Small domestic garbage incineration purification treatment system

A technology for incineration and purification of domestic waste, applied in the treatment of combustion products, incinerators, combustion methods, etc., can solve problems such as difficulties, transfer difficulties, and large initial investment, so as to reduce production, avoid garbage piles, improve Effect of gas-liquid contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described through specific embodiments below.

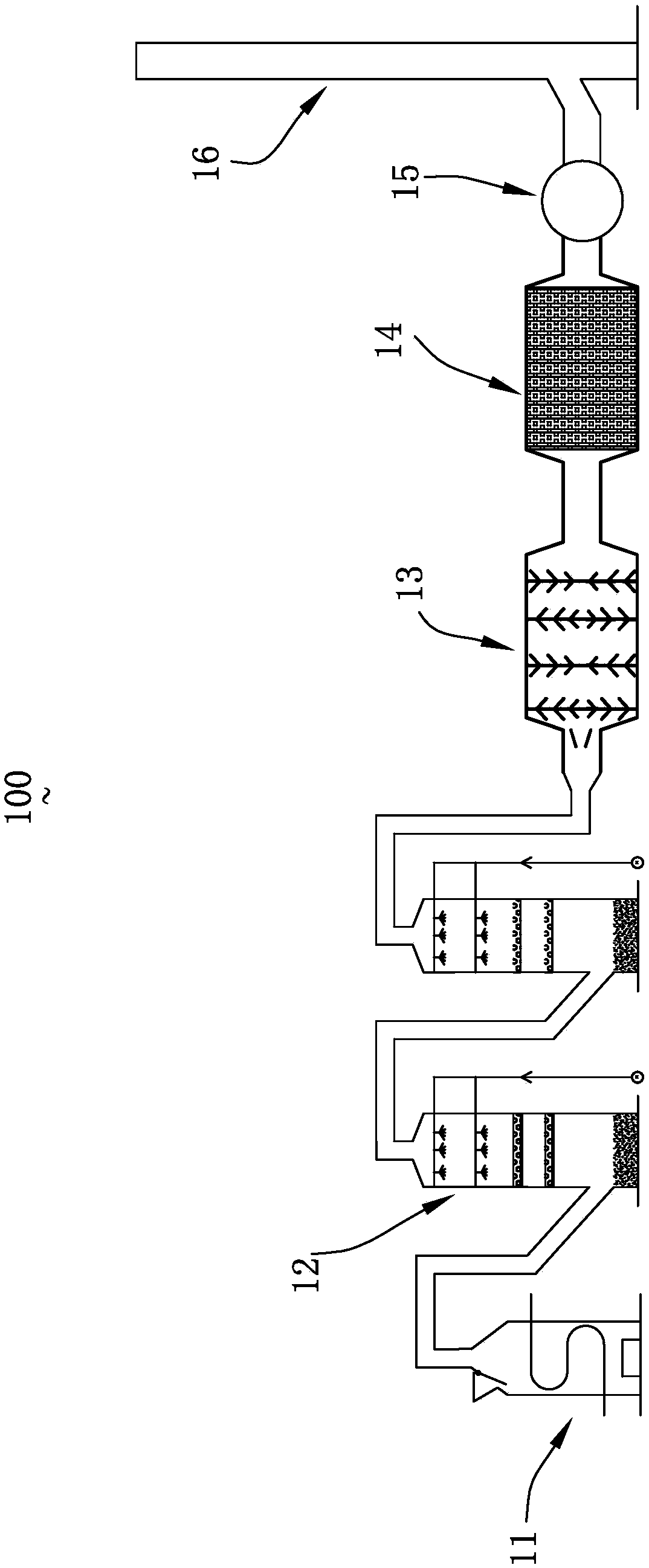

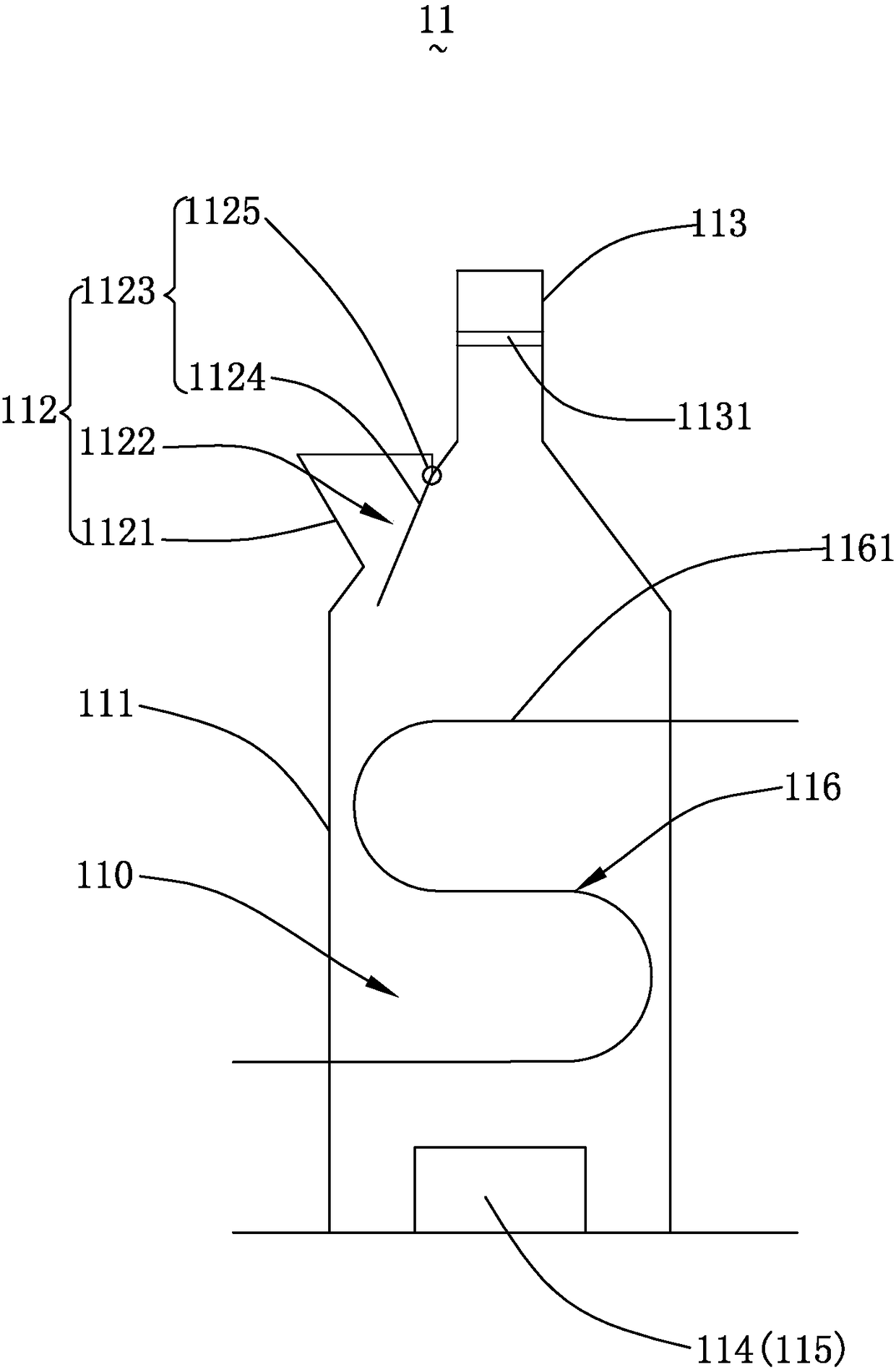

[0031] see figure 1 , is a schematic structural diagram of a small domestic waste incineration purification treatment system provided by the present invention. The small domestic waste incineration and purification treatment system 100 includes a garbage incinerator 11, a spray absorption tower 12, a demisting device 13, an activated carbon adsorption device 14, an induced draft fan 15 and an exhaust chimney 16 arranged in sequence, so that the smoke generated by the waste incineration The air is introduced into the exhaust chimney 16 by the induced draft fan after spraying absorption treatment, demisting treatment, and activated carbon adsorption treatment in sequence, and is discharged up to the standard.

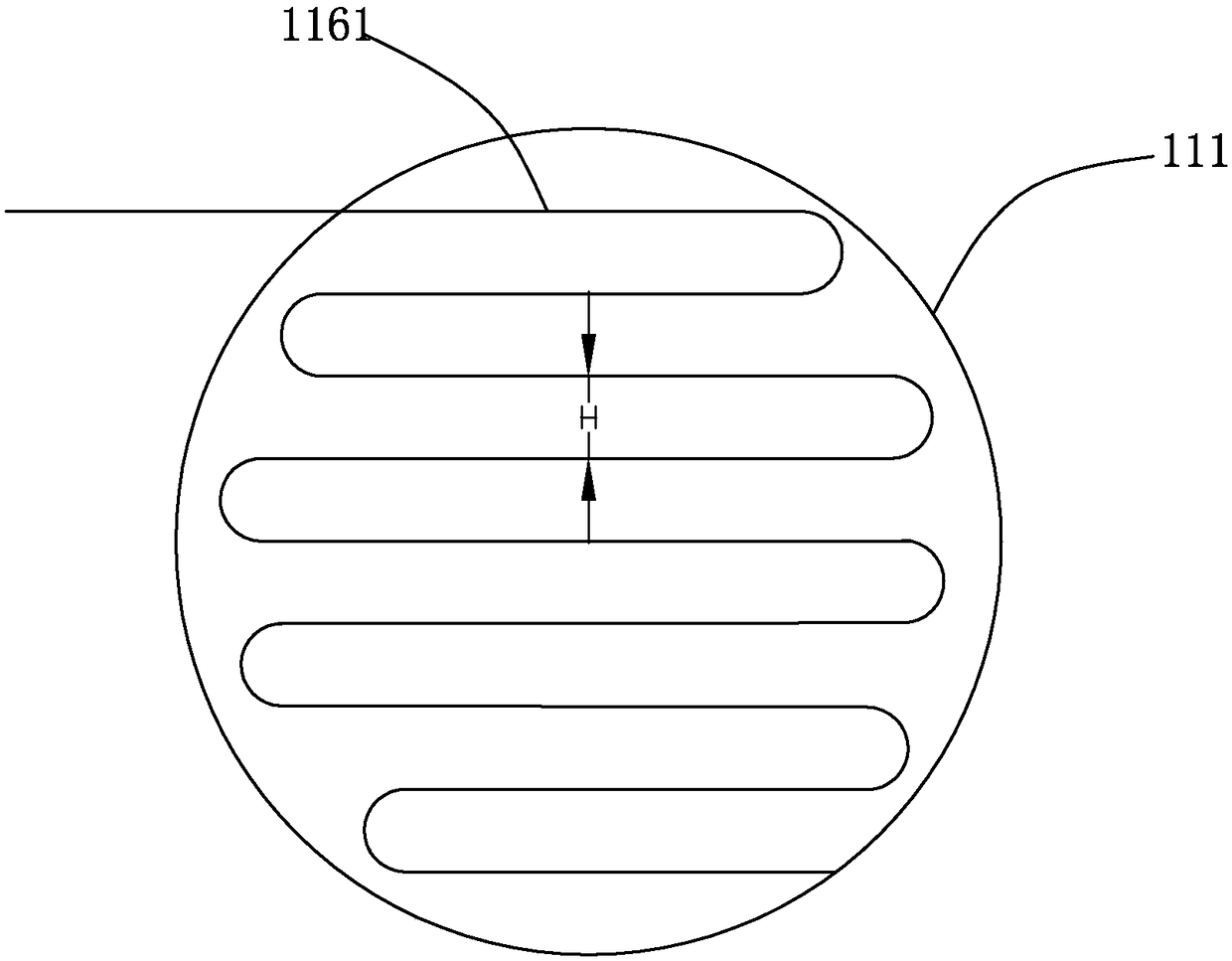

[0032] The working principle of the small domestic waste incineration and purification treatment system 100 provided by the present invention will be explained below by describin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com