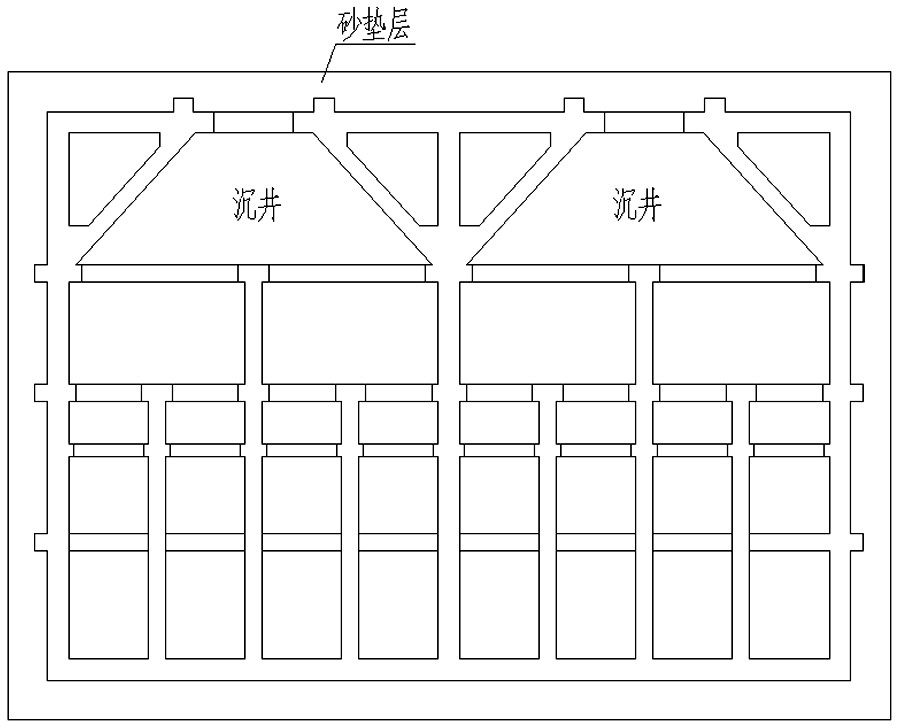

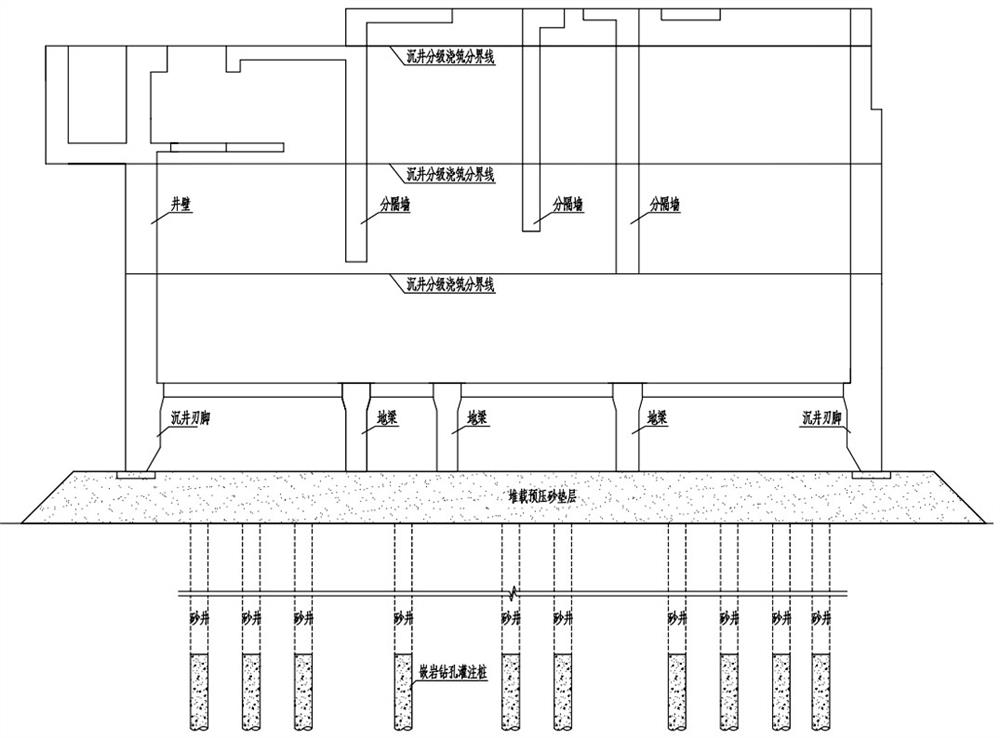

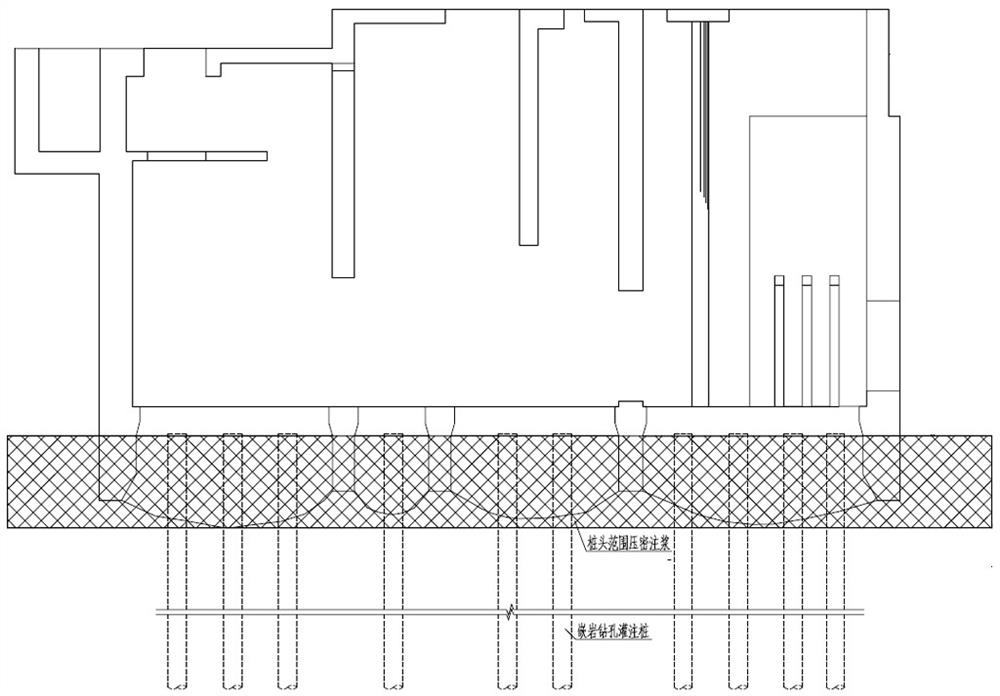

Ultra-large open caisson structure combined foundation construction method

A construction method and ultra-large technology, applied in infrastructure engineering, soil protection, water supply equipment, etc., can solve problems such as high compressibility, natural foundations that cannot meet the foundation bearing capacity requirements of the construction of large-scale water intake pump houses, disturbances, etc. To achieve the effect of preventing over-sinking accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Zheneng Yueqing Power Plant is built adjacent to Yueqing Bay, with a total installed capacity of 2×600MW+2×660MW. The large-scale circulating water pump house is built on a deep and soft soil layer. The lower part of the pump house adopts a super-large caisson structure. The tidal flat where the pump house is located is deeply muddy , with an average of 40m~60m. The prominent features of tidal mud are high water content, low foundation bearing capacity, and strong compressibility. If an effective foundation treatment plan is not adopted, construction will become very difficult. After adopting the above-mentioned joint foundation treatment plan, the project has been successfully constructed and has been in safe operation for many years.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com