Preparation and application of silicon nitride coated carbon nano tube

A silicon nitride package, carbon nanotube technology, applied in nitrogen compounds, nanotechnology, nanotechnology and other directions, can solve the problems that have not yet met the requirements of industrial application, achieve controllable reaction rate, obvious toughening effect, and uniform solution dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

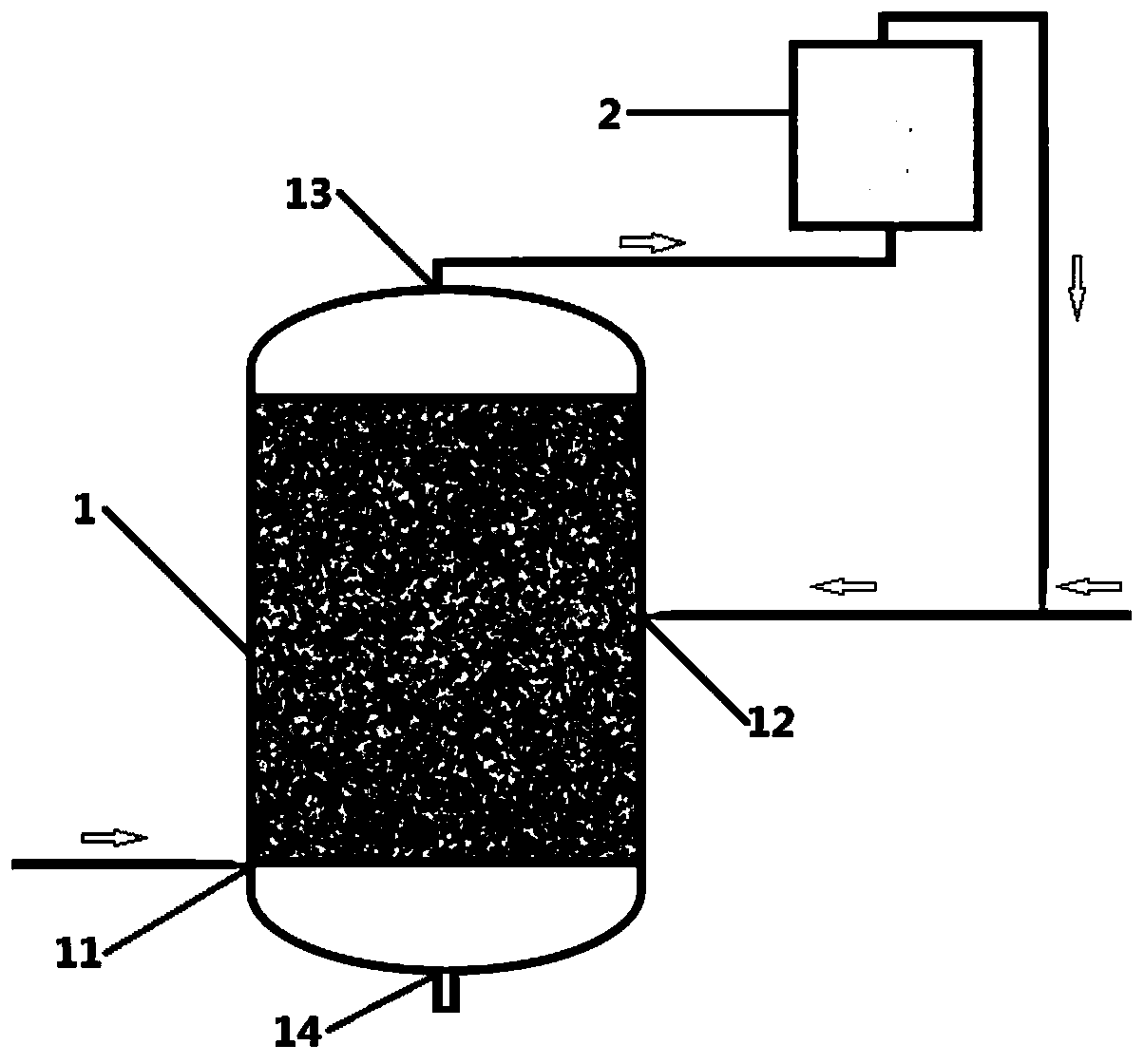

[0023] The embodiment of the present invention relates to a method for preparing silicon nitride-coated carbon nanotubes, comprising the following steps:

[0024] S1, loosely pack carbon nanotubes into and fill the entire reactor, and then evacuate to 0.1-100Pa; then pass silicon tetrachloride gas into the reactor until the initial pressure in the reactor is in the range of 1-2atm; Inject ammonia gas to make silicon tetrachloride gas react with ammonia gas at -20-60°C, and keep the pressure in the reactor within the range of 0.5 atm less than the initial pressure to the initial pressure during the reaction process; silicon tetrachloride The nitrogen-containing silane compound generated by the reaction of gas and ammonia is deposited on the surface of carbon nanotubes;

[0025] S2, under an ammonia atmosphere, heating the carbon nanotubes with the nitrogen-containing silane compound attached to the surface in step S1 to 500-600° C., and heat-treating for 1-2 hours to remove the...

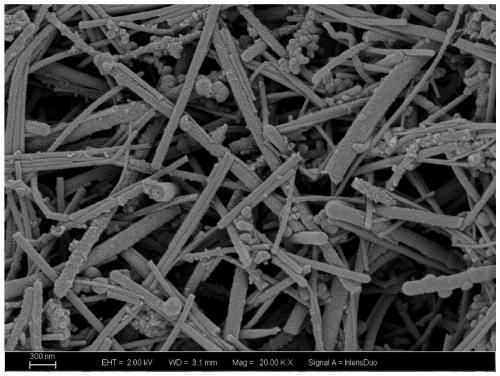

Embodiment 1

[0031] This embodiment relates to a method for preparing silicon nitride-coated carbon nanotubes, comprising the following steps:

[0032] S1, set the bulk density to 0.15g / cm 3 After loading and filling the whole reactor with carbon nanotubes, evacuate to 100Pa, feed silicon tetrachloride gas into the reactor from the first feeding port until the pressure reaches 1 atm; then continuously feed ammonia gas from the second feeding port , so that silicon tetrachloride gas and ammonia react at 25 ° C, and keep the pressure in the reactor within the range of 0.5 to 1 atm during the reaction; the nitrogen-containing silane compound generated by the reaction of silicon tetrachloride gas and ammonia is deposited on the On the surface of carbon nanotubes, when the pressure in the reactor continues to rise above 1 atm, stop passing ammonia and keep the pressure for 1 hour to ensure the complete reaction;

[0033] S2, heat the reactor to 550°C, keep it warm for 2 hours, and remove the b...

Embodiment 2

[0037] This embodiment relates to a method for preparing silicon nitride-coated carbon nanotubes, comprising the following steps:

[0038] S1, set the bulk density to 0.2g / cm 3 After loading and filling the whole reactor with carbon nanotubes, evacuate to 10Pa; feed silicon tetrachloride gas into the reactor from the first feeding port until the pressure reaches 1.5atm, and then continuously feed ammonia from the second feeding port Gas, so that silicon tetrachloride gas and ammonia react at -10 ° C, and keep the pressure in the reactor within the range of 1 to 1.5 atm during the reaction; nitrogen-containing silane formed by the reaction of silicon tetrachloride gas and ammonia The compound is deposited on the surface of the carbon nanotubes. When the pressure in the reactor continues to rise above 1.5 atm, the ammonia gas is stopped and the pressure is maintained for 1 hour to ensure the complete reaction;

[0039] S2, heat the reactor to 550°C, keep it warm for 2 hours, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com