Recovery device for suction nozzle and dyeing machine

A technology of recovery device and sliding mechanism, which is applied in the field of cytopathological detection, can solve the problems of occupying a large space and position, hindering the flexible recovery of suction nozzles, and the quality of film production is very different, so as to achieve short time required and economical control. Time-saving, space-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

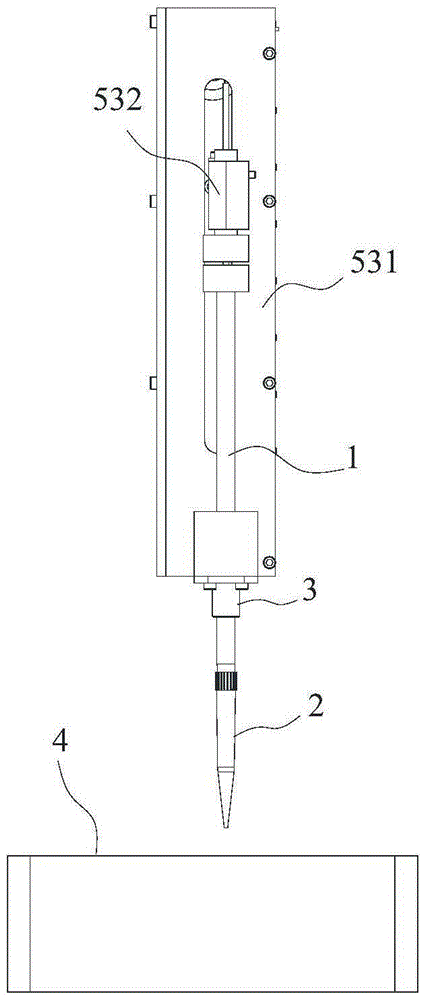

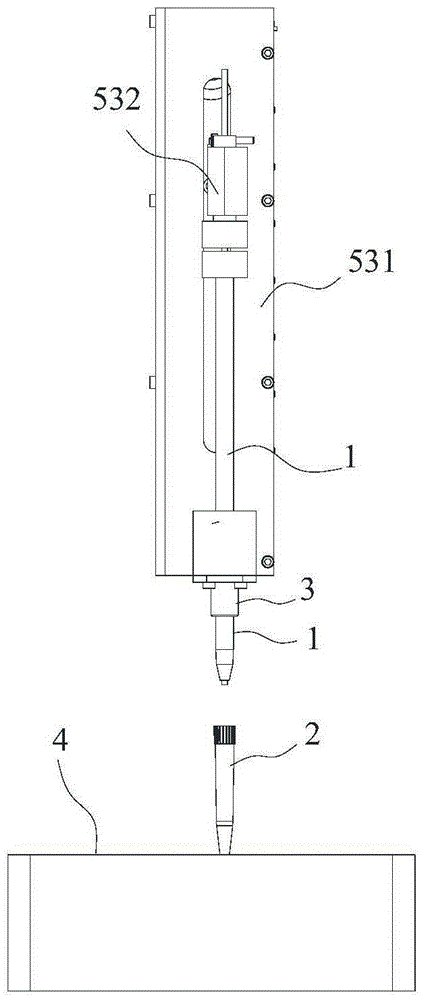

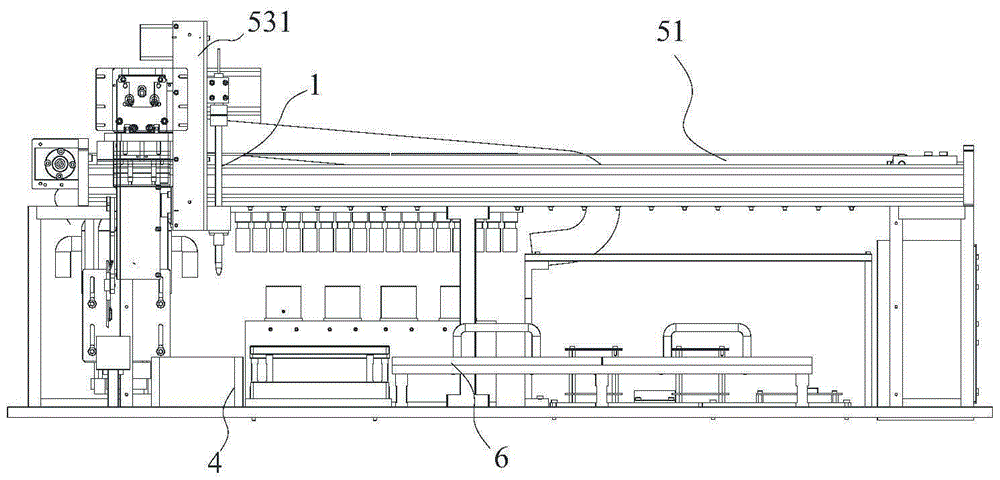

[0024] Such as Figure 1~2 The suction nozzle recovery device shown includes a sampling needle 1, a suction nozzle 2, a stopper 3, a waste box 4, a Z1-axis support 531 and a Z1-axis drive mechanism 532, and the stopper 3 is fixed at the bottom of the Z1-axis support 531 , the sampling needle 1 slides and fits with the Z1-axis bracket 531 along the Z-axis direction, the Z1-axis driving mechanism 532 is used to drive the sampling needle 1 to slide vertically, and the sampling needle 1 slides through the stopper 3, correspondingly, The stopper 3 has a perforation for the injection needle 1 to penetrate, and the top of the suction nozzle 2 is detachably socketed on the bottom of the injection needle 1, and the top of the suction nozzle 2 is used to match with the perforation to make the suction The nozzle 2 cannot pass through the perforation and falls off...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com