Polyamino acid graft copolymer, preparation method thereof and injectable hydrogel

A technology of graft copolymers and polyamino acids, which can be used in pharmaceutical formulations, medical preparations of non-active ingredients, and pharmaceutical sciences, and can solve problems such as difficult performance control and single natural polymer components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention also provides a preparation method of the polyamino acid graft copolymer represented by the above formula (I), comprising the following steps:

[0055] Mix tyramine, polyethylene glycol monomethyl ether with the structure of formula (IV), poly(L-glutamic acid) with the structure of formula (V) and organic solvent, and under the action of coupling agent, condensation reaction occurs , to obtain the polyamino acid graft copolymer represented by formula (I).

[0056]

[0057] Wherein, m and n are polymers, and the m is the same as above, and will not be repeated here; the n=x+y+z.

[0058] The present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0059] The polyamino acid graft copolymer of the present invention has poly(L-glutamic acid) with the structure of formula (V) as the main chain, which can simulate natural proteins and polypeptides to a certain extent, and has good biocomp...

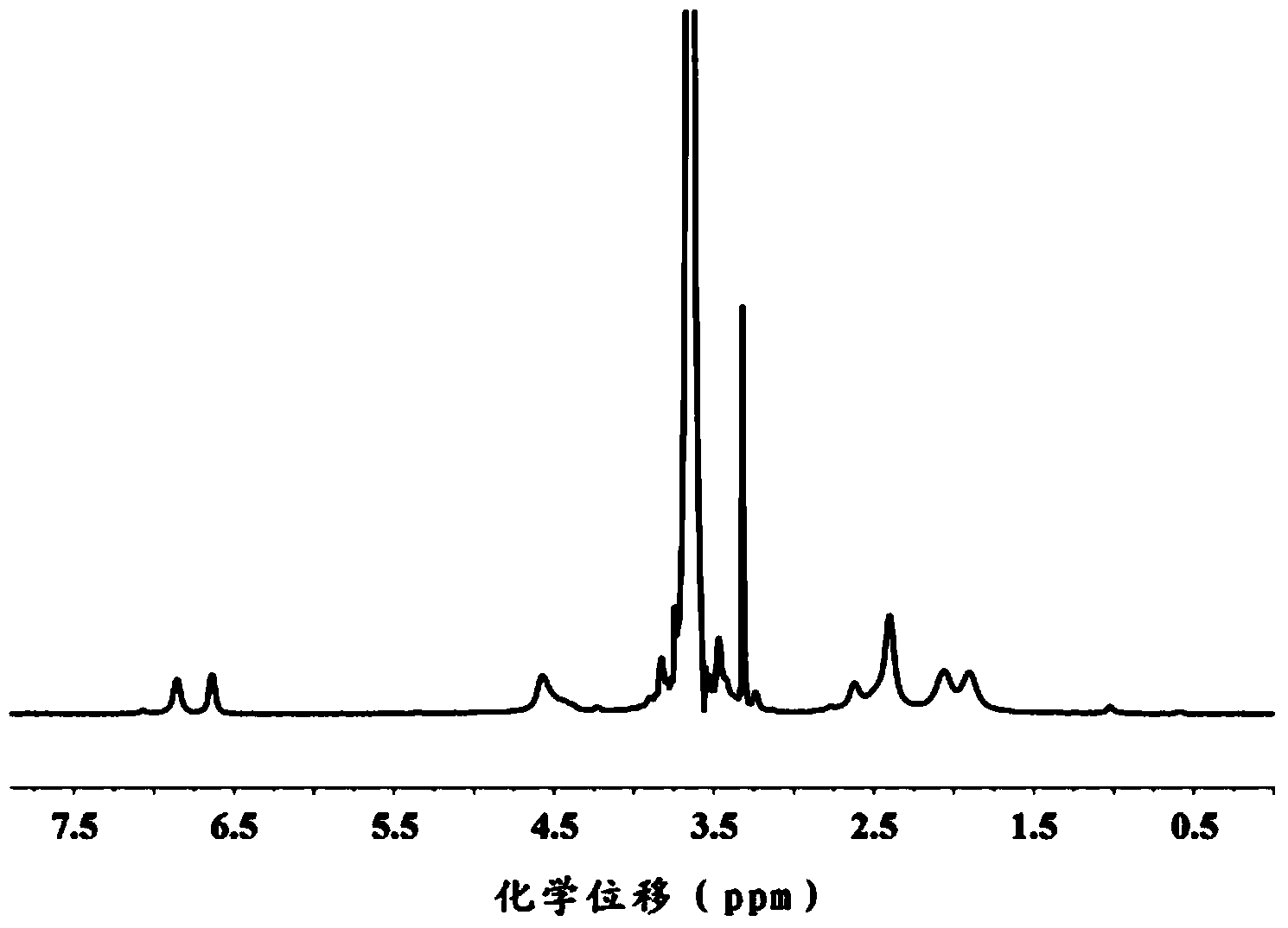

Embodiment 1

[0078] 1.1 10g of polyethylene glycol monomethyl ether with a number average molecular weight of 1000 and 100ml of toluene were azeotroped to remove water at 140°C, then the toluene was removed under reduced pressure, and 50ml of dichloromethane was added to dissolve to obtain a polyethylene glycol monomethyl ether solution. Under the condition of 0°C and anhydrous, slowly add 8ml triethylamine and 16ml methanesulfonyl chloride to the polyethylene glycol monomethyl ether solution, react at 0°C for 2h, rise to room temperature and stir for 24h, filter and remove after the reaction Precipitate, the filtrate was settled with ether, and the solid was obtained by filtration. After vacuum drying at room temperature for 24 hours, polyethylene glycol monomethyl ether methanesulfonate was obtained.

[0079]1.2 Dissolve 5g of polyethylene glycol monomethyl ether methanesulfonate obtained in 1.1 and 5g of ammonium chloride in 250ml of ammonia water, and react at room temperature for 72 ho...

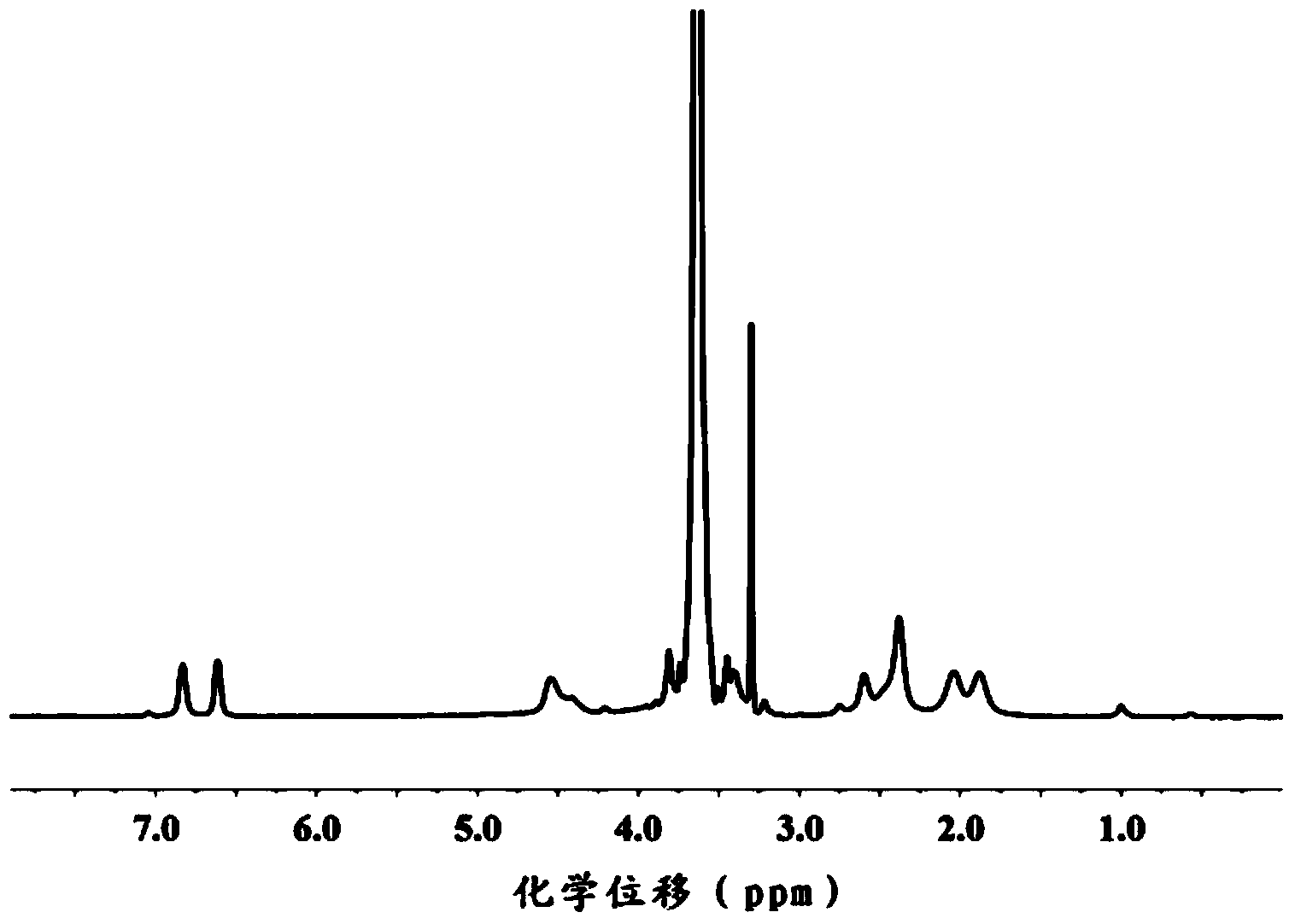

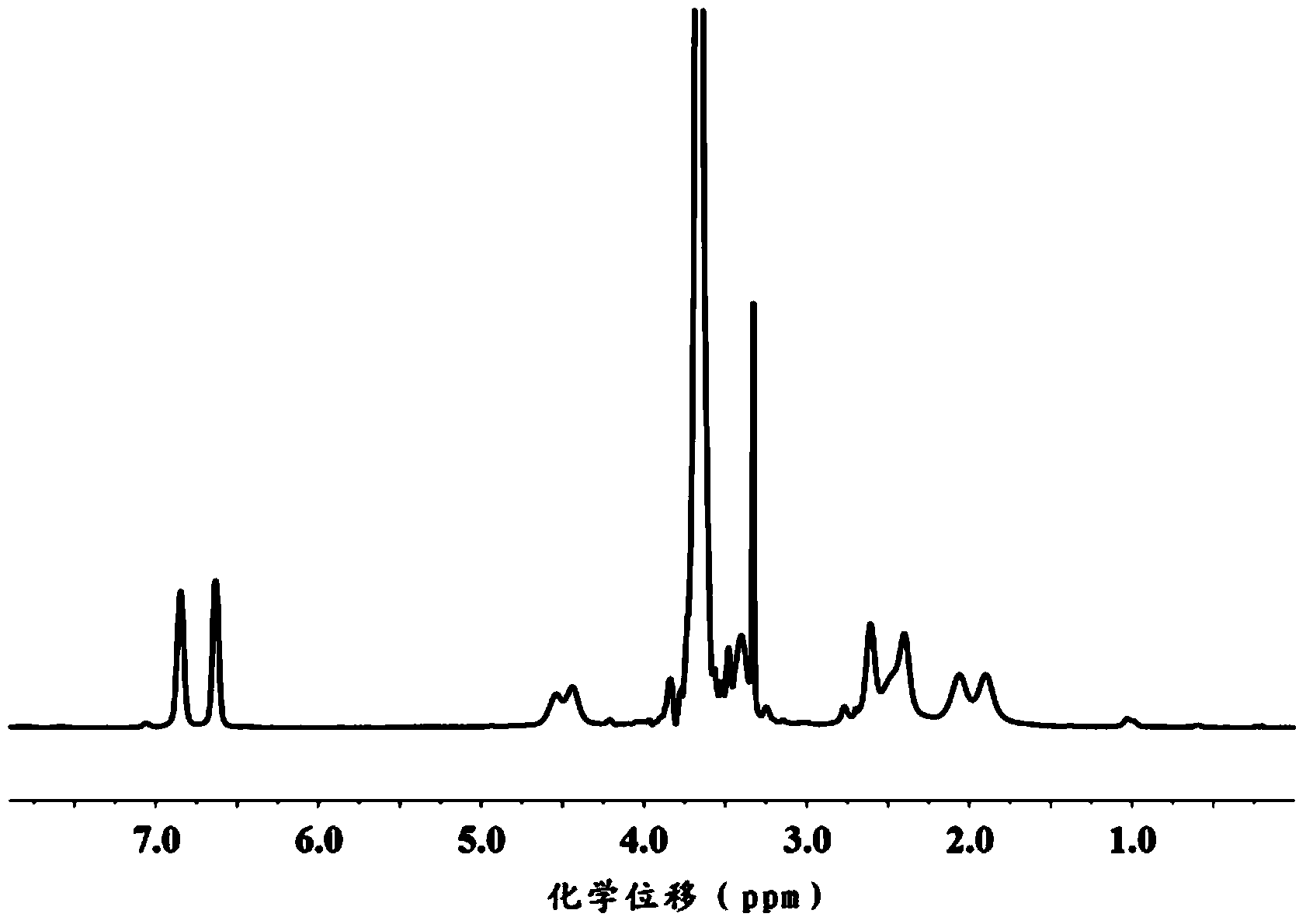

Embodiment 2

[0087] 2.1 10 g of polyethylene glycol monomethyl ether with a number average molecular weight of 1000 and 100 ml of toluene were removed by azeotropy at 140° C., then the toluene was removed under reduced pressure, and 50 ml of dichloromethane was added to dissolve to obtain a polyethylene glycol monomethyl ether solution. Under the condition of 0°C and anhydrous, slowly add 8ml triethylamine and 16ml methanesulfonyl chloride to the polyethylene glycol monomethyl ether solution, react at 0°C for 2h, rise to room temperature and stir for 24h, filter and remove after the reaction Precipitate, the filtrate was settled with ether, and the solid was obtained by filtration. After vacuum drying at room temperature for 24 hours, polyethylene glycol monomethyl ether methanesulfonate was obtained.

[0088] 2.2 Dissolve 5g of polyethylene glycol monomethyl ether methanesulfonate obtained in 2.1 and 5g of ammonium chloride in 250ml of ammonia water, and react at room temperature for 72 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com