Drag reducer, preparation method thereof and application of drag reducer

A drag reducer and initiator technology, which is applied in the field of drag reducer and preparation, can solve the problems of low dispersion ability and rheological performance, and achieve the effects of improving salt resistance, rheological performance, and dispersion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

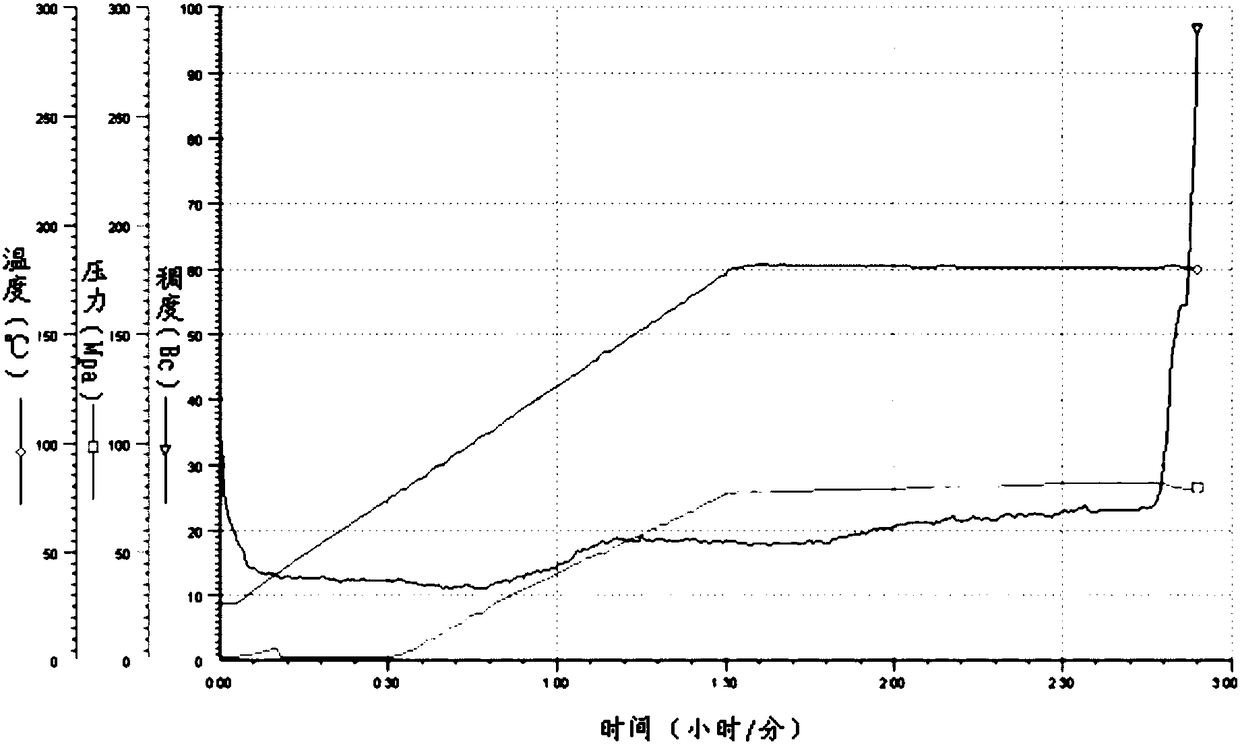

Image

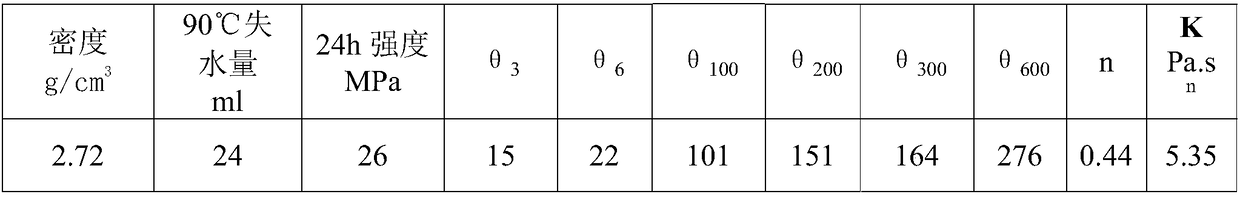

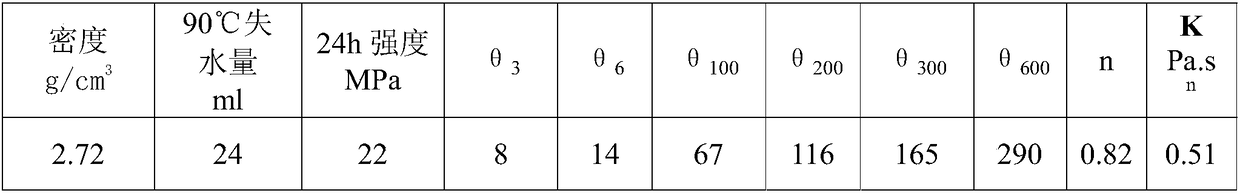

Examples

preparation example Construction

[0045] In a second aspect, a method for preparing a drag reducer is provided, the method comprising:

[0046]Add in sequence an unsaturated sulfonic acid monomer with a mass fraction of 10 to 60%, an unsaturated ester monomer with a mass fraction of 1 to 20%, a methacrylic acid monomer with a mass fraction of 1 to 15%, and a mass fraction of 10 to 30% of polyethylene glycol monomers containing saturated groups and 20% to 70% of polyethylene glycol monomers containing unsaturated groups in water (calculated based on the total mass of the monomers as 100%), stirred Until dissolved, adjust the pH to 1-9, place the system in a constant temperature water bath at 25°C and stir for half an hour, then raise the temperature to 55-95°C, add an initiator to react for 2-12 hours.

[0047] It should be noted that, in order to make each monomer more soluble in water, the above-mentioned unsaturated sulfonic acid monomers, unsaturated ester monomers, methacrylic acid monomers, polyethylene g...

Embodiment 1

[0072] This embodiment provides a drag reducer and a preparation method thereof.

[0073] Measure 400ml of water, add it into a four-necked bottle equipped with a stirrer and a thermometer, and add 20g of 2-acrylamido-2-methylpropanesulfonic acid, 10g of butyl methacrylate, 10 g of methacrylic acid, 20 g of methoxy polyethylene glycol (MPEG-600) and 40 g of allyl polyethylene glycol (APEG-2400) were stirred at room temperature until dissolved, and sodium hydroxide was added to adjust the pH to 4. Then put the four-necked bottle in a constant temperature water bath at 25°C and stir for half an hour, then raise the temperature of the water bath to 85°C, then add 0.25g of ammonium persulfate solution to the above mixture and react for 3 hours to obtain a drag reducer with a weight average molecular weight of 96,000 .

Embodiment 2

[0075] This embodiment provides a drag reducer and a preparation method thereof.

[0076] The difference between the preparation method of the drag reducer provided in this example and Example 1 is that the addition amount of 2-acrylamido-2-methylpropanesulfonic acid is 25g, the addition amount of butyl methacrylate is 8g, and the addition amount of allyl Base polyethylene glycol (APEG-2000) is 37g, obtains the drag reducer that weight average molecular weight is 85000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com