Preparation method of concrete anti-mud agent

A kind of anti-mud agent and concrete technology, which is applied in the preparation of concrete anti-mud agent and concrete admixture, to achieve the effects of significant steric hindrance effect, hindering adsorption and strong adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A method of preparing a concrete anti-laminator comprising the preparation of an organic amine initiator and the preparation of the anti-mud agents, the specific steps are as follows,

[0041] (1) Preparation of organic amine initiator

[0042] The glycidyl ether monomer, the secondary amine monomer, reacted under a certain temperature and pressure, and then continued to add an alcoholamine monomer, reacted under a certain temperature and pressure conditions to obtain an organic amine starting agent;

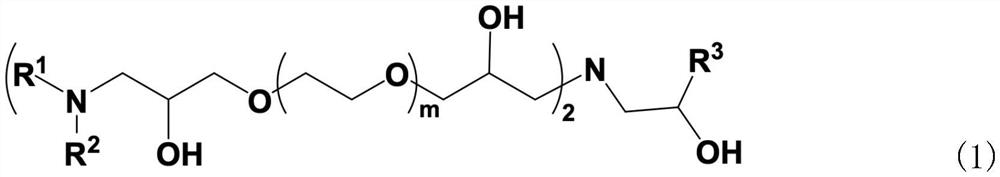

[0043] One of the structural formulas of the organic amine initiator in the above step (1) is shown in the formula (1),

[0044]

[0045] Among them, R 1 R 2 The alkyl group having a carbon atom of methyl, ethyl, butyl, n-hexyl, cyclohexyl group, between 1 to 10; R 3 One of the hydrogen and methyl; M is an integer between 0 to 10;

[0046] In the above steps (1), the structural formula is shown in the following formula (2),

[0047]

[0048] Among them, R 1 R 2 The number...

Embodiment 1

[0073] 100 parts (MW = 130) (MW = 130) were weighed, and the mixture was added 3 times, and 34.6 parts of dimethylamine (MW = 45) was added to 50 ° C (MW = 45), and the reaction temperature was controlled in the reaction temperature. 50 ° C, the reaction time was 3.0 h, the reaction pressure was the pressure generated by the reaction system itself, and the reaction was continued to be added to 23.5 parts (MW = 61), and the incubation continued to react 3.0 h, resulting in a yellowish yellow liquid, that is, the organic amine start The agent is named Q-1.

[0074] Similarly, the following organic amine starting agents were prepared for the synthesis of the amine polyether polyol.

[0075] Organine amine starter Q-2: 100 parts of ethylene glycol dihydrate (MW = 174), N-methylethylamine 33.9 parts (MW = 59), reaction temperature 60 ° C, time 2.0 h; dietholane 60.3 Series (MW = 105), the reaction temperature is 60 ° C, the reaction time is 2.0 h, named Q-2.

[0076] Organic amine star...

Embodiment 2

[0081] It is weighed with an organic amine starter Q-1100.0 parts, and 0.1 parts of catalyst sodium hydroxide, adding a sealed reaction kettle, replaced by nitrogen, and raised to 100 ° C, sequentially add 214.1 parts of ethylene oxide, 70.6 parts of propylene oxide, control. The reaction temperature is between 100 ° C to 130 ° C, the reaction pressure is between 0.0 mPa ~ 0.4 MPa, and the heat is continuously charged from 0.5 h to 1.0 h, cooling to 50 ° C, under -0.1 MPa conditions under reduced pressure distillation volatility The components gave a brown-yellow amine polyether polyol, and the polyether molecular weight was 1572.

[0082]103.6 parts of the iodide (MW = 141.9) were weighed, and the above reaction system was added, and the nitrogen was suppressed to 0.1 MPa, warmed to 60 ° C, and the insulation reaction was 10.0 h, and the volatile component was evaporated under -0.1 MPa. The chemical titration method test the quaternization rate of 93.4%, and the water was diluted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com