Method for preparing starch-based high-performance water reducing agent and product thereof

A starch-based, high-performance technology, which is applied in the field of concrete admixtures, to achieve the effects of improving concrete workability, good steric hindrance effect, and reducing segregation and bleeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

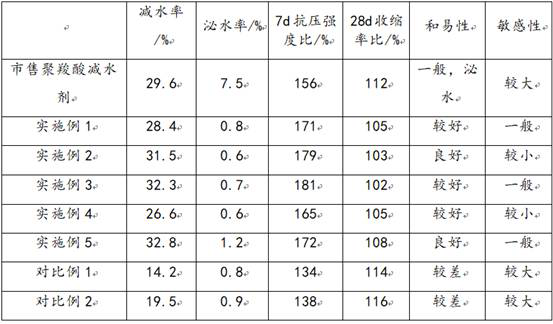

Examples

preparation example Construction

[0039] The preparation of the starch-based high-performance water reducer comprises the following steps:

[0040] Preparation of controllable acid-degradable starch raw material: using water as the reaction medium, making starch into a starch mixture with a mass percentage of 20% to 90%, adding an acidolysis catalyst and an oxidant to react to obtain a controllable acid-degradable starch raw material; preferably, The starch is one or more of corn starch, tapioca starch, sweet potato starch, potato starch, wheat starch, bean starch or modified starch; in addition, the acidolysis catalyst is sulfuric acid, nitric acid, sodium bisulfate, One or more of sulfamic acid or p-toluenesulfonic acid in an amount of 1% to 15% of the starch quality; and the oxidizing agent is potassium permanganate, hydrogen peroxide, ammonium persulfate, potassium persulfate or high One or more kinds of iodic acids are used in an amount of 1% to 10% of the starch mass.

[0041] Preparation of starch-base...

Embodiment 1

[0050] The embodiment of the present invention provides a starch-based functional macromonomer and a method for preparing a starch-based high-performance water reducer. The specific steps are as follows:

[0051] (1) Weigh 40g of cornstarch and 60g of water to make a 40% starch mixture, slowly add 1.2g of sulfuric acid and stir evenly, heat up to 60°C for 6 hours, then add 3.4g of hydrogen peroxide and mix well, vacuum at 55°C Drying for 2 hours and reacting at 110°C for 2 hours to obtain controllable acid-degraded starch (weight average molecular weight Mw is 2500-17800).

[0052] (2) Add 40g of controllable acid-degraded starch and 3.6g of methacrylic acid into the reactor, add 0.6g of p-toluenesulfonic acid and 0.05g of methylaniline, stir and heat to 120°C for esterification reaction, react for 3 hours, and prepare Obtain starch-based functional macromonomers (weight-average molecular weight Mw is 2800-19200, wherein the proportion of starch-based functional macromonomers ...

Embodiment 2

[0055] The embodiment of the present invention provides a starch-based functional macromonomer and a method for preparing a starch-based high-performance water reducer. The specific steps are as follows:

[0056](1) Weigh 35g of cornstarch, 15g of potato starch and 50g of water to make a 50% starch mixture, slowly add 1.2g of sulfuric acid and stir evenly, heat up to 60°C for 8 hours, then add 5.6g of hydrogen peroxide and mix well, Vacuum drying at 55°C for 2 hours, and reaction at 115°C for 2 hours to obtain controllable acid-degraded starch (weight-average molecular weight Mw: 2680-17400).

[0057] (2) Add 50g of controllable acid-degraded starch and 3g of maleic anhydride into the reactor, add 0.7g of p-toluenesulfonic acid and 0.03g of tert-butylcatechol, stir and heat to 115°C for esterification reaction, and react for 4h. The obtained starch-based functional macromonomer (the weight-average molecular weight Mw is 3150-18820, wherein the proportion of the starch-based fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| water reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com