Marine garbage salvage device with water removal function for marine environmental protection

A marine environment and salvage device technology, which is applied to the cleaning of open water, water conservancy projects, transportation and packaging, etc., can solve the problems of slow salvage speed, heavy work burden, and low efficiency, so as to improve efficiency, reduce work burden, and avoid piles of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

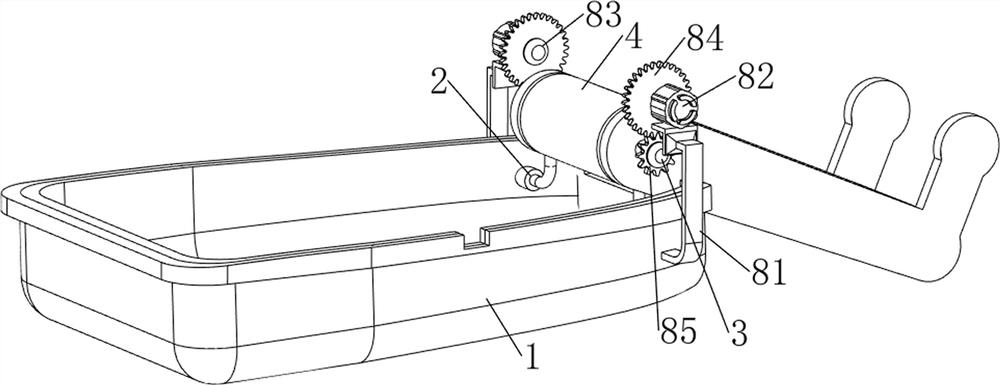

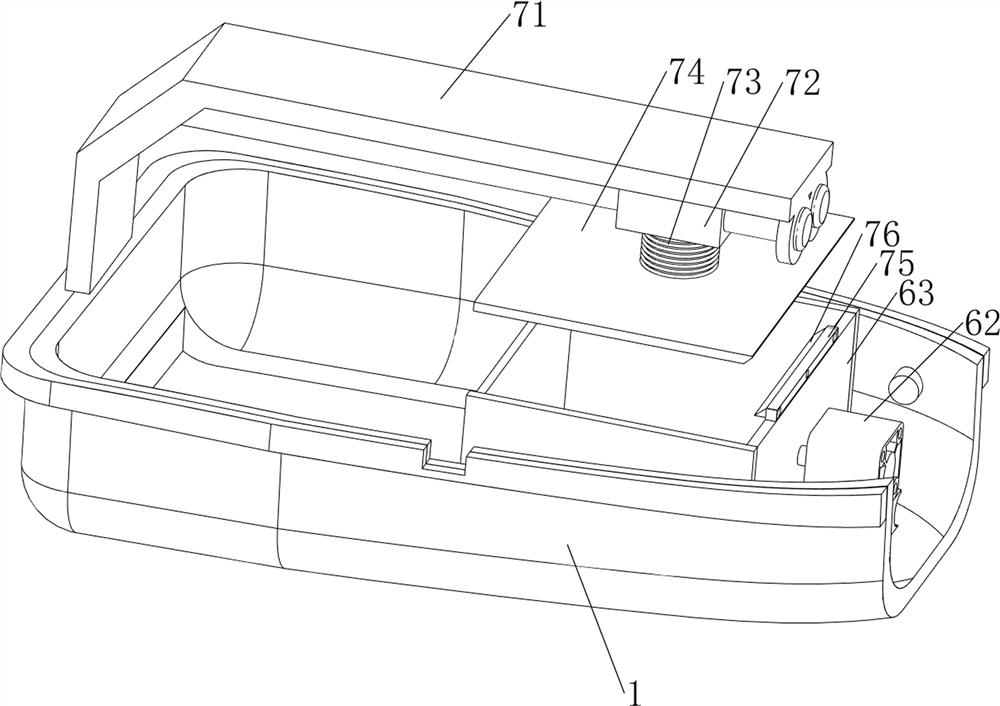

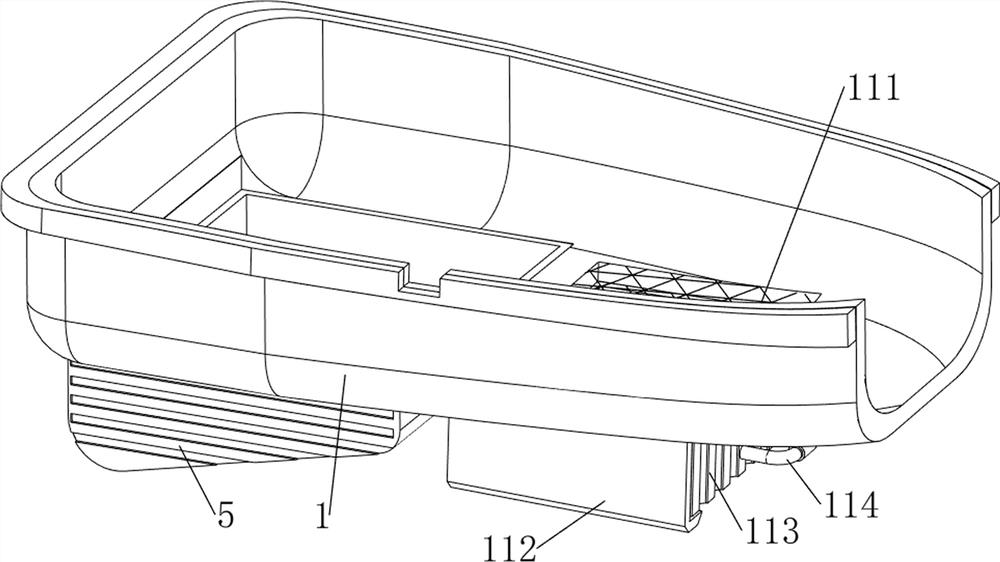

[0068] A marine garbage salvage device with dewatering function for marine environment protection, such as Figure 1-5As shown, it includes a first support frame 1, a support frame 2, a conveying roller 3, a conveyor belt 4, a collection frame 5, a pushing mechanism 6, an extruding mechanism 7 and a driving mechanism 8, and the front and rear sides of the right part of the first support frame 1 Both sides are connected with a support frame 2, and the support frame 2 is arranged in an inclined manner. The left and right sides between the two support frames 2 are connected to the conveyor roller 3 through bearing rotation, and the conveyor belt 4 is wound between the two conveyor rollers 3. The left side of the bottom of the first support frame 1 is detachably installed with a collection frame 5 through bolts, a pushing mechanism 6 is installed in the first support frame 1, an extrusion mechanism 7 is installed on the top of the first support frame 1, and the right side of the fi...

Embodiment 2

[0074] On the basis of Example 1, such as figure 1 , Figure 6 , Figure 7 and Figure 8 As shown, a locking mechanism 9 is also included, and the locking mechanism 9 includes a connecting rod 91, a second wedge block 92, a fourth support plate 93, a card frame 94 and a third spring 95, and the front side of the top of the pressing plate 74 is connected with a connecting rod 91 The bottom end of the connecting rod 91 is connected with a second wedge block 92, the middle of the upper part of the front side of the first support frame 1 is connected with a fourth support plate 93, and the fourth support plate 93 is slidingly provided with a card holder 94, and the card holder 94 and the first Two wedge-shaped blocks 92 cooperate, and the left side of the card frame 94 contacts with the first movable plate 65. The rear side of the card frame 94 is an inclined plane. When the first movable plate 65 swings to the right, it can cross the card frame 94. The card frame 94 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com