Environment-friendly antibacterial putty powder processing equipment and process

A kind of processing equipment and putty powder technology, applied in the direction of mixer, mixing method, mixed material pretreatment, etc., can solve problems such as easy agglomeration, affecting putty powder production efficiency, putty powder quality, uneven material mixing, etc., to ensure quality , Shorten the mixing time of the material, and the effect of mixing the material evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

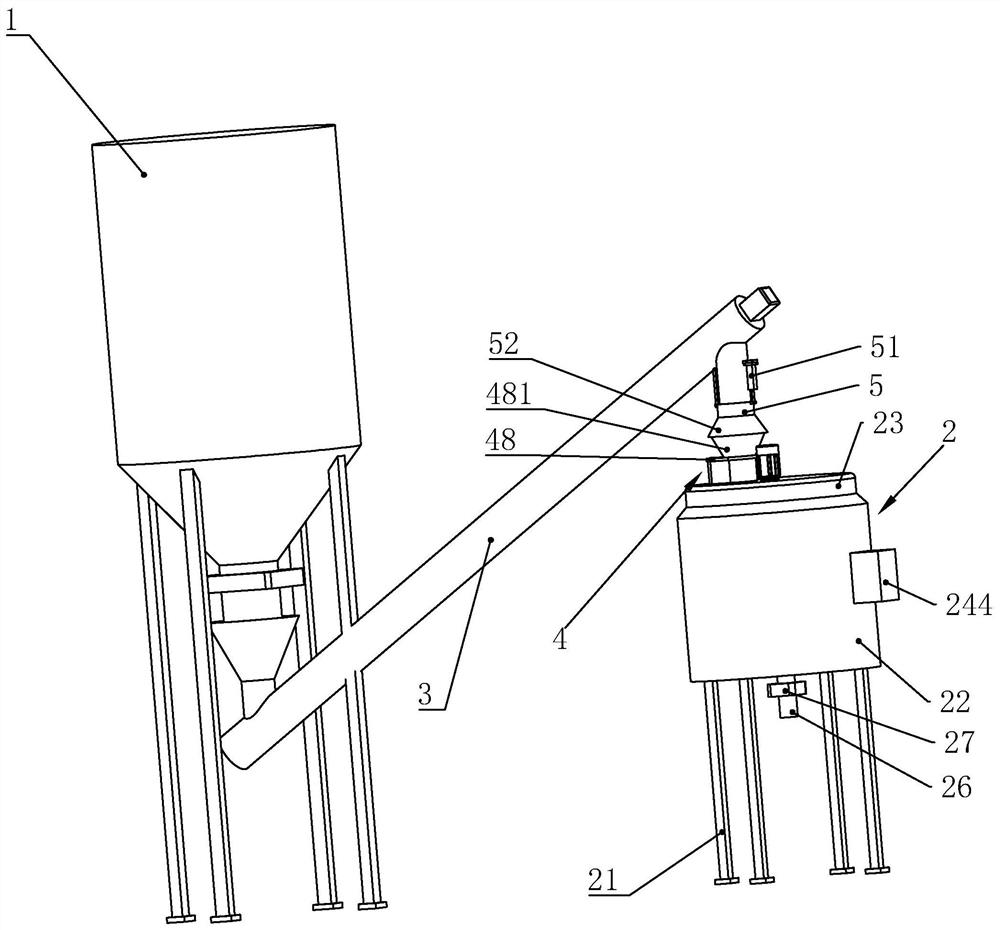

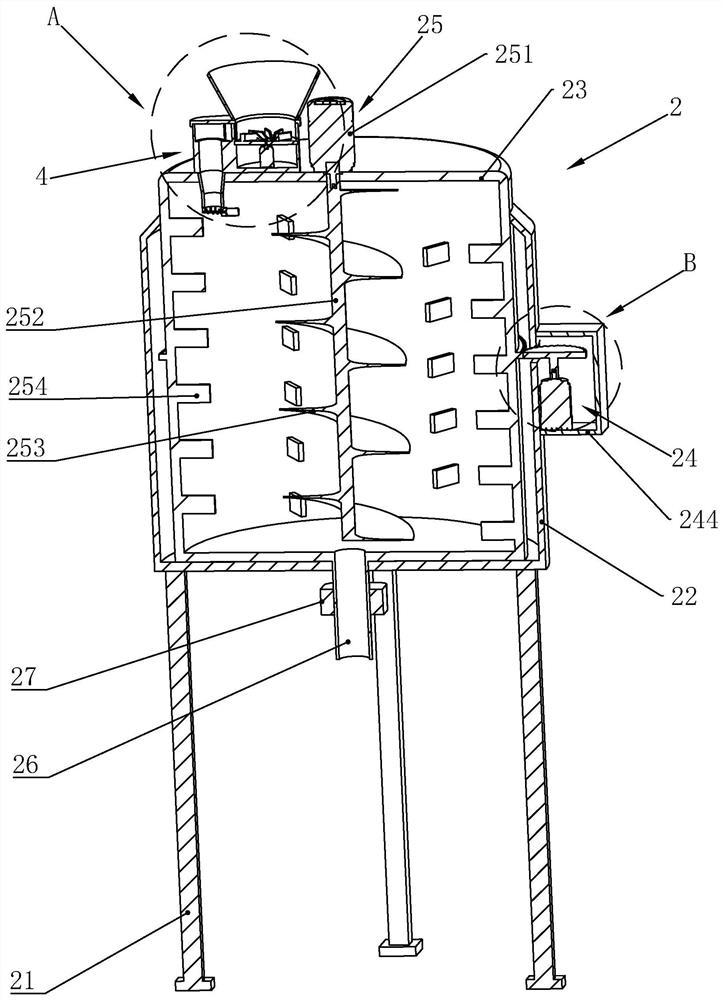

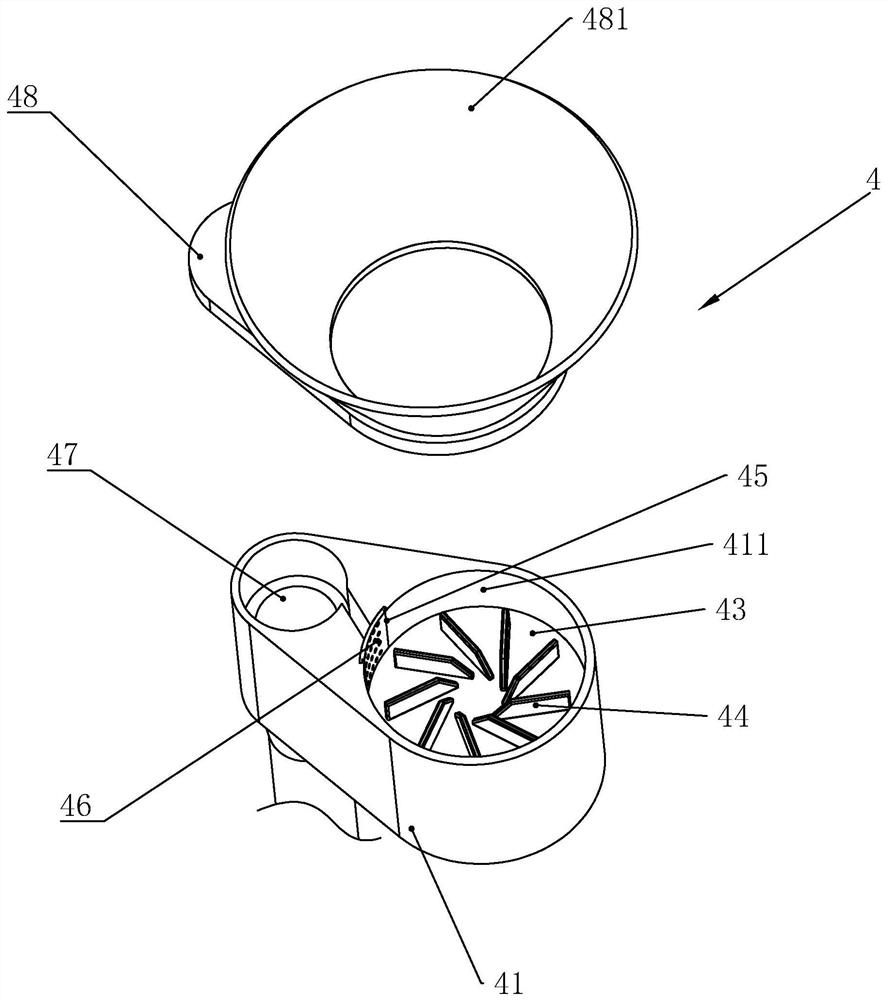

[0045] like figure 1 , figure 2 As shown, it is an environmentally friendly antibacterial putty powder processing equipment disclosed by the present invention, including a raw material storage device 1, a mixing and stirring device 2, and a screw feeder 3 obliquely arranged at the bottom of the raw material storage device 1 and the top of the mixing and stirring device 2, mixing and stirring The top of the device 2 is provided with a pulverizing and grinding feeding device 4. The mixing and stirring device 2 includes a bracket 21 and an outer cylinder 22 with a top opening fixed on the bracket 21. The outer cylinder 22 is rotated with an inner cylinder 23. The pulverizing and grinding feeding device 4 Located at the top of the inner cylinder 23, the inner cylinder 23 is provided with a driving device 24 to drive its rotation, and the inner cylinder 23 is provided with a stirring device 25, the stirring speed of the stirring device 25 is greater than the rotation speed of the ...

Embodiment 2

[0058] like Figure 6 As shown, the present invention also includes a kind of environmental protection antibacterial putty powder processing technology, comprises the following steps,

[0059] S1. Store heavy calcium powder, ash calcium powder, environmentally friendly interior wall putty masterbatch powder, antibacterial and anti-mildew shell powder into corresponding raw material storage devices 1;

[0060] S2. Transport heavy calcium powder, ash calcium powder, environmental protection inner wall putty masterbatch powder, antibacterial and anti-mildew shell powder to the crushing and grinding feeding device 4 through the screw feeder 3 according to the proportion and order;

[0061] S3. Grinding the material through the pulverizing and grinding feeding device 4;

[0062] S4, adding the ground materials into the inner cylinder 23 in sequence;

[0063] S5, the material is mixed uniformly by the stirring device 25;

[0064] S6, sieving and checking the fineness of the mixed m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com