Air locking and feeding device

A technology of feeding device and air lock, which is applied in the direction of transportation and packaging, conveying bulk materials, conveyors, etc., can solve problems such as unfavorable inspection and refueling, replacement, equipment use, untimely maintenance, high use and maintenance costs, etc. Achieve the effects of avoiding shutdown processing, no jamming, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples.

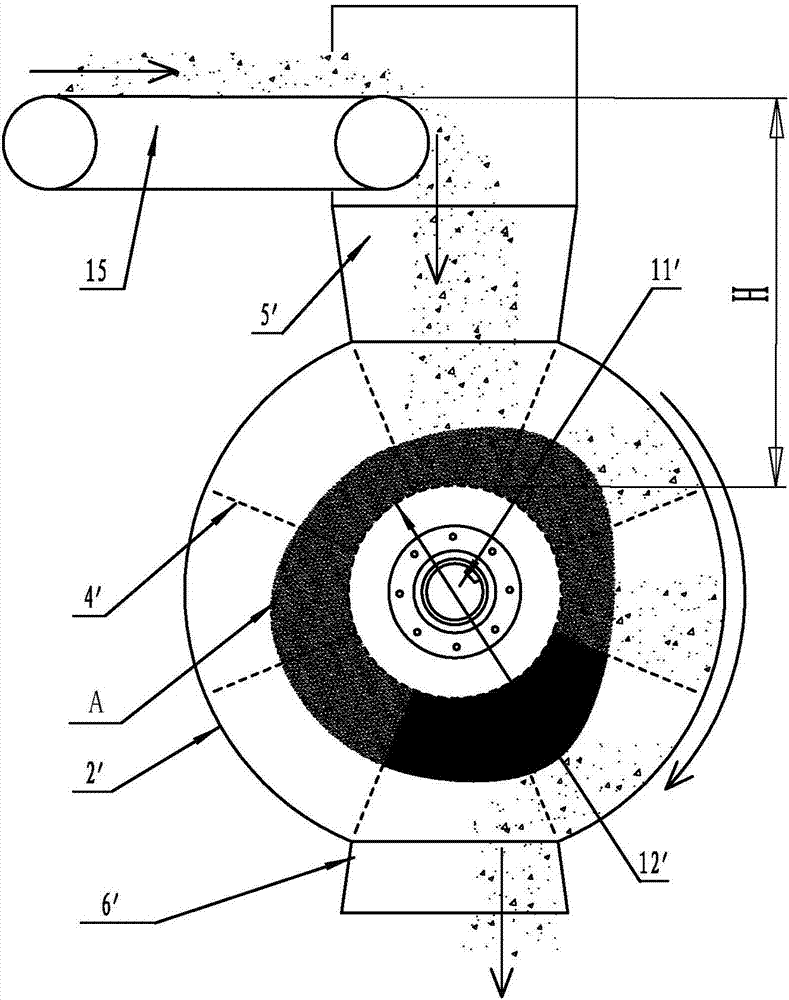

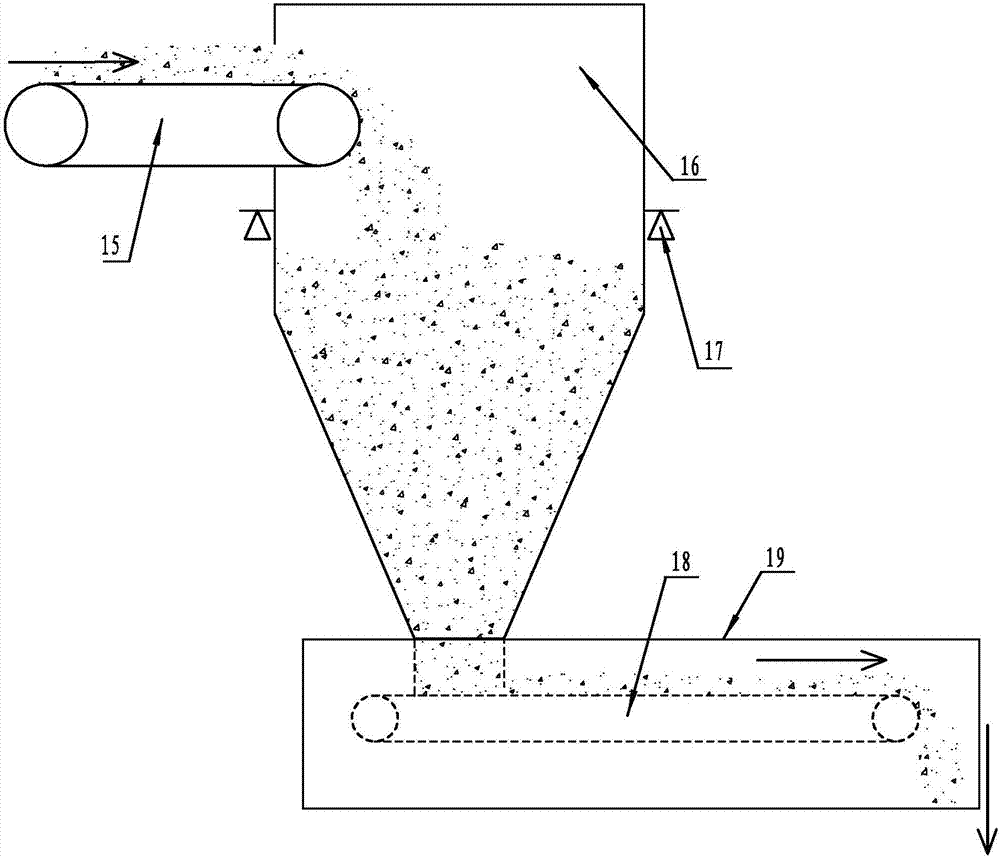

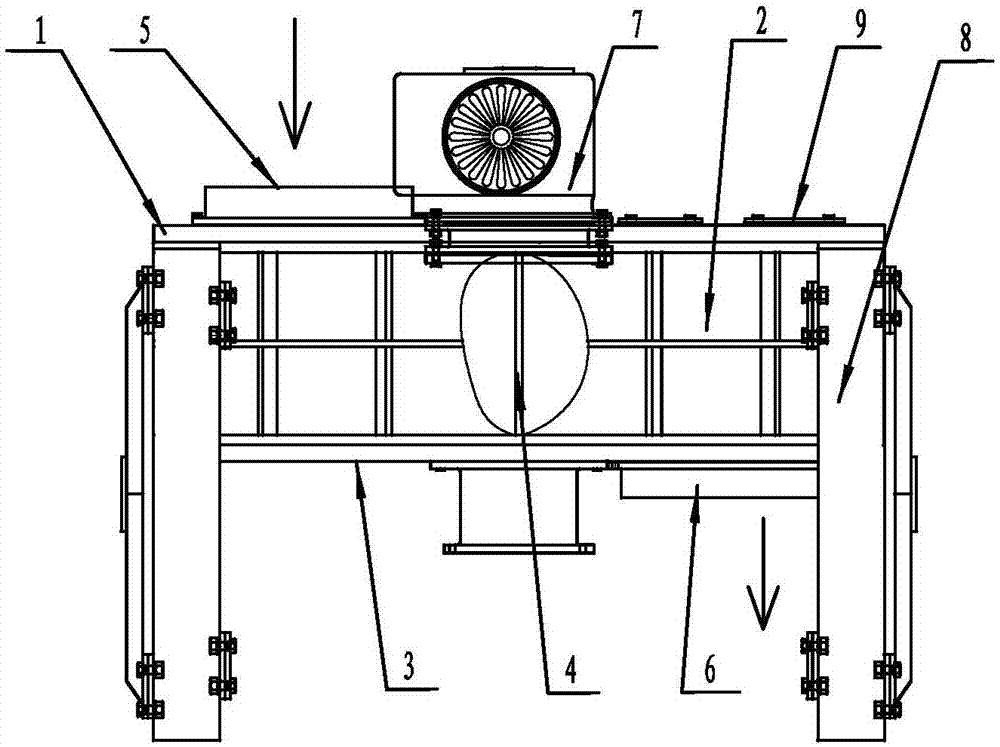

[0035] Such as image 3 and Figure 4 As shown, the windlock feeding device of the present invention includes: a housing fixed on the frame 8 and a rotor assembly 4 rotatably arranged in the cavity of the housing. Wherein, for the convenience of manufacture, the housing adopts a component structure, including a vertically arranged cylinder 2, a cylinder bottom 3 fixed at the bottom of the cylinder 2, and a cylinder cover 1 fixed at the top of the cylinder 2. 2. The tube bottom 3 and the tube cover 1 together enclose the cavity, the tube cover 1 is provided with a feed port 5 , and the tube bottom 3 is provided with a discharge port 6 . The rotor assembly 4 is vertically arranged in the cavity, and the power input end of the rotor assembly 4 is connected with the power device.

[0036] Such as Figure 5 and Figure 6As shown, the rotor assembly 4 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com