Mixed type foundry waste sand scrubbing and recovering equipment

A technology for casting waste sand and recycling equipment, which is applied in casting molding equipment, metal processing equipment, manufacturing tools, etc. It can solve the problems of easy blockage and failure of equipment, failure to meet foundry enterprises, low yield of recycled products, etc., and achieve sand water Good separation effect, good scrubbing effect, and low equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

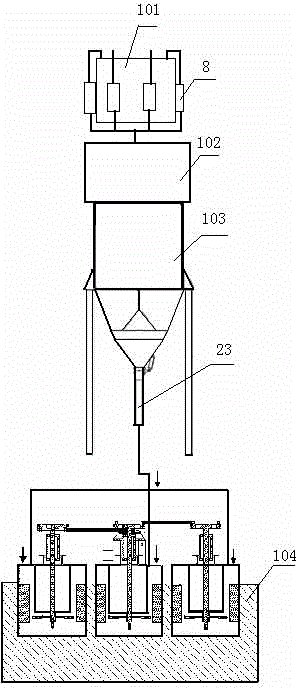

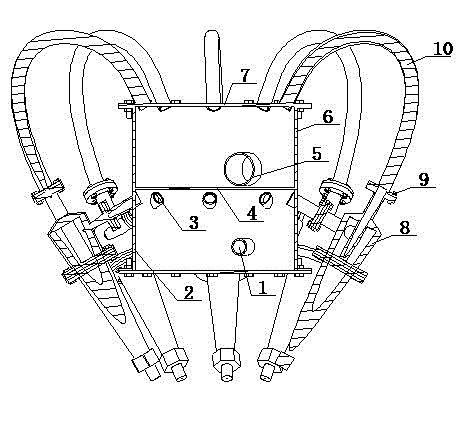

[0031] like figure 1 , 2 , 3 and 5, the connection mode of the equipment of the present invention:

[0032]Sand-water separator (101) has 8 separators around its box body, and the box body (1) is divided into two parts with a partition (4) in the middle, the upper part is the water outlet tank (6), and the lower part is the water inlet tank (2), The water outlet tank (6) is provided with a water outlet (5); the water inlet tank (2) is provided with a water inlet (1); the water inlet tank (2) contains a diversion port and is connected with the corresponding separator, and the top outlet of the separator is used The elbow passes through the large flange (7) on the top of the water outlet box to communicate with the water outlet box (6); the sand outlet of the separator is connected to the material inlet of the centrifugal separator (102) with a pipeline, and the bottom of the centrifugal separator (102) The material outlet links to each other with the feed port on the top of t...

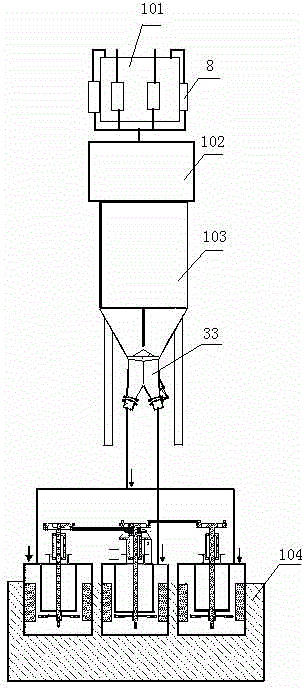

Embodiment 2

[0034] like figure 2 , 4 As shown in 5, the connection mode is basically the same as that in Example 1, except that the sand-water buffer concentration tank has a diversion effect, that is, the 90° cone is changed into a double cone, and the two sand outlet pipes of the double cone are aligned The raw material inlet of the first scrubbing cylinder of the multi-cylinder combined scrubbing machine, and the function of the two sand outlet pipes are to make the flow rate of the discharged sand uniform and moderate.

[0035] Manufacturers can choose the number of separators around the sand-water separator box according to production needs (generally 6-8 are more suitable, the more separators, the greater the sand-water separation capacity) and the multi-cylinder combined scrubbing machine in series The number of scrubbing cylinders (4 to 6 is more suitable), the sand water buffer concentration tank to choose the buffer concentration tank with diversion effect is more beneficial t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com