Polypyrrole modified magnetic kaolin nano composite material as well as preparation method and application thereof

A nanocomposite material, kaolin technology, applied in the field of polypyrrole modified magnetic kaolin nanocomposite material and its preparation, can solve the problems of low adsorption efficiency, limited material development space, weak adsorption performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

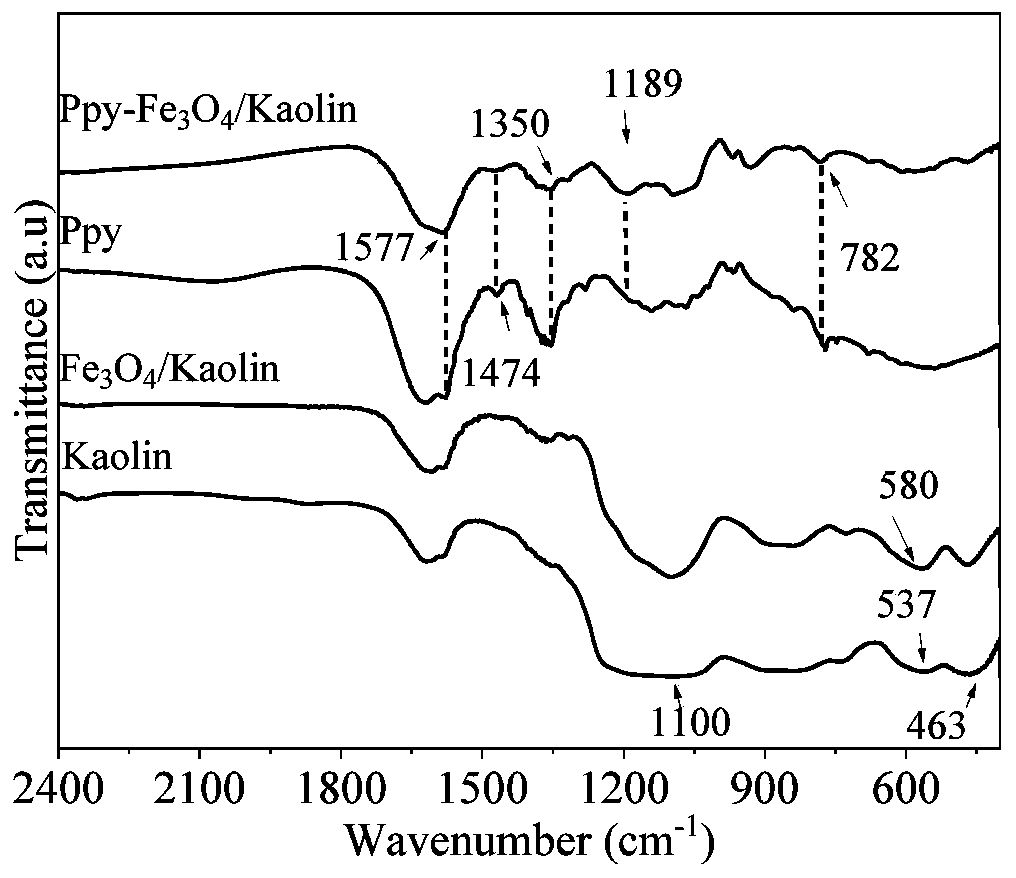

[0026] The invention provides a method for preparing a polypyrrole modified magnetic kaolin nanocomposite material, comprising the following steps:

[0027] mixing the first ferric chloride, sodium acetate, kaolin, polyether polyol and ethylene glycol, and performing a hydrothermal reaction to obtain magnetic kaolin;

[0028] The magnetic kaolin, sodium dodecylbenzene sulfonate, water, pyrrole and second ferric chloride are mixed, and after polymerization reaction, washing and drying are carried out in sequence to obtain the polypyrrole modified magnetic kaolin nanocomposite material.

[0029] In the present invention, unless otherwise specified, the raw materials used are conventional commercial products in the field or prepared by conventional methods in the field.

[0030] The invention mixes the first ferric chloride, sodium acetate, kaolin, polyether polyalcohol and ethylene glycol, and carries out hydrothermal reaction to obtain magnetic kaolin.

[0031] In the present ...

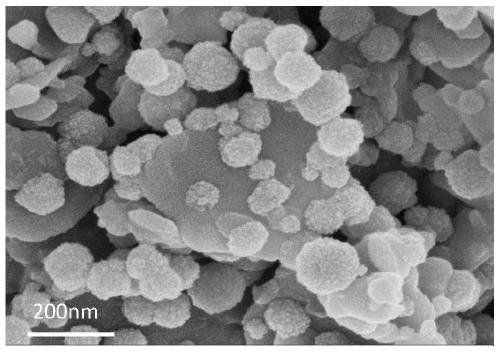

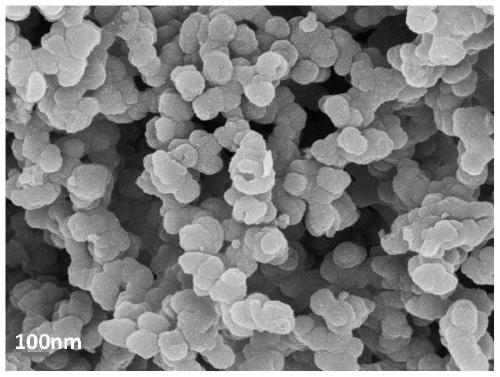

Embodiment 1

[0059] (1) Dissolve 3g of ferric chloride hexahydrate and 2g of sodium acetate in 100mL of ethylene glycol and stir until uniform to obtain the first mixed solution; 2g of kaolin and 2g of polyethylene glycol are added to the mixed solution and ultrasonicated for 2 hours. Move it to a reaction kettle for 6 hours at 150°C, wash the obtained product and dry it at 60°C to obtain magnetic kaolin powder;

[0060] (2) Dissolve 0.15 g of magnetic kaolin powder and 0.025 g of sodium dodecylbenzenesulfonate in 50 mL of pure water, ultrasonicate for 30 min and mechanically stir for 30 min, then add 0.25 mL of pyrrole to obtain a second mixed solution.

[0061] (3) Weigh 3g of ferric chloride hexahydrate and dissolve it in 10mL of pure water, sonicate until it is completely dissolved, slowly add it dropwise into the second mixed solution at a dropping rate of 1mL / s, and continue to react with mechanical stirring for 4h. Washing, drying at 60°C, the product polypyrrole modified magnetic k...

Embodiment 2

[0067] (1) Dissolve 6g of ferric chloride hexahydrate and 5g of sodium acetate in 150mL of ethylene glycol and stir until uniform to obtain the first mixed solution; 3g of kaolin and 3g of polypropylene glycol are added to the mixed solution, ultrasonicated for 2h, and transferred to React in a reaction kettle at 200°C for 6h, wash the obtained product and dry at 50°C to obtain magnetic kaolin powder;

[0068] (2) Dissolve 0.15 g of magnetic kaolin powder and 0.035 g of sodium dodecylbenzenesulfonate in 100 mL of pure water, ultrasonicate for 30 min and mechanically stir for 30 min, then add 0.5 mL of pyrrole to obtain a second mixed solution.

[0069] (3) Weigh 6g of ferric chloride hexahydrate and dissolve it in 25mL of pure water, sonicate until it is completely dissolved, slowly add it dropwise into the second mixed solution at a dropping rate of 1mL / s, and continue to react with mechanical stirring for 6h. Wash and dry at 50°C to obtain the product polypyrrole modified ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com