Method for preparing epoxy resin base polyalcohol integral pole and special mold thereof

A technology of epoxy resin and monolithic column, which is applied in separation methods, chemical instruments and methods, and other chemical processes, and can solve the problems of loss of monolithic column, degraded column performance, difficulty in molecular/ion imprinting, etc., and avoid temperature interference , the reaction conditions are mild, and the effect of improving the preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

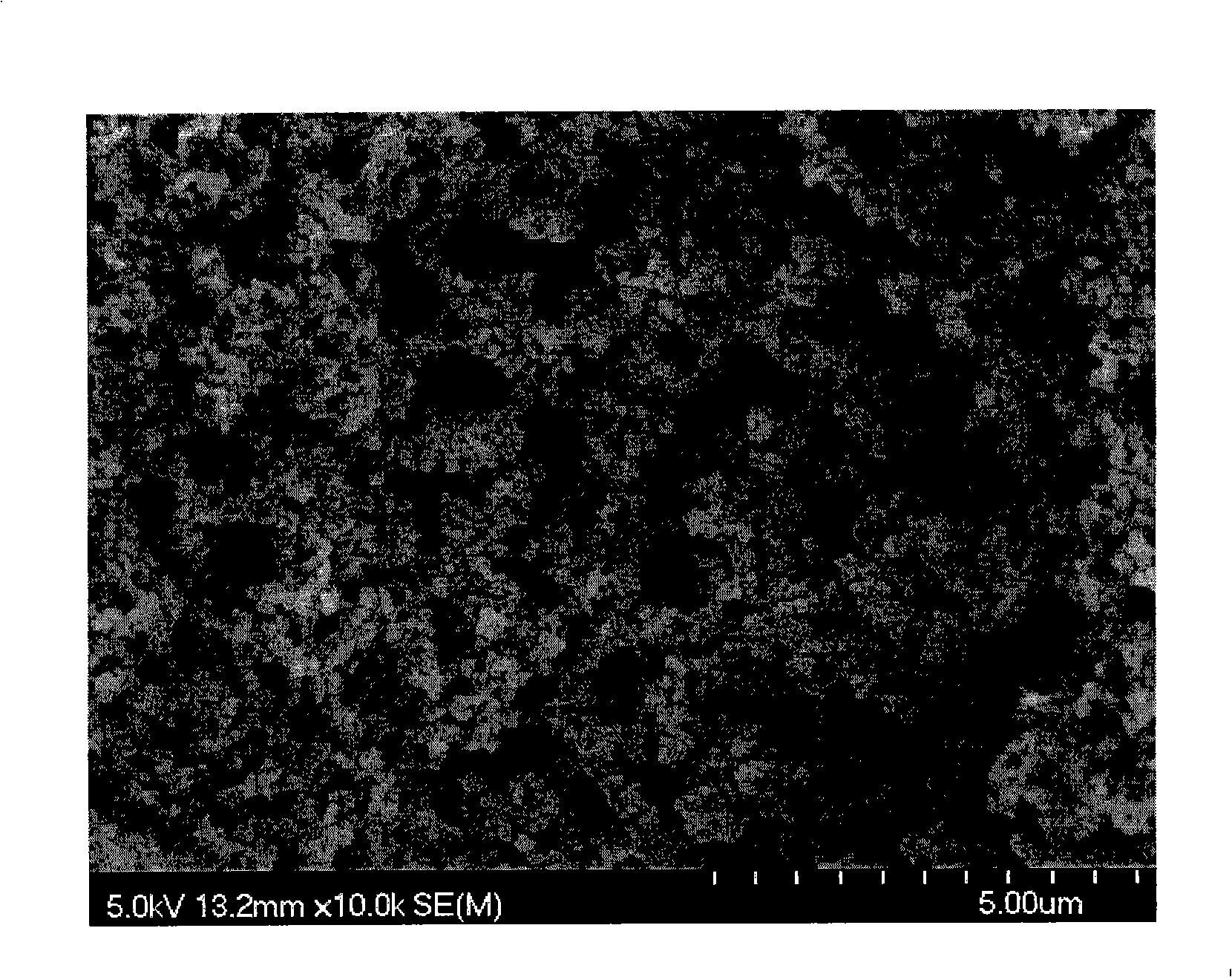

[0064] 10 grams of epoxy resin and 10 grams of polyamine-thiourea adduct (25°C intrinsic viscosity 8000mPas) are dissolved in 40 grams of mixed porogen (polyvinyl alcohol: polyvinylpyrrolidone=80:20) to obtain a clear viscosity The liquid is transferred into a glass tube with ID5cm*10cm, polymerized at 20°C for 10 minutes and gelled, 2 hours showing excellent curing performance, and fully cured after 100 hours (if you need to significantly reduce the time for complete curing, you can react in two After hours, the temperature is increased by more than 40°C), and finally the white solid is put into water to dissolve and remove the porogen to obtain a monolithic column. The average pore diameter is 1μm, the porosity is 75%, and the adsorption capacity of typical heavy metal ions: 210mg copper ion / g dry monolithic column, 380mg palladium ion / g dry monolithic column, and will not dissociate in the hydrochloric acid medium with pH>2 .

Embodiment 2

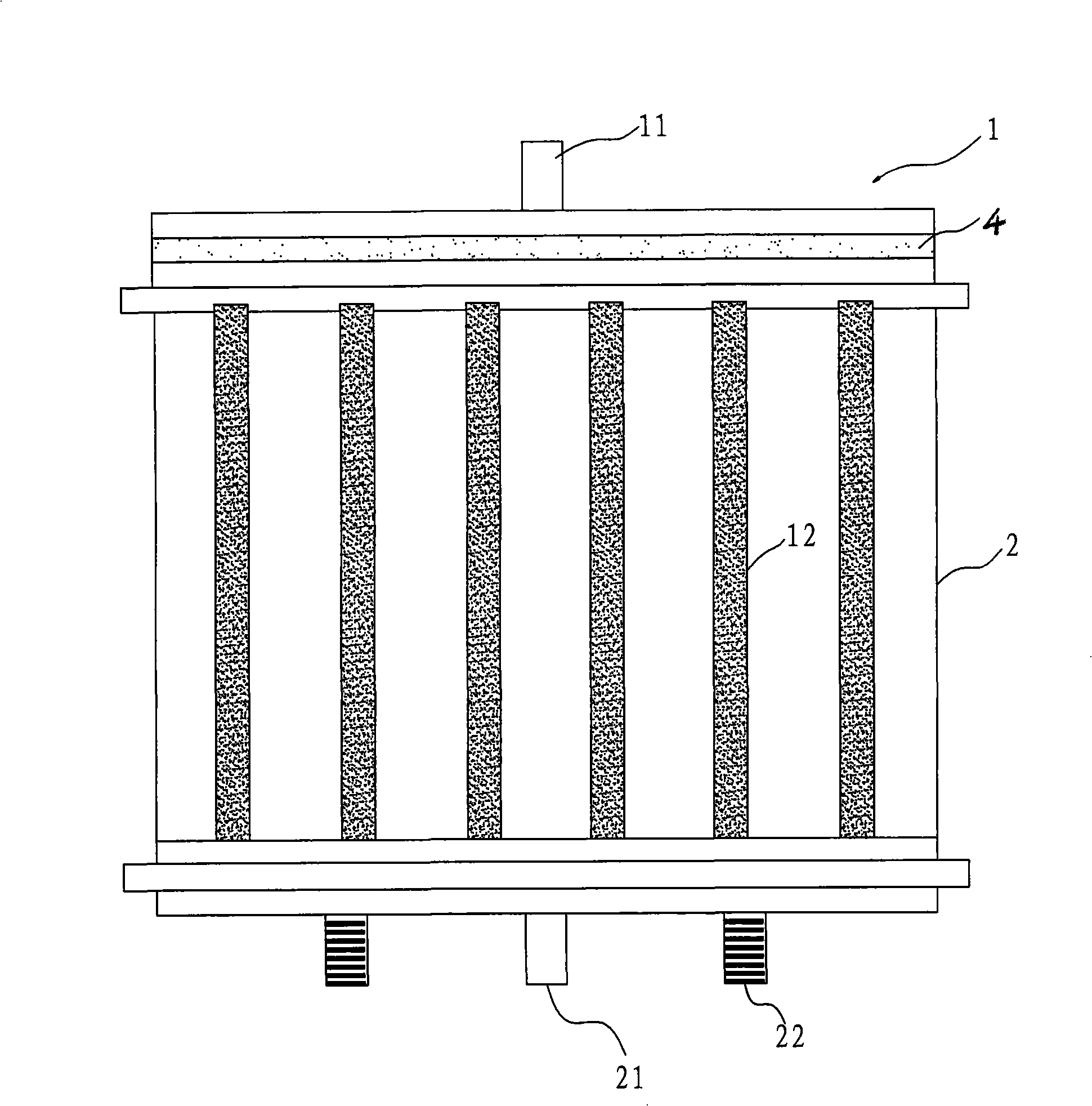

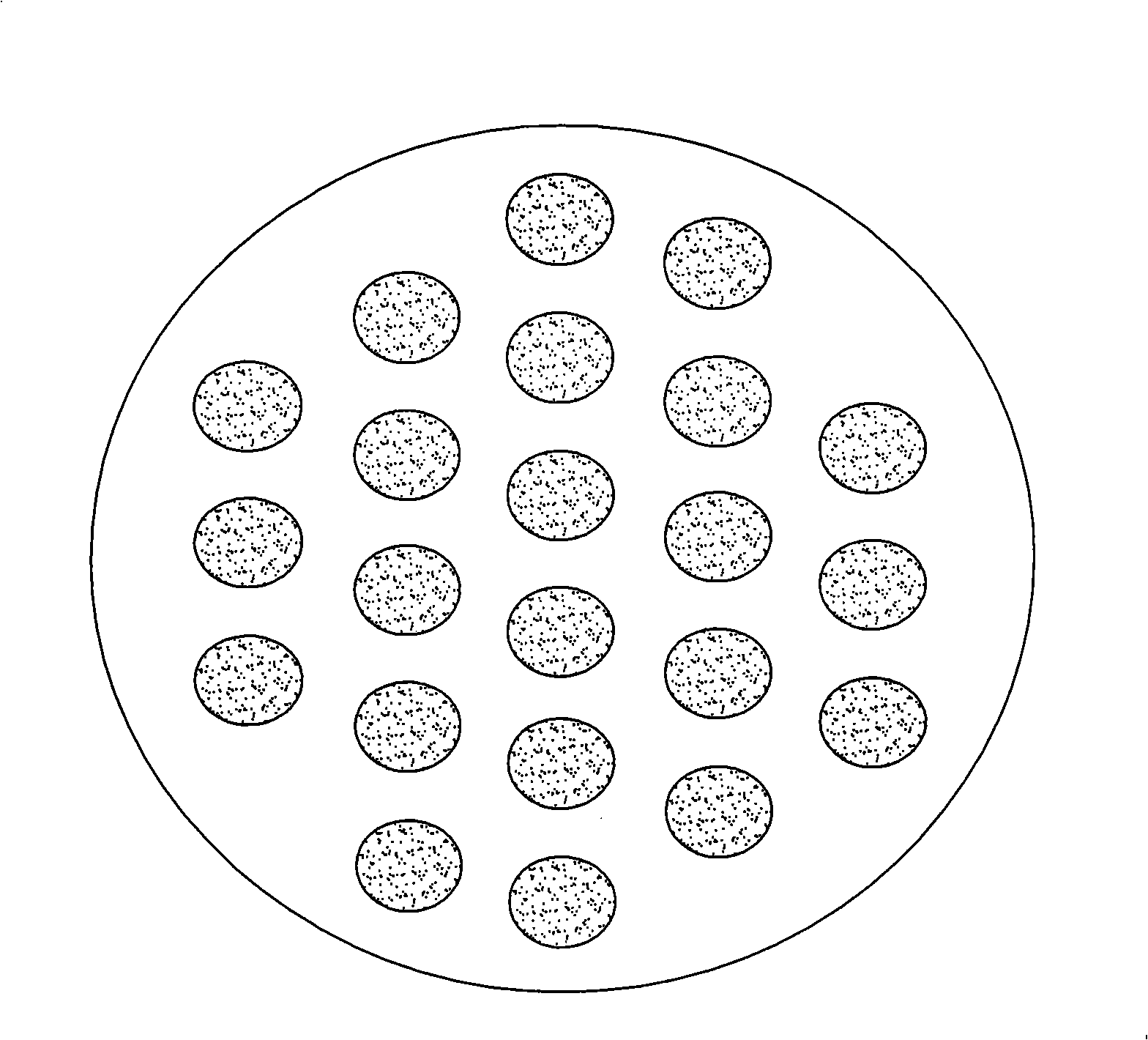

[0066] 20 grams of epoxy resin and 15 grams of polythiol (25°C intrinsic viscosity 10mPas, containing accelerator, sulfhydryl equivalent 230) are dissolved in 100 grams of mixed porogen (polyvinyl alcohol: polyvinylpyrrolidone = 90:10) to obtain Translucent viscous liquid, transferred to a customized stainless steel mold, gelatinized at 25°C for 5 minutes, and completely solidified after 6 hours. Finally, put the white solid into water, dissolve and remove the porogen, and get it in the mold The monolithic column.

Embodiment 3

[0068] According to the operating steps and experimental conditions given in Example 1, only the weight ratio of the mixed porogen in the system was changed to 30%, 50%, and 70% respectively, and the average pore diameter of the monolithic column was measured to be 0.3 respectively. μm, 0.9μm, 1.5μm, the increase of the porogen content leads to the increase of the average pore size, but the uniformity of the pore distribution is not affected by the sampling location.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com