Pretreatment method of waste water containing fluoronitrophenol

A nitrophenol pretreatment technology, which is applied in the field of pesticide chemical industry, can solve the problems such as the difficulty of biochemical treatment of fluorine-containing nitrophenol wastewater, and achieve the effects of controllable reaction rate, no risk of explosion, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

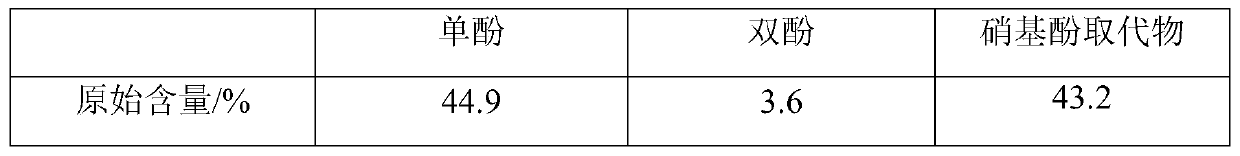

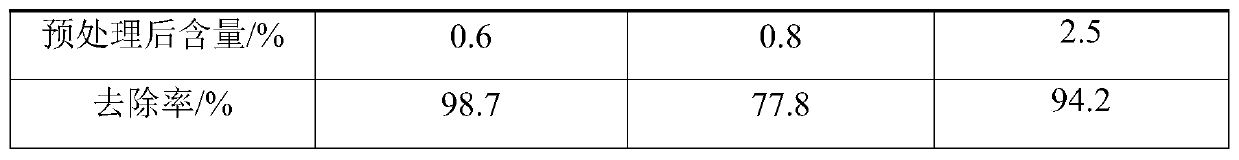

[0034] Take 198g of nitrophenol waste water, wherein the content of nitrophenol organic matter is 1.6%, add 2g of sodium hydroxide solid, the alkali concentration is 1%, after stirring and dissolving, put it into a high-temperature and high-pressure reactor, and react at 160°C for 5h , the pressure is 6bar, after the reaction, the waste water is taken out, detected by liquid chromatography, and the content of nitrophenols organic matter is calculated, and the test results are shown in Table 1, wherein "content" refers to the relative HPLC ratio of each nitrophenol in the organic matter contained in waste water. content.

[0035] Table 1

[0036]

Embodiment 2

[0038] Take 196g of nitrophenol waste water, the content of nitrophenol organic matter is 1.6%, add 4g of sodium hydroxide solid, the alkali concentration is 2%, after stirring and dissolving, put it into a high-temperature and high-pressure reactor, and react at 160°C for 5h, The pressure was 6 bar. After the reaction, the waste water was taken out and detected by liquid chromatography to calculate the content of nitrophenol organic matter. The detection results are shown in Table 2.

[0039] Table 2

[0040]

[0041]

Embodiment 3

[0043] Take 196g of nitrophenol wastewater, the content of nitrophenol organic matter is 1.6%, add 4g of sodium hydroxide solid, the alkali concentration is 2%, after stirring and dissolving, put it into a high-temperature and high-pressure reactor, and react at 180°C for 4h, The pressure was 10 bar. After the reaction, the waste water was taken out and detected by liquid chromatography to calculate the content of nitrophenol organic matter. The detection results are shown in Table 3.

[0044] table 3

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com