Material conveying device for biogas engineering

A conveying device and feeding device technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of high dry matter concentration, reduced surface area, feeding interruption, etc. Solid crust, the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

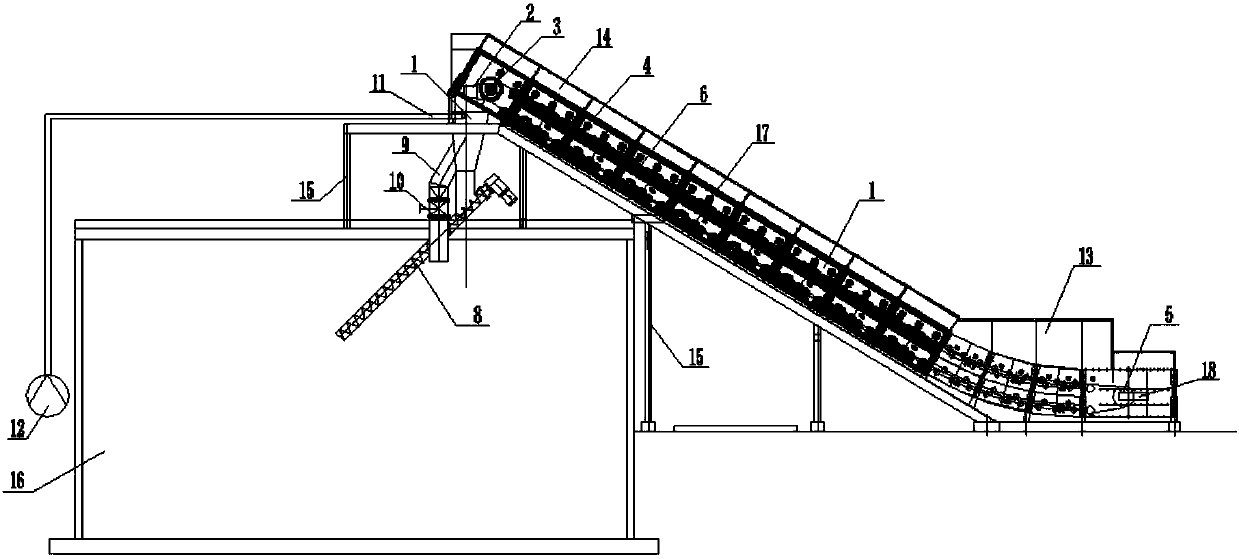

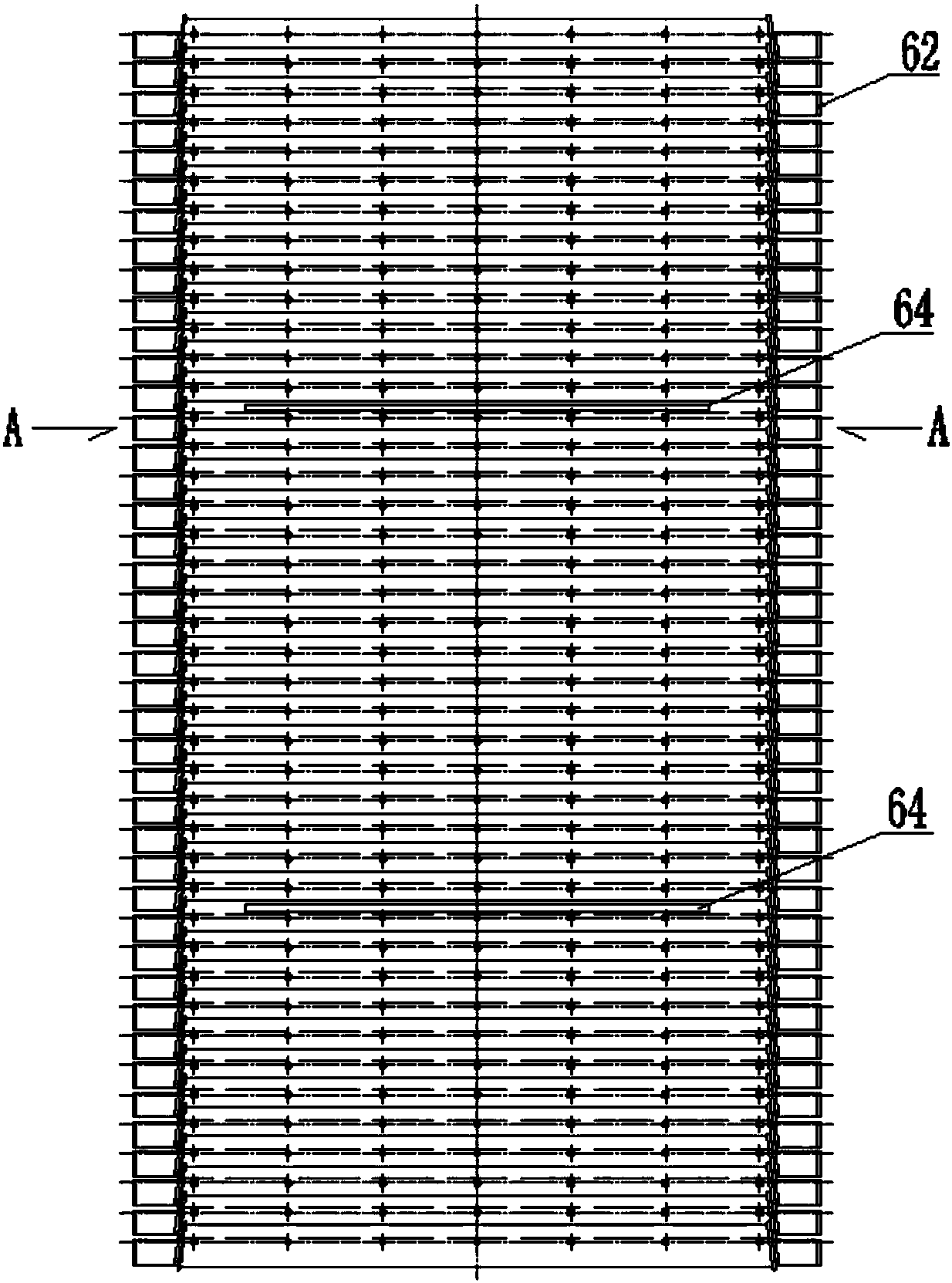

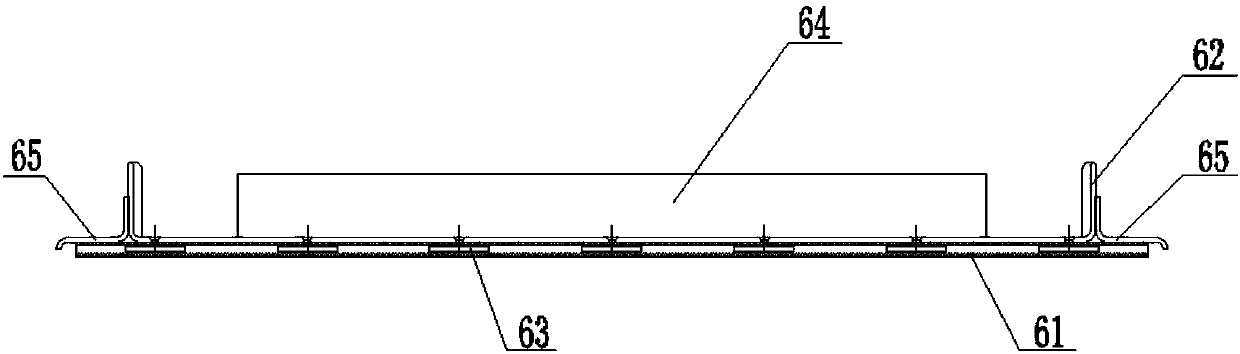

[0024] Such as Figures 1 to 2 As shown, the embodiment of the present invention provides a material conveying device for biogas engineering. The device includes a conveying steel belt machine and an intermediate feeding device. The conveying steel belt machine is obliquely arranged between the top of the fermentation tank 16 and the ground, located The part on the ground is the feed end, and the top is the discharge end. The conveying steel belt machine comprises a frame 1, a driving mechanism 2, a main driving wheel 3, a plurality of supporting rollers 4, a driven wheel 5 and a convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com