Charging/discharging method for accumulator formation, formation method and device

A formation method and storage battery technology, applied in secondary battery charging/discharging, lead-acid battery, lead-acid battery construction, etc., can solve the problems of lower production efficiency of storage battery, long formation time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

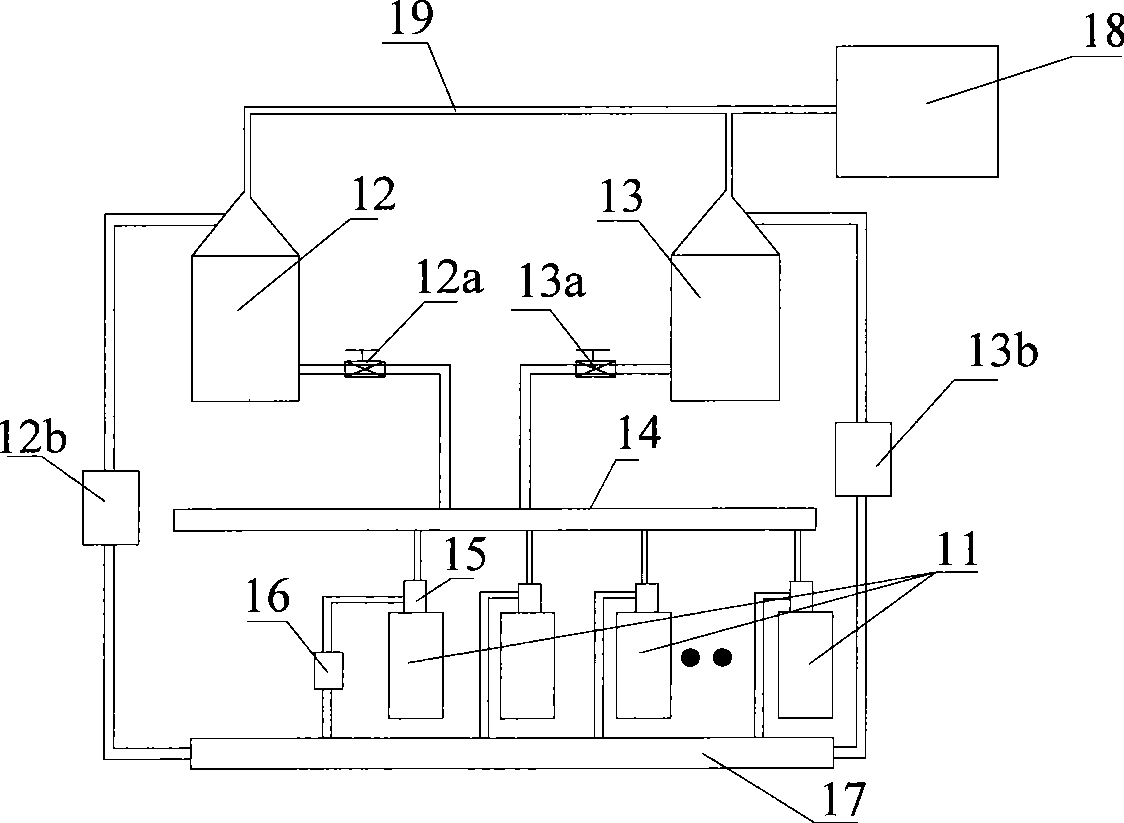

[0069] like figure 1 Shown, in the low-concentration acid tank 12, packing density is 1.04g / cm 3 ~1.05g / cm 3 The low-concentration sulfuric acid, packing density in high-concentration acid tank 13 is 1.28g / cm 3 of high concentration sulfuric acid.

[0070] Continuous injection density of 1.04g / cm in multiple battery cases 3 ~1.05g / cm 3 A plurality of raw plate storage batteries are obtained after sulfuric acid, and then the raw plate storage batteries are connected to figure 1 In the chemical conversion device shown, close the second valve 13a, open the first valve 12a at the same time, open the pneumatic diaphragm pump 16 and the first circulation pump 12b, and the continuous circulation density in the raw plate battery is 1.04g / cm 3 ~1.05g / cm 3 sulfuric acid for 1 to 2 hours. Since the rising plate absorbs sulfuric acid, the specific gravity of the sulfuric acid in the battery will decrease, so after circulating the low-concentration sulfuric acid in the battery for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com