Magnesium or magnesium alloy surface autocatalytic degradation coating and preparation method thereof

A magnesium alloy, self-catalysis technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, metal material coating technology, etc., can solve the adverse effects of magnesium alloy mechanical properties, complex alloying process operation, and uncontrollable corrosion rate and other problems, to achieve the effect of obvious self-catalytic degradation, good biocompatibility and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Magnesium alloy device: the material composition is Mg-3AlLi-1Zn (AZ31).

[0085] The preparation method is as follows:

[0086] The first step, the preparation of the precursor solution

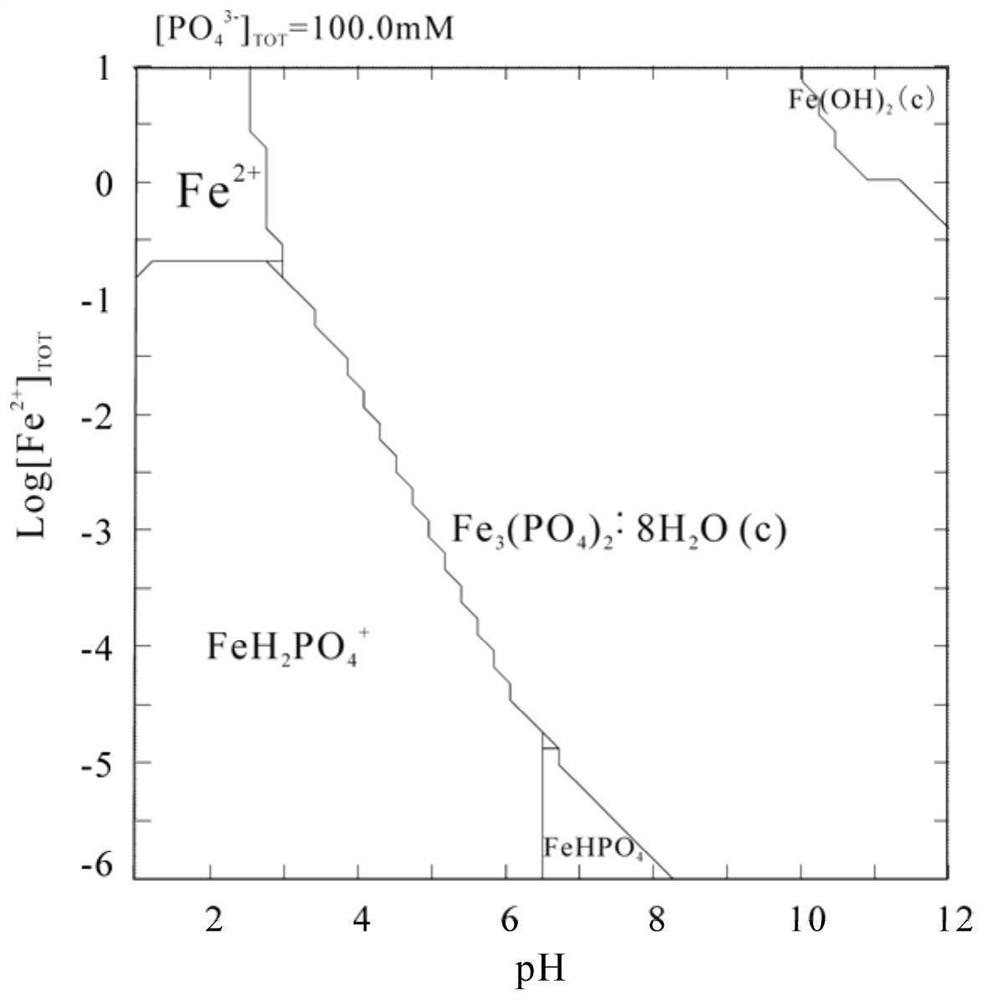

[0087] Take ferrous sulfate heptahydrate and trisodium phosphate dodecahydrate respectively, add deionized water to prepare a mixed aqueous solution; among them, FeSO 4 ·7H 2 O is 100mmol / L, Na 3 PO 4 12H 2 O is 100mmol / L;

[0088] Using phosphoric acid to adjust the pH value of the above mixed solution to 3.27 to obtain a precursor solution;

[0089] The second step, pretreatment of the coated substrate

[0090] The magnesium alloy workpiece is mechanically polished to remove its surface burrs, and is sequentially washed with first water, alkali, second water, pickling and third water, and dried to obtain a magnesium alloy workpiece with a fresh surface ;

[0091] The third step is the surface coating treatment of magnesium alloy components

[0092] The ratio of the surface...

Embodiment 2

[0098] Ferrous sulfate heptahydrate and trisodium phosphate dodecahydrate are 34.4mmol / L and 100mmol / L respectively; react in a water bath at 25°C for 30min; use phosphoric acid to adjust the pH value of the above mixed solution to 3.77 to obtain a precursor solution;

[0099] All the other are the same as in Example 1. The obtained self-catalytic degradation coating on the surface of the magnesium alloy is marked as coating II.

[0100] Product testing and inspection:

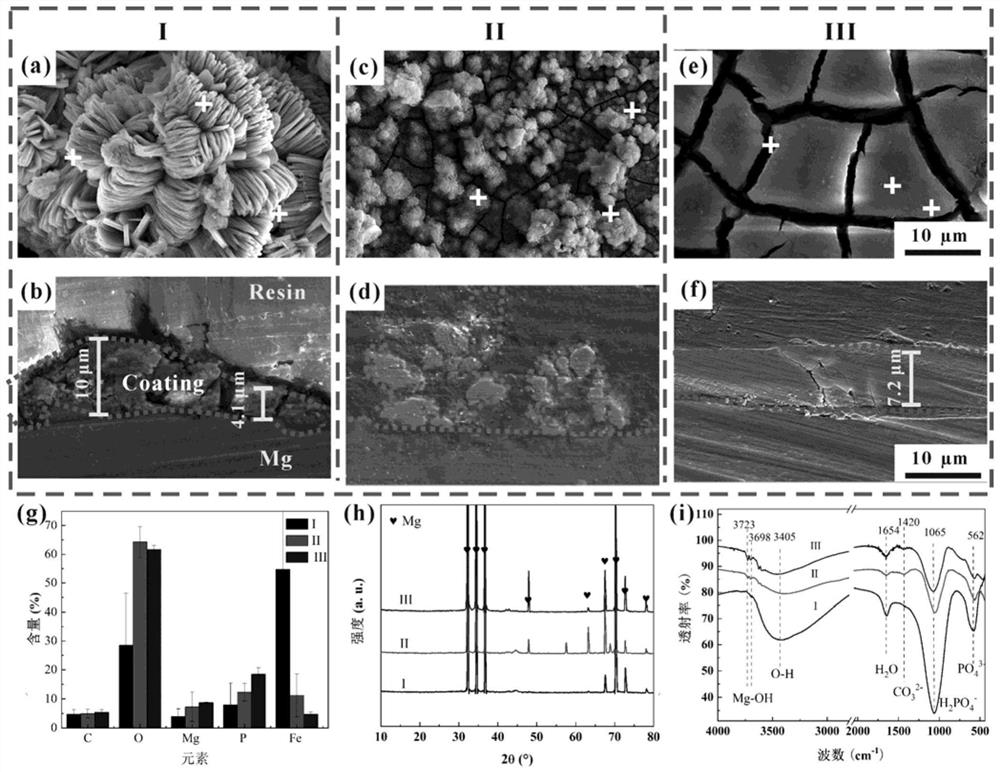

[0101] The thickness of the coating is 15-20μm, the whole film layer is porous structure, the distribution of the coating is uneven, and the scattered accumulation is on the surface of the substrate.

[0102] The open circuit potential is -1.56±0.01V / SCE, which is higher than the substrate but lower than Example 1, and has a tendency to accelerate corrosion relative to the substrate; the self-corrosion current is 2.20×10 -4 A / cm 2 ~2.40×10 -4 A / cm 2 , about 1 / 3 of the current of Example 1, also has a cert...

Embodiment 3

[0104] Ferrous sulfate heptahydrate and trisodium phosphate dodecahydrate are 8.43mmol / L and 100mmol / L respectively; react in a water bath at 25°C for 30min;

[0105] Using phosphoric acid to adjust the pH value of the above mixed solution to 4.27 to obtain a precursor solution;

[0106] All the other are the same as in Example 1. The obtained self-catalytic degradation coating on the surface of the magnesium alloy is marked as coating III.

[0107] Product testing and inspection:

[0108] The thickness of the film layer is 7-8μm, relatively dense and uniform, and there are many dry river-like cracks on the surface.

[0109] The open circuit potential and current are: -1.56±0.04V / SCE, 1.04×10 -5 A / cm 2 ~1.30×10 -5 A / cm 2 It is 1 / 2 of the self-corrosion current density of the substrate. At the same time, the hydrogen evolution rate after soaking in 3.5wt.% NaCl for 78 hours was 0.08±0.01mL cm -2 h -1 . It shows that the coating III has a certain protective effect on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com