Preparation method for nano-scale spinel nickel-doped lithium manganate material

A technology of spinel lithium manganese oxide and positive electrode materials, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., and can solve the problems of restricting the large-scale production of lithium manganate, long holding time, and harsh sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

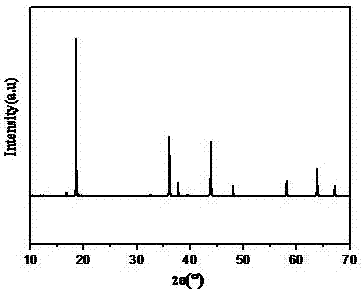

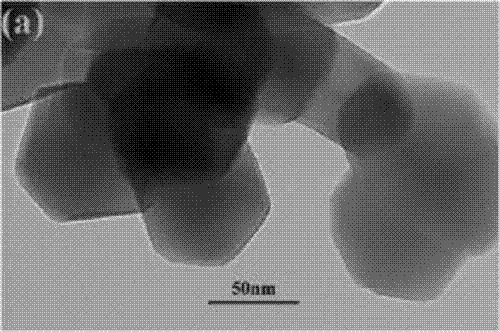

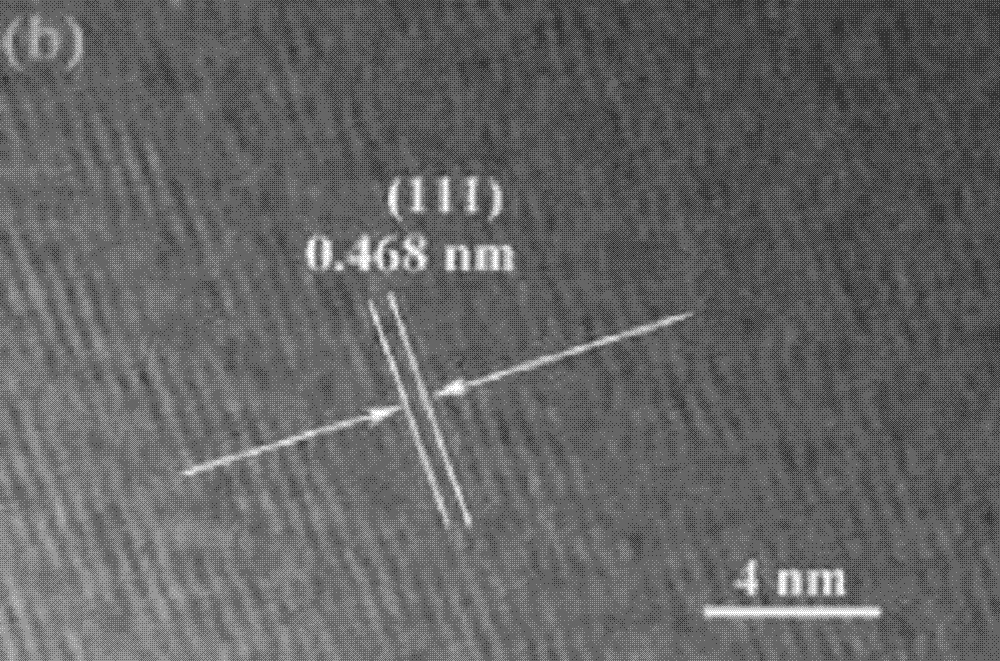

Image

Examples

Embodiment 1

[0027]According to the molar ratio of lithium, manganese and nickel ions is 1:1.92:0.08, accurately weigh 1.1427 g of solid salt lithium nitrate, 7.9215 g of manganese acetate and 0.2062 g of nickel acetate with the target product as 3 g in a beaker, and add 10 mL of distilled water to the beaker , heated and stirred at a constant temperature at 50°C to form a uniform mixed solution, then added 5 mL of 6 mol / L nitric acid solution dropwise under constant temperature and stirred to form a light red mixed solution, and kept warm for 10 minutes. Heat and stir the solution at a constant temperature of 100° C. to evaporate one-fifth of the total volume of the solution, and then transfer the mixed solution to a porcelain crucible. Move the porcelain crucible to a temperature-programmed box-type resistance furnace at 150°C, heat it for 5 minutes in an air atmosphere, then raise the temperature to 400°C at a rate of 20°C / min, heat and burn for 30 minutes in an air atmosphere, and final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com