Chlorination reactor for preparing 1,1,1,2,3-pentachloropropane

A chlorination reactor and chlorination reaction technology, applied in the direction of halogen addition preparation, organic chemistry, etc., can solve problems affecting product yield, etc., achieve the effects of reducing impurity content, increasing yield, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

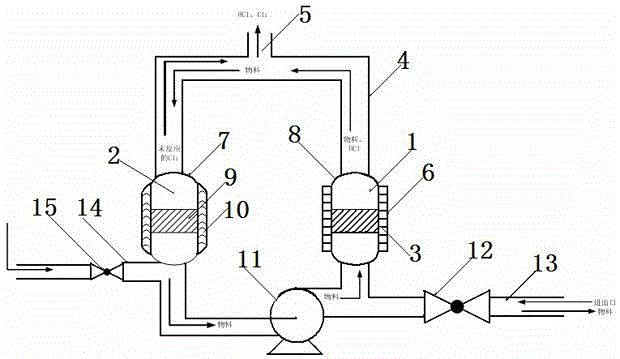

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] See attached figure 1 , a chlorination reactor for preparing 1,1,1,2,3-pentachloropropane, comprising a dechlorination reaction unit 1 and a chlorination reaction unit 2, the dechlorination reaction unit 1 comprising a reaction barrel A8, reacting Barrel A8 inwall is provided with heating layer 6 and catalyst layer 3, is also provided with temperature measuring device in reaction barrel A8; Chlorination reaction device 2 comprises reaction barrel B7, is provided with cooling layer 10, catalyst in reaction barrel B7. Filling layer 9 and temperature measuring device, reaction tank body B7 bottom is provided with chlorine feed port 14; The by-product gas-phase hydrogen chloride is discharged from the discharge port 5 in the middle of the connecting pipeline for processing, and the bottom of the dechlorination reaction device 1 and the chlorination reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com