered manner to form an open porous structure. The preparation method of the powder comprises specific preparation steps as follows: micron-order metal cobalt powder, amorphous boron powder and alkali metal chloride powder are mixed; the mixed powder is placed in an corundum crucible, heated to 800 DEG C or above under the protection of argon, kept at the temperature for 0.5-2 h and then cooled naturally; an obtained product is soaked in water, filtered, cleaned and dried, and the sheet-like porous CoB powder is obtained. The obtained CoB powder is in the crystalline state, adopts the sheet-like porous structure, can be used as a catalyst carrier material and is a potential inorganic functional material.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

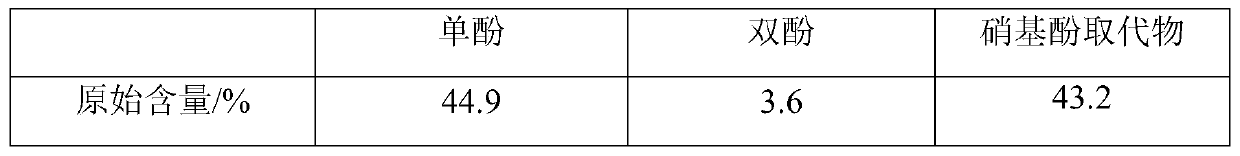

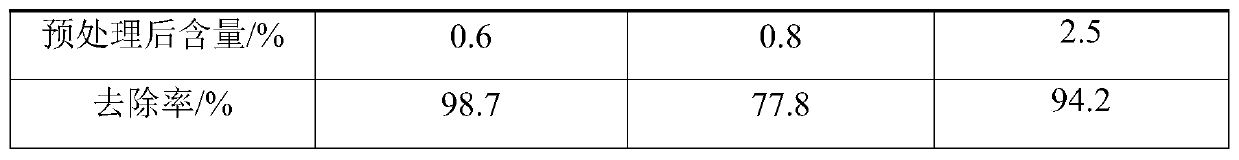

Pretreatment method of waste water containing fluoronitrophenol

InactiveCN109809508AControllable reaction rateEnsure safetyWater contaminantsWater/sewage treatmentPesticideChemistry

The invention relates to a pretreatment method of waste water containing fluoronitrophenol, and belongs to the pesticide chemical field. The invention aims to solve the technical problems that biochemical treatment of the waste water containing fluoronitrophenol is difficult to realize and unsafety problem of concentration and enrichment process is obvious. The invention discloses the pretreatmentmethod of the waste water containing fluoronitrophenol. The method comprises the steps of firstly adjusting the pH of the waste water, then performing thermal degradation under certain temperature and finally detecting the degraded waste water by liquid chromatogram. According to the pretreatment method of waste water containing fluoronitrophenol, organic matters containing the fluoronitrophenolare thermally degraded into substances that are relatively safe and can be subjected to advanced treatment, the operation is safe and no explosion risk exists.

Owner:LIER CHEM CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com