Cross-linked electrolyte membrane and preparation method thereof

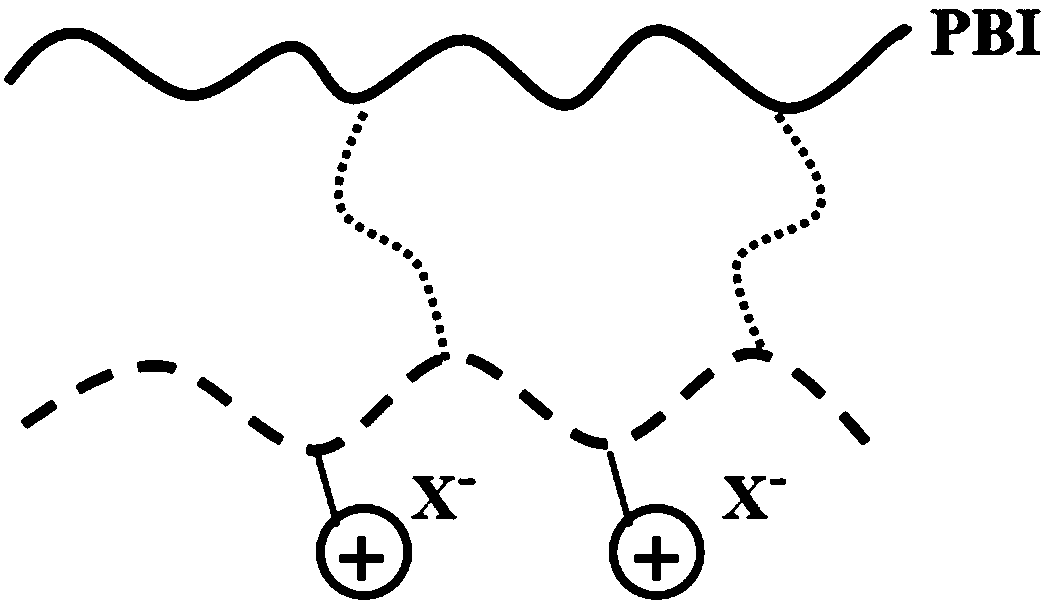

An electrolyte membrane and cross-linked technology, which is applied in the field of preparation of cross-linked high-temperature polymer electrolyte membranes, can solve the problems of battery performance degradation, increase in battery ohmic polarization, weak force, etc., to improve mechanical properties and increase bonding The effect of energy and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Dissolve 0.2g of chloromethylated polysulfone in 3.9mL of dimethylacetamide, add 0.04g of trimethylamine ethanol solution, and stir at 40°C for 4h. At the same time, 0.26 g of mPBI was dissolved in 3 mL of dimethylacetamide. Then add the quaternized ammonium salted polysulfone solution prepared above into the mPBI solution while stirring, stir for 30 minutes, after vacuum degassing, pour it on a glass plate, dry in an oven at 40°C for 40min, at 80°C for 10h, and at 130°C Dry for 4h. After returning to room temperature, place it in water for demoulding. Wash thoroughly with boiled deionized water, dry, and then soak in 85% phosphoric acid at room temperature for 8 hours. The acid doping amount of this type of film is about 500%. Perform mechanical properties and electrical conductivity tests.

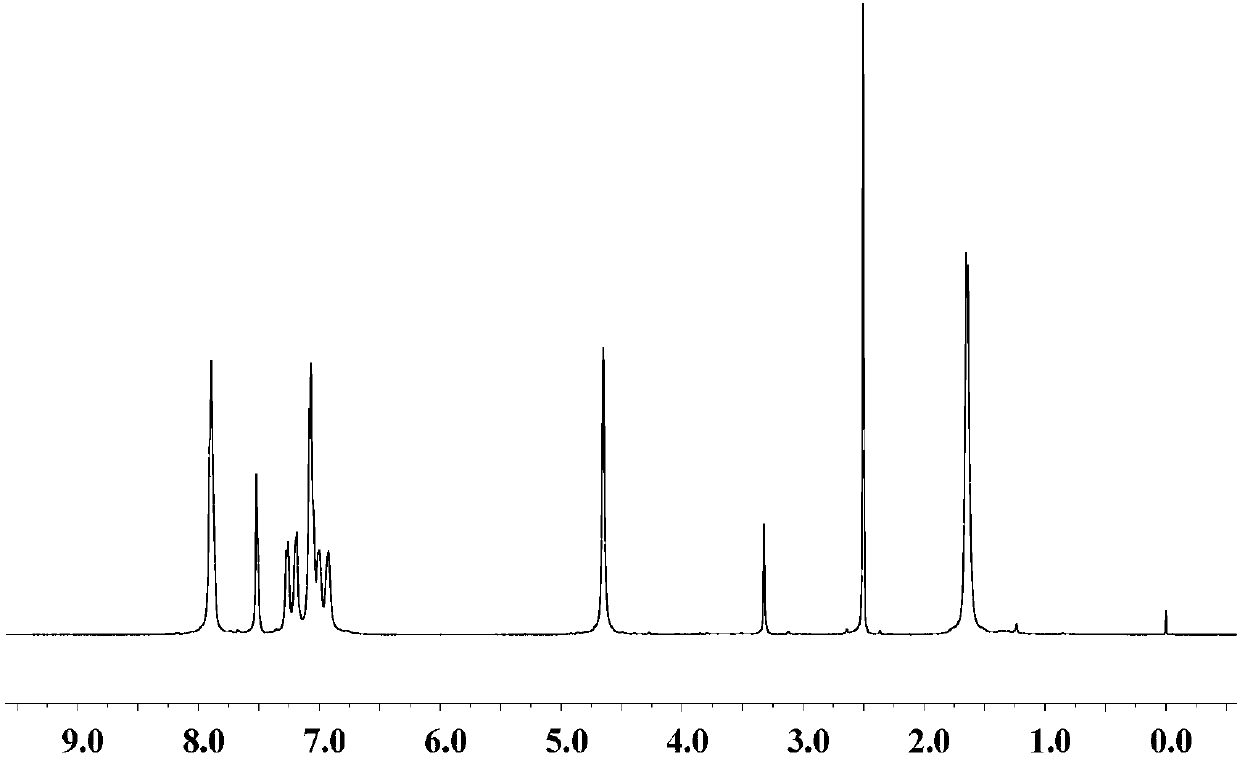

[0030] The electrical conductivity of the cross-linked high-temperature film prepared above was tested by AC impedance method.

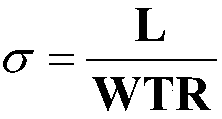

[0031] The formula for calculating conductivit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com