Granite coating preparation system

A granite coating and preparation system technology, applied in the coating field, can solve the problems of reducing the quality of granite coatings, not easy to disperse, etc., and achieve the effects of convenient installation, improved stability, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

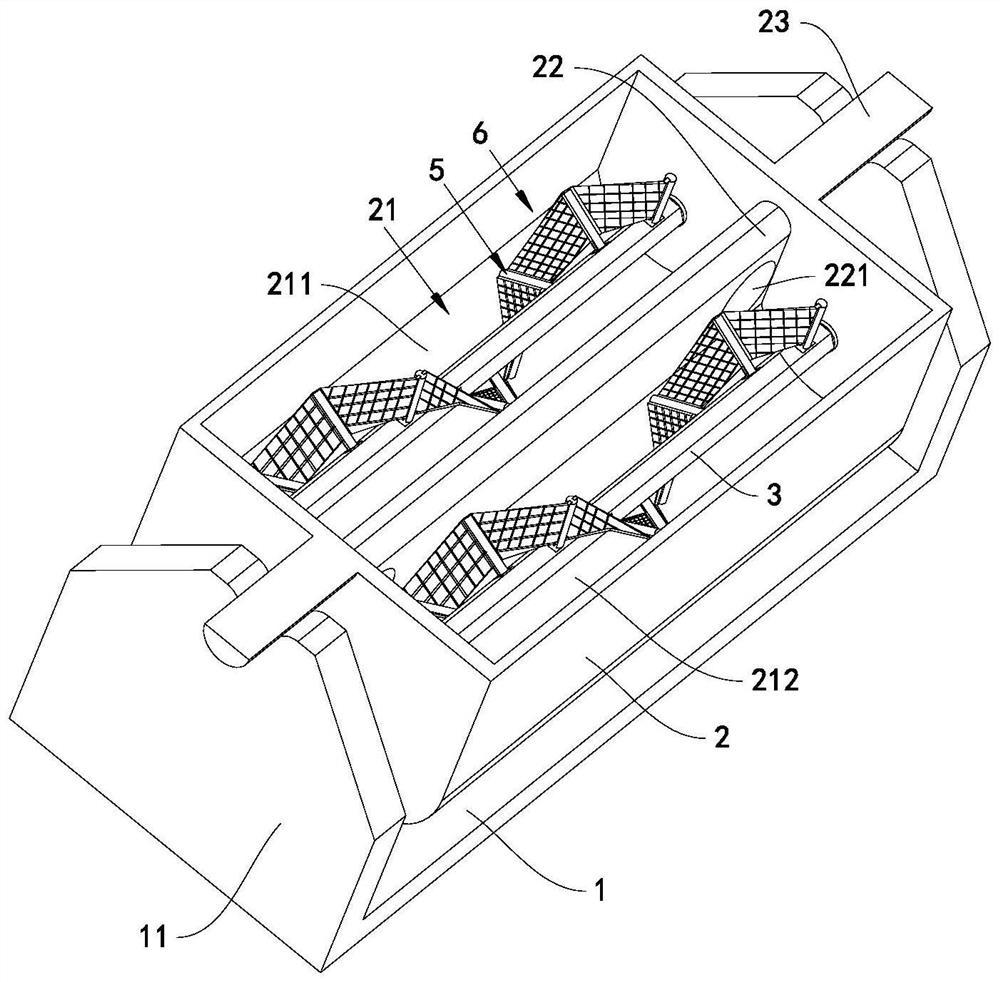

[0039] refer to Figure 1 to Figure 4 As shown, it is a granite paint preparation system disclosed in the present invention. This granite paint preparation mixer is mainly used in the preparation of granite paint, which can more fully stir the paint, and effectively prevent the granite flakes from sticking and piling up at the bottom of the equipment. Improve the effect of stirring.

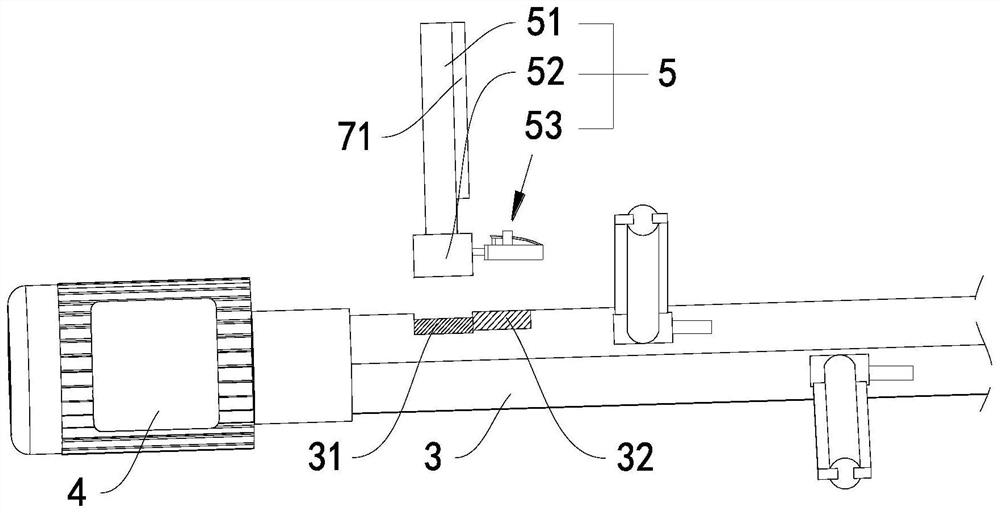

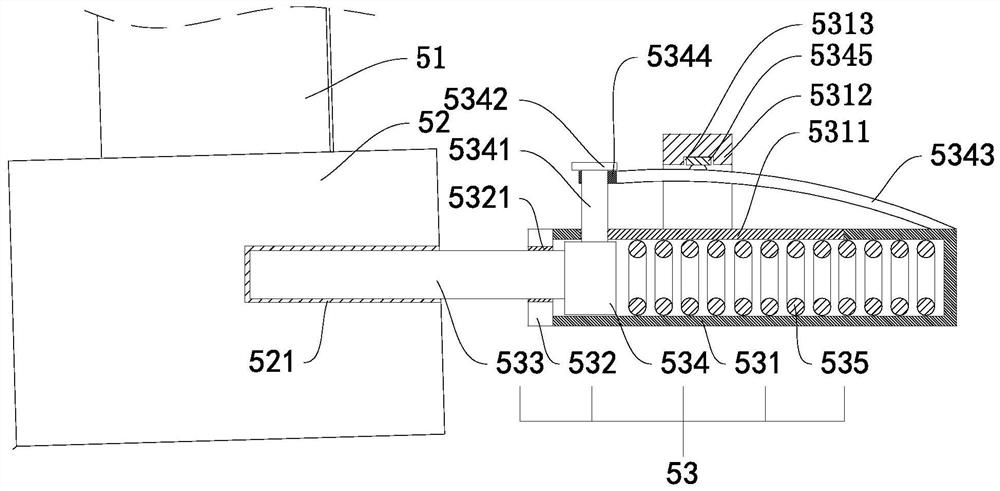

[0040] In the present embodiment, the mixer for preparing granite paint includes a base 1 and a mixing box 2 arranged on the base 1. A stirring chamber 21 is provided in the mixing box 2. In order to achieve sufficient grinding of the materials in the mixing box 2, the stirring Turning roller 3 is provided with in the case 2, and the turning motor 4 that drives turning roller 3 rotations is installed on the stirring box 2 casings; Drives turning roller 3 to rotate by the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com