Self-heating composite foam fracturing fluid capable of being controlled in real time and on-site construction method

A composite foam, real-time control technology, applied in drilling compositions, chemical instruments and methods, earthwork drilling, etc., can solve the problems of poor temperature and salt resistance of foam fracturing fluids, and methods and constructions that do not provide reasonable control methods, poor heating effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

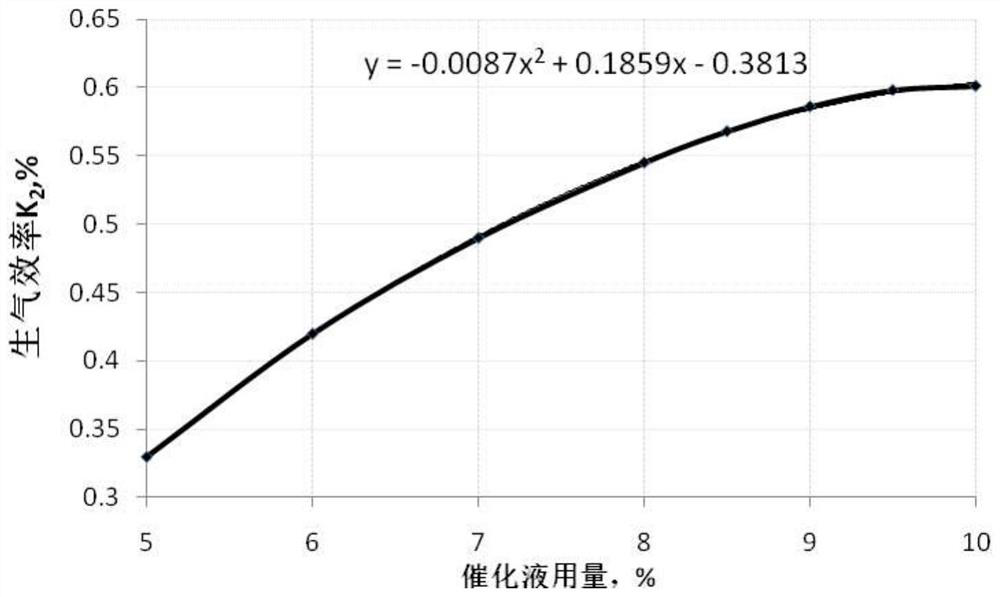

[0113] Gas heat agent design coefficient R 1 The value is 1, and the cross-link coefficient K 1 The value is 1, the gas efficiency K 2 A real-time controllable self-generating syntactic foam fracturing fluid with a value of 0.65, based on 100% by weight, the main components and weight percentages are as follows:

[0114] Fracturing fluid base fluid 88.9%, catalytic fluid 10%, crosslinking fluid 1.0%, gel breaker 0.1%.

[0115] The fracturing fluid base fluid is based on 100% by weight, and its components and weight percentages are as follows:

[0116] Composite thickener: carbon dioxide foam fracturing fluid polymer thickener SFJ-1, 0.3%;

[0117] Gas heating agent A: 40% NaNO 2 Concentrated aqueous solution, 12.5%;

[0118] Gas heating agent B: 50% CO (NH 2 ) 2 Concentrated aqueous solution, 8%;

[0119] Foaming agent: imidazoline sodium acetate surfactant, 0.2%;

[0120] Acid stabilizer: 0.2%, made of dodeca sodium phytate, ethylene glycol, polyvinylpyrrolidone (K30...

Embodiment 2

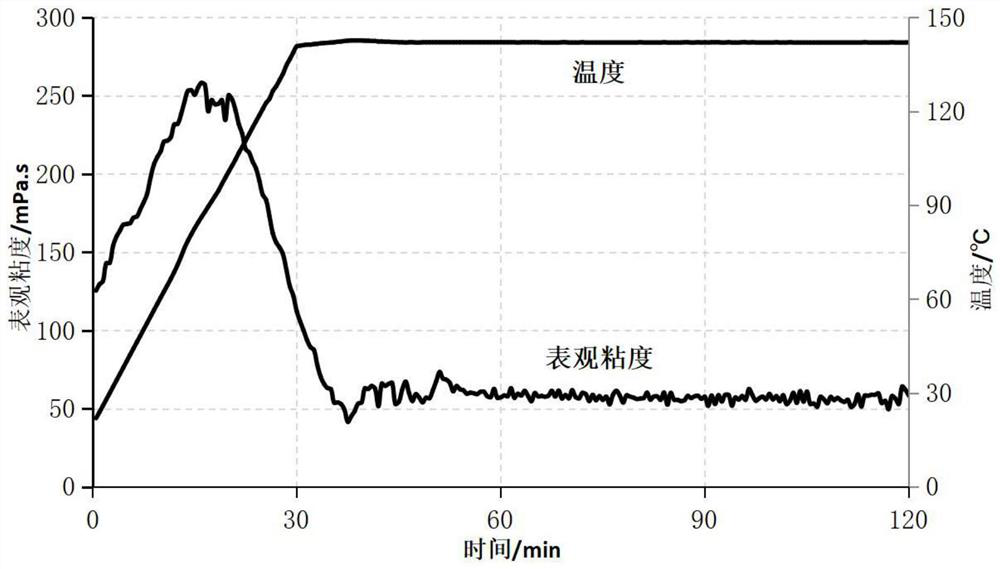

[0134] Gas heat agent design coefficient R 1 The value is 0.6, the crosslink coefficient K 1 The value is 1, the gas efficiency K 2 A real-time controllable self-generating syntactic foam fracturing fluid with a value of 0.42, based on 100% by weight, the main components and weight percentages are as follows:

[0135] Fracturing fluid base fluid 92.4%, catalytic fluid 6%, crosslinking fluid 1.4%, gel breaker 0.2%.

[0136] The fracturing fluid base fluid is based on 100% by weight, and its components and weight percentages are as follows:

[0137] Composite thickener: carbon dioxide foam fracturing fluid polymer thickener SFJ-1, 0.5%;

[0138] Gas heating agent A: 40% NaNO 2 Concentrated aqueous solution, 7.5%;

[0139] Gas heating agent B: 50% CO (NH 2 ) 2 Concentrated aqueous solution, 4.8%;

[0140] Foaming agent: imidazoline sodium acetate surfactant, 0.1%;

[0141] Acid stabilizer: 0.4%, made of dodeca sodium phytate, ethylene glycol, polyvinylpyrrolidone (K30 so...

Embodiment 3

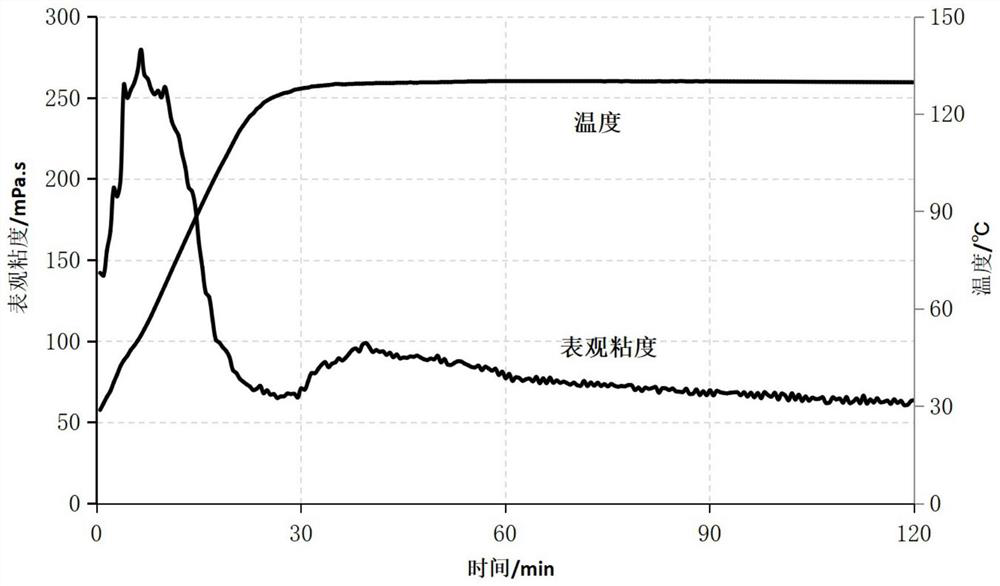

[0155] Gas heat agent design coefficient R 1 The value is 0.80, the crosslink coefficient K 1 The value is 1, the gas efficiency K 2 A real-time controllable self-generating syntactic foam fracturing fluid with a value of 0.5, based on 100% by weight, the main components and weight percentages are as follows:

[0156] Fracturing fluid base fluid 91.28%, catalytic fluid 7.12%, crosslinking fluid 1.5%, gel breaker 0.1%.

[0157] The fracturing fluid base fluid is based on 100% by weight, and its components and weight percentages are as follows:

[0158] Composite thickener: carbon dioxide foam fracturing fluid polymer thickener SFJ-1, 0.7%;

[0159] Gas heating agent A: 40% NaNO 2 Concentrated aqueous solution, 10%;

[0160] Gas heating agent B: 50% CO (NH 2 ) 2 Concentrated aqueous solution, 6.4%;

[0161] Foaming agent: Alkyl sugar APG1214, 0.1%;

[0162] Acid stabilizer: 0.3%, mixed with sodium phosphite, isopropanol, N-vinylacetamide-sodium acrylate binary copolymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com