Patents

Literature

65results about How to "Prevent piles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

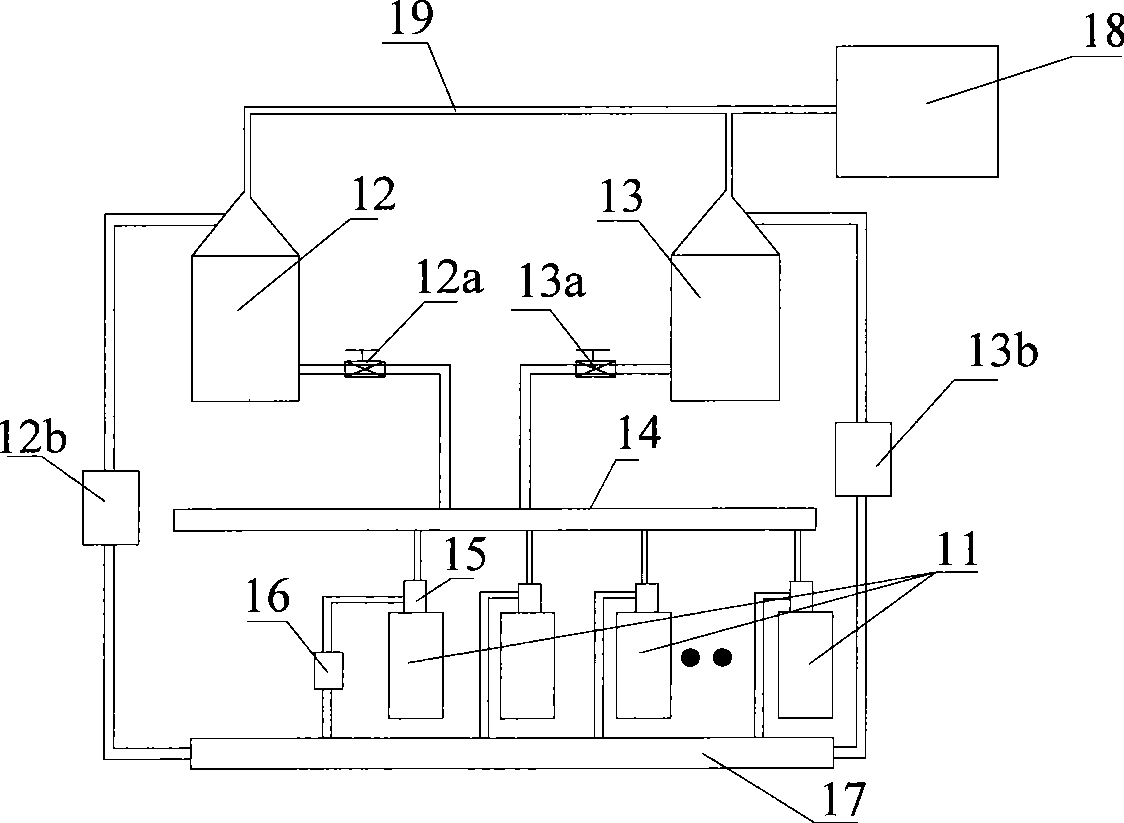

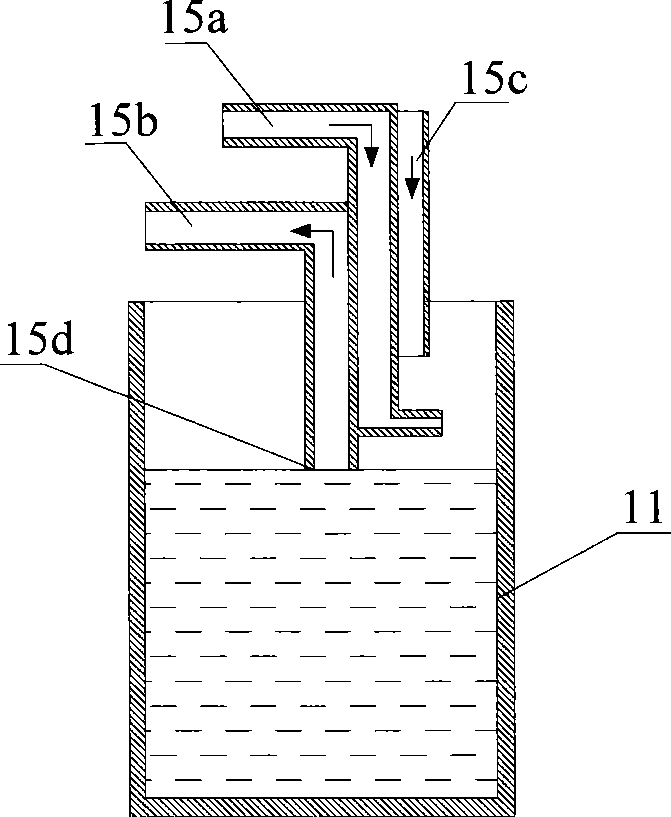

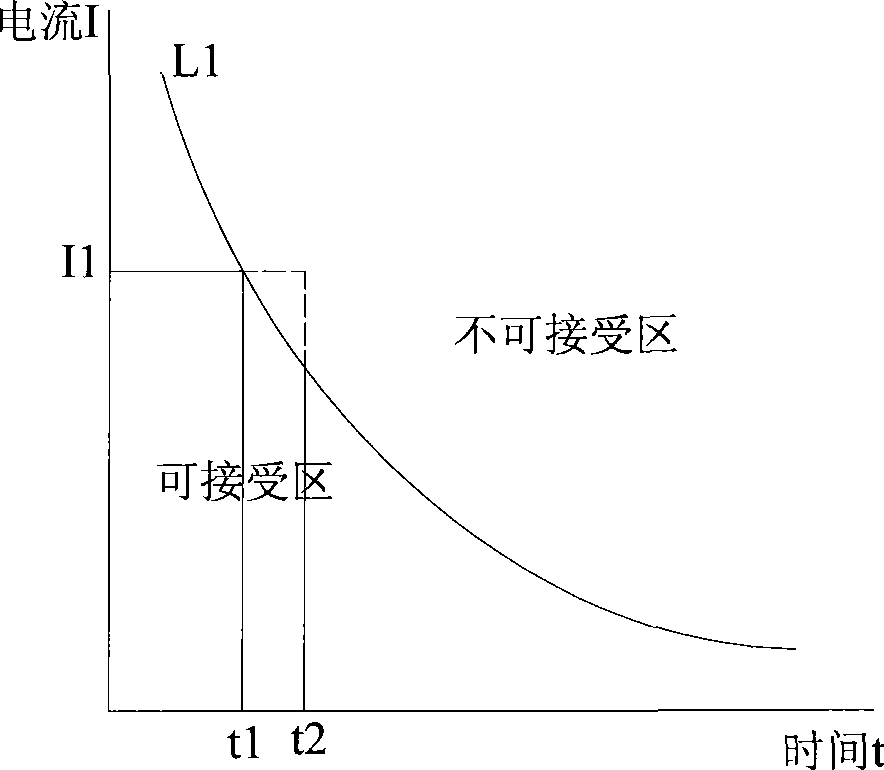

Charging/discharging method for accumulator formation, formation method and device

InactiveCN101510627APrevent pilesImprove formation efficiencyFinal product manufactureSecondary cells charging/dischargingProcess engineeringCharge and discharge

The invention discloses a charging and discharging method on storage battery formation, which comprises the following steps: a) the storage battery is charged for the first time at a first time, the electric quantity charged into a pole plate is 1.9 times to 2.1 times of the rated electric quantity of the storage battery and the first time is 6.5h to 7.5h; b) the storage battery is discharged for the first time; c) the storage battery is charged for the second time at a second time, the electric quantity charged into the pole plate is 1.4 times to 1.5 times of the rated electric quantity of the storage battery and the second time is 4.5h to 5.5h; d) the storage battery is discharged for the second time; and e) the storage battery is charged for the third time at a third time, the electric quantity charged into the pole plate is 4.0 times to 4.5 times of the rated electric quantity of the storage battery and the third time is 2.5h to 3h. Compared with the prior art, the result of the charging and discharging method shows that the charging and discharging time can be effectively shortened and the content of PbO2 of a positive plate can be caused to reach above 88 percent by choosing appropriate time to discharge for at least two times in the charging process, thus shortening the formation time of the storage battery effectively.

Owner:赵恒祥

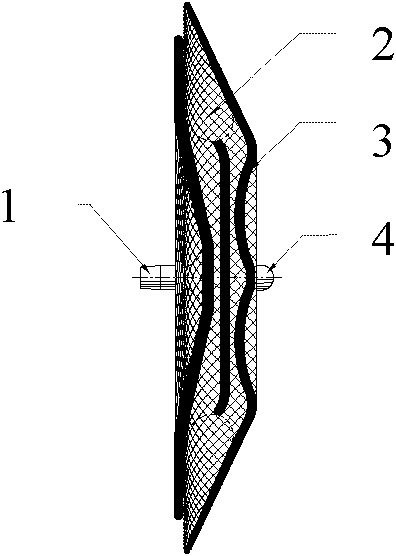

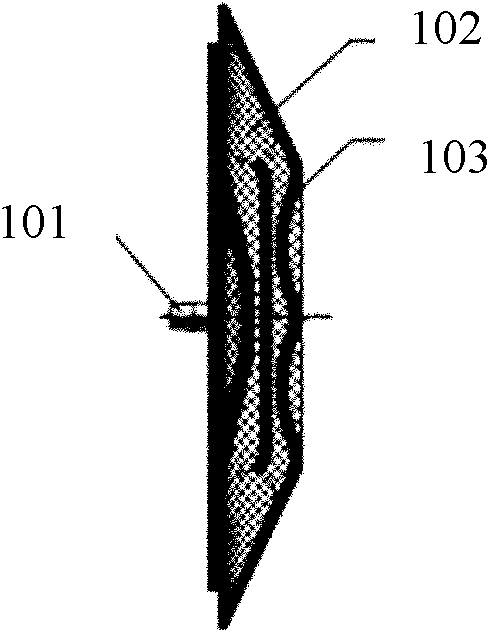

Stopper and manufacturing method thereof

ActiveCN101933850AReduce long-term metal releasePrevent pilesStentsOcculdersCatheterMechanical engineering

The invention relates to a stopper, comprising a remote end, a near end and an elastic weaving body arranged between the remote end and the near end and waved by meshes. The elastic weaving body is waved by multi-step rayon meshes which at least comprise a first-step rayon mesh arranged most closely to the remote end and waved by a plurality of first-step meshes and a second-step rayon mesh waved by a plurality of first-step meshes and a plurality of second-step meshes. The minimal cross section of the first-step rayon mesh after being compressed towards a direction vertical to the axial direction of the elastic weaving body is smaller than the minimal cross section of any other-step rayon mesh after being compressed towards the axial direction. The invention also relates to a method for manufacturing the stopper. Because of the use of multi-step rayon meshes, the stopper does not need a permanent plug, thereby not only reducing the risk of the damage of a metal plug to the human body, but also well avoiding the stacked meshes when the remote end of the traditional stopper without a plug is withdrawn and put back to the scabbard, and greatly reducing the sheathing resistance. In addition, the stopper is suitable for smaller sheath catheter, and reduces the operation difficulty.

Owner:LIFETECH SCI (SHENZHEN) CO LTD

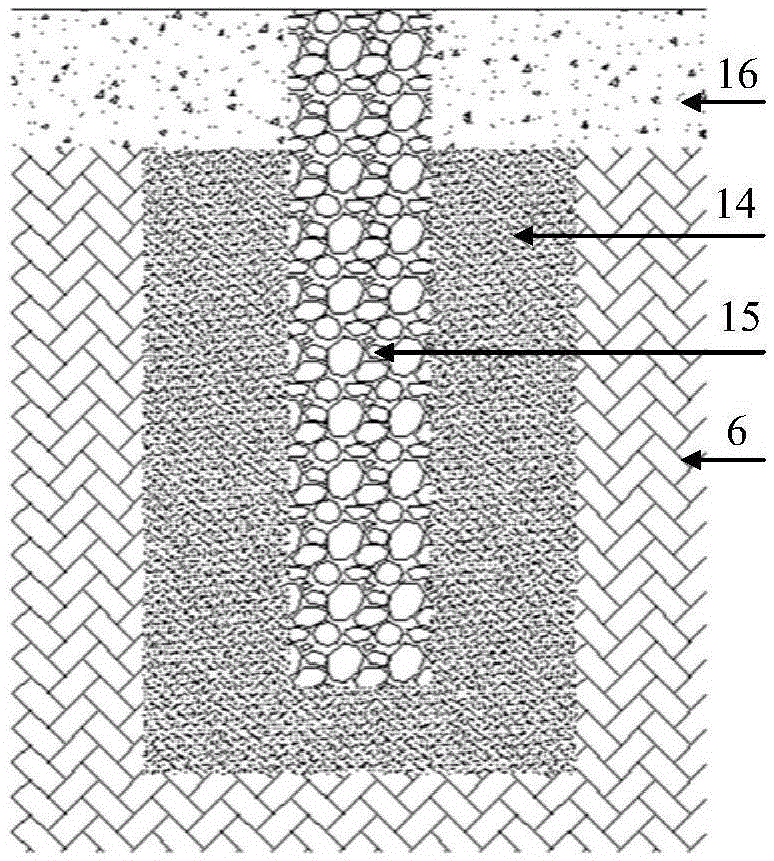

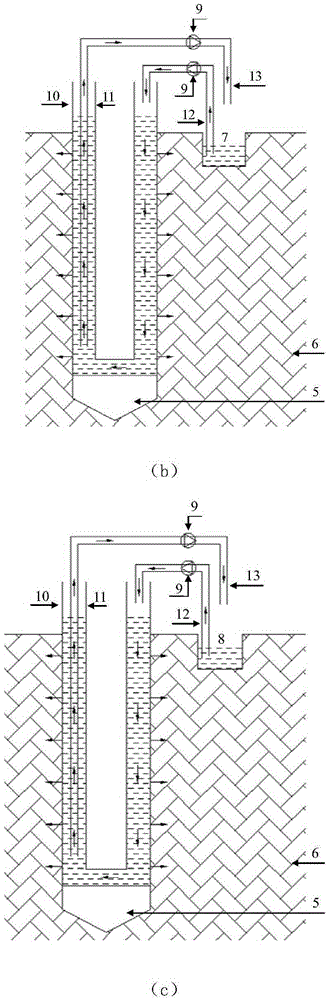

Composite foundation with discrete material pile restrained through microorganism soil solidification and construction method

ActiveCN105386436AImprove bearing capacityIncrease profitBuilding constructionsOrganic fertilisersMicroorganismSoil science

The invention relates to a composite foundation with a discrete material pile restrained through microorganism soil solidification and a construction method. The construction method includes the steps that a, a pile pipe is pressed into a foundation body; b, meanwhile, microorganism bacterium liquid is injected into a gap between an inner steel sleeve and an outer steel sleeve and diffused into the foundation body around the pile; c, the microorganism bacterium liquid is pumped out, a cementing solution is injected and diffused into the foundation body around the pile and reacts with the microorganism bacterium liquid to generate calcium carbonate crystals, and loose sandy soil or floury soil is cemented; d, the step b and the step c are repeated until the soil around the pile meets reinforcement requirements; e, discrete materials are poured into a hole of the inner steel sleeve; and f, a bed course is laid, so that the composite foundation is formed. According to the composite foundation with the discrete material pile restrained through microorganism soil solidification, the microorganism bacterium liquid and the cementing solution react to generate calcium carbonate so as to solidify the soil around the pile, so that the strength of the soil around the pile is improved, and the discrete material pile is protected against the problems of different pile diameters, bulging damage, pile hole caving and the like; the microorganism solidified soil and the pile can be combined to bear loads, and thus the bearing capacity of the single pile is improved.

Owner:NANJING FORESTRY UNIV

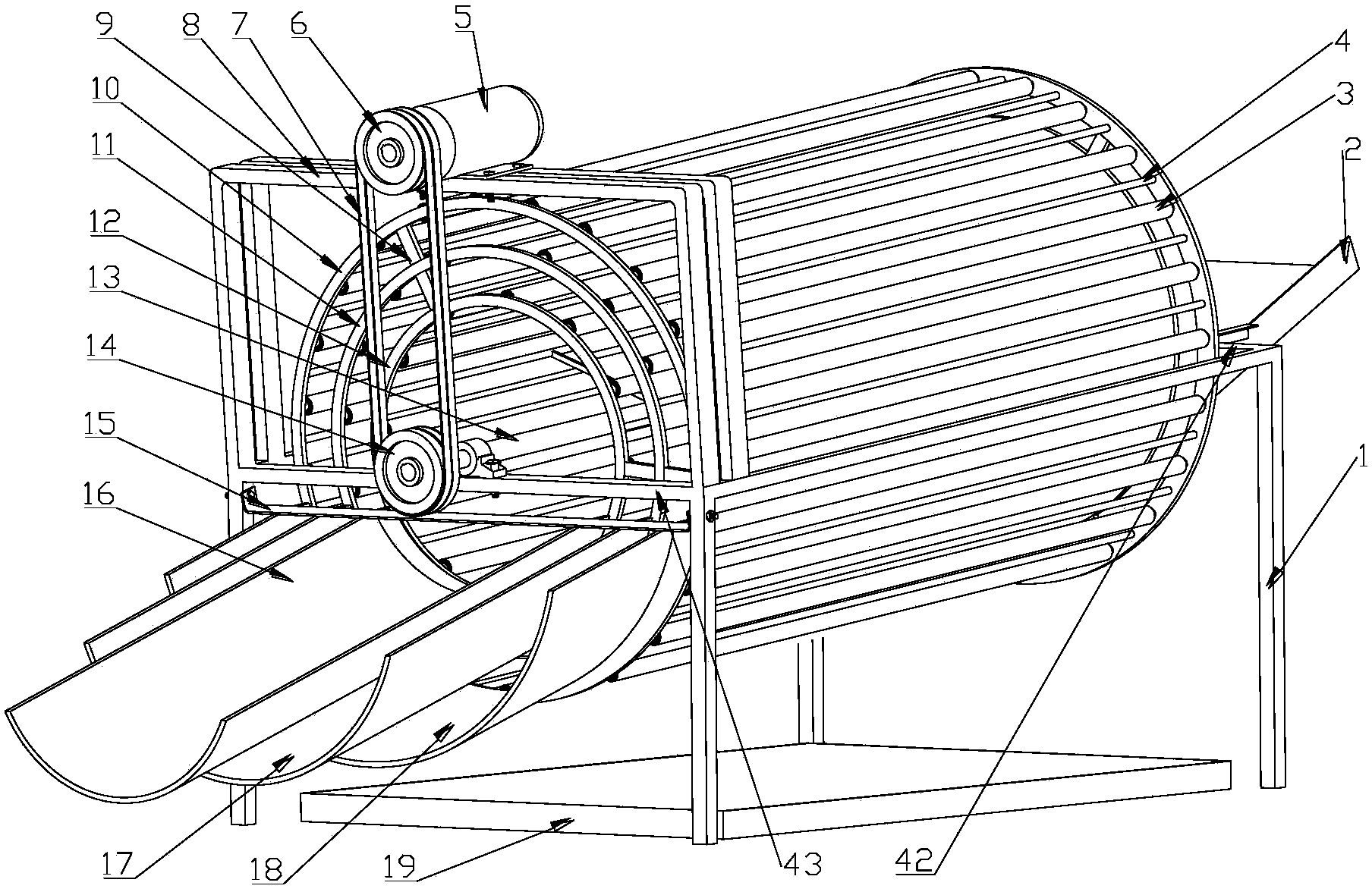

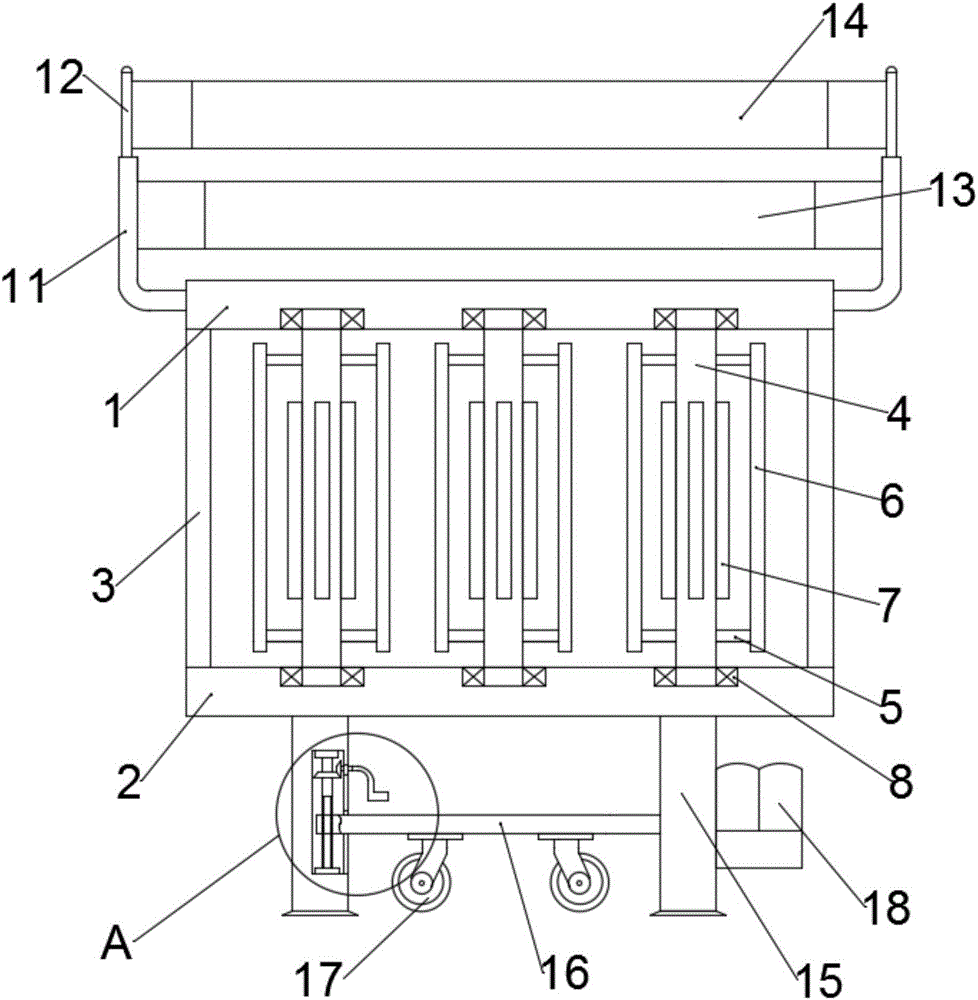

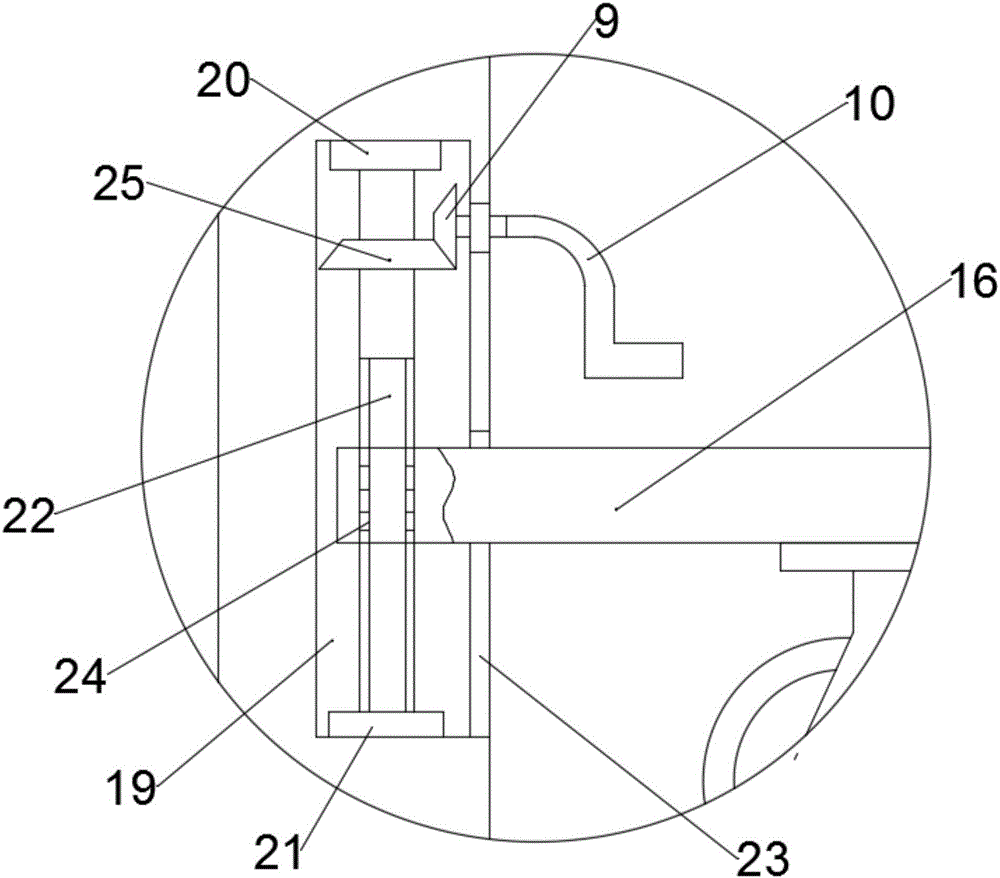

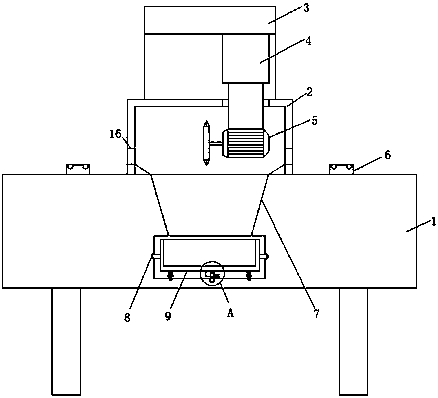

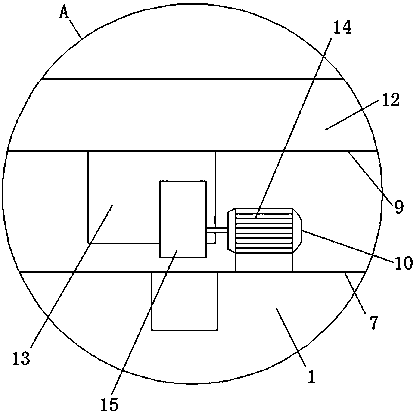

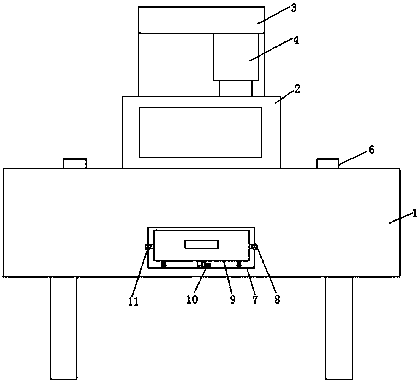

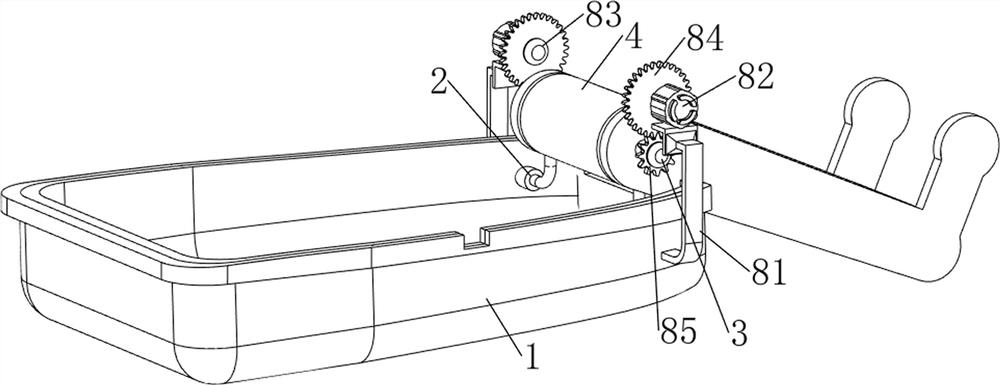

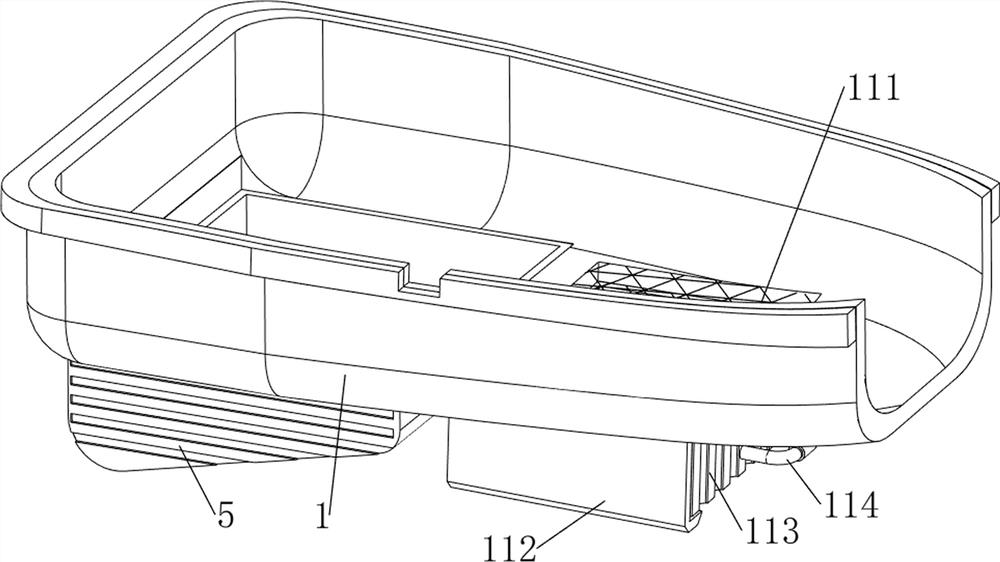

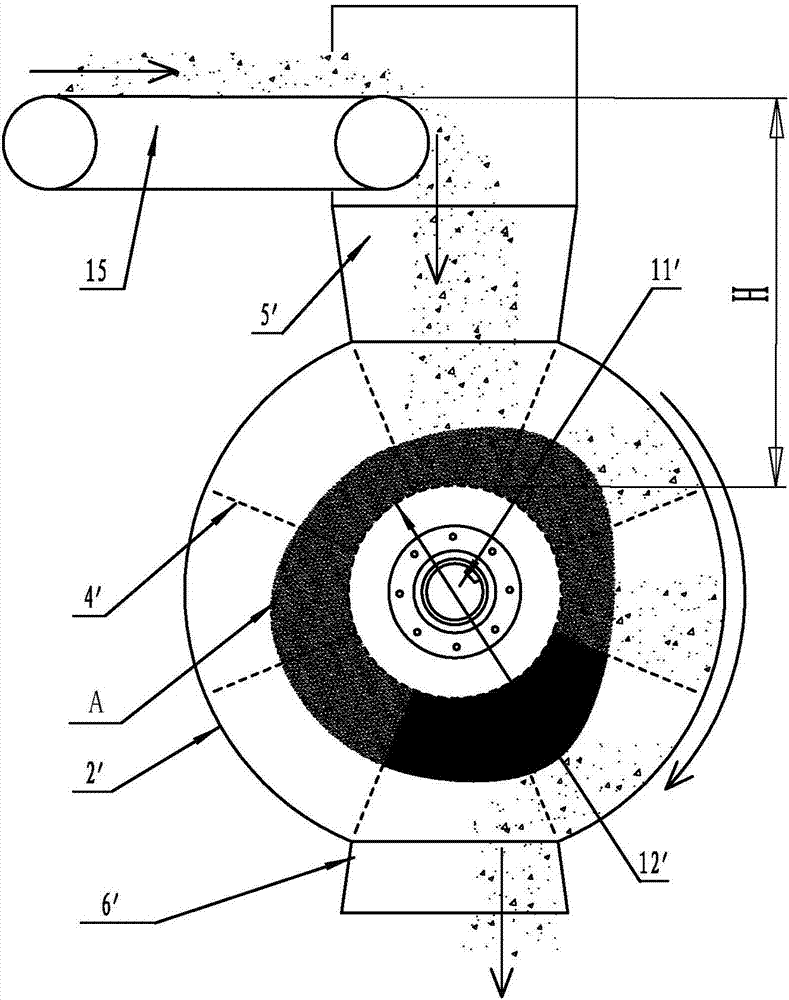

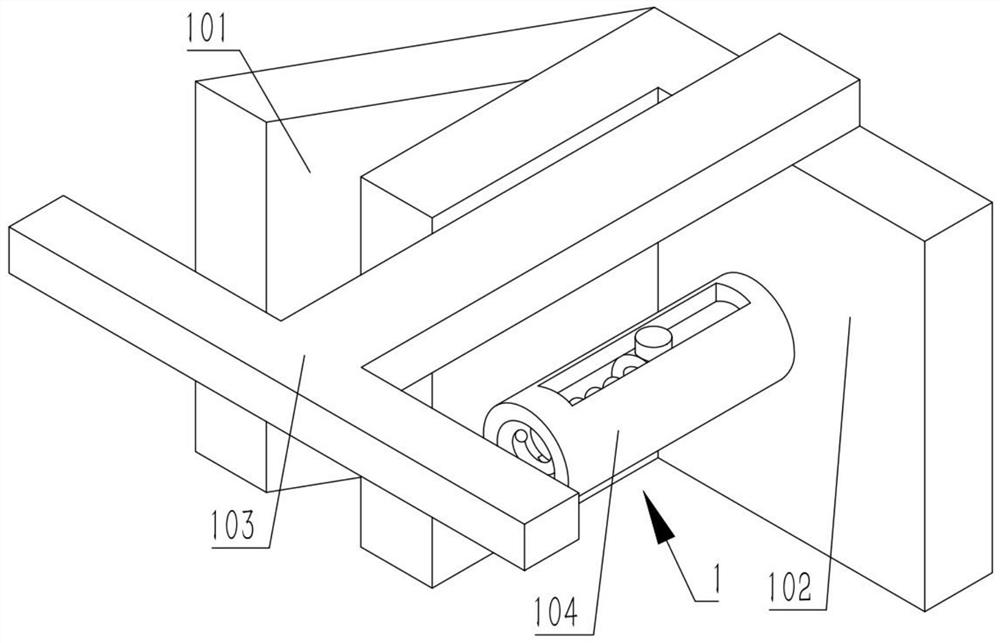

Rotary cage-type walnut classifying screen

ActiveCN103831230APrevent pilesImprove classification accuracySievingScreeningSmall footprintEngineering

The invention relates to a rotary cage-type walnut classifying screen which is high in classifying efficiency and classifying precision, small in occupied area and low in cost and is used for classifying walnuts. The rotary cage-type walnut classifying screen comprises a support. A cage-type classifying screen body is installed on the support and driven by a driving device to rotate. The driving device is installed on the support. One end of the cage-type classifying screen body serves as a feeding end, and the other end of the cage-type classifying screen body serves as a discharging end inclining towards the feeding end. The cage-type classifying screen body is composed of multiple layers of screening cages, the body of each layer of screening cage is composed of cage bars, the distance between every two adjacent cage bars of the innermost layer of screening cage is the largest, the distances are gradually decreased layer by layer, the distance between every two adjacent cage bars of the outermost layer of screening cage is the smallest, and the walnuts are classified by adjusting the distance between every two adjacent cage bars of each layer of screening cage. After fed into the cage-type classifying screen body, the walnuts with different sizes can be left in the screening cages of corresponding classes when the cage-type classifying screen body rotates and are discharged by discharging devices fixed to the support and located at the positions corresponding to the screening cages of the classes respectively.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

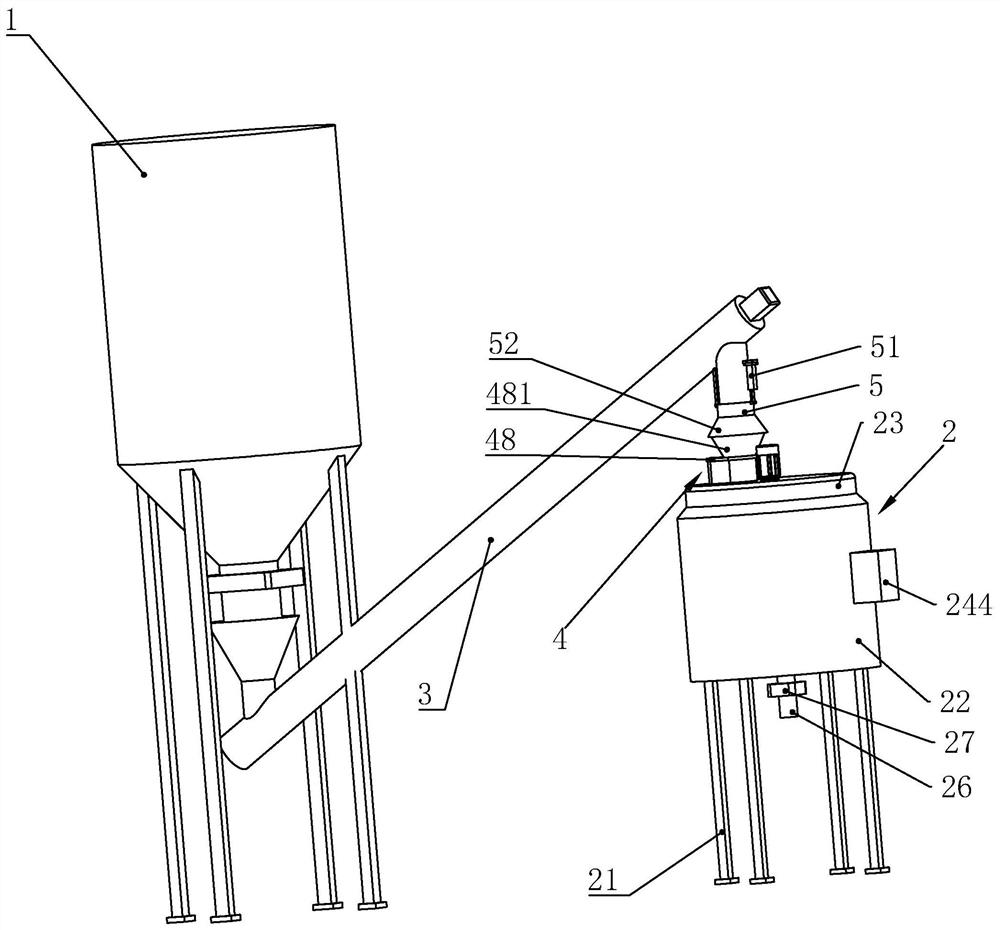

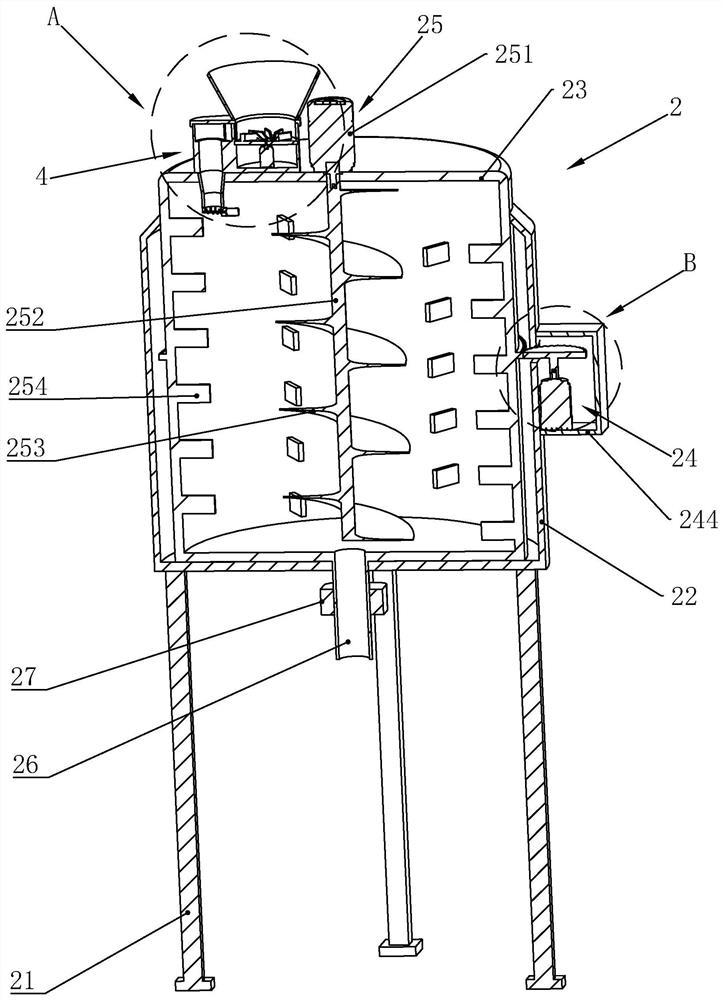

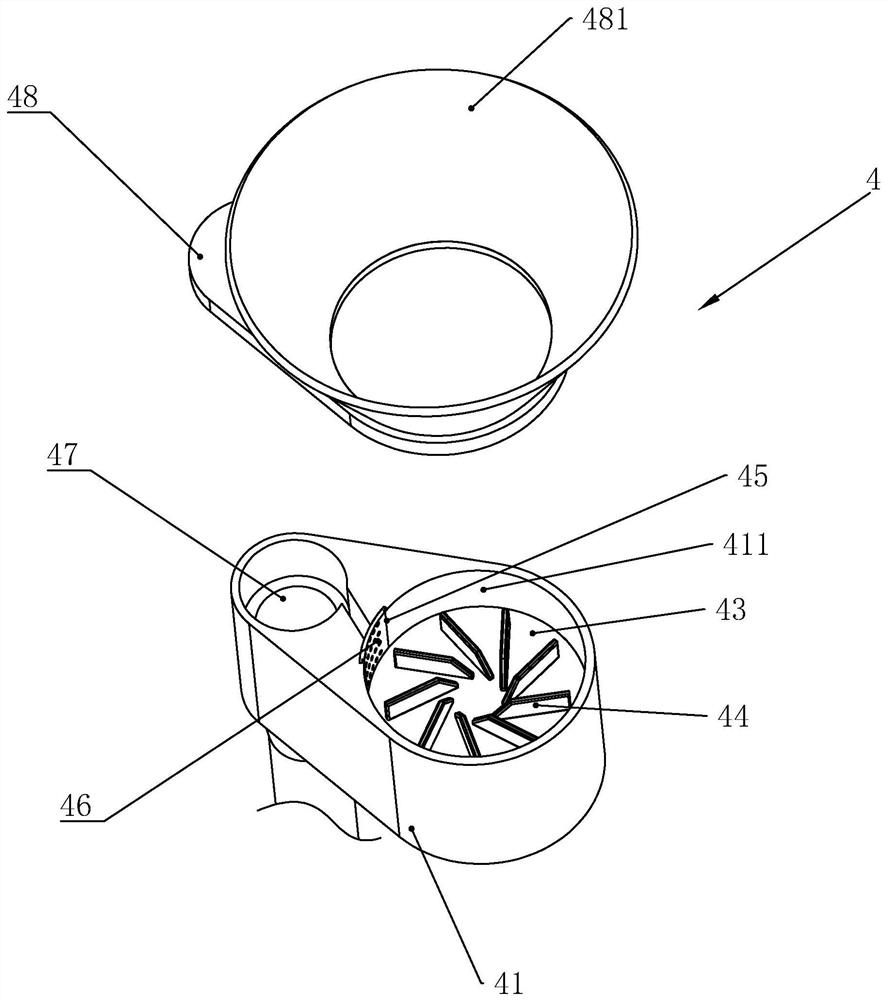

Environment-friendly antibacterial putty powder processing equipment and process

InactiveCN111701494AThe principle is simpleEasy to useRotating receptacle mixersTransportation and packagingEngineeringCaking

The invention relates to environment-friendly antibacterial putty powder processing equipment. The equipment comprises a raw material storage device, a mixing and stirring device and spiral feeders obliquely arranged at the bottom of the raw material storage device and the top of the mixing and stirring device; a crushing, grinding and feeding device is arranged at the top of the mixing and stirring device; the mixing and stirring device comprises a bracket and an outer barrel, which is provided with an opening in the top and is fixedly arranged on the bracket; an inner barrel is rotatably arranged in the outer barrel, the crushing, grinding and feeding device is located at the top of the inner barrel, a driving device for driving the inner barrel to rotate is arranged outside the inner barrel, a stirring device is arranged in the inner barrel, the stirring speed of the stirring device is higher than the rotation speed of the inner barrel, a discharging pipe is arranged at the bottom of the inner barrel and penetrates out of the bottom of the outer barrel, and a discharging valve is arranged on the discharging pipe. The environment-friendly antibacterial putty powder processing equipment has the characteristics of scattering material cakes and mixing the materials more uniformly, can effectively shorten the material stirring time, and ensures the quality of the mixed putty powder.

Owner:西安德润九州新材料有限公司

Suspended removal cleaning device for hydraulic engineering

InactiveCN111516815AReasonable designPrevent garbage from stickingWater cleaningWaterborne vesselsLeather beltStructural engineering

The invention belongs to the field of cleaning equipment, and especially relates to a suspended garbage removal device for hydraulic engineering. The device aims at the problem that an existing cleaning device is inconvenient to clean a belt conveying assembly, garbage is inconvenient to extrude, so that the collection amount is increased. The device comprises a hull, an installation frame is fixedly mounted at the top of the hull, a belt conveying assembly is fixedly installed on the installation frame, a collecting box is placed at the top of the hull, a push plate is slidably installed at the bottom of the collecting box, an inclined plate is fixedly installed at the top of the push plate and penetrates through the collecting box, a connecting plate is fixedly installed on one side of the installation frame, a first hole is formed in the connecting plate, and rotating rods are rotatably installed on the inner walls of the two sides of the first hole. The device is reasonable in design, garbage can be prevented from adhering to the belt conveying assembly through rotation and movement of a brush roller, the garbage can be extruded through rotation of a pressing roller, and the collection amount is increased.

Owner:耿纪鲜

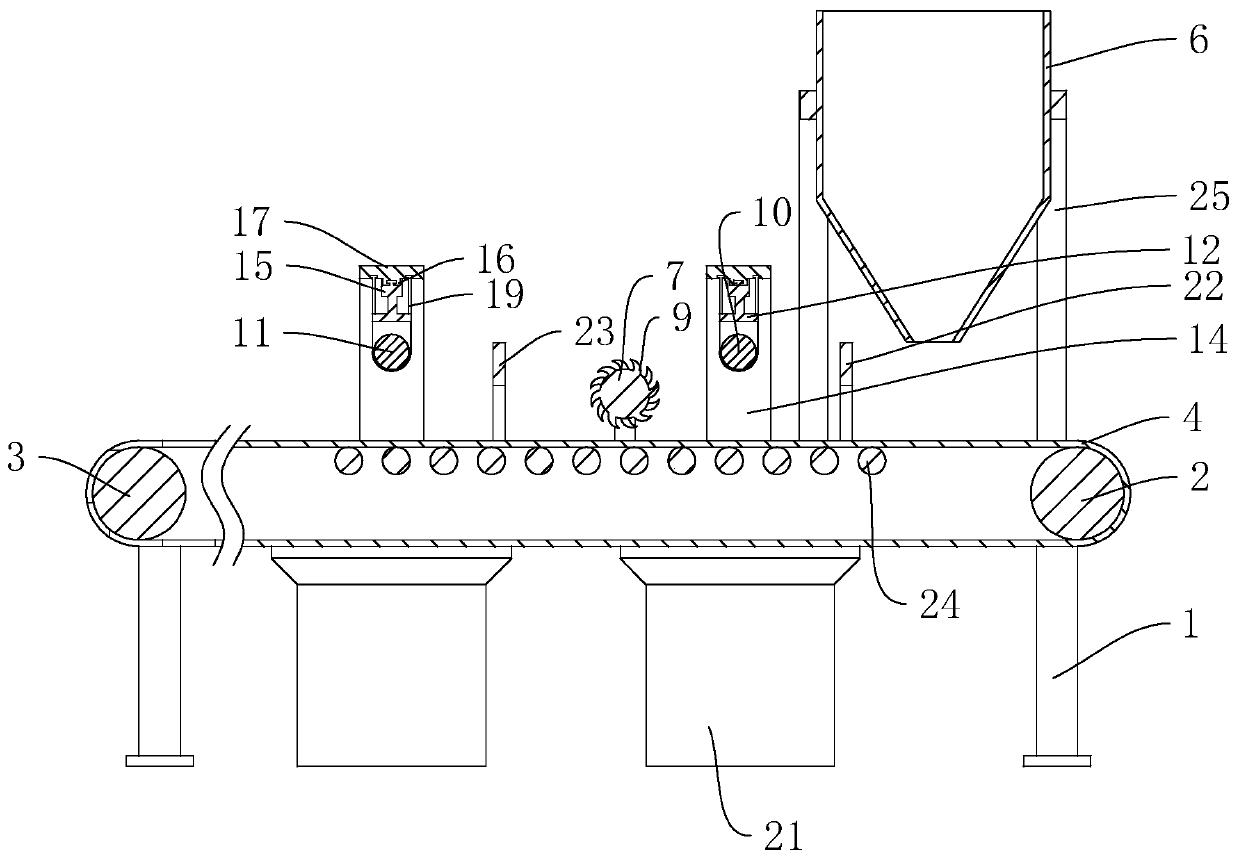

Building broken excess material deironing device

InactiveCN111468290APrevent pilesHigh removal rateMagnetic separationIron removalArchitectural engineering

The invention discloses a building broken excess material deironing device, and relates to the technical field of building excess material regeneration. According to the technical key points, the device comprises a rack; a driving roller and a driven roller are rotationally connected with the two ends of the rack correspondingly; a conveying belt is wound on the peripheral sides of the driving roller and the driven roller; a driving assembly for driving the driving roller to rotate is arranged on the rack; a feeding hopper is arranged above the feeding end of the conveying belt; a material overturning roller is horizontally arranged on the side, away from the feeding end, of the feeding hopper; the material overturning roller is located above the conveying belt and is perpendicular to themoving direction of the conveying belt; a rotating assembly for driving the material overturning roller to rotate is arranged on the rack; a plurality of arc-shaped material overturning teeth are anticlockwise arranged on the circumferential side of the material overturning roller in the circumferential direction, and concave faces of the material overturning teeth face the circumferential side ofthe material overturning roller; a first electromagnetic deironing roller parallel to the axis of the material overturning roller is arranged between the material overturning roller and the outlet ofthe feeding hopper; and a second electromagnetic deironing roller parallel to the axis of the material overturning roller is arranged on the side, away from the feeding hopper, of the material overturning roller. The device has the advantage of improving the iron impurity removal rate of the recycled aggregate.

Owner:陕西盛泰浩景建材有限公司

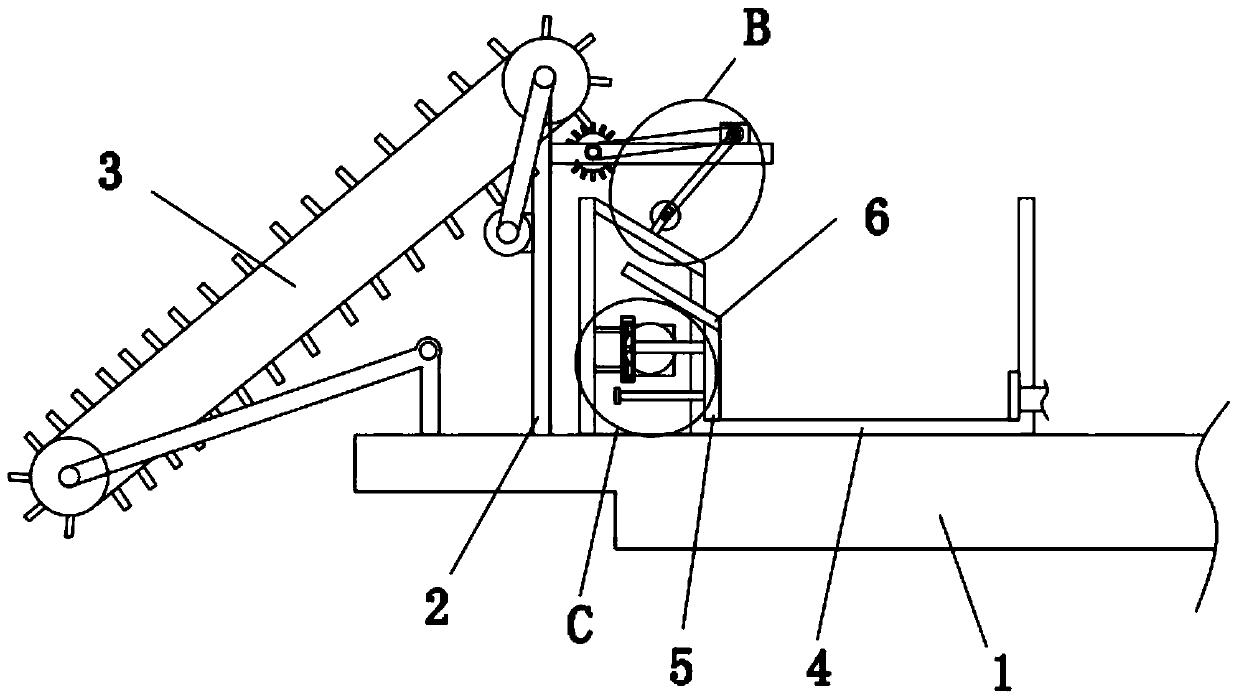

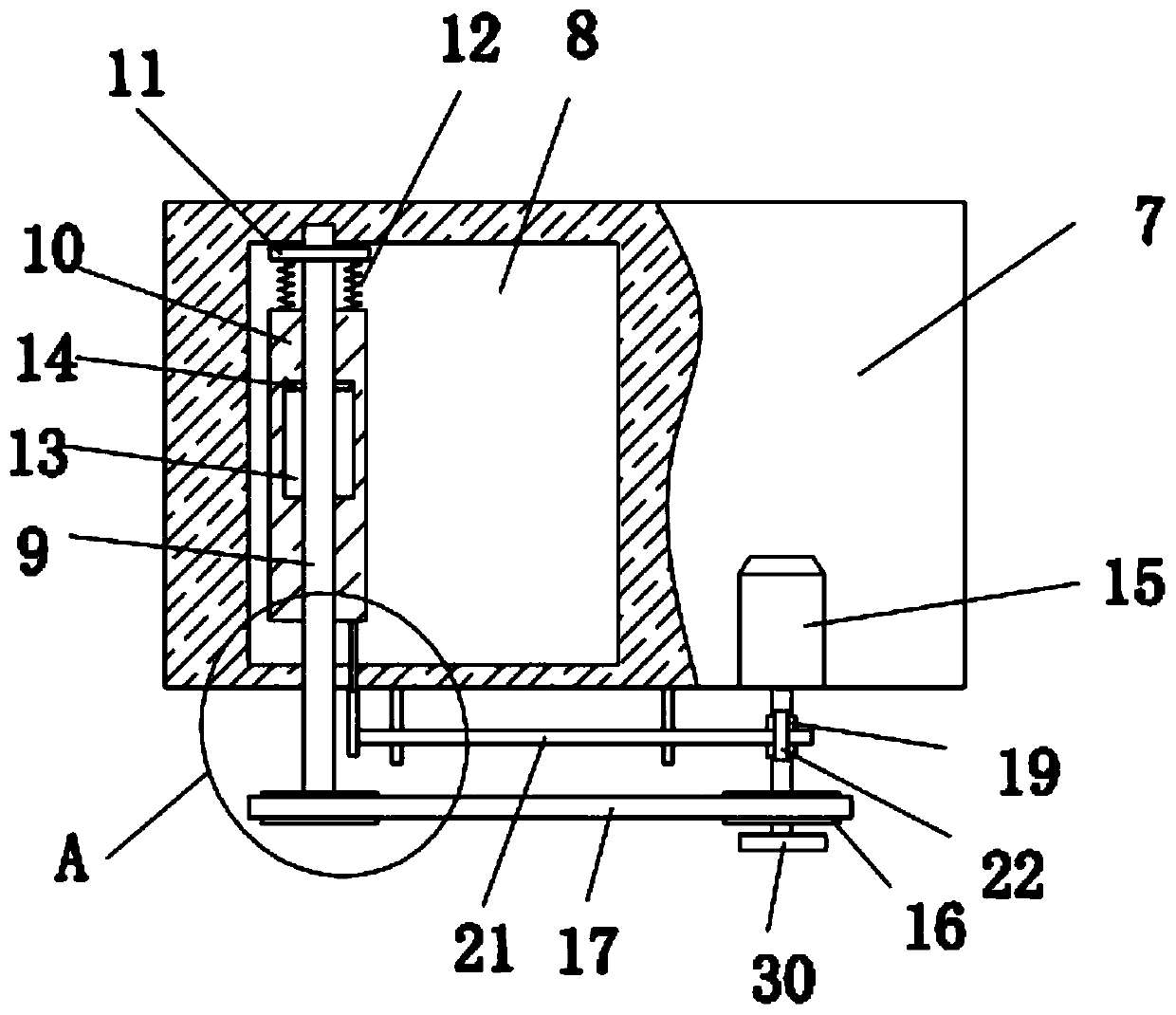

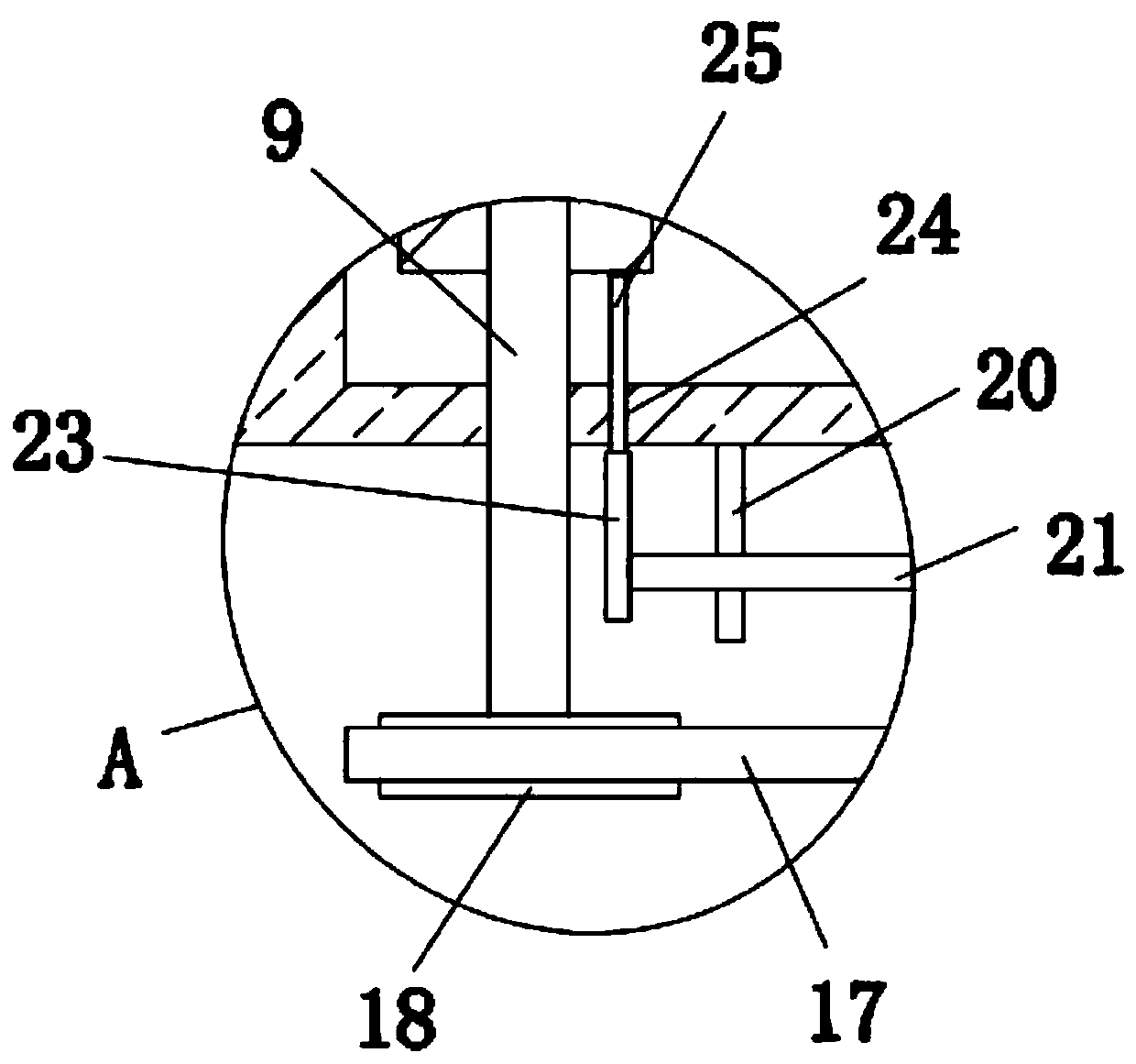

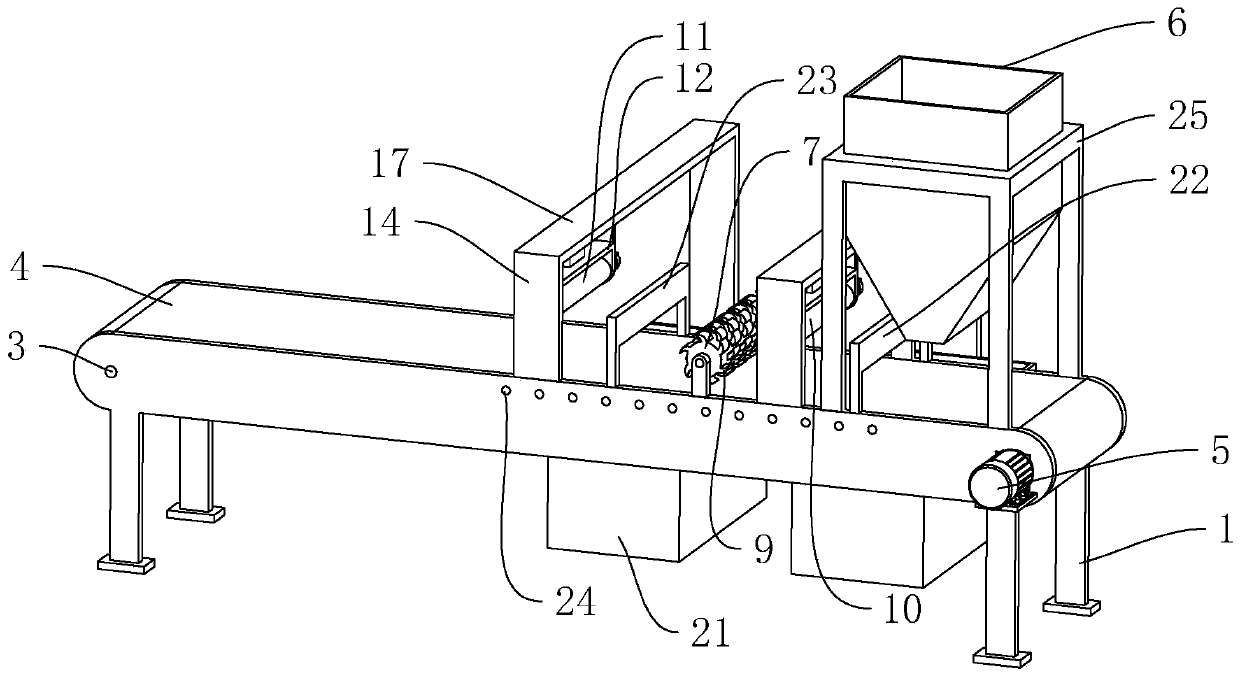

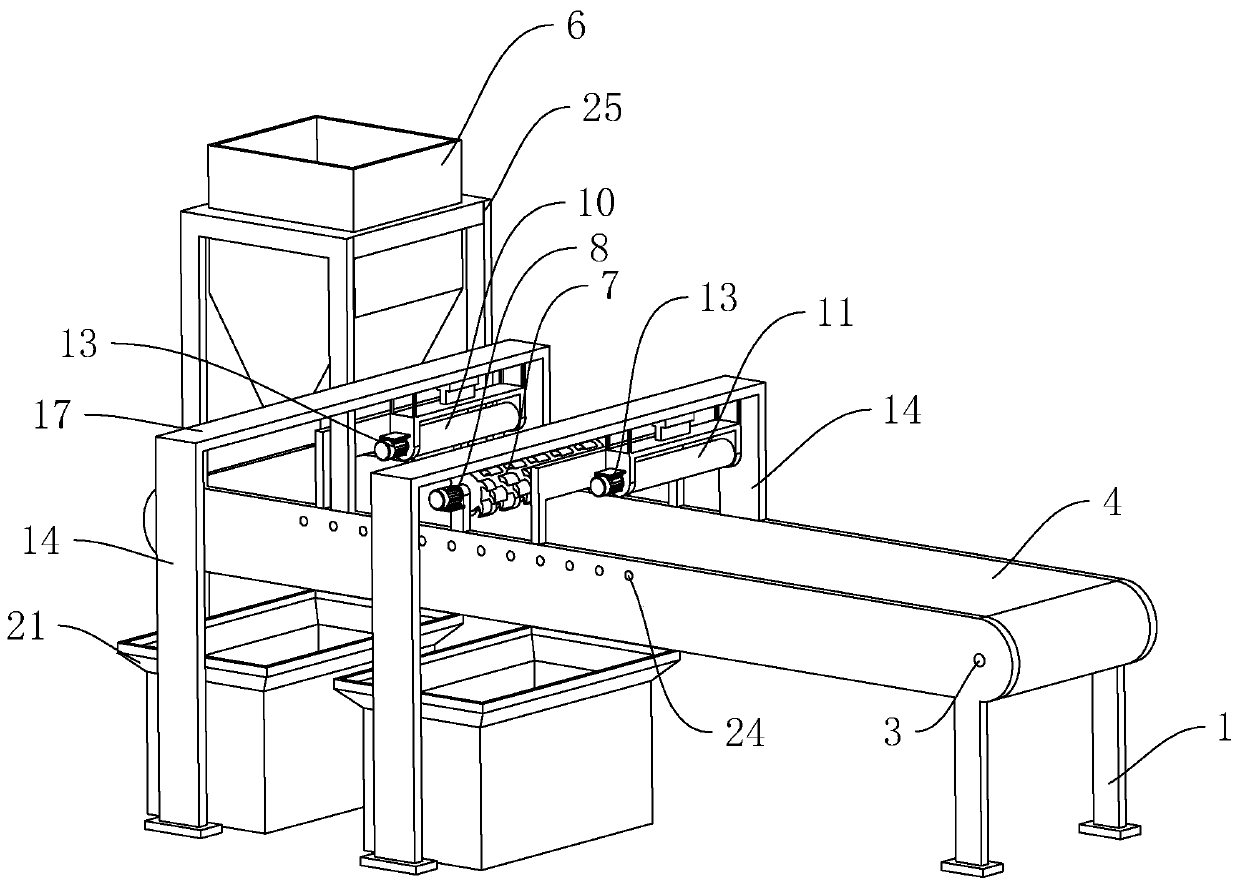

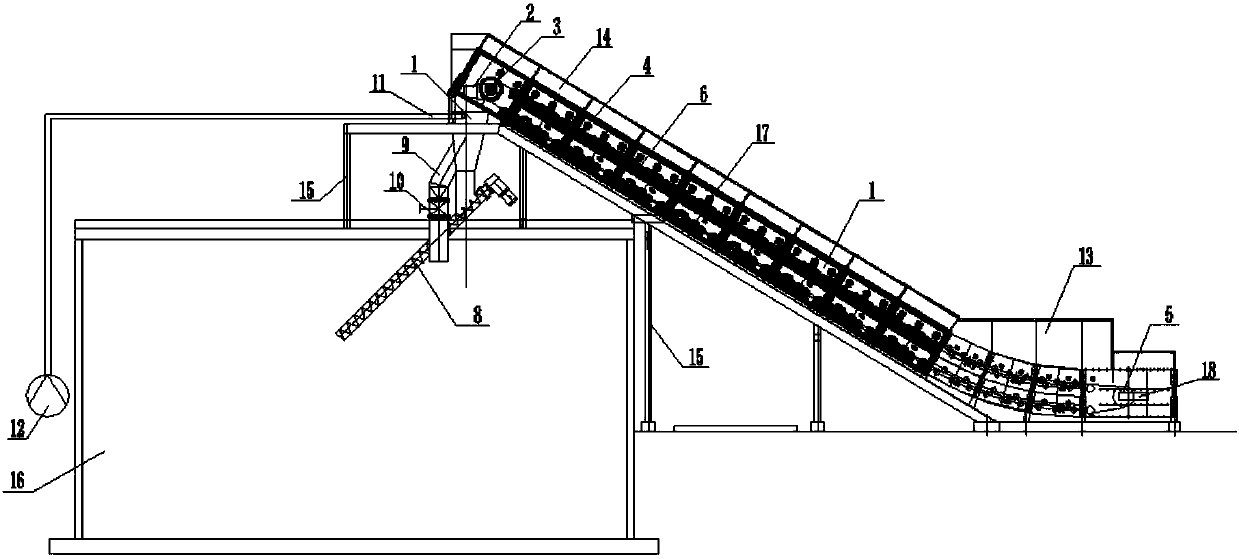

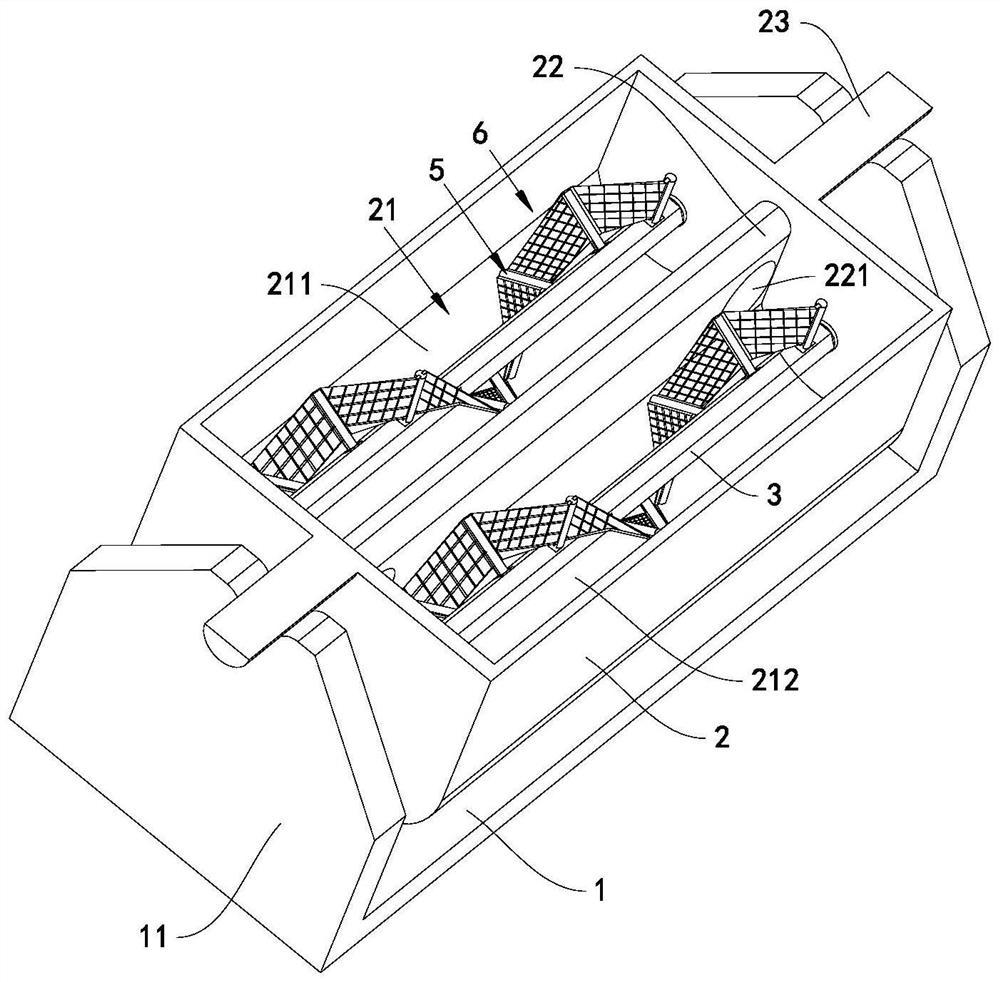

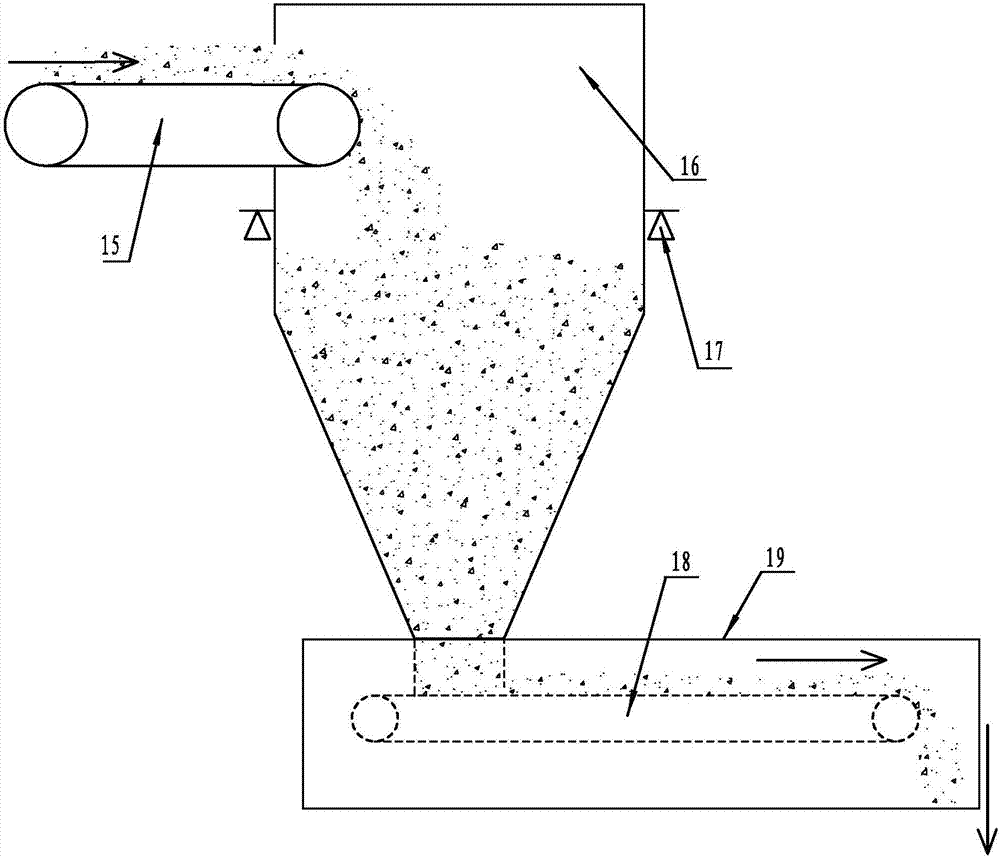

Material conveying device for biogas engineering

InactiveCN107697562AGuaranteed uniformityPrevent pilesGas production bioreactorsPackagingEngineeringSlurry

The invention discloses a material conveying device for biogas engineering. The device includes a conveying steel belt machine and an intermediate feeding device. The conveying steel belt machine is installed obliquely between the top of the fermenter and the ground. The intermediate feeding device is installed on the top of the fermenter. The upper end of the machine is connected, and the lower side is connected with a screw conveyor, and the lower end of the screw conveyor is arranged below the biogas slurry liquid level in the fermenter. The invention transports the loose straw through the steel belt conveyor, and a baffle plate is arranged on the steel belt conveyor, which ensures the uniformity of the straw conveying and avoids the phenomenon of straw piling and jamming caused by the ordinary belt conveying; by controlling the movement of the steel belt The speed can control the conveying volume of the straw, which is suitable for the adjustment of the feed volume of the biogas project; the straw is in the middle warehouse, mixed with the return biogas slurry sprayed from the spray pipe on the top of the warehouse, and then enters the fermentation tank, which ensures the solid-liquid mixing. Adequacy, avoiding the phenomenon of solid crusting in the tank.

Owner:南京通用电气装备有限公司

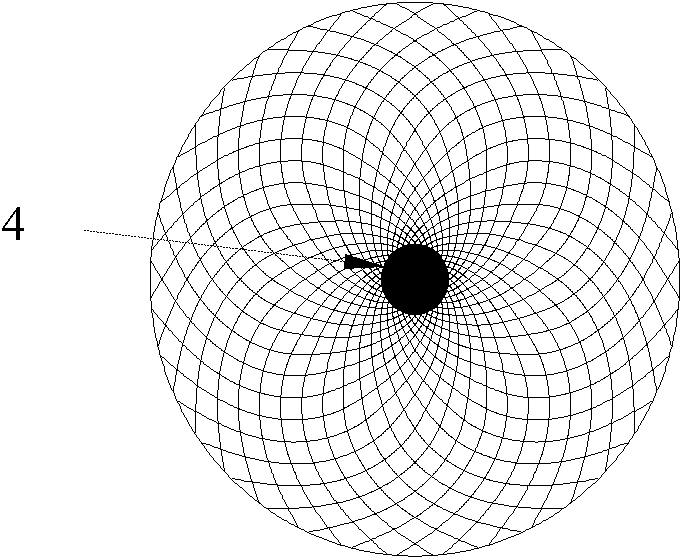

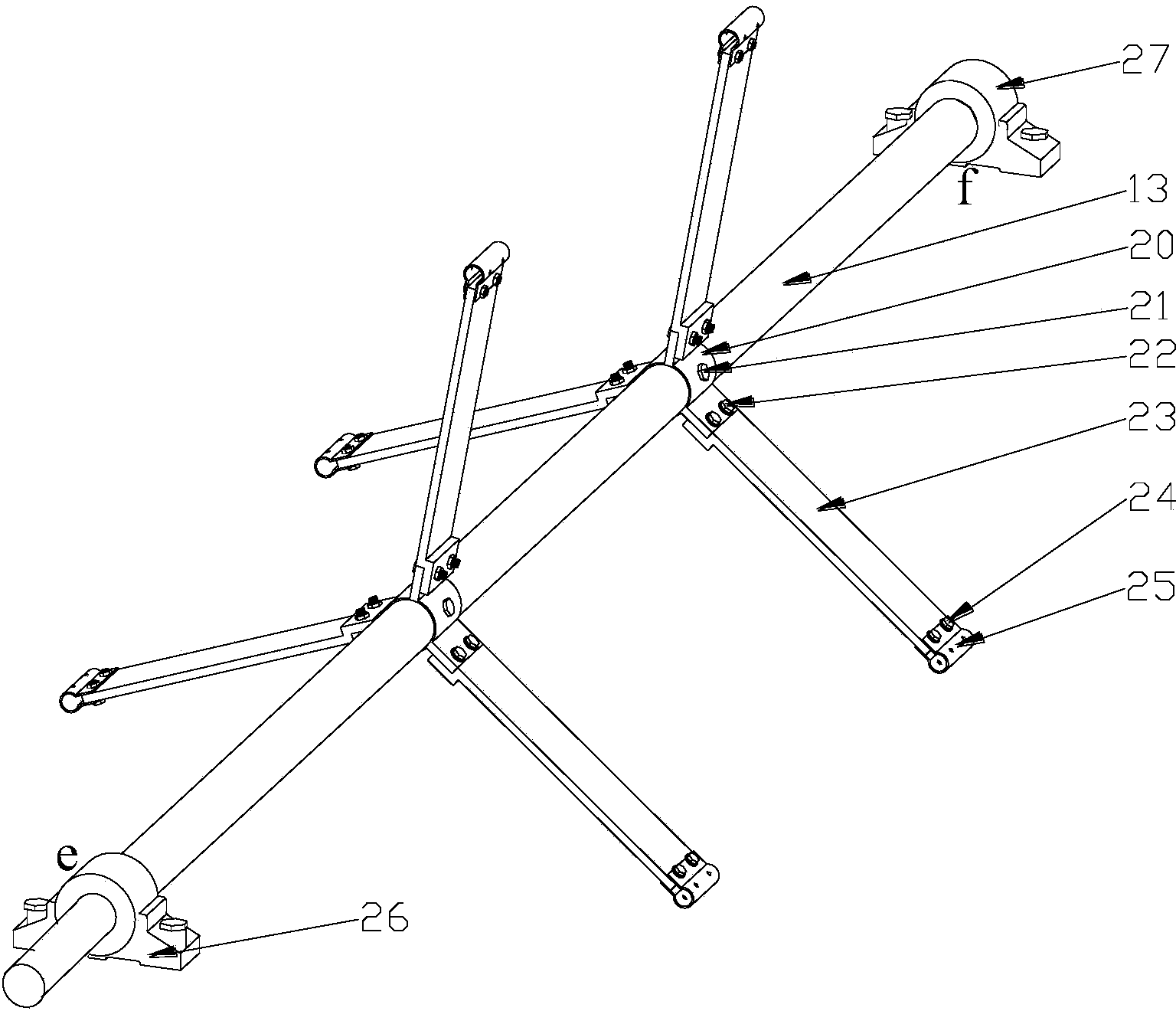

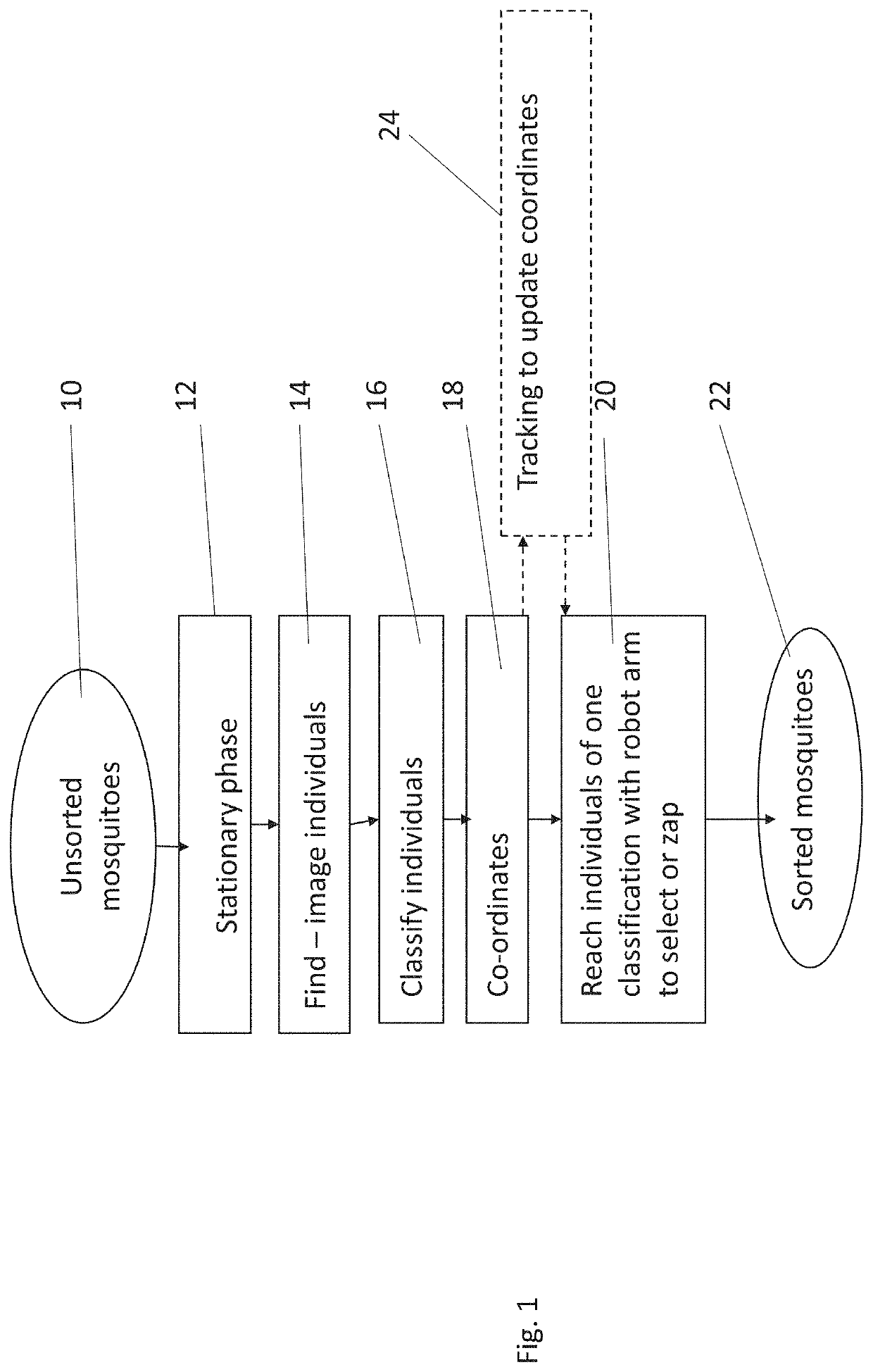

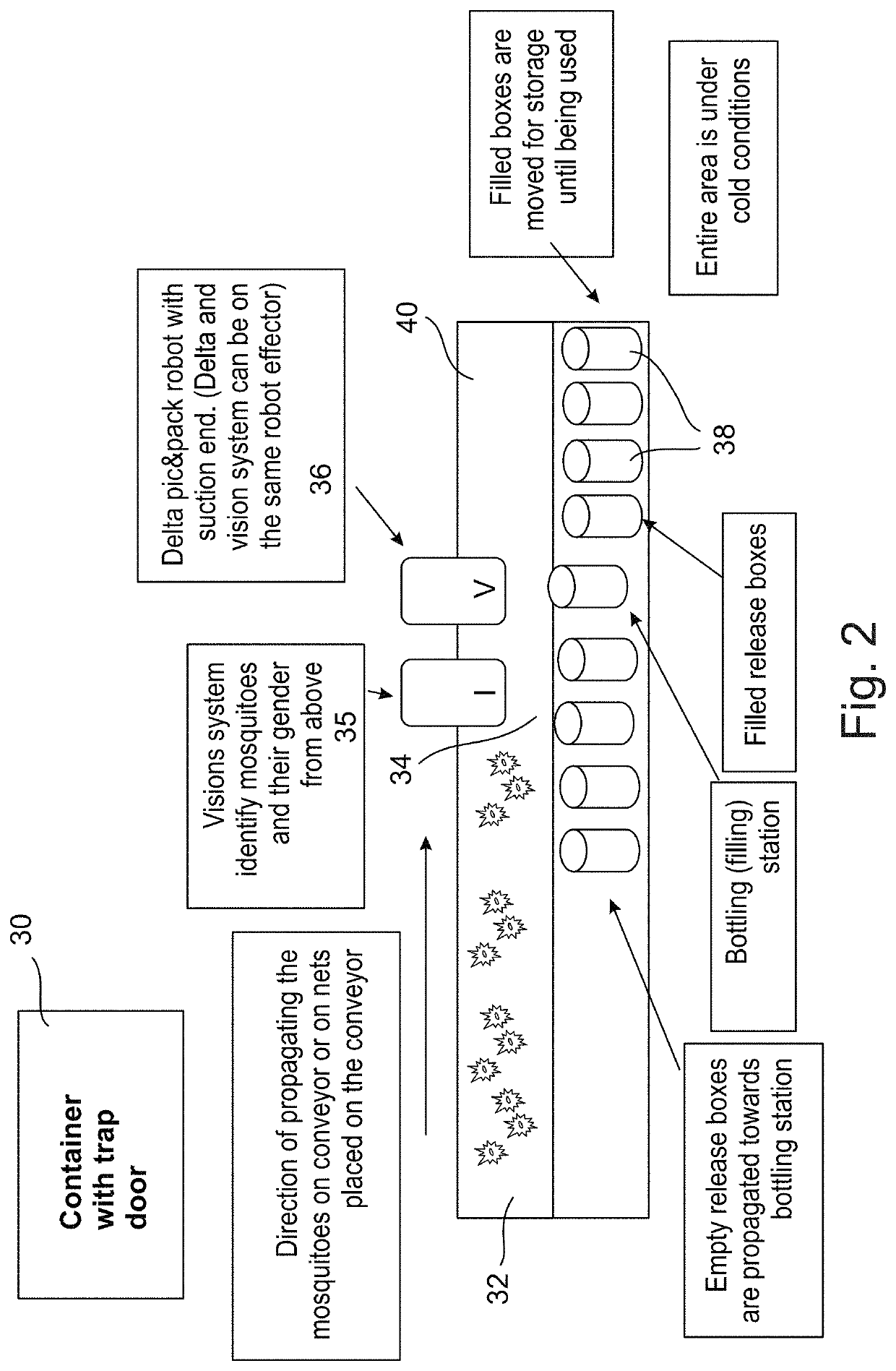

Method for sex sorting of mosquitoes and apparatus therefor

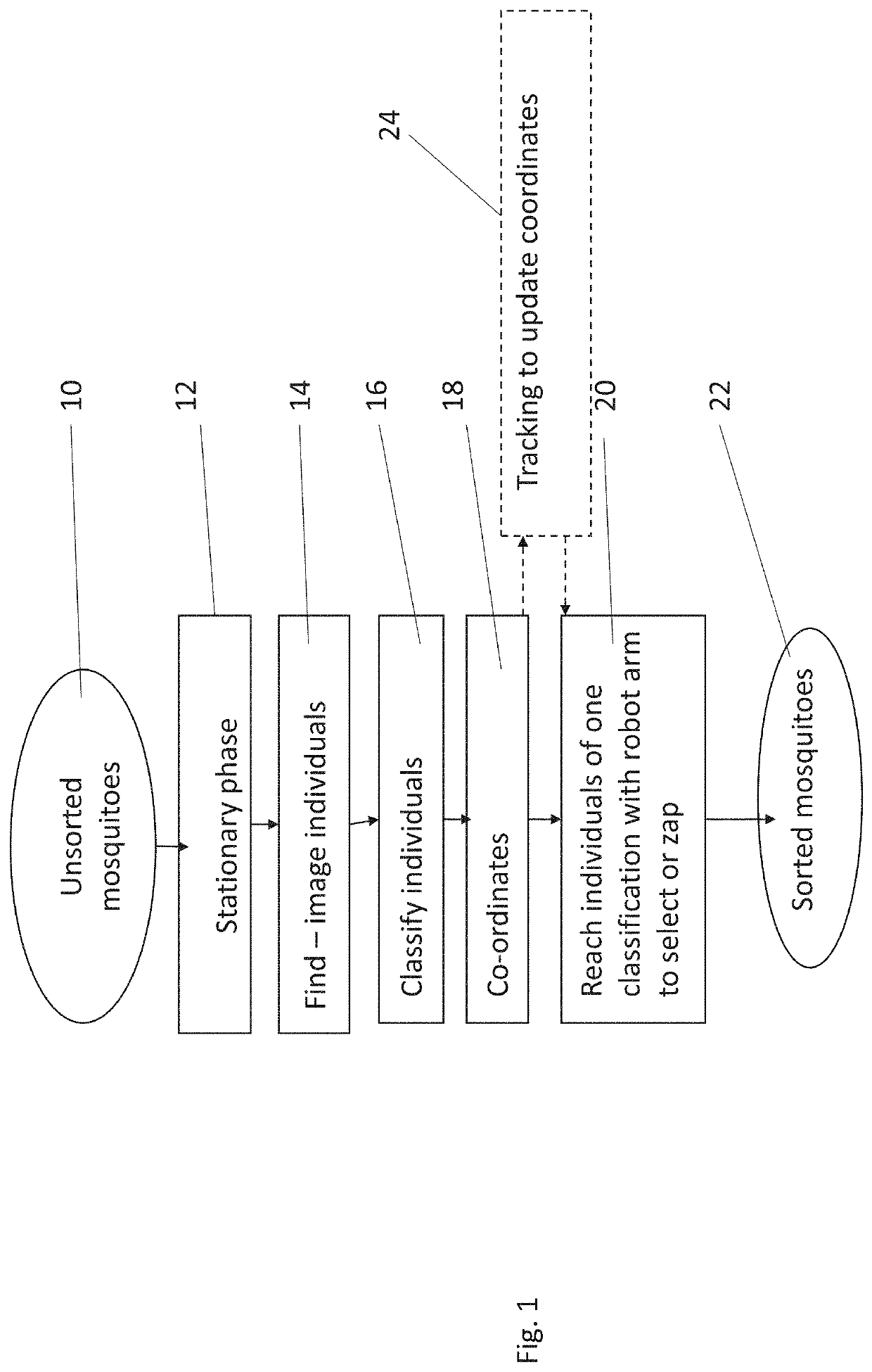

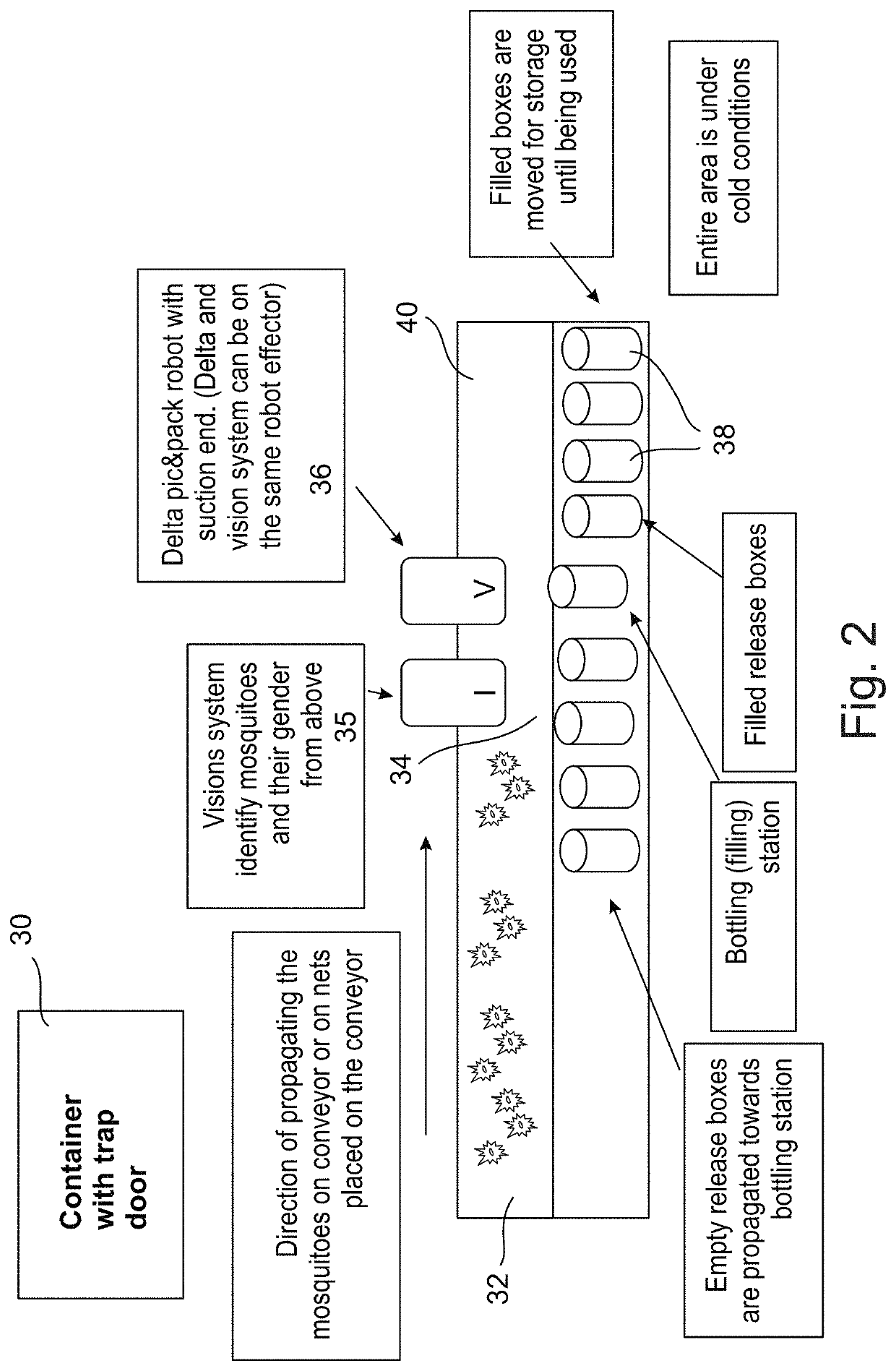

Method and apparatus for mechanical sex-sorting of mosquitoes by extracting a class of mosquitoes from unsorted mosquitoes comprises obtaining unsorted mosquitoes, obtaining images of individual mosquitoes in a stationary phase, electronically classifying the individuals from the images into male mosquitoes and / or female mosquitoes, and possibly also unclassified objects; obtaining co-ordinates of individuals of at least one of the male mosquito and female mosquito classifications, and using a robot arm to reach an individual identified by the obtained coordinates to store or remove the individuals, thereby to provide sex-sorted mosquitoes.

Owner:SENECIO

Revolving type publicity display stand for management and education in college

The invention discloses a revolving type publicity display stand for management and education in college. The publicity display stand comprises a main body top tray and a main body base. The main body top tray and the main body base are fixedly connected through a side support plate. The upper and lower parts of a rotating shaft are fixed connected with display shafts through a connection rod body. A first auxiliary banner is hung between the L-shaped fixing rods on both sides, support frame legs are arranged under the main body base, a lifting frame plate is arranged between the support frame legs corresponding to the two sides, two universal rollers are arranged on the lifting frame plate, a horizontal bevel gear is arranged at the upper part of the connection rod body, and garbage bins are arranged on the side walls of the support frame legs. The revolving type publicity display stand has good publicity effect by the arrangement of three groups of display shafts, rotating shaft publicity and auxiliary banner publicity methods are combined together, functions are more diversified, the utilization rate of finite space is increased, fast movement and positioning as well as effective classified arrangement of the garbage are achieved.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

Cutting machine for aluminum plate processing

InactiveCN108568557AConvenient loading workSpeed up cutting workMetal-working feeding devicesShearing machinesAgricultural engineering

The invention discloses a cutting machine for aluminum plate processing. The cutting machine comprises a worktable, wherein the top of the worktable is fixedly connected with a protective cover; the rear side of the top of the worktable is fixedly connected with a supporting plate; the top of the front side of the supporting plate is fixedly connected with an electric push rod extending to the interior of the protective cover; the bottom of the electric push rod is fixedly connected with a cutting mechanism; guide mechanisms are fixedly connected to the left and right sides of the top of the worktable; a collection tank is arranged on the top of the worktable and positioned below the protective cover; threaded grooves are formed in groove walls of the left and right sides of the collectiontank; and collection boxes in sliding connection with the threaded grooves are arranged inside the collection tank. According to the cutting machine for aluminum plate processing, convenience can bebrought to feeding of aluminum plates during cutting, the cutting operation of the aluminum plates can be accelerated, chips can be efficiently collected, the utilization rate of aluminum products canbe increased, and the chips can be prevented from injuring workers.

Owner:昆山力维拓工业自动化科技有限公司

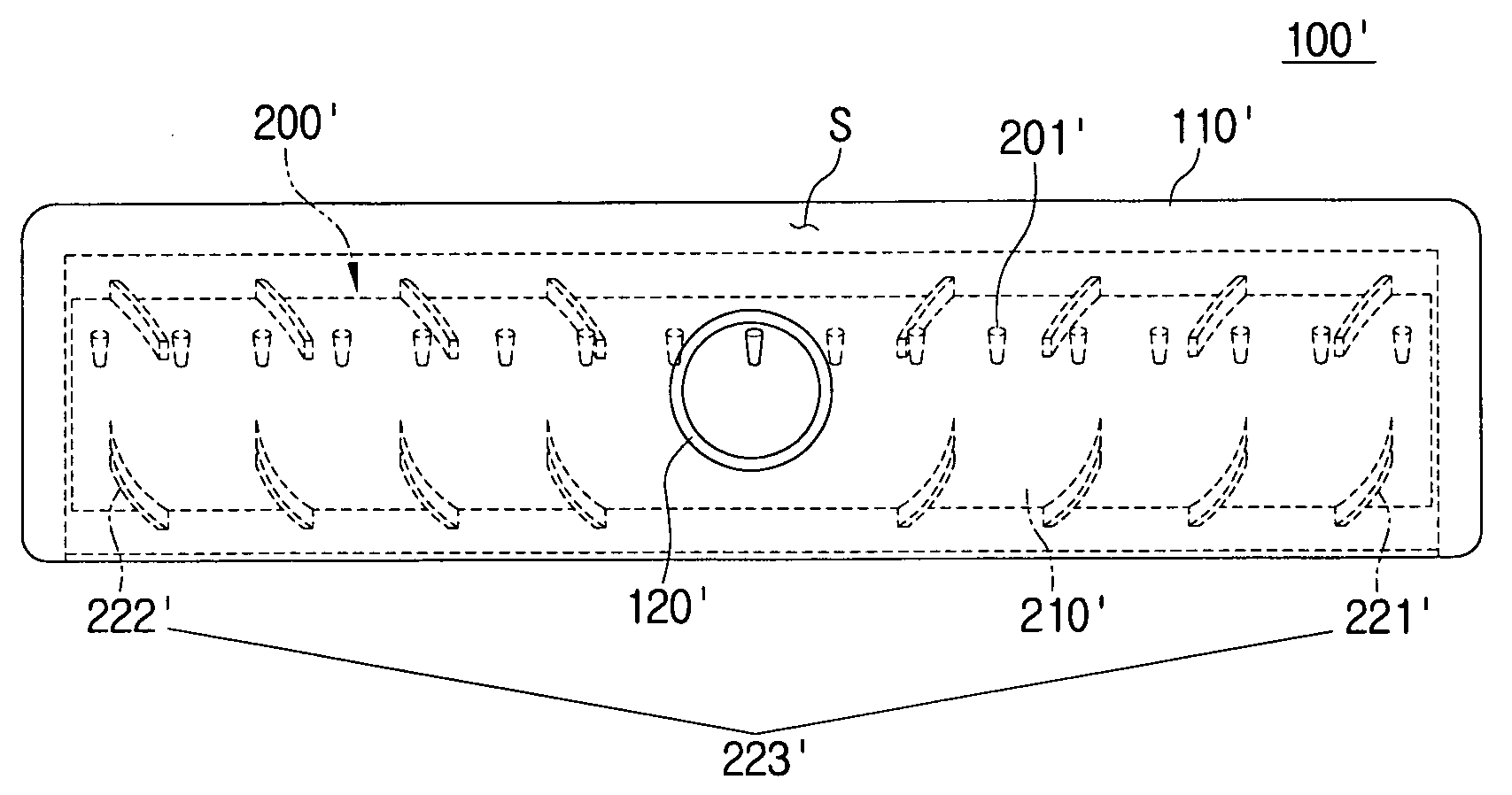

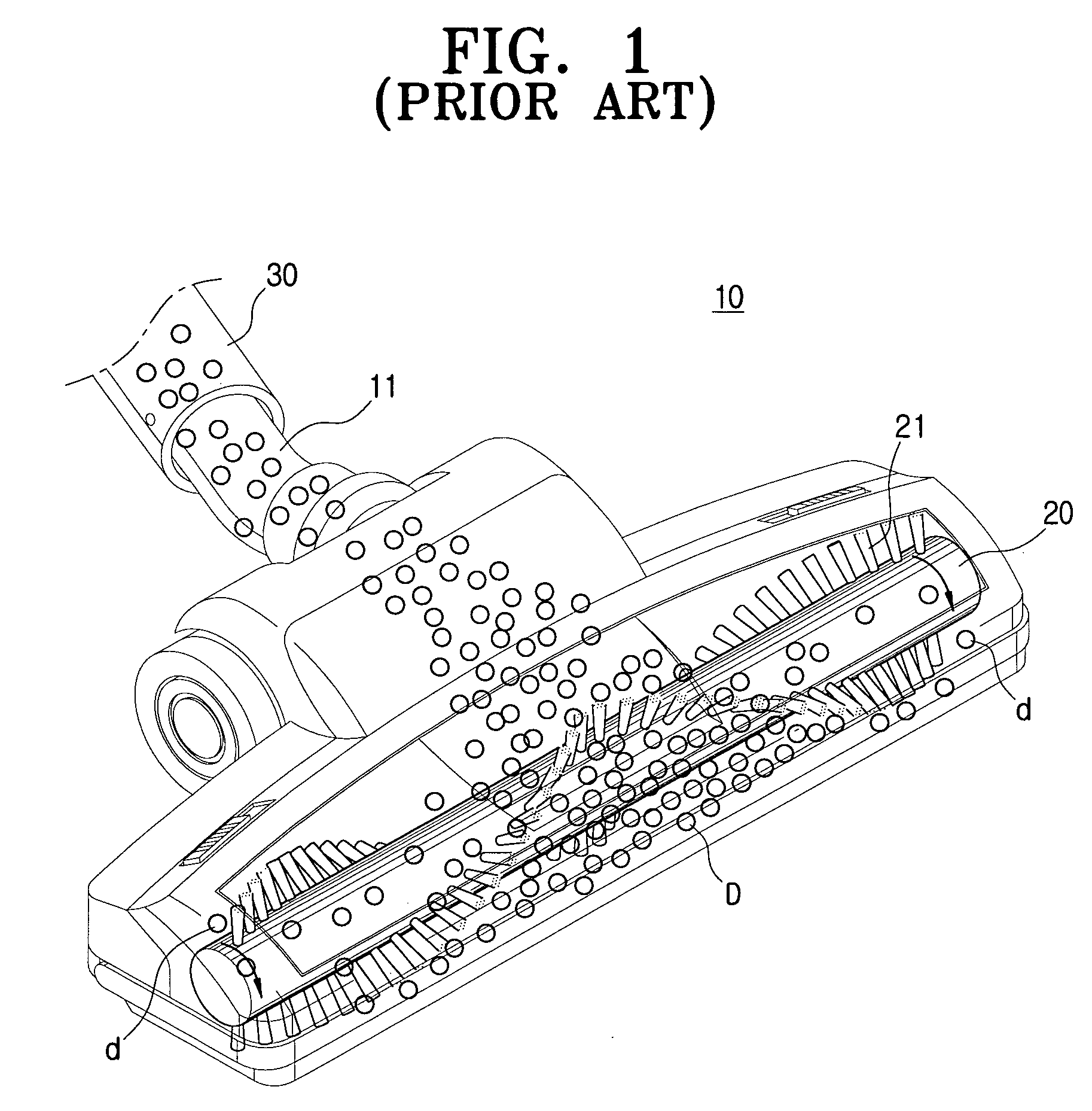

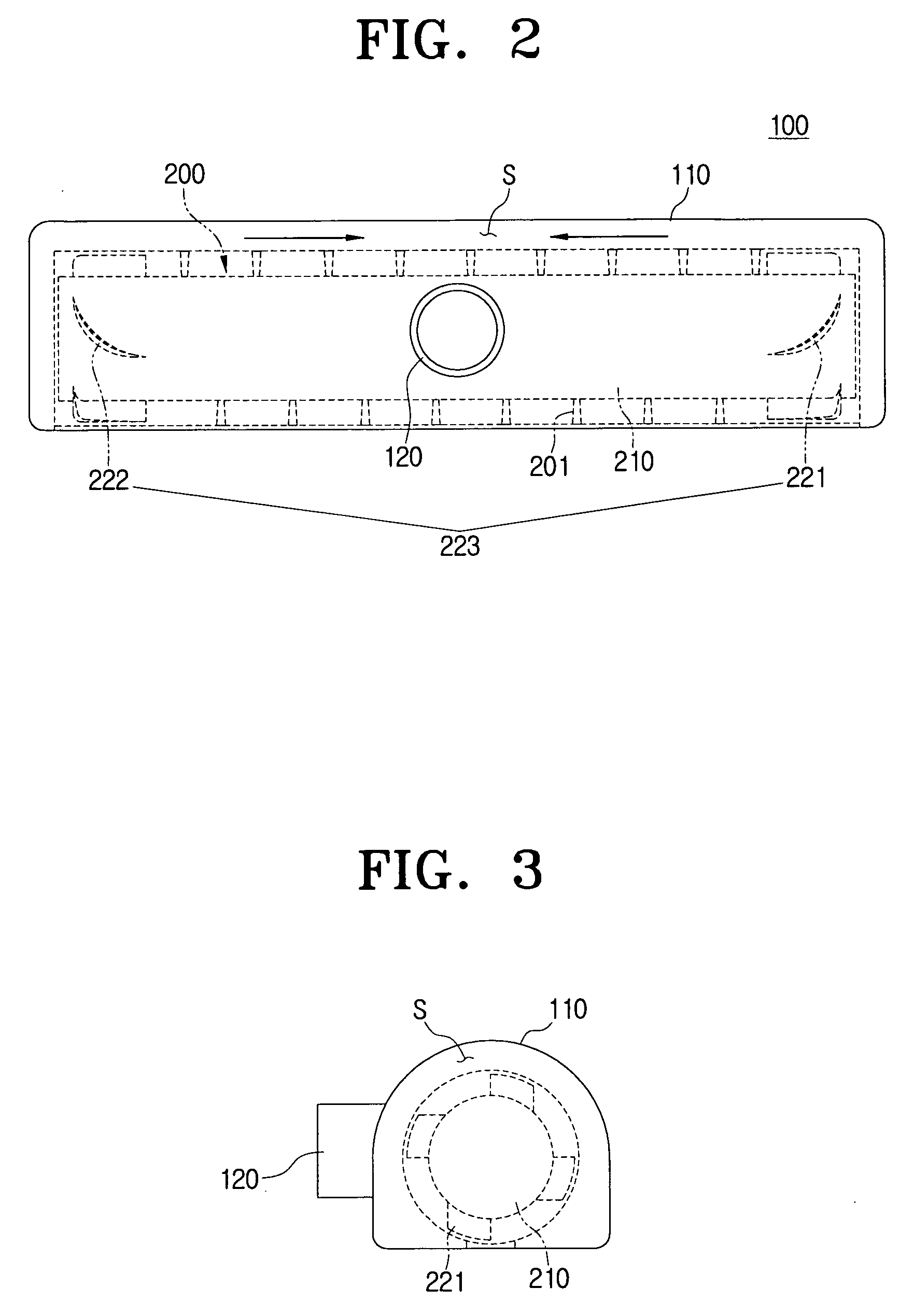

Agitator and suction nozzle for vacuum cleaner having the same

An agitator includes an agitator body rotatably accommodated within a suction nozzle having a suction port, and comprising a plurality of bristles planted in an outer circumference, and an air moving device formed on the outer circumference of the agitator body to cause air to move in a space defined between the agitator body and an inner wall of the suction nozzle, if the agitator body is rotated.

Owner:SAMSUNG ELECTRONICS CO LTD

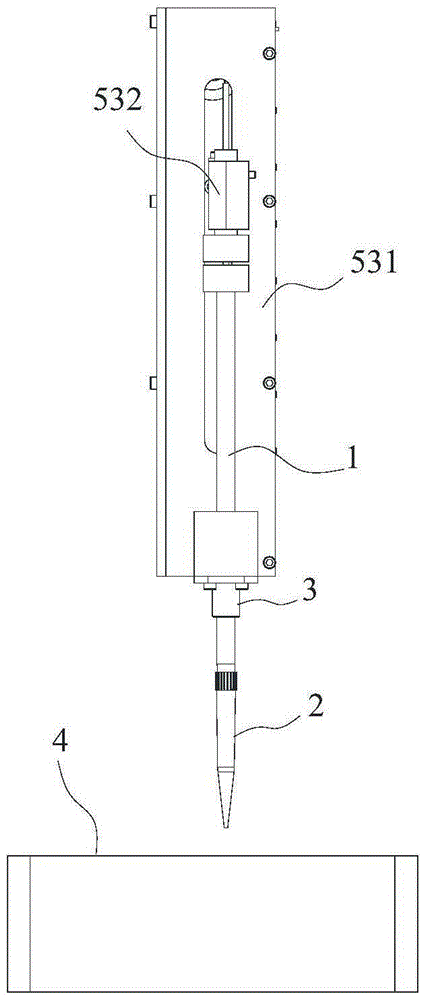

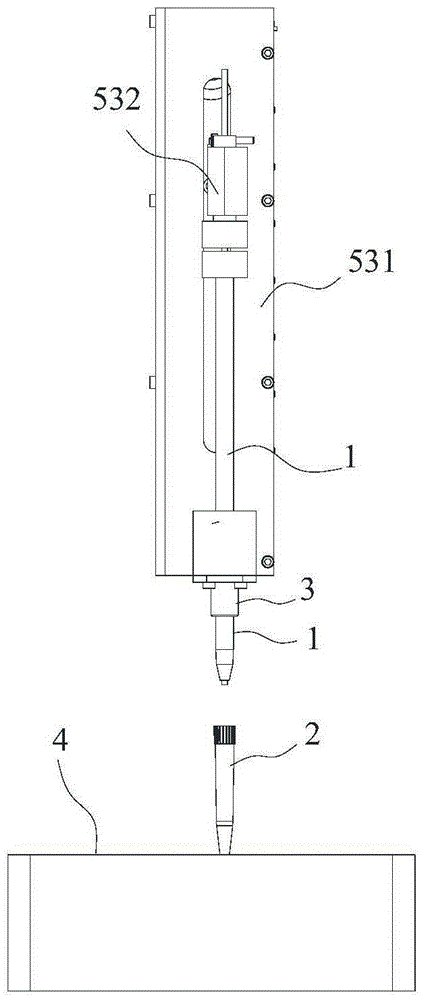

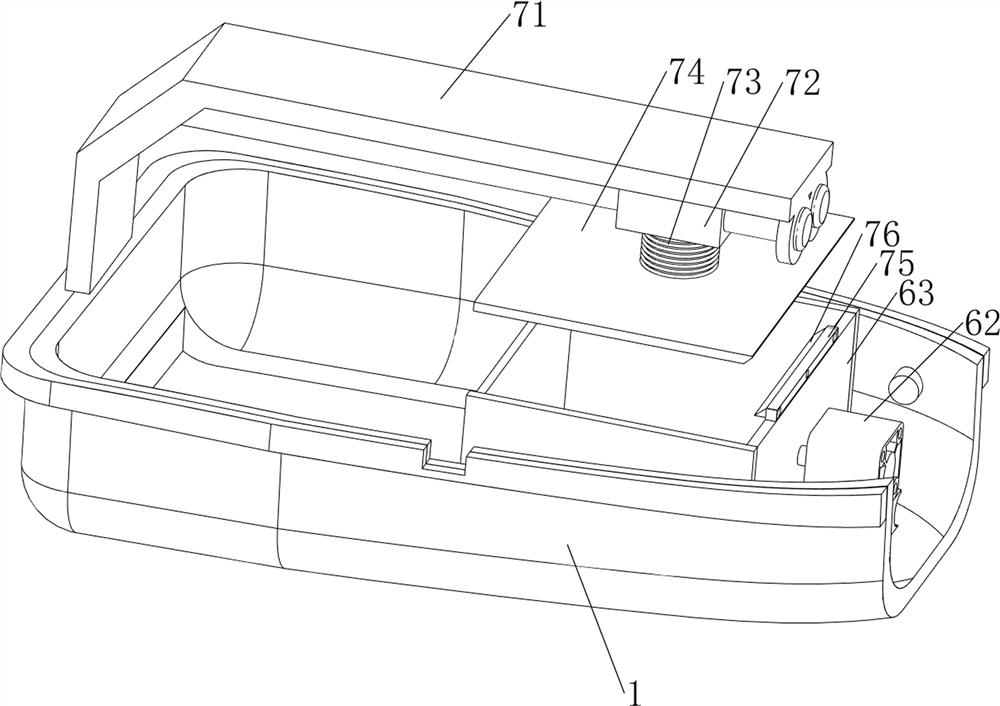

Recovery device for suction nozzle and dyeing machine

The invention discloses a recovery device for a suction nozzle. The recovery device comprises a sample-adding needle, a suction nozzle, a baffle base, a waste box, a Z1 axis bracket and a Z1 axis driving mechanism, wherein the baffle base is fixedly arranged at the bottom end of the Z1 axis bracket; the sample-adding needle is in sliding fit with the Z1 axis bracket along the Z axis direction; the Z1 axis driving mechanism is in driving connection with the sample-adding needle and is used for driving the sample-adding needle to vertically slide; the sample-adding needle is sleeved on the baffle base in a sliding form; correspondingly, the baffle base is provided with a penetrating hole, into which the sample-adding needle can be penetrated; the top end of the suction nozzle is detachably sleeved on the bottom end of the sample-adding needle; the top end of the suction nozzle is in resisting fit with the penetrating hole; the waste box is used for recovering the suction nozzle. The invention also discloses a dyeing machine adopting the recovery device for the suction nozzle. The recovery device for the suction nozzle can effectively save space.

Owner:GUANGZHOU HONGQI OPTICAL INSTR TECH

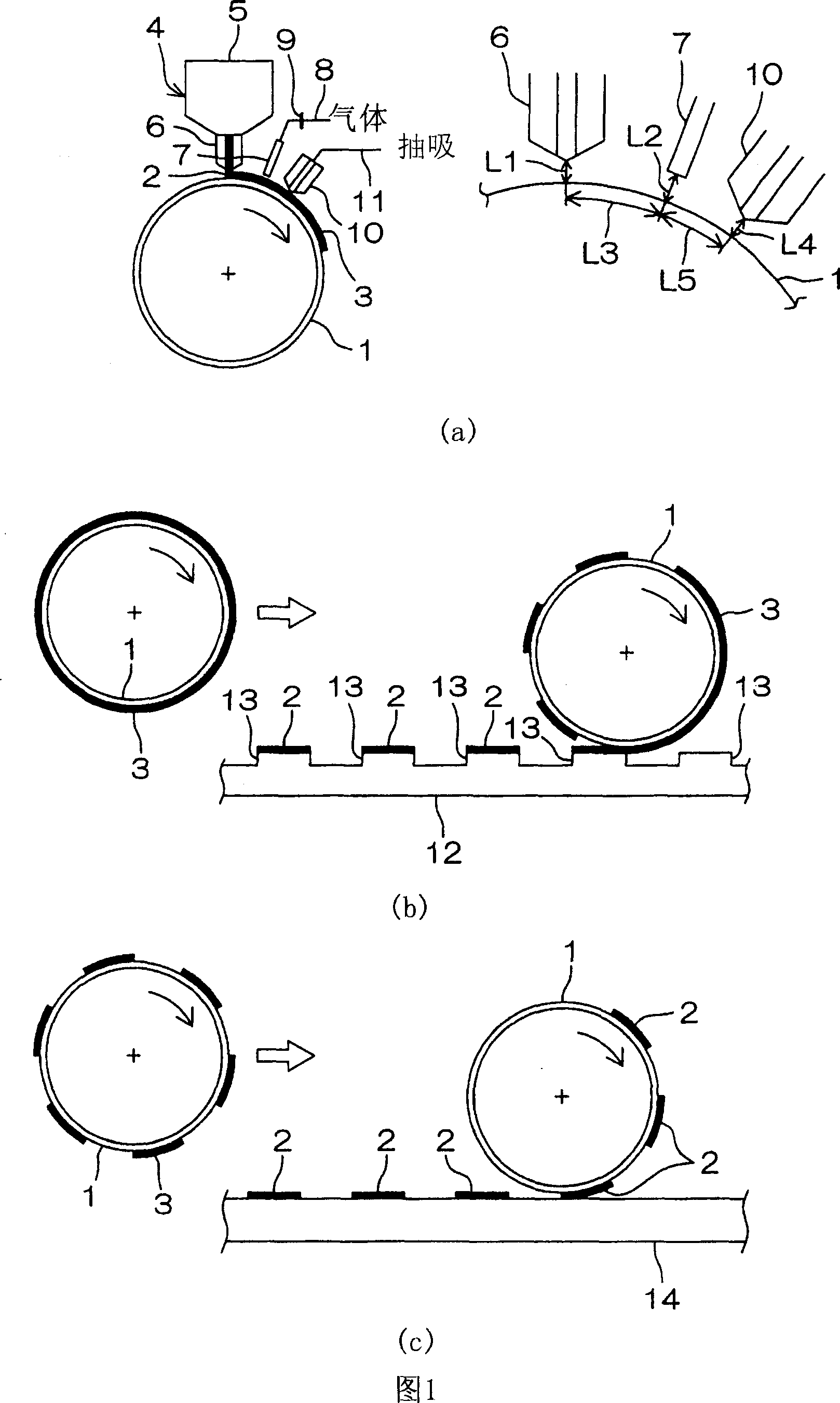

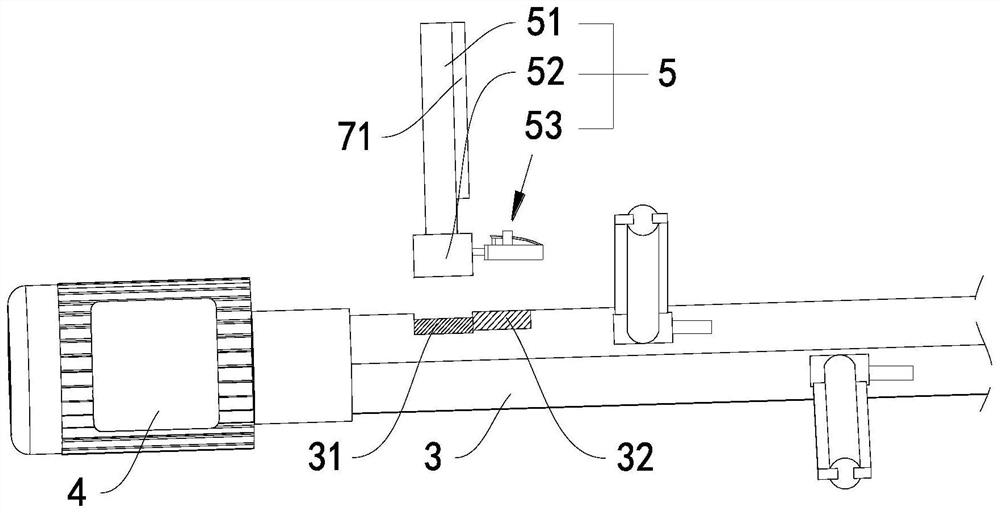

Printing method and printing device

Provided is a printing method which can form a uniform ink coating surface with stable coating properties, on the surface of a silicone blanket, prevent an ink from piling by improving transferability, and further, meet the requirements of an oversized printable object, and a printing device to be used for this printing method. In this printing method, the ink is applied by a slit die coater so as to allow forming of a coating surface of the ink on the surface of a silicone blanket, then a drying gas is blown to the coating surface of the ink from a gas nozzle and a solvent contained in the ink is sucked by a suction nozzle. After that, the coating surface of the ink is removed partially by rolling the silicone blanket over an indented plate, and the coating surface of the residual ink is transferred to the surface of a substrate.

Owner:SUMITOMO RUBBER IND LTD +1

Marine garbage salvage device with water removal function for marine environmental protection

The invention relates to a salvaging device, in particular to a marine litter salvaging device with a water removal function for marine environmental protection. The technical problem to be solved is to provide the marine litter salvaging device with the water removal function for marine environmental protection, which is high in working efficiency and capable of reducing the workload of people. A marine garbage salvage device with a water removal function for marine environmental protection comprises a first supporting frame and supporting frames, and the supporting frames are fixedly connected to the two sides of the interior of the first supporting frame; the two conveying rollers are rotationally connected between the supporting frames through bearings; and the conveying belt is wound between the conveying rollers. According to the device, marine garbage can be conveyed into the collecting frame through the conveying belt, the marine garbage is fished, the marine garbage is continuously conveyed, the efficiency is improved, manual operation of people is not needed, and the workload of people is relieved.

Owner:李平昕

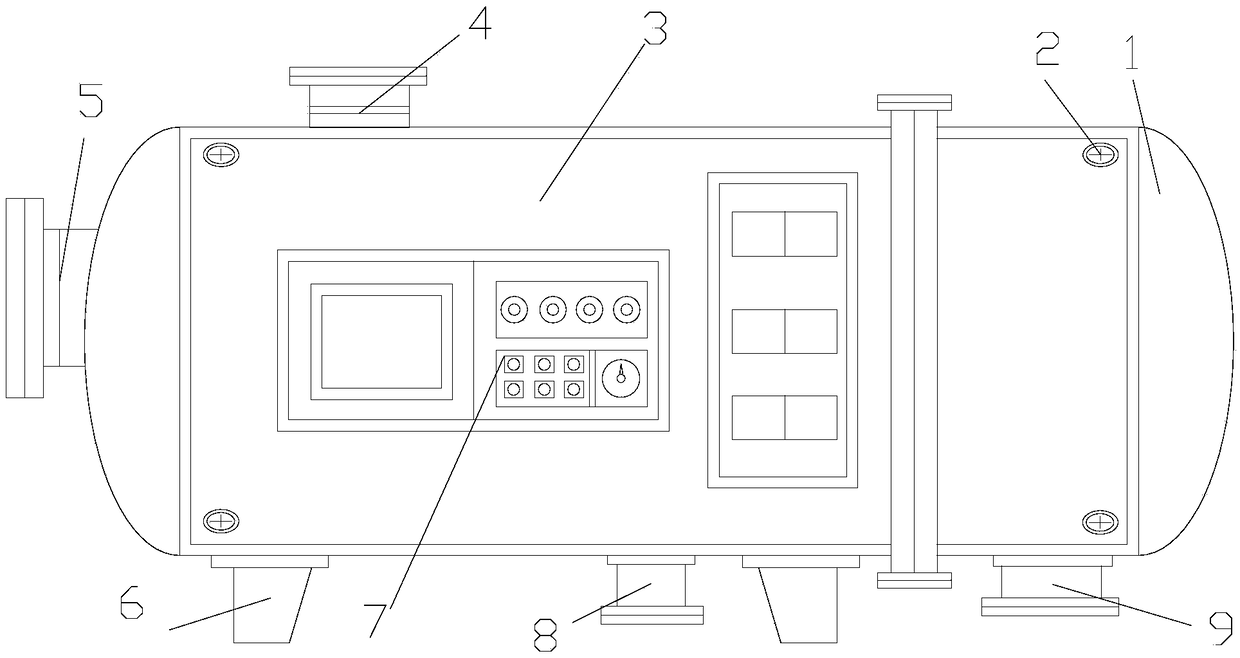

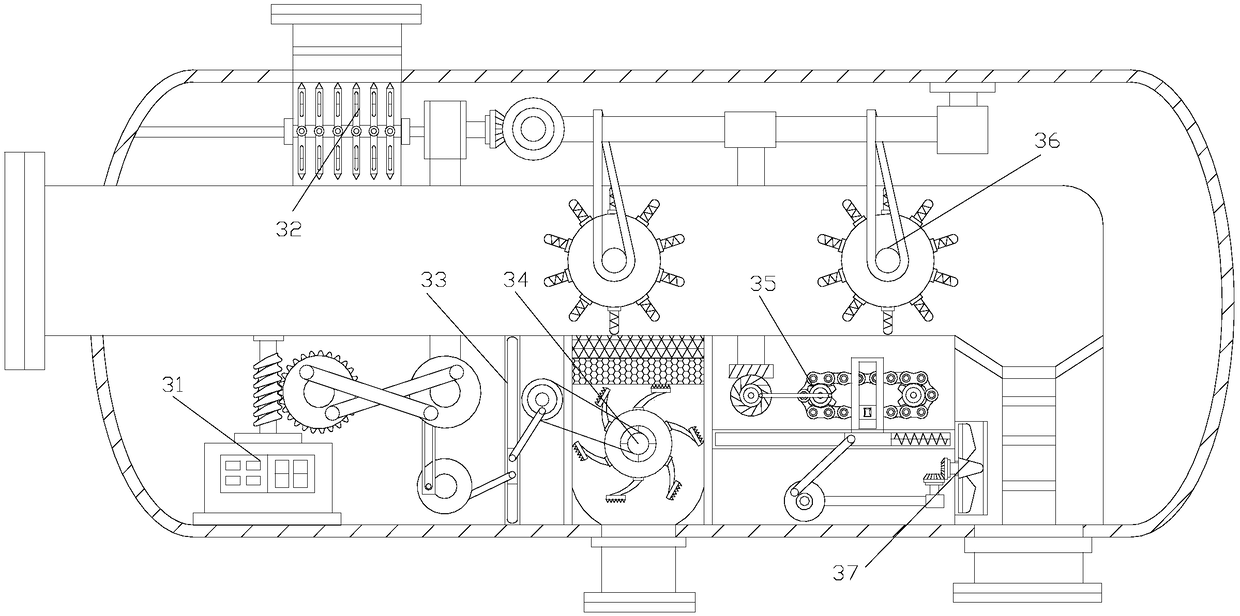

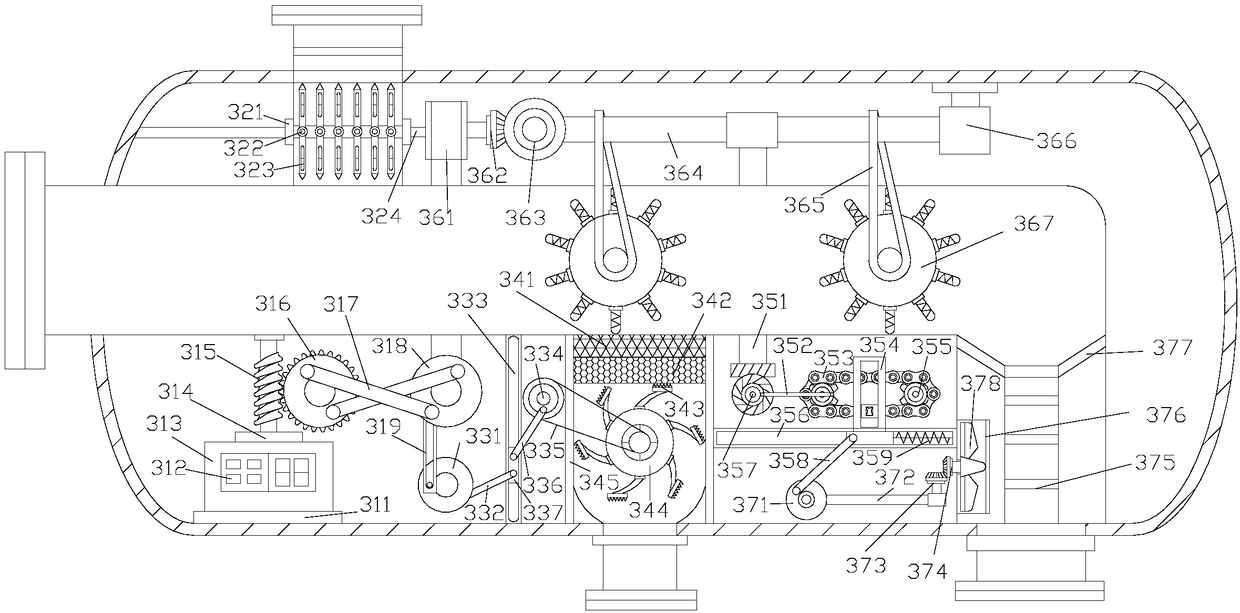

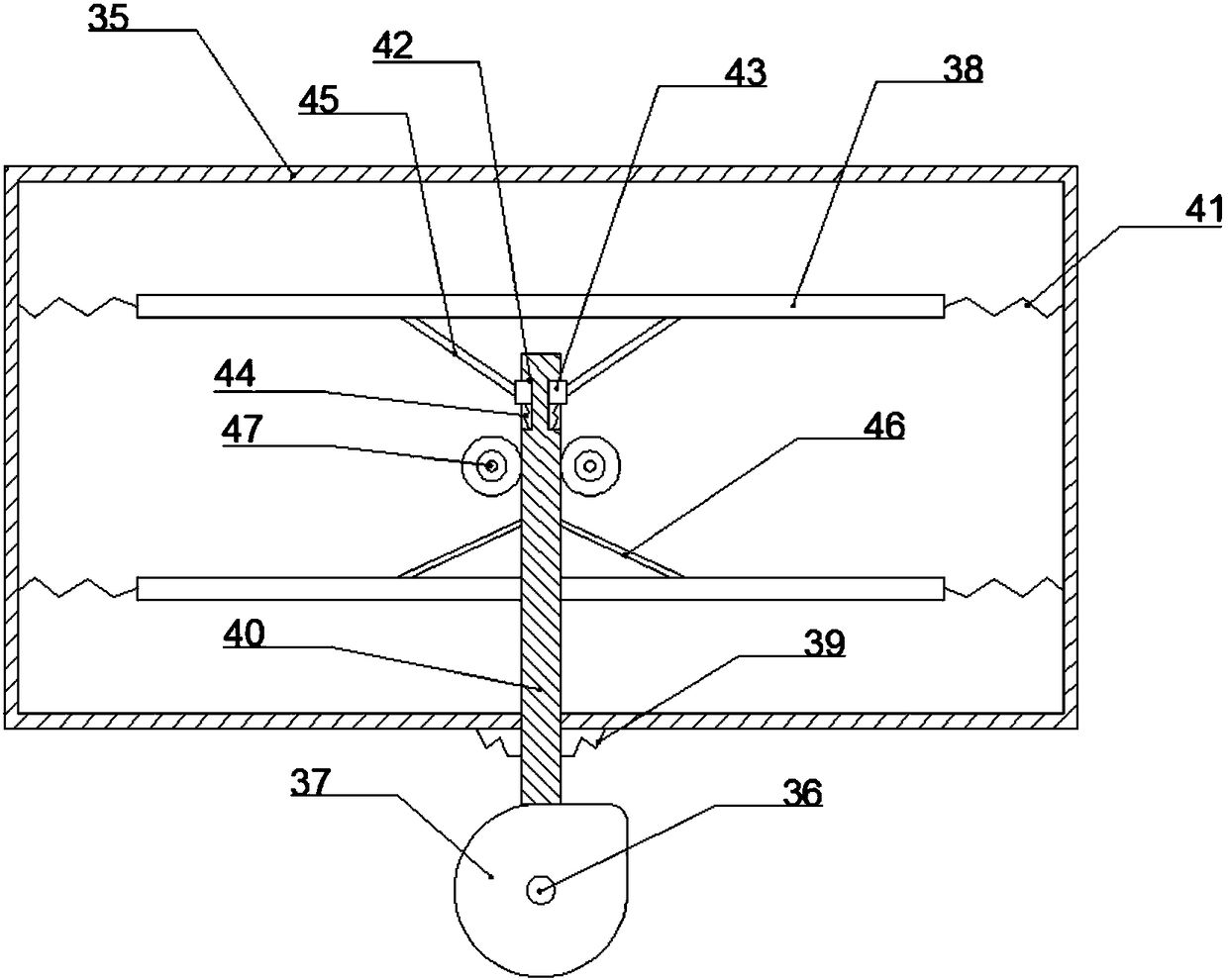

Granite coating preparation system

InactiveCN111617689ANot easy to fall offImprove stabilityTransportation and packagingMixer accessoriesMetallurgyElectric machine

The invention relates to a granite coating preparation system, belonging to the technical field of coatings. The granite coating preparation system comprises a base, wherein a stirring box is arrangedon the base; a stirring cavity is formed in the stirring box; rotating rollers are arranged in the stirring box; a rotating motor for driving the rotating rollers to rotate is mounted on the stirringbox body; a plurality of material stirring assemblies are arranged on the rotating rollers and spirally distributed on the rotating rollers; a material guide plate is arranged between every two adjacent rotating rollers; a material scraping device is arranged on the side, away from the corresponding rotating roller, of each material guide plate; and the material scraping devices abut against theinner side wall of the stirring cavity in a sliding mode. The granite coating preparation system in the invention has the effect that composite granite does not stick to the bottom in the stirring process, so the quality of a granite coating is improved.

Owner:郭侠

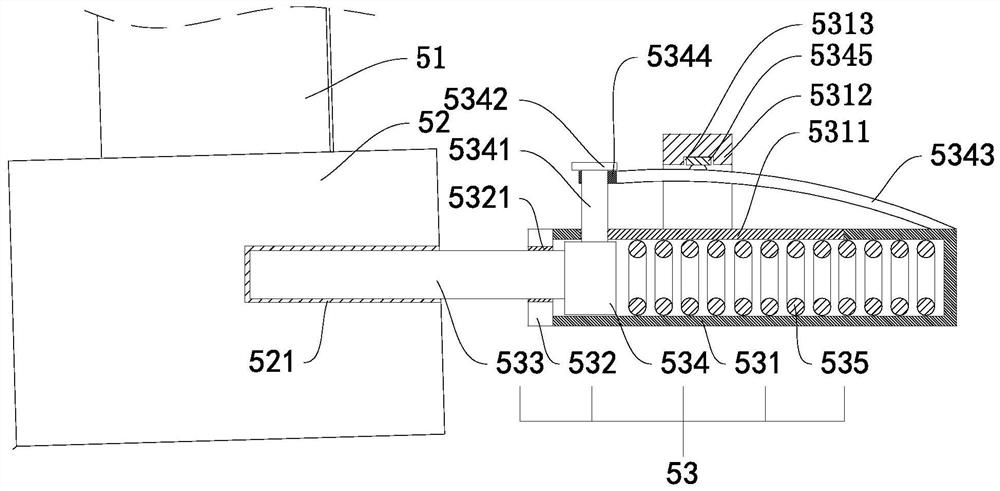

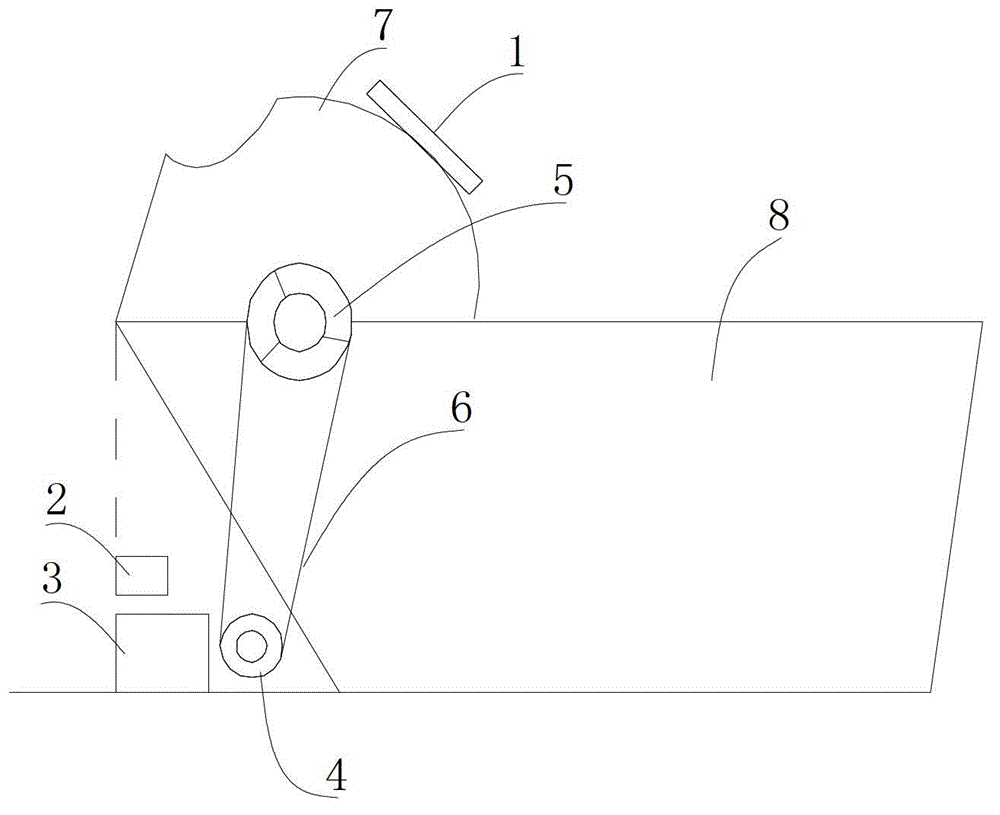

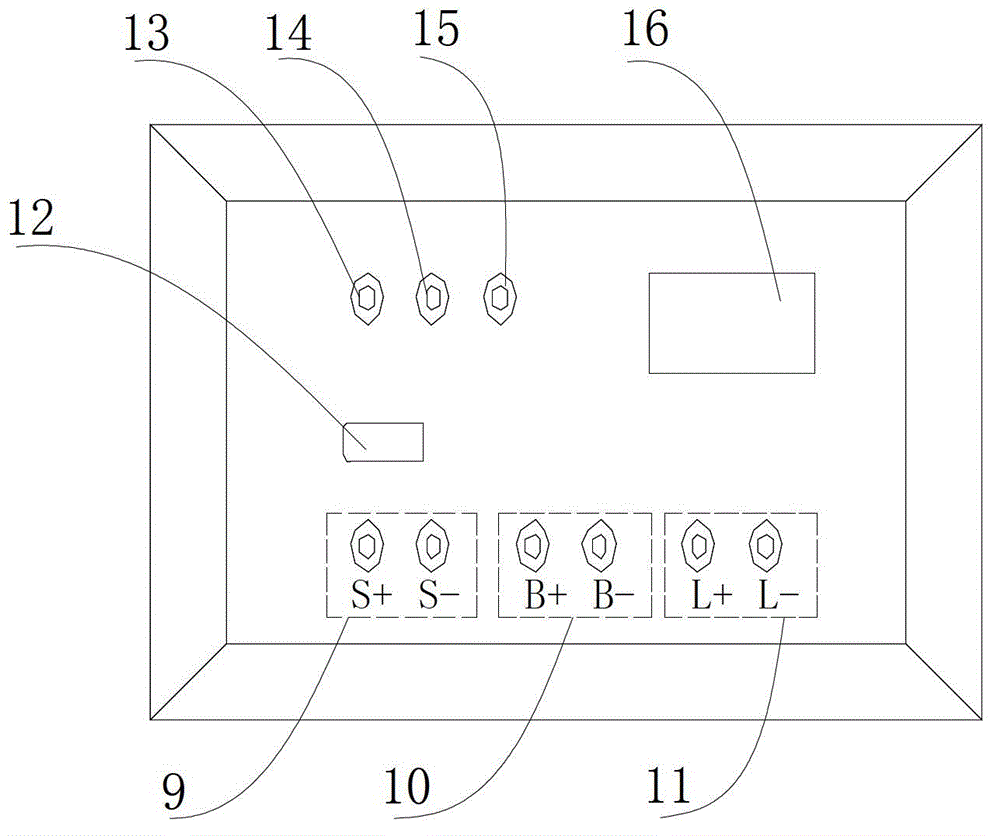

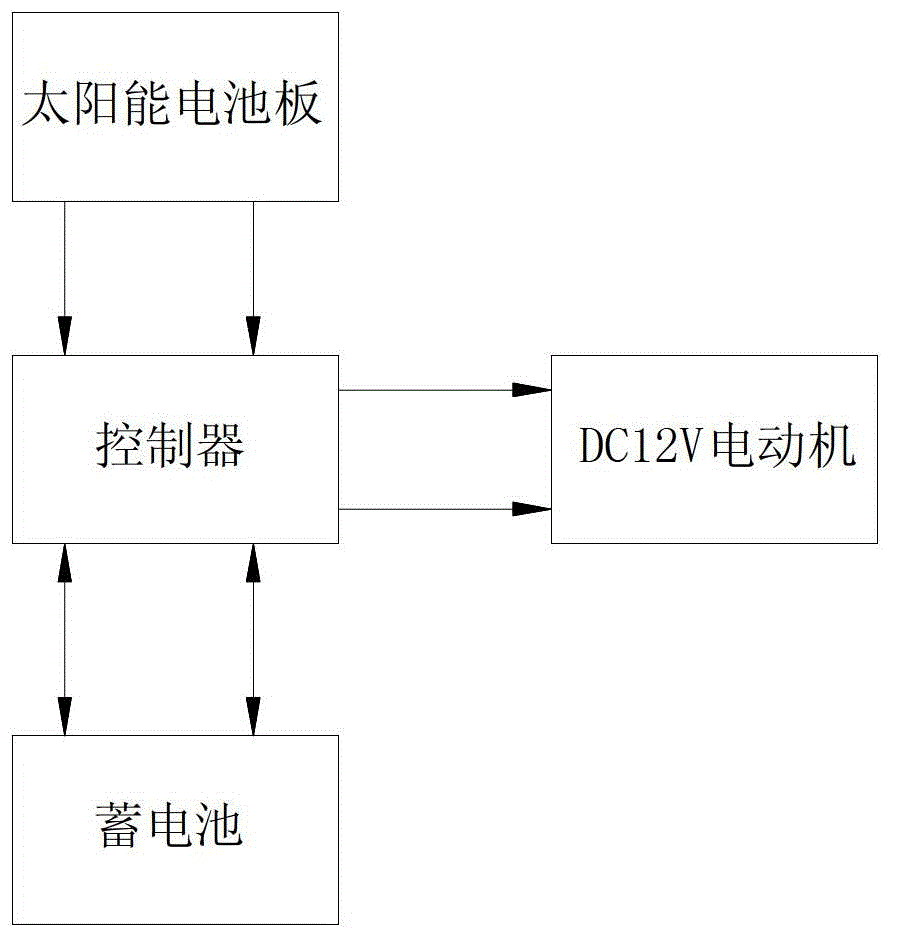

Energy-saving thresher

InactiveCN102907219AImprove efficiencyRealize development and utilizationRenewable energy machinesSaving energy measuresGasolineSolar cell

The invention discloses an energy-saving thresher, which comprises a solar cell panel, a controller, a storage cell, a motor and a grain bin, wherein the solar cell panel is arranged above the grain bin; the controller, the storage cell and the motor are arranged at the bottom of the bevel of the grain bin respectively; the solar cell panel is connected with a photoelectric cell end of the controller; a storage cell end of the controller is connected with the storage cell; a load end of the controller is connected with the motor; and the motor is connected with a rotating shaft through a rotating shaft belt so as to drive the rotating shaft to rotate in the grain bin, thereby fulfilling the aim of harvesting the grains by using solar energy. According to the energy-saving thresher, solar energy is used as power energy of the thresher, i.e., development and utilization of renewable energy are realized, the waste in the non-renewable energy such as diesel oil and petroleum is also reduced, the energy is greatly saved, meanwhile, the pollution caused to the environment by the gasoline or diesel oil burned by the thresher is avoided, and a good environmental protection effect is realized.

Owner:FENGGANG COUNTY QIANBEI NEW ENERGY

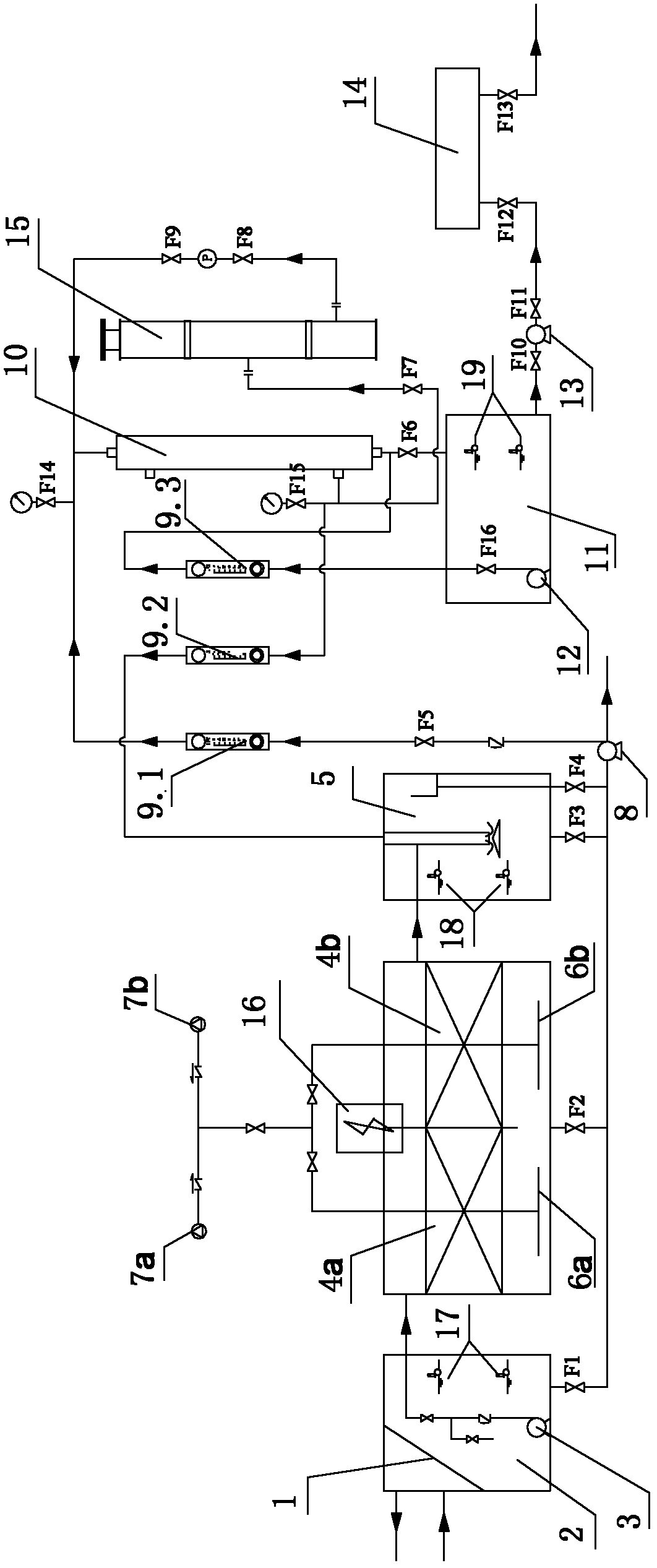

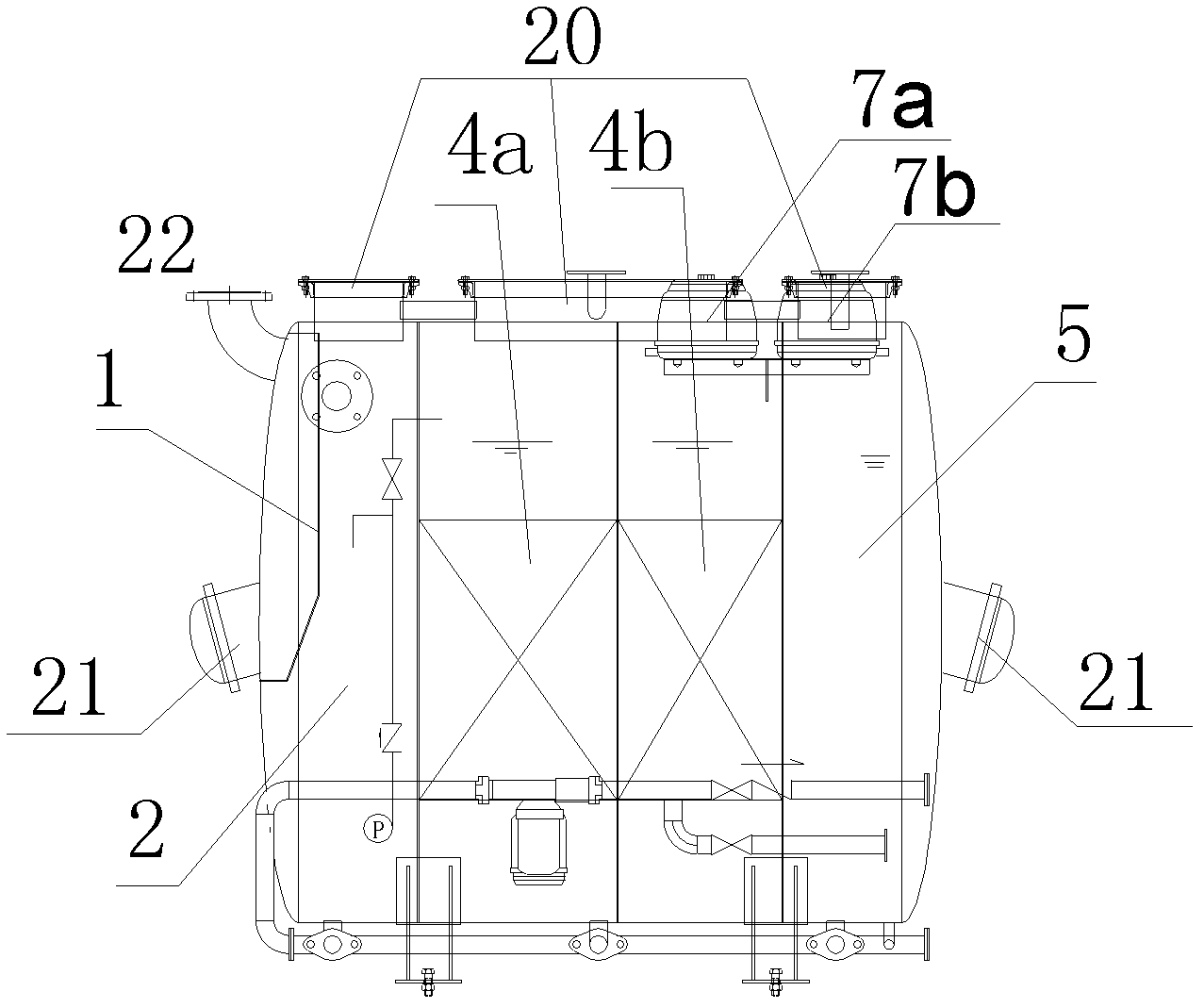

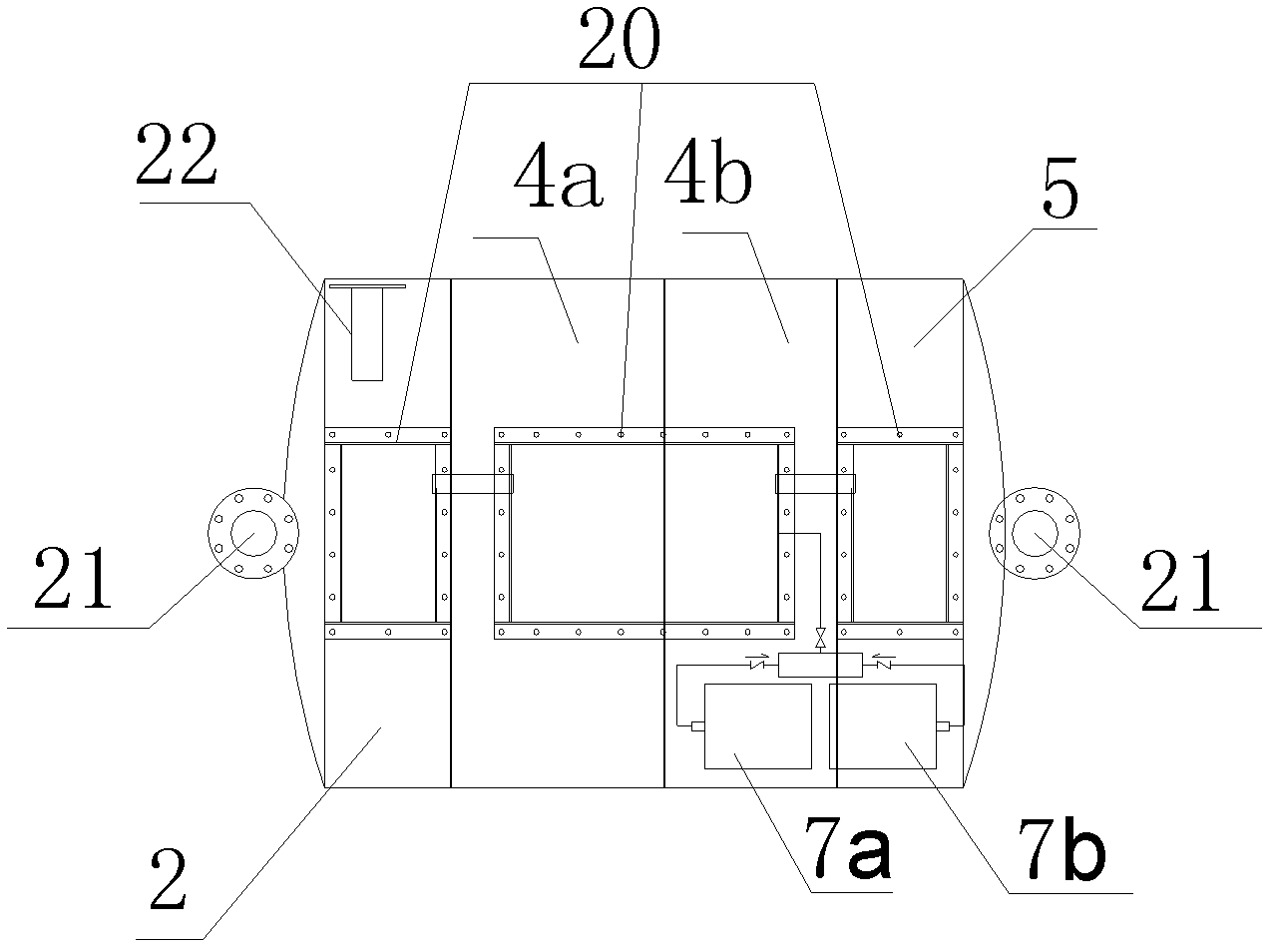

Marine sewage treatment integrated device on basis of biological moving beds

InactiveCN102329056AImprove hydrophilicityImprove adhesionMultistage water/sewage treatmentGratingUv disinfection

The invention relates to a marine sewage treatment integrated device on the basis of biological moving beds, which comprises a grating, a regulating basin, two stages of biological moving beds, a sedimentation tank, a backwashing water tank, an external membrane module, a reagent bucket and an ultraviolet disinfector. Sewage sequentially enters the regulating basin, the two stages of biological moving beds and the sedimentation through the grating. Supernatant fluid can be disinfected by ultraviolet rays and be directly discharged and can also be disinfected to be reused as recycled water after entering the membrane module. The external membrane module is connected with the backwashing water tank and can be used for effectively preventing a membrane from being blocked. The ultraviolet disinfector not only can be arranged behind the sedimentation tank, but also can be arranged behind the membrane module so as to meet different drainage requirements. The membrane module is kept working normally by regular backwashing and medicine washing. Due to the adoption of the marine sewage treatment integrated device on the basis of biological moving beds, the biodegrability of organic matter is effectively strengthened, effluent can directly reach the standard to be discharged after passing through the sedimentation tank, and the high efficiency degradation on marine domestic wastewater is realized. The marine sewage treatment integrated device has simple and reasonable structure and good working performance. The defect of short service life of the membrane module is overcome. Compared with a like reactor, the marine sewage treatment integrated device has obviously improved sewage treatment capability.

Owner:DALIAN UNIV OF TECH

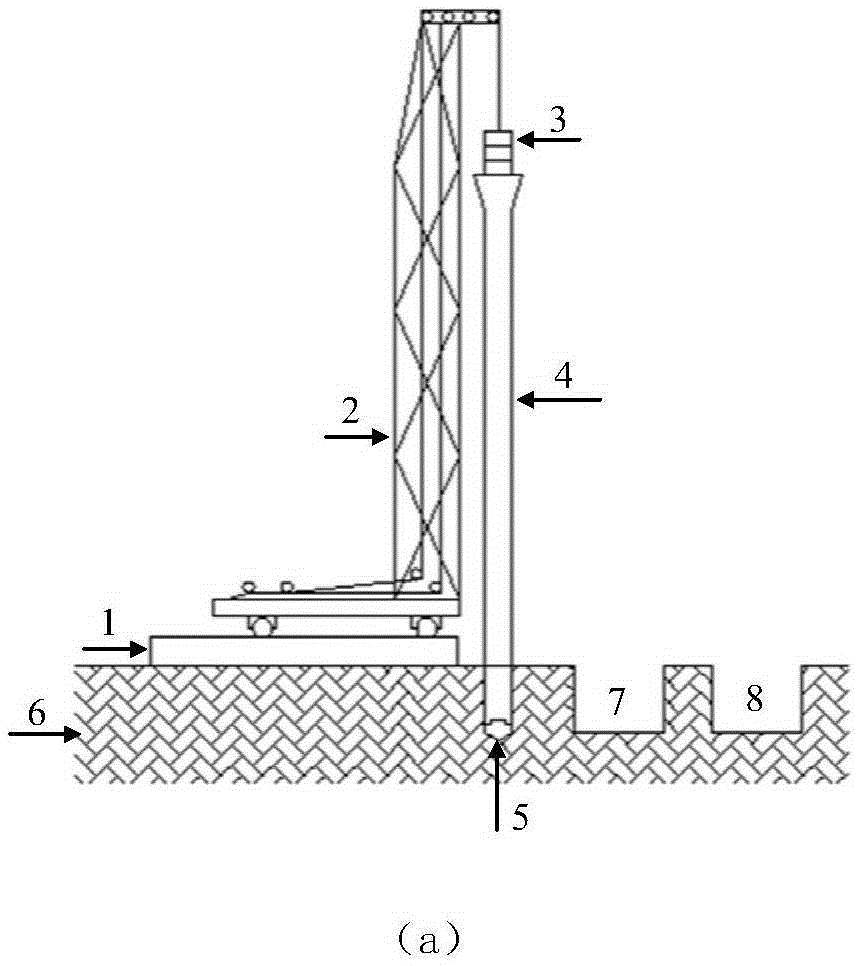

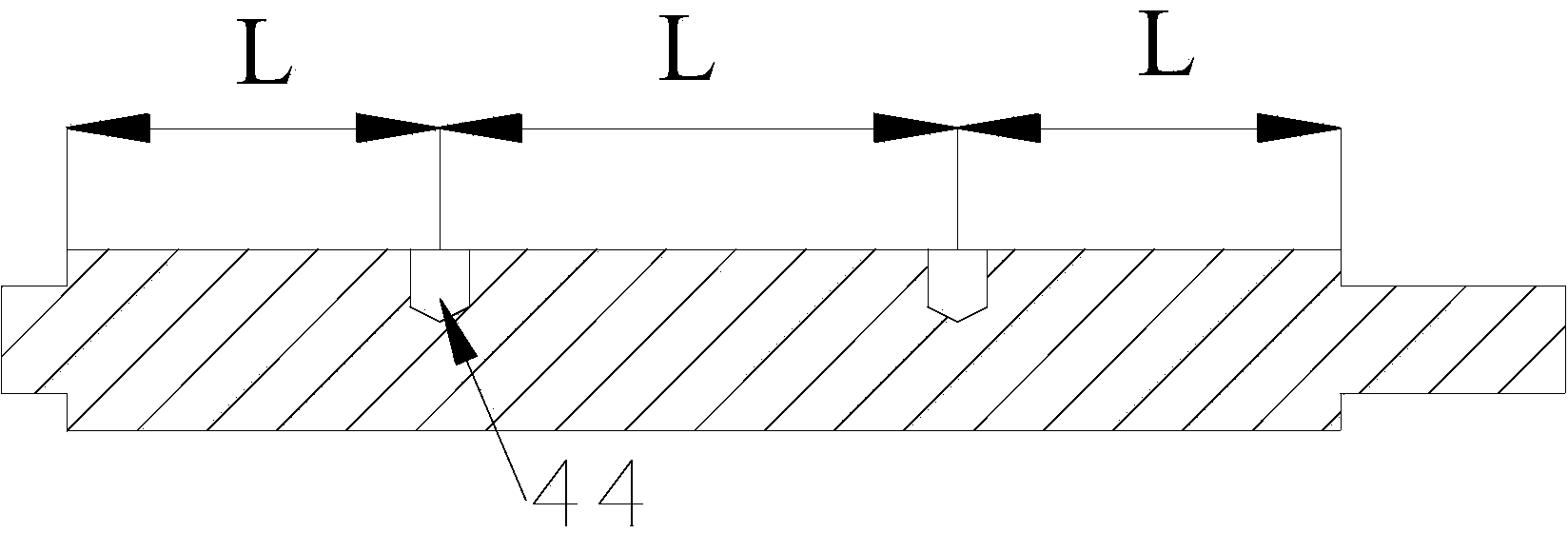

Pile construction method

InactiveCN109098172AAvoid pilesImprove bearing capacityBulkheads/pilesHollow coreBuilding construction

The invention discloses a construction method of piles comprising the steps of positioning, immersing a pipe, implanting a precast pile and filling a void. The method for implanting the prefabricatedpile is to lift the inner immersed pipe system in the outer pipe out to form a hollow pile of the guard sleeve of the outer tube, and then to implant the precast pile into the hollow pile. Filling thegap between the hole-building soil wall on the lateral side of the guard sleeve of the outer tube and the outer side of the precast pile in the hollow pile; for which the specific method is to, a) pull up the guard sleeve of the outer tube to expose the space between the hole-building soil wall on the lateral side of the guard sleeve of the outer tube and the outer side of the precast pile gradually and fill the void space with the filler falling through the cavity passage. The invention has the advantages of convenient construction and good effect.

Owner:朱建新

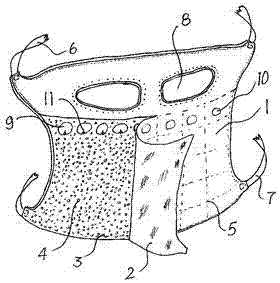

Dense smoke preventing mask

InactiveCN107456674APrevent pilesAvoid inhalationBreathing filtersFire rescueRespiratorNatural water

An anti-smoke mask, the main body of the mask is made of medical gauze as an interlayer, and hair balls are laid in the interlayer, the upper and lower corners of the main body of the mask are connected with the upper and lower fixing belts, the The upper part is heightened and the eyes are covered. Holes are opened in the eyes, and plano lenses are installed in the holes. A plurality of spherical blisters are arranged in the gauze interlayer under the lenses. Pre-cuts are made on the lower part of the blisters. It is distributed on the upper part of the breathing port of the mask, and the natural water that has passed through the technical treatment is poured into the blisters.

Owner:宁波市镇海西门专利技术开发有限公司

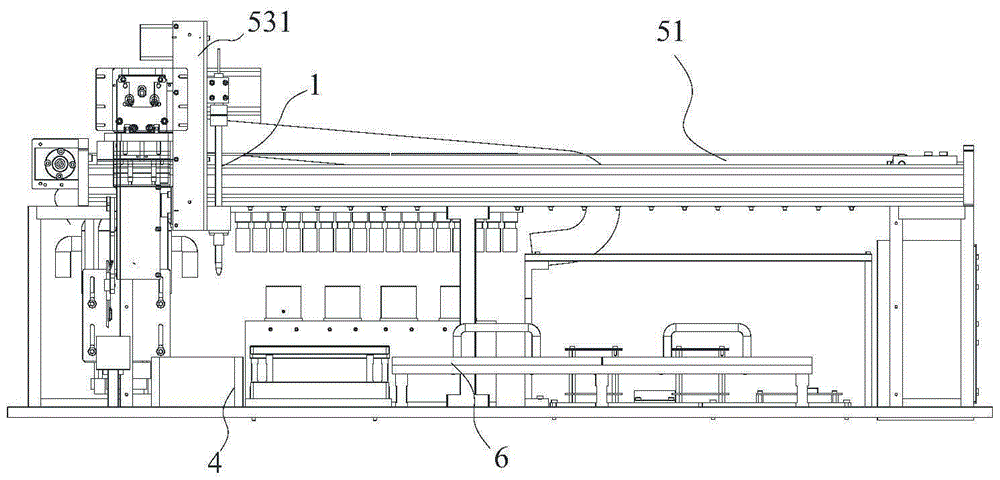

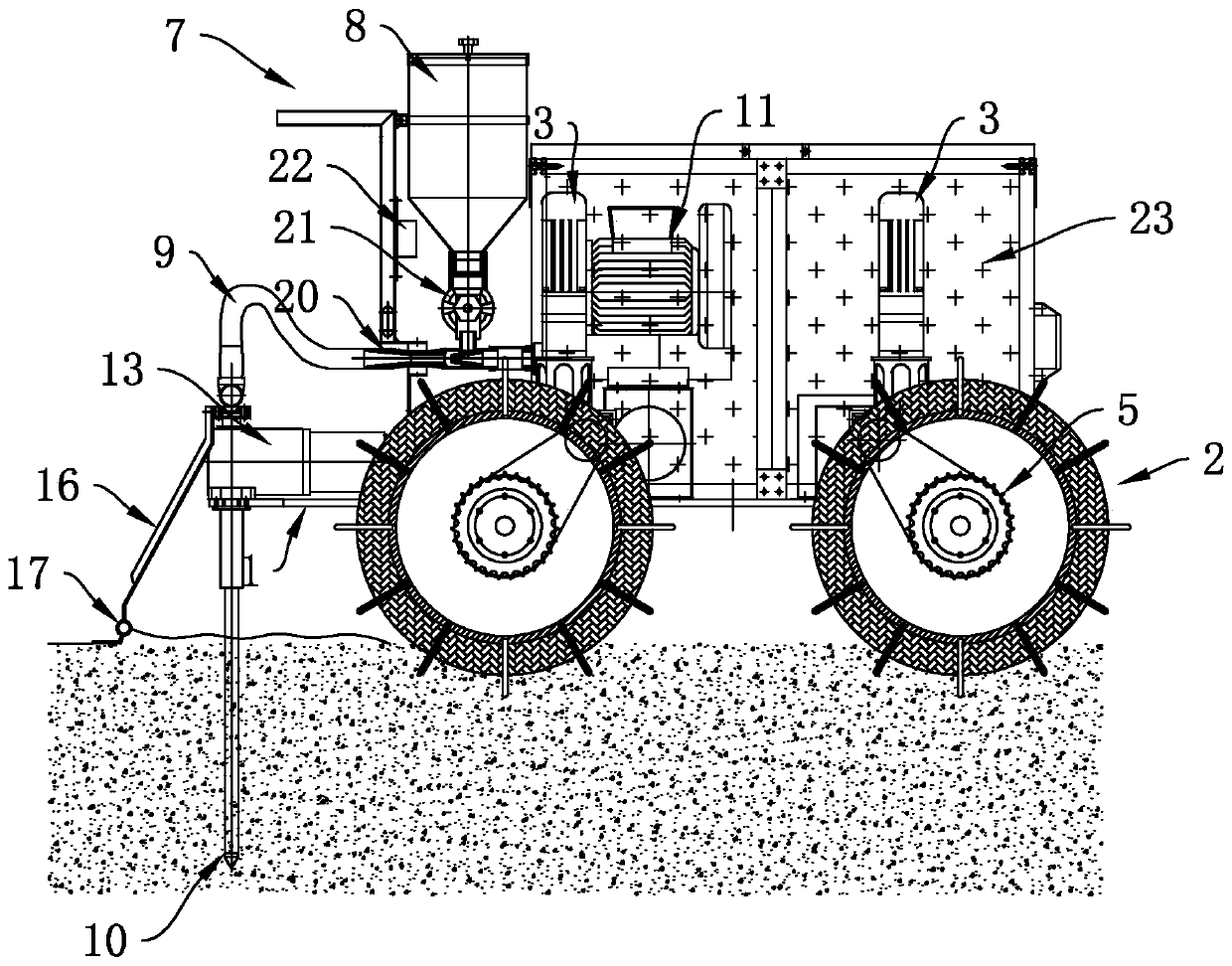

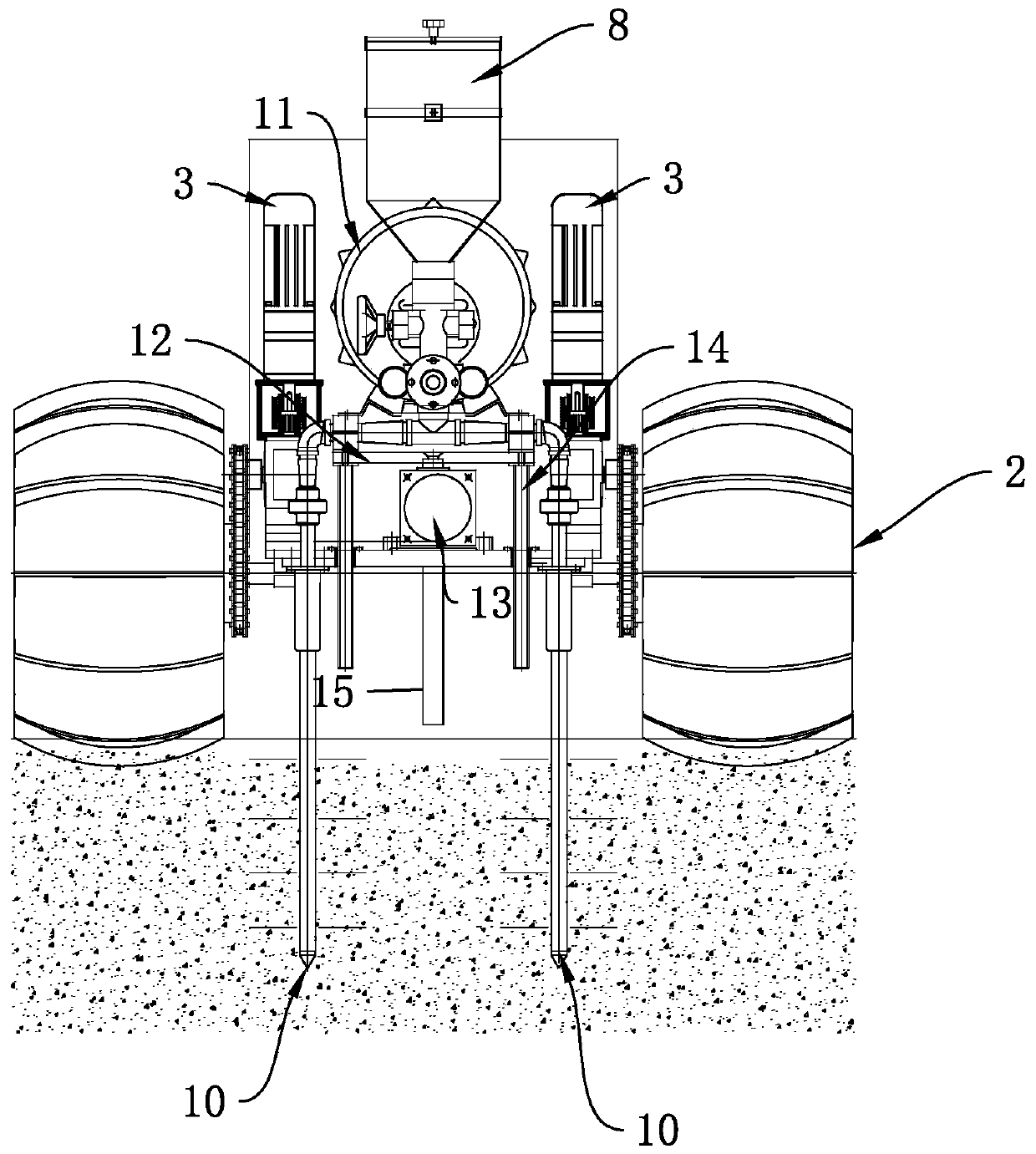

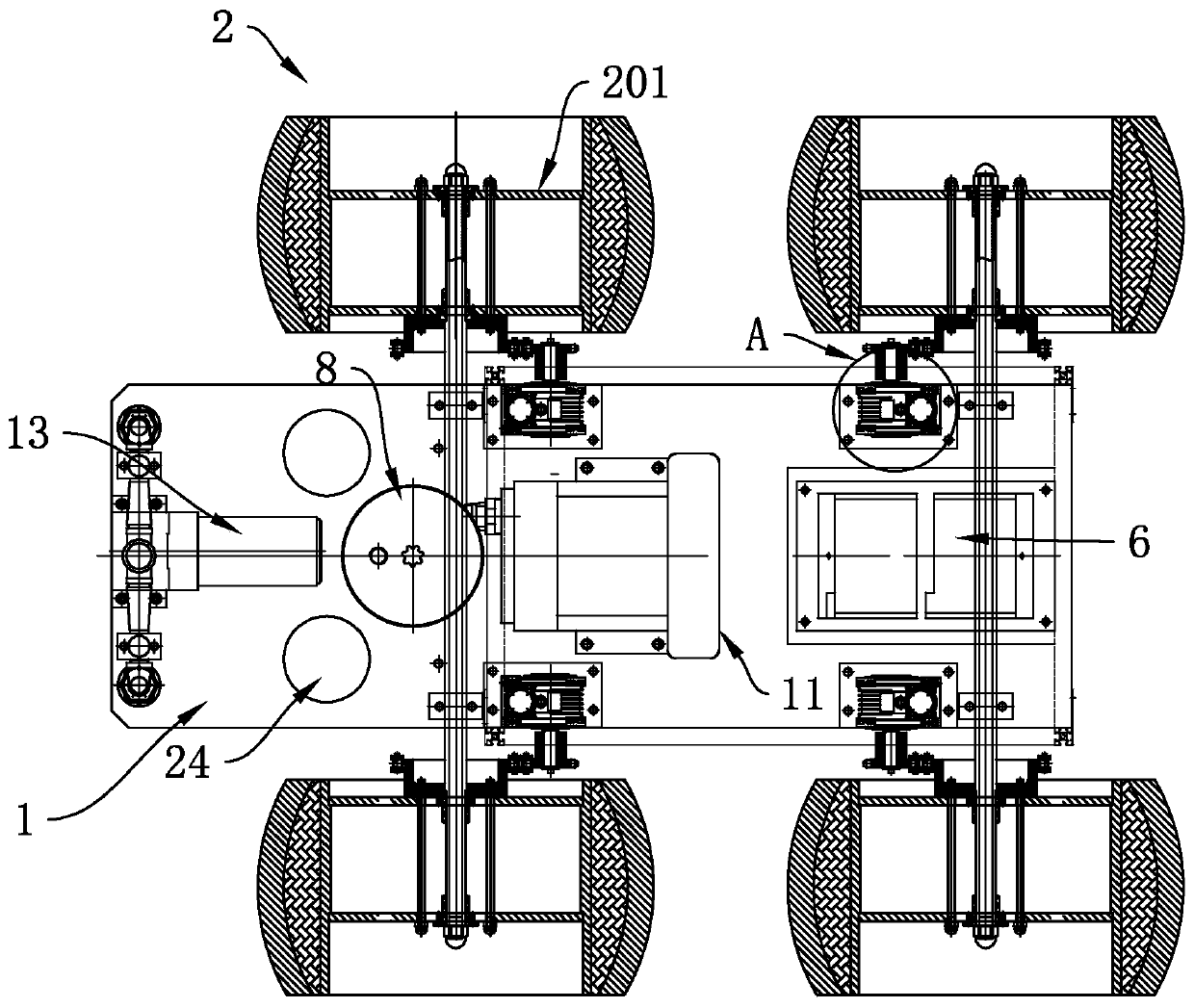

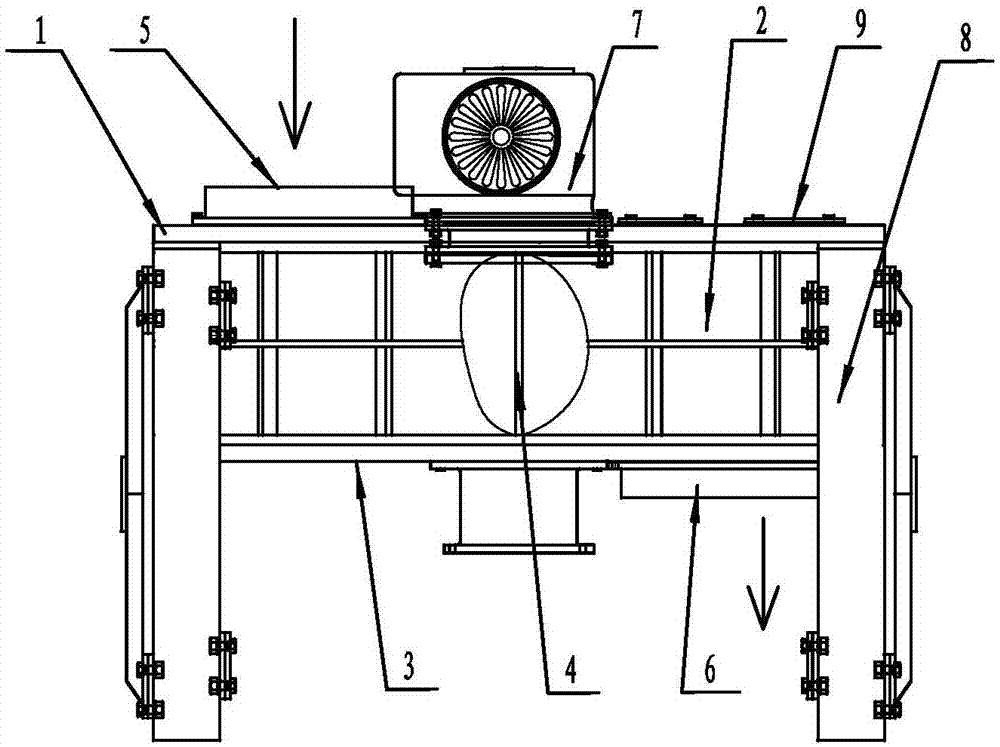

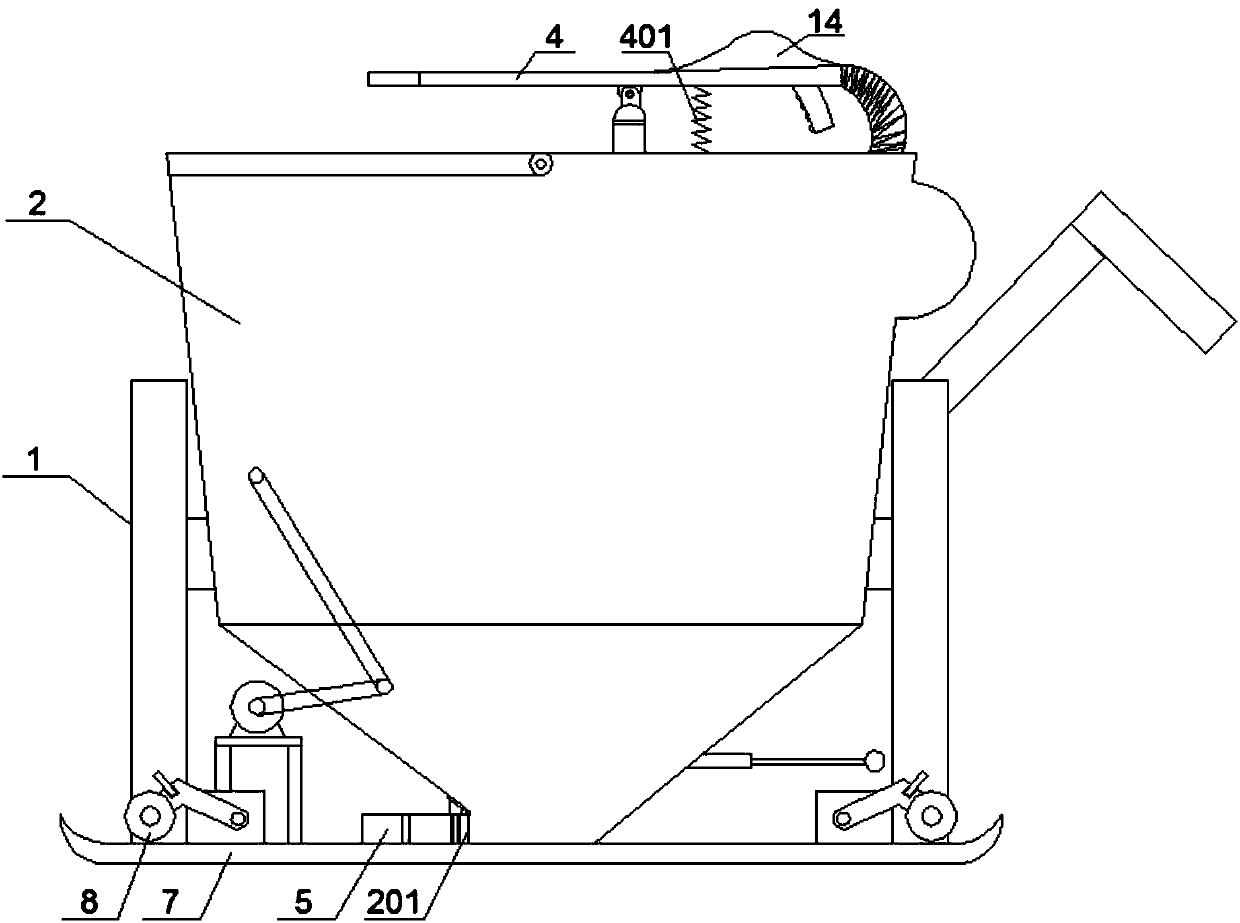

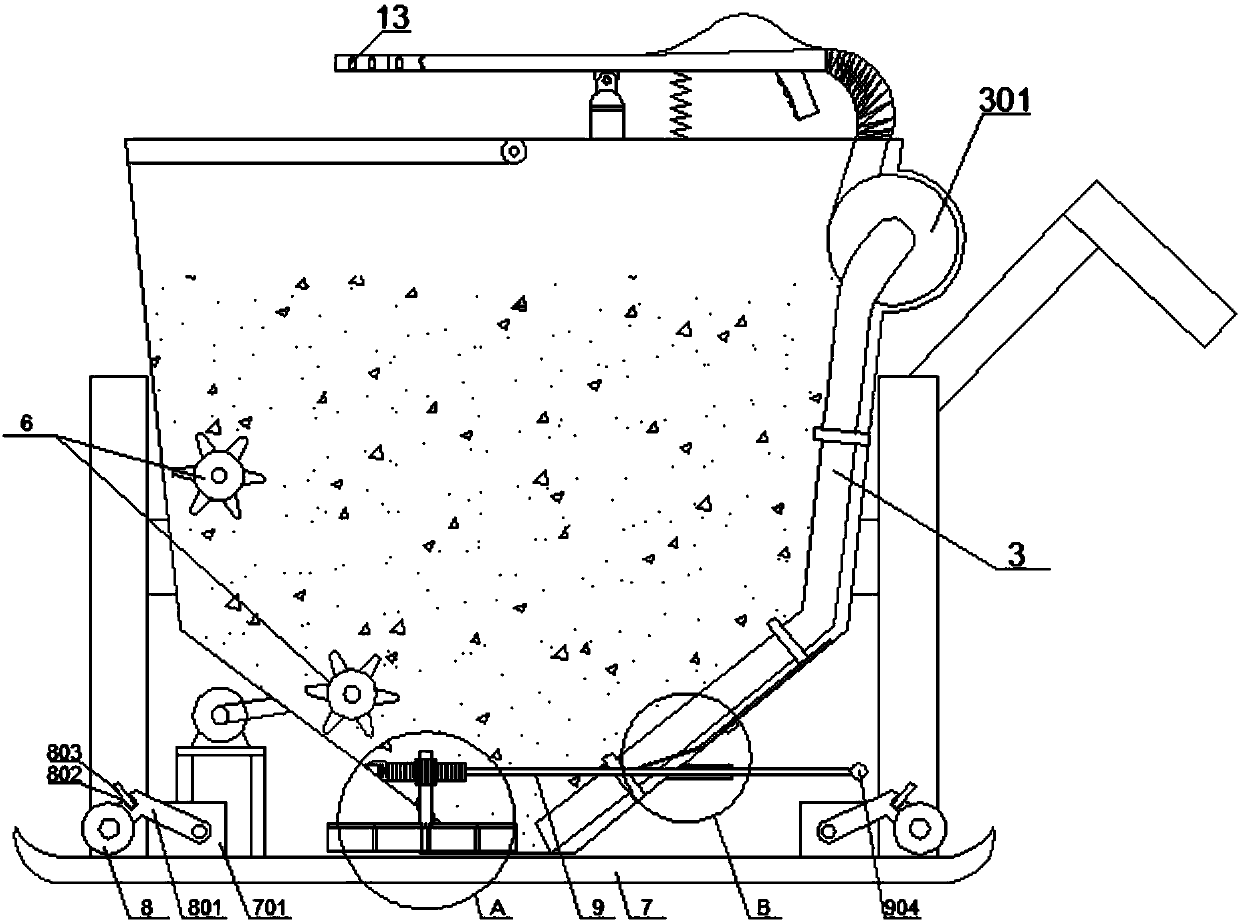

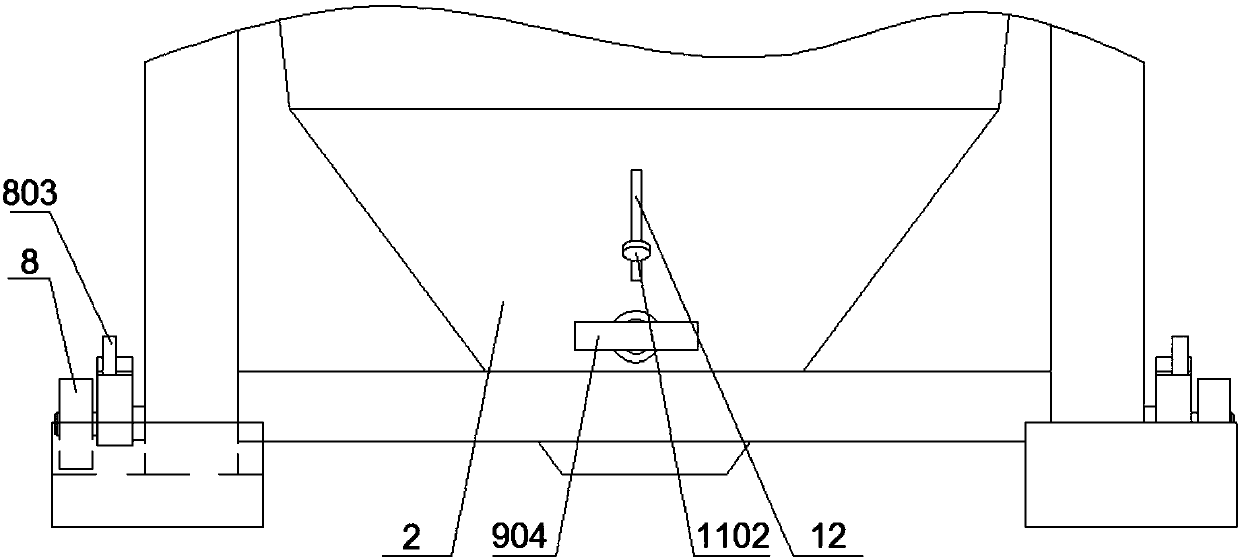

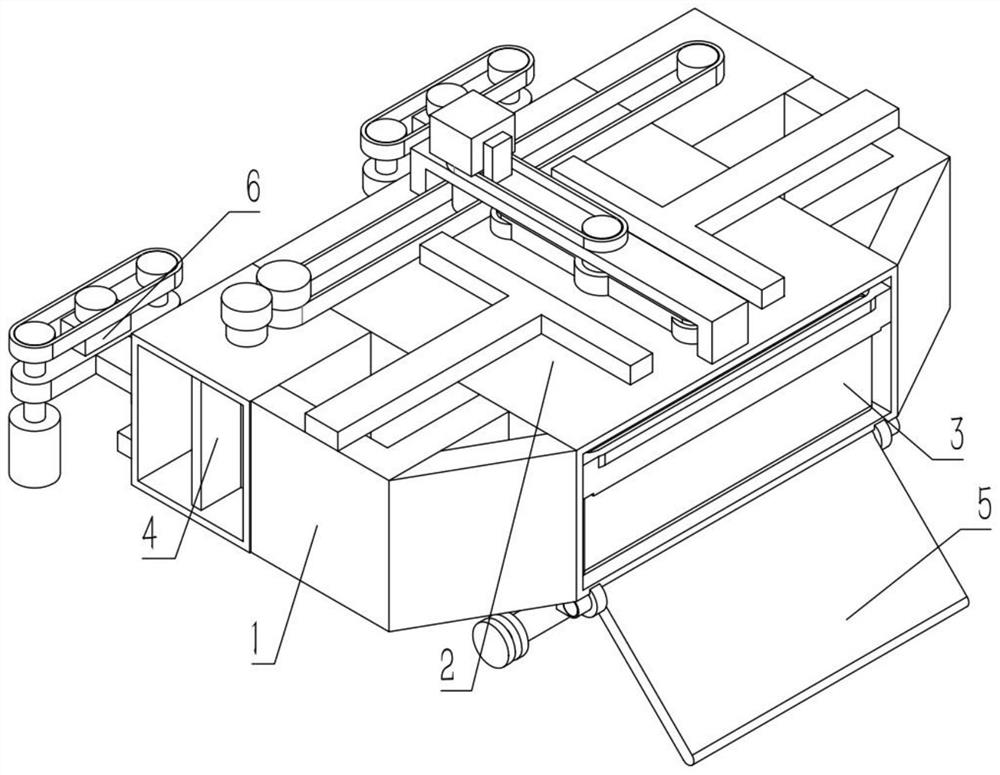

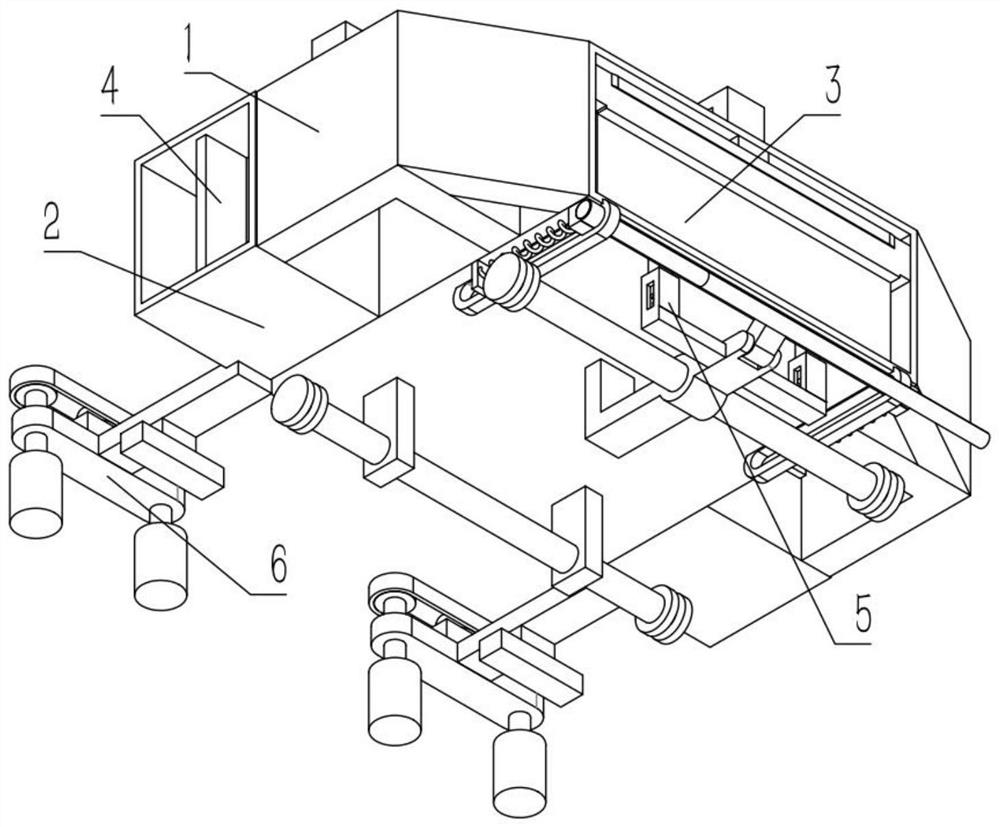

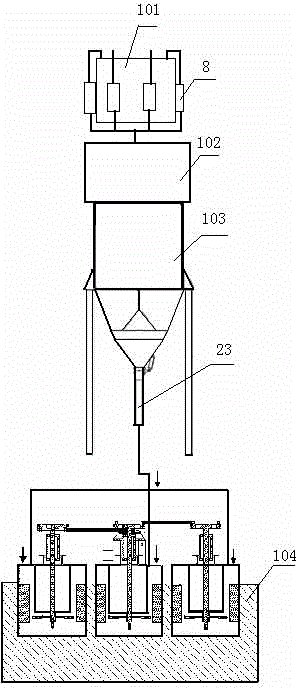

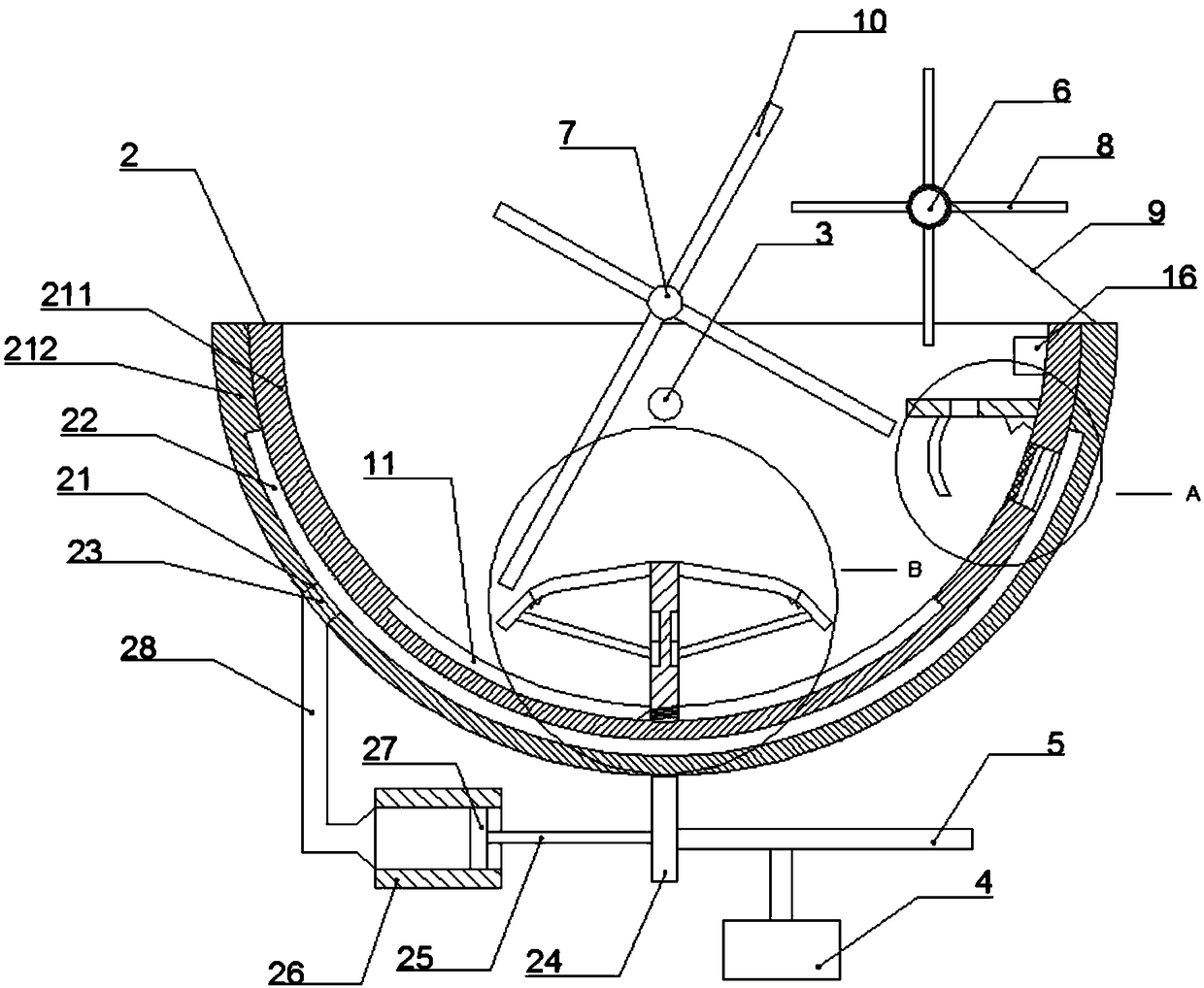

Automatic granary pesticide application equipment for preventing from lying down

PendingCN111034792AImprove application efficiencyGood application effectEdible seed preservationClimate change adaptationAgricultural scienceAgricultural engineering

The invention relates to the technical field of pesticide application equipment and discloses automatic granary pesticide application equipment for preventing lying down, the automatic pesticide application equipment comprises a main substrate, a transmission mechanism, a pesticide application mechanism and a PLC control module are arranged on the main substrate, the transmission mechanism comprises drum-shaped walking wheels, the drum-shaped walking wheels are driven by a servo motor, and the servo motor is electrically connected with the PLC control module; wherein a supporting frame is erected on the main substrate, a storage cylinder is fixedly arranged on the supporting frame, a pesticide spraying pipe is communicated with the bottom end of the storage cylinder, a pesticide spraying nozzle is communicated with the end, away from the storage cylinder, of the pesticide spraying pipe, a high-pressure fan is further arranged on the main substrate, an air outlet of the high-pressure fan is communicated with the pesticide spraying pipe through a guide pipe, and the high-pressure fan is electrically connected with the PLC module. The automatic pesticide application equipment is equipment walking in grains, is good in pesticide application effect and high in pesticide application efficiency, the labor cost is reduced, and the equipment is effectively prevented from lying down.

Owner:SHANGHAI FORWARD MASCH CO LTD

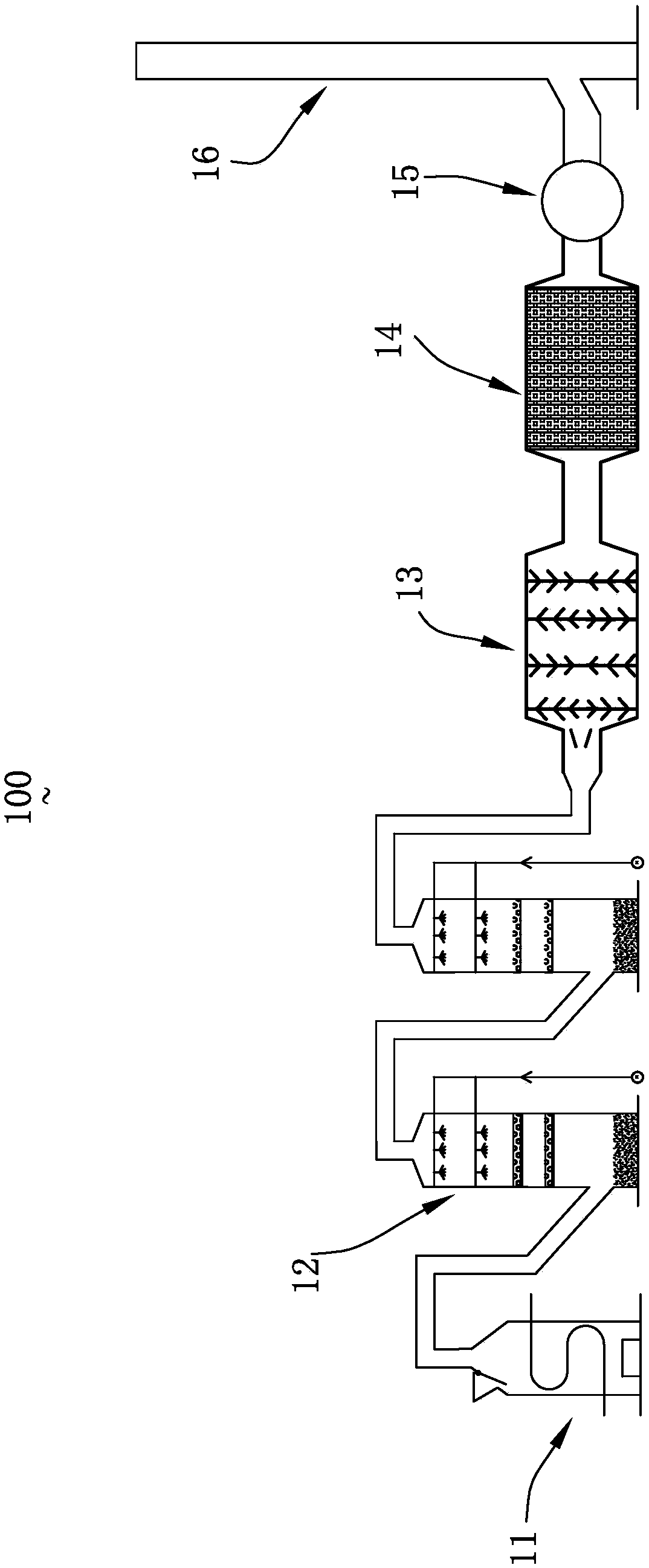

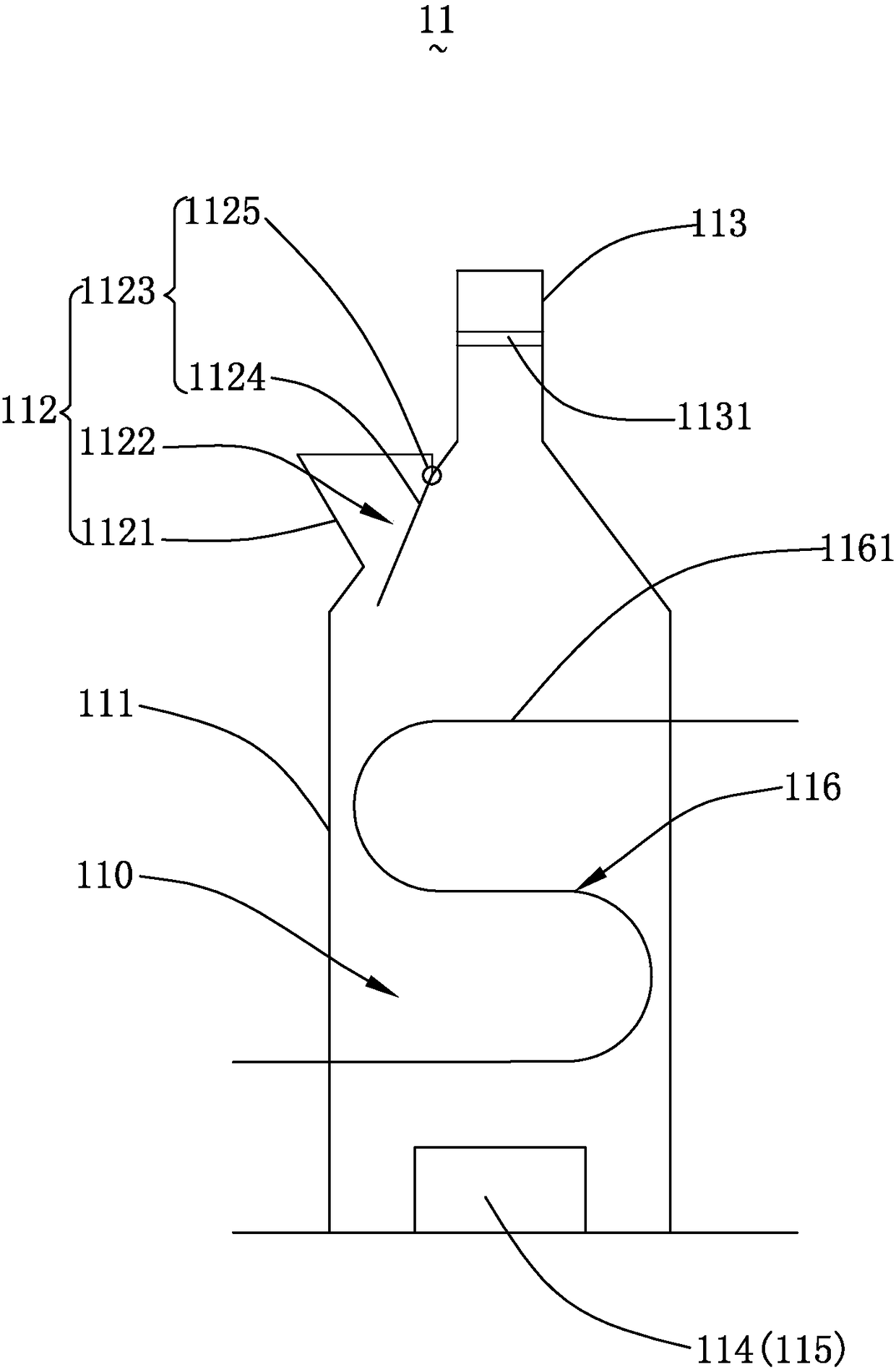

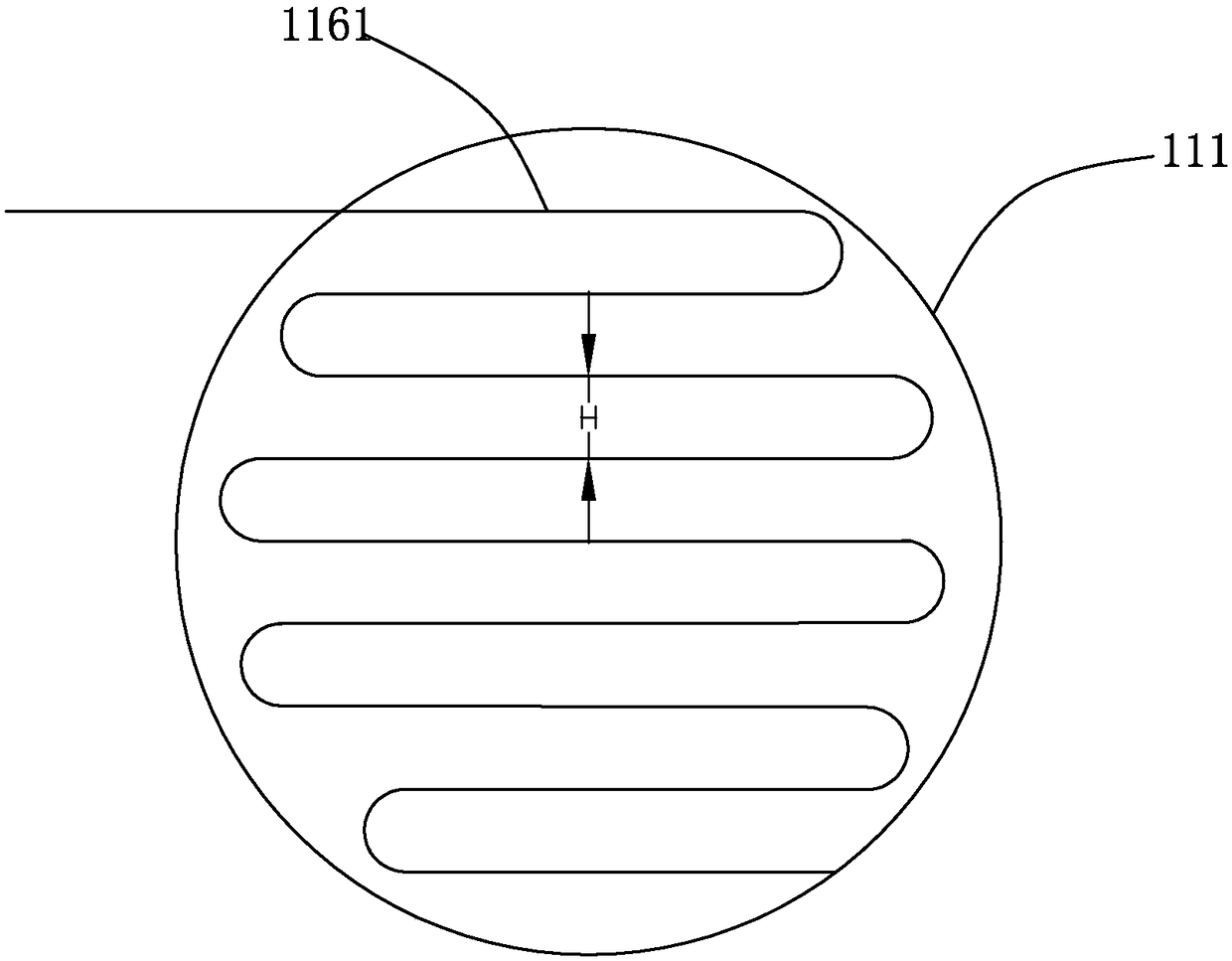

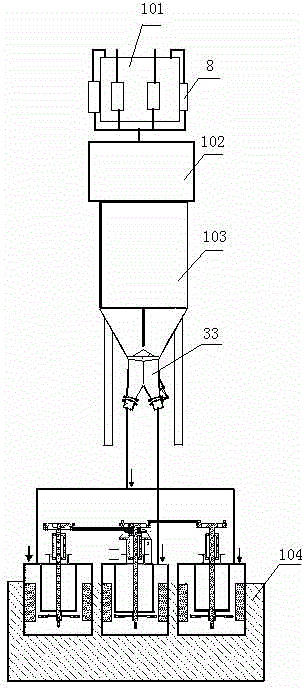

Small domestic garbage incineration purification treatment system

InactiveCN108072043APrevent pilesAvoid insufficient combustionEmission preventionIncinerator apparatusActivated carbonHeat transmission

The invention discloses a small domestic garbage incineration purification treatment system. The small domestic garbage incineration purification treatment system comprises a garbage incinerator, a spraying absorption tower, a smog removal device, an activated carbon adsorption device and an exhaust chimney, wherein the garbage incinerator, the spraying absorption tower, the smog removal device, the activated carbon adsorption device and the exhaust chimney are connected in sequence. The garbage incinerator comprises a furnace body with a hearth, and a heat transmitter arranged in the hearth.The heat transmitter comprises multiple layers of heat transmission pipes which are arranged perpendicular to the flow direction of air flows and communicate with one another. Each layer of heat transmission pipes are distributed in the shape of a snake. The interval between every two adjacent layers of heat transmission pipes increases step by step in the direction from air inlet to air outlet. According to the small domestic garbage incineration purification treatment system, garbage can sufficiently and effectively burn quickly, the amount of generated toxic and harmful smoke can be reduced, and purification treatment can be effectively carried out on the generated smoke.

Owner:湖南云平环保科技有限公司

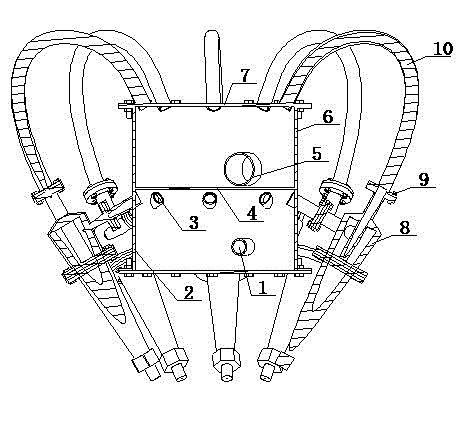

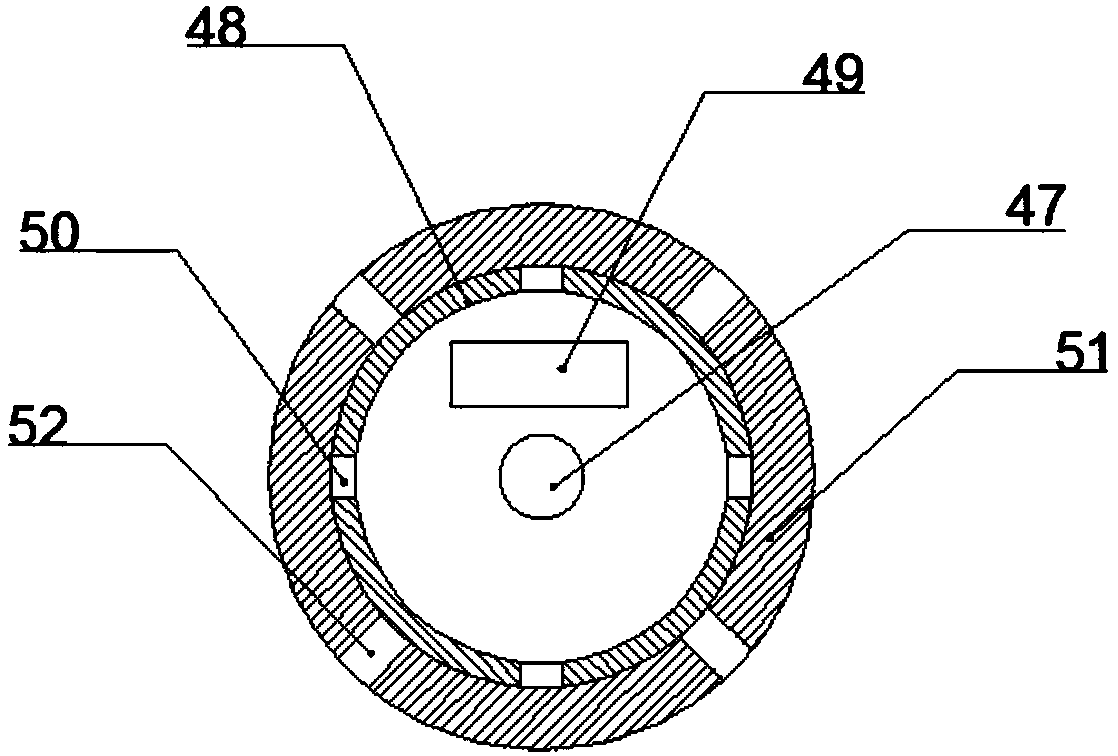

Air locking and feeding device

The invention discloses an air locking and feeding device. The air locking and feeding device comprises a shell and a rotor assembly, wherein the shell is fixed to a rack, the rotor assembly is rotatably arranged in the shell, and the rotor assembly is connected with a power plant; the shell comprises a vertical cylinder, a cylinder bottom which is fixedly arranged at the bottom of the cylinder and a cylinder cover which is fixedly arranged on the top of the cylinder, a feed opening is formed in the cylinder cover, and a discharge opening is formed in the cylinder bottom; the rotor assembly comprises a vertical rotating shaft and an impeller which is fixed to the rotating shaft, the impeller comprises an inner sleeve which is arranged on the rotating shaft and is fixedly connected with the rotating shaft, an outer sleeve which is arranged on the outer side of the inner sleeve and a plurality of vertical blades which are arranged between the inner sleeve and the outer sleeve at intervals, the inner edges of the blades are fixed to the inner sleeve, and the outer edges of the blades are fixed to the outer sleeve. According to the air locking and feeding device, no accumulation body is formed in rotor lattices of the rotor assembly, so that the phenomena of jamming and shutdown are reduced, the air locking capability is greatly increased, the energy consumption of unit product is obviously reduced, and the operation and maintenance are convenient.

Owner:WEIFANG TIANSHENG ELECTRIC

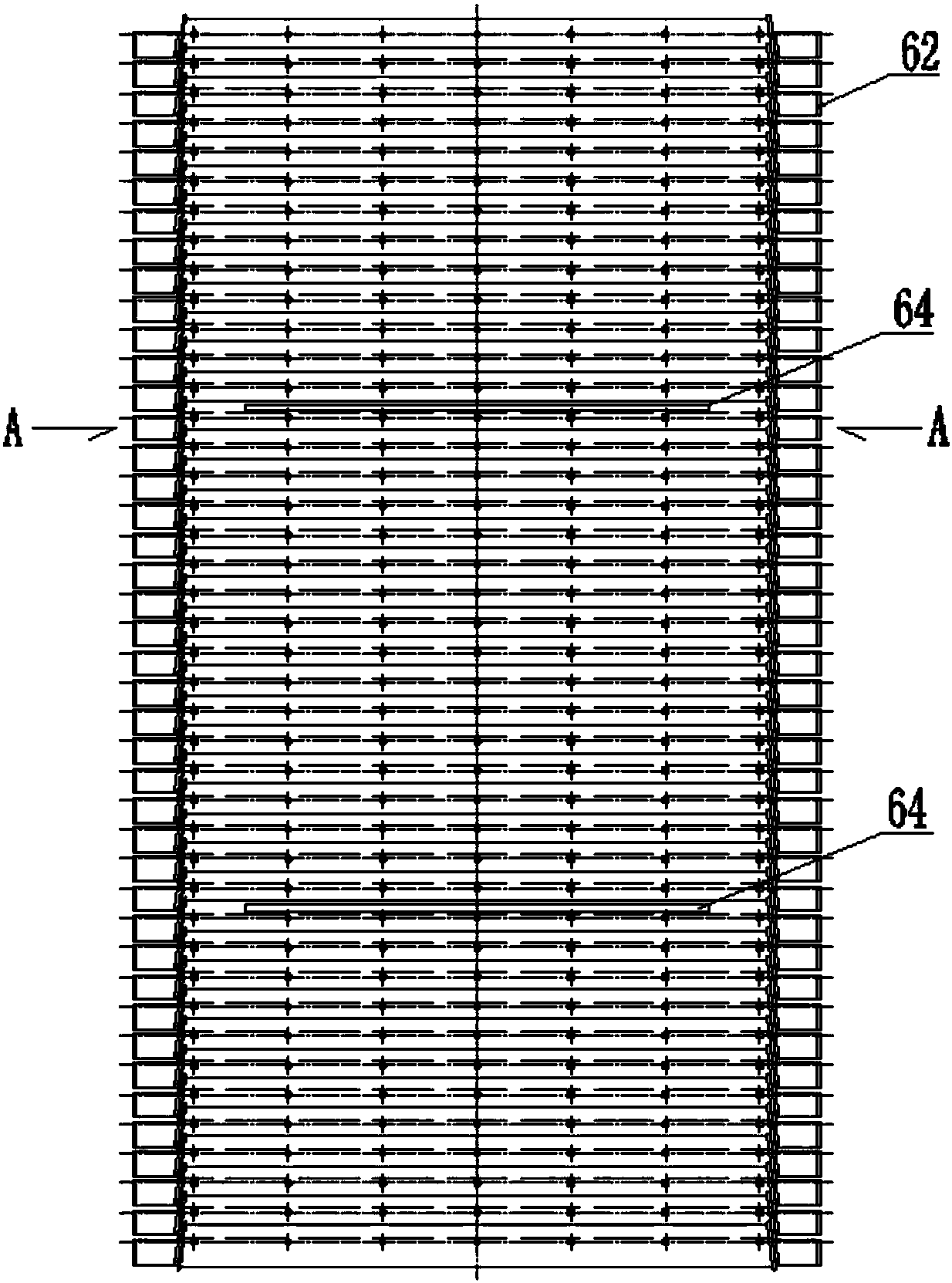

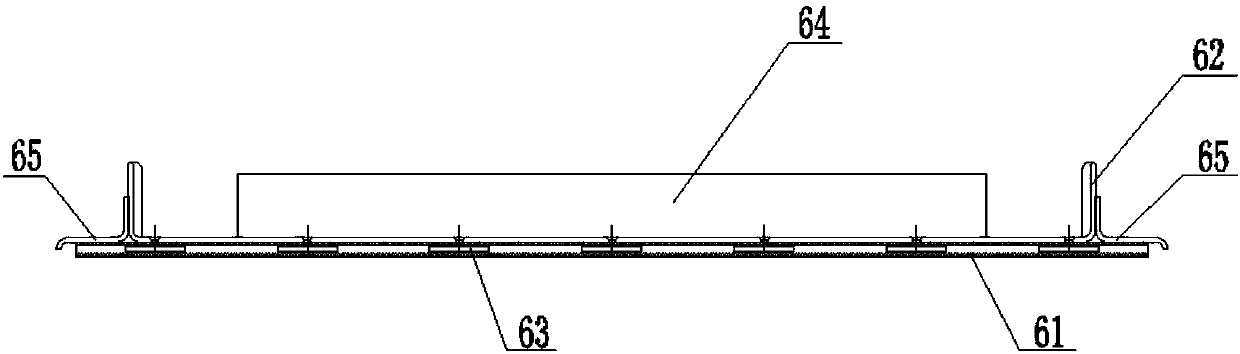

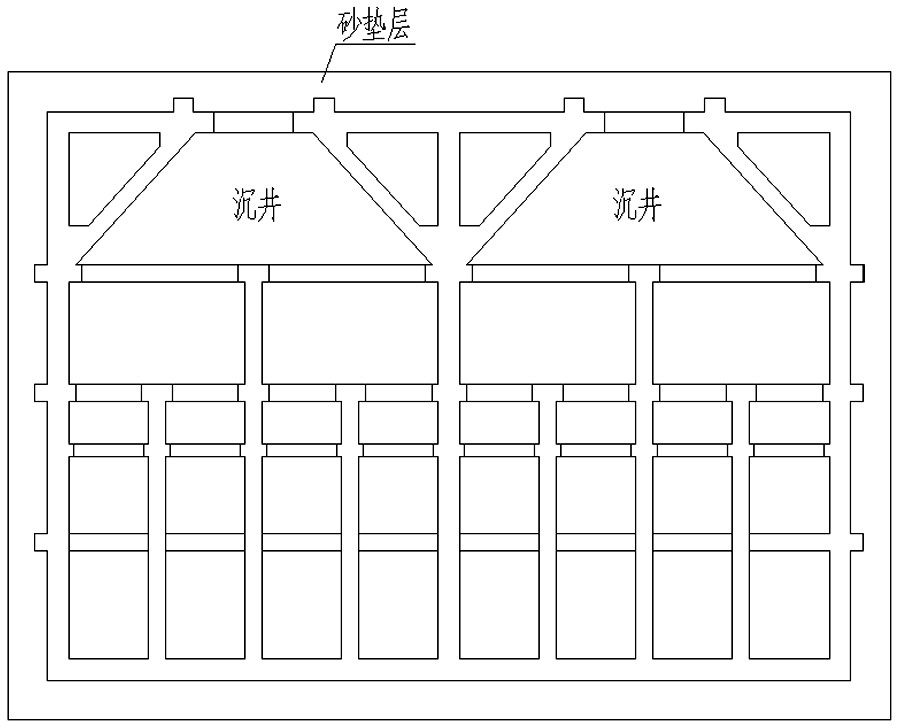

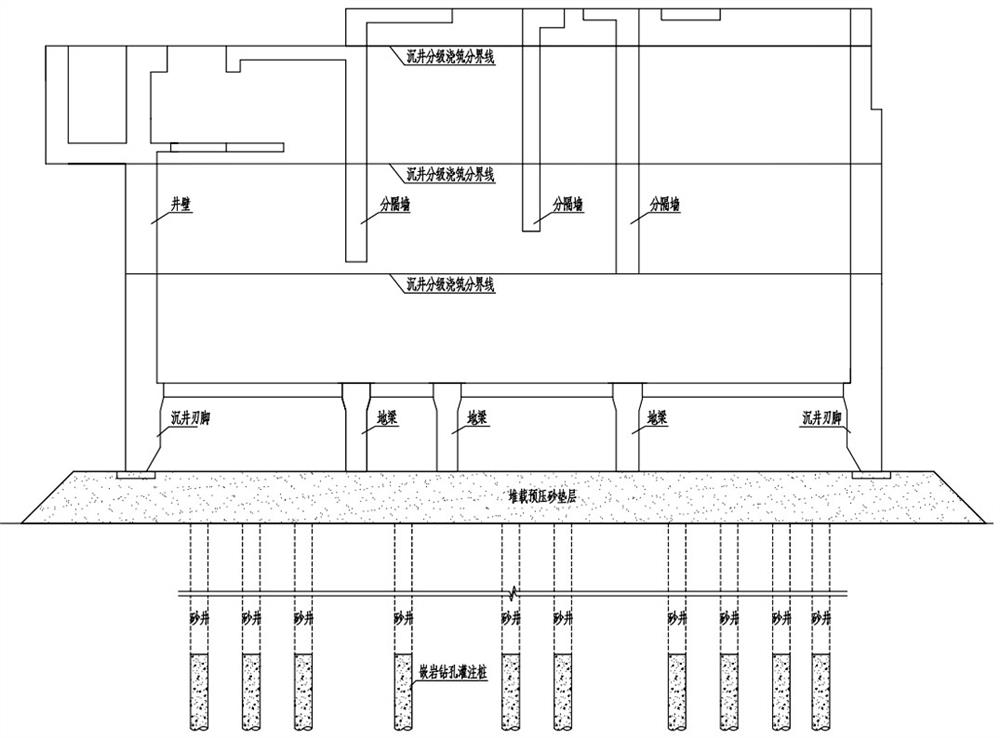

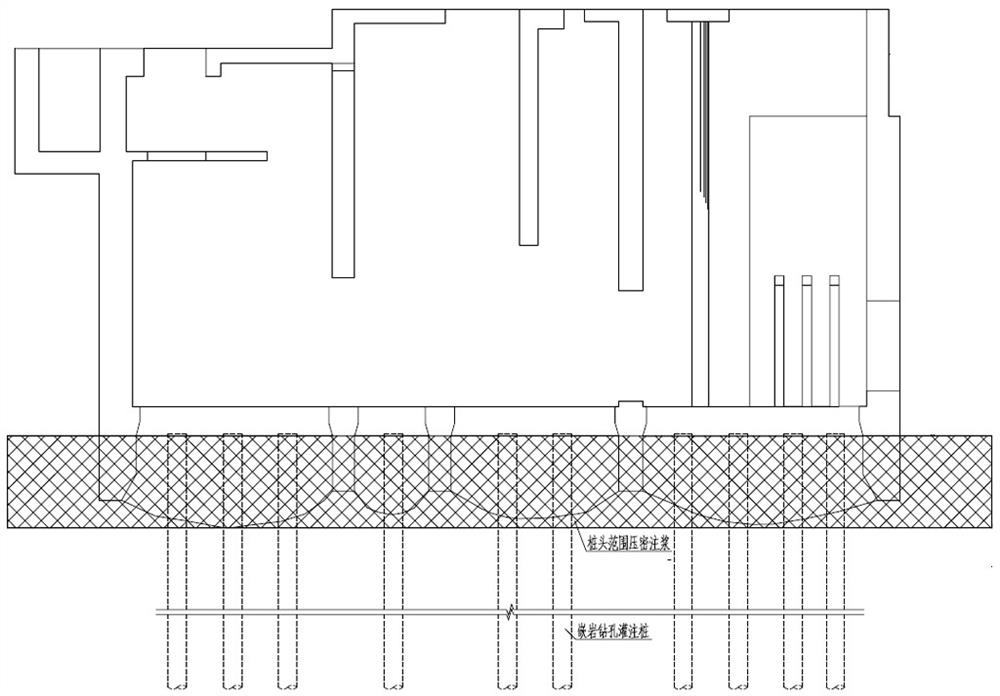

Ultra-large open caisson structure combined foundation construction method

InactiveCN112663664AWith carrying capacityEasy to precastPumping plantsSoil preservationReinforced concreteRebar

The invention discloses an ultra-large open caisson structure combined foundation construction method. The method mainly includes the steps that (1) a medium-coarse sand cushion layer is filled on a mud flat of a to-be-newly-built large circulating water taking area; (2) the medium-coarse sand cushion layer is used as a pile frame bearing layer, and rock-socketed cast-in-situ bored pile construction is conducted; (3) rock-socketed construction is conducted on the lower portion of a cast-in-situ bored pile, reinforced concrete is filled, and the cast-in-situ bored pile serves as a permanent supporting structure of an ultra-large open caisson structure; (4) the pile top of the cast-in-situ bored pile is subjected to compaction grouting, and a soil body at a pile head is reinforced, so that the pile and the soil body form a whole; and (5) an open caisson is manufactured and sunk in a graded mode or integrally sunk in a graded mode, after the open caisson is sunk to a designed elevation, plain concrete bottom sealing is conducted, a reinforced concrete bottom plate is poured, and the rock-socketed cast-in-place piles are connected with the bottom plate to form a whole. According to the ultra-large open caisson structure combined foundation construction method, the problems of sudden sinking and super sinking in the manufacturing and sinking process of the open caisson are effectively solved, and the problem of post-construction settlement after the open caisson is in place is also solved.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST

Portable electric salt spreader

The invention relates to a portable electric salt spreader which comprises a bearing vehicle with a traveling mechanism, wherein a salt storage box and a salt spreading mechanism are arranged on the bearing vehicle; the salt spreading mechanism comprises a suction tube with an adsorption fan; a spray gun is hinged at the upper end of the salt storage box; an input end of the suction tube stretchesinto the bottom of the salt storage box, and the output end of the suction tube is connected with the input end of the spray gun; a salt spreading port is formed in the front side at the bottom of the salt storage box; a salt spreading disc is arranged at the salt spreading port and comprises a rotating shaft and a group of salt spreading plates arranged in a radial shape along the rotating shaft; an outline of the salt storage box at the salt spreading port corresponds to a shape formed by two salt spreading plates from top to bottom; rubber plates are arranged on the upper end faces of thesalt spreading plates; and the upper ends of the rubber plates are higher than the upper end of the salt spreading port. According to the portable electric salt spreader disclosed by the invention, the salt spreading machine can travel on multiple road surfaces, the salt spreading operation is performed in the close-range and medium-far range surrounding an operator, the operation is simple, convenient and labor-saving, and salt spreading is uniform. Moreover, salt particles inside the salt storage box are not stacked and can be fully utilized.

Owner:STATE GRID CORP OF CHINA +2

Method for sex sorting of mosquitoes and apparatus therefor

Method and apparatus for mechanical sex-sorting of mosquitoes by extracting a class of mosquitoes from unsorted mosquitoes comprises obtaining unsorted mosquitoes, obtaining images of individual mosquitoes in a stationary phase, electronically classifying the individuals from the images into male mosquitoes and / or female mosquitoes, and possibly also unclassified objects; obtaining co-ordinates of individuals of at least one of the male mosquito and female mosquito classifications, and using a robot arm to reach an individual identified by the obtained coordinates to store or remove the individuals, thereby to provide sex-sorted mosquitoes.

Owner:SENECIO

Steel rail accumulated snow removing robot

The invention relates to the technical field of steel rail accumulated snow removal, in particular to a steel rail accumulated snow removing robot which comprises a snow pushing mechanism and a collecting mechanism, the snow pushing mechanism comprises a snow pushing inclined plate, a snow pushing plate, a snow pushing sliding rod and a snow pushing sleeve, the snow pushing plate is slidably connected to the snow pushing inclined plate, and a sliding rod is arranged on the snow pushing plate. The snow pushing plate is slidably connected into the snow pushing sleeve, the snow pushing plate is fixedly connected to the lower end of the snow pushing sliding rod, the collecting mechanism comprises a snow pushing rotating rod and snow pushing rotating wheels, the two snow pushing rotating wheels are rotationally connected to the front end and the rear end of the snow pushing rotating rod respectively, and the two snow pushing rotating wheels are in friction transmission with the two snow pushing sliding rods. When the steel rail accumulated snow removing robot removes the snow on the steel rail, the cleaned snow can be pushed away from the steel rail, so that the steel rail is prevented from being covered again by collapse of snow piles.

Owner:陈波浪

Mixed type foundry waste sand scrubbing and recovering equipment

ActiveCN103350186BImprove concentrationEasy to separateMould handling/dressing devicesFoundrySmall footprint

The invention discloses mixed type foundry waste and scrubbing and recovering equipment, which includes a sand-water separating unit, a centrifugal separator, a sand-water buffering and concentrating tank and a multi-cylinder combined scrubber, and is characterized in that multiple separators are arranged on the periphery of a cylinder body of the sand-water separating unit; the middle part of the cylinder body is divided by a partition board into two parts, namely a water outgoing tank and a water ingoing tank; two cones at different angles are arranged at the bottom of a tank body of the sand-water buffering and concentrating tank; a pressure reduction inverted cone is arranged between the two cones; a high pressure water pipe is arranged above the pressure reduction inverted cone; multiple scrubbing cylinders which are connected in series are arranged on the multi-cylinder combined scrubber; every 2 to 3 scrubbing cylinders share one motor; each scrubbing cylinder is composed of an inner cylinder and an outer cylinder. The combined foundry waste and scrubbing and recovering equipment occupies a small area, is compact in structure, has high waste sand recovery rate and waste sand regeneration performance, and is long in service life and simple and convenient to maintain.

Owner:广西兰科资源再生利用有限公司

Chinese herbal medicine washing and filtering device for agriculture

InactiveCN108722985APrevent pilesWash carefullyDispersed particle filtrationTransportation and packagingMedicinal herbsSludge

The invention discloses a Chinese herbal medicine washing and filtering device for agriculture. The Chinese herbal medicine washing and filtering device for agriculture structurally comprises a machine body, bolts, a washing and filtering device, a feeding pipe, a water inlet pipe, a rack, a controller, a blow-off pipe, a discharging pipe, a servo motor device, a Chinese herbal medicine scatteringmechanism, a power transmission mechanism, a dirt removal and filtration mechanism, a hinge transmission mechanism, a washing stirring mechanism and a fan air drying mechanism. The Chinese herbal medicine washing and filtering device for agriculture can carry out stirring washing on Chinese herbal medicine in a high efficiency manner, a fan is used for blowing the Chinese herbal medicine dry after the Chinese herbal medicine is washed clean, and the production efficiency and quality of the Chinese herbal medicine are improved; and because residues left by the Chinese herbal medicine can be brush away completely, and it is avoided that equipment is blocked because residues and sludge retain for a long time.

Owner:ANHUI KECHUANG PRODUCTIVITY PROMOTION CENT CO LTD

White tea processing technology

InactiveCN108522677ADry evenlyDrying slowlyPre-extraction tea treatmentTea flavoringBudIntermittent heating

The invention discloses 1. a white tea processing technology. The white tea processing technology comprises the following steps of carrying out picking, namely picking fresh tea-tree leaves with one bud and one leaf or one bud and two leaves as raw materials; carrying out withering, namely timely spreading the picked fresh tea-tree leaves, in uniform thickness, by using a bamboo tray without performing turning, and carrying out withering selected from natural withering, compound withering or heated withering; and carrying out storing, namely putting the withered white tea into an ice house ofwhich the temperature is 1-5 DEG C. The white tea processing technology further comprises a step of carrying out drying and a step of carrying out fermenting between the step of carrying out witheringand the step of carrying out storing; the step of carrying out drying comprises the processes of adopting a drying apparatus, putting the duly withered white tea into the drying apparatus, and performing vibration and intermittent heating treatment so as to have the white tea uniformly dried; and the step of carrying out fermenting comprises the processes of adopting a fermenting apparatus, putting the dried white tea into the fermenting apparatus, performing stir-frying, and intermittently heating a rosin layer so as to have the white tea uniformly fermented. The white tea processing technology mainly solves the problems of existing white tea, namely non-uniform drying effects and lack of aroma.

Owner:贵州茗香茶业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com