Method for synthesizing composite modified starch slurry

A compound modified starch and synthetic method technology, which is applied in fiber types, textiles and papermaking, fiber treatment, etc., can solve the problems of high molecular weight, poor adhesion performance of starch size film, and difficulty in chain segment movement, so as to improve adhesion Performance, improvement of serous film performance, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

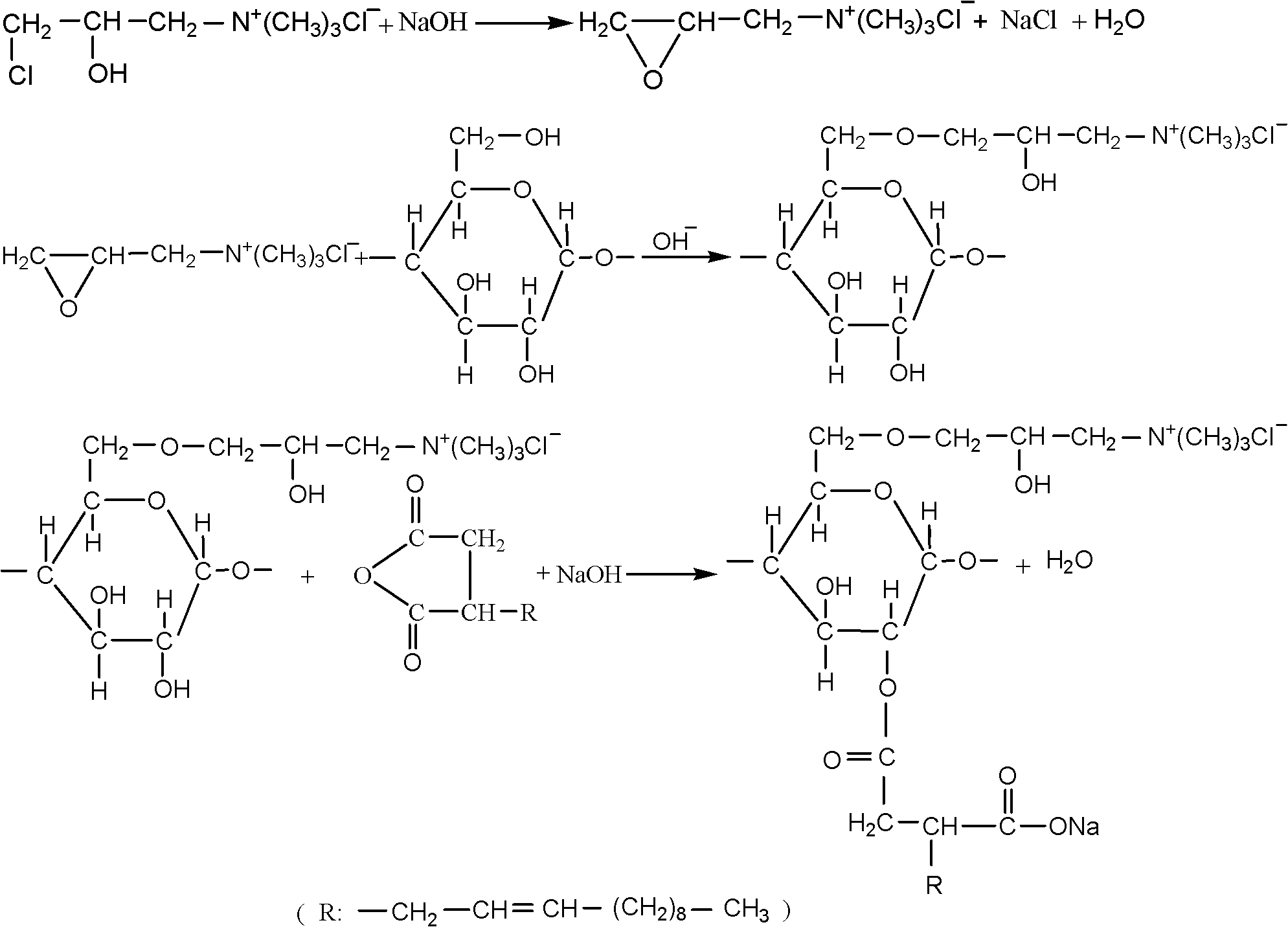

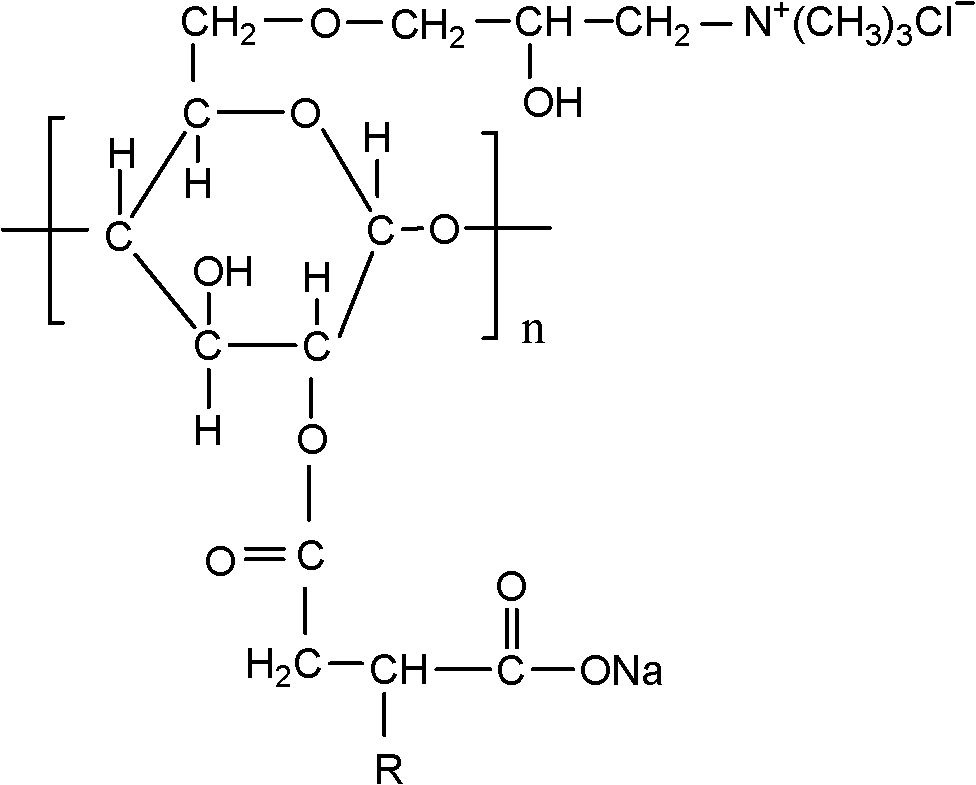

Method used

Image

Examples

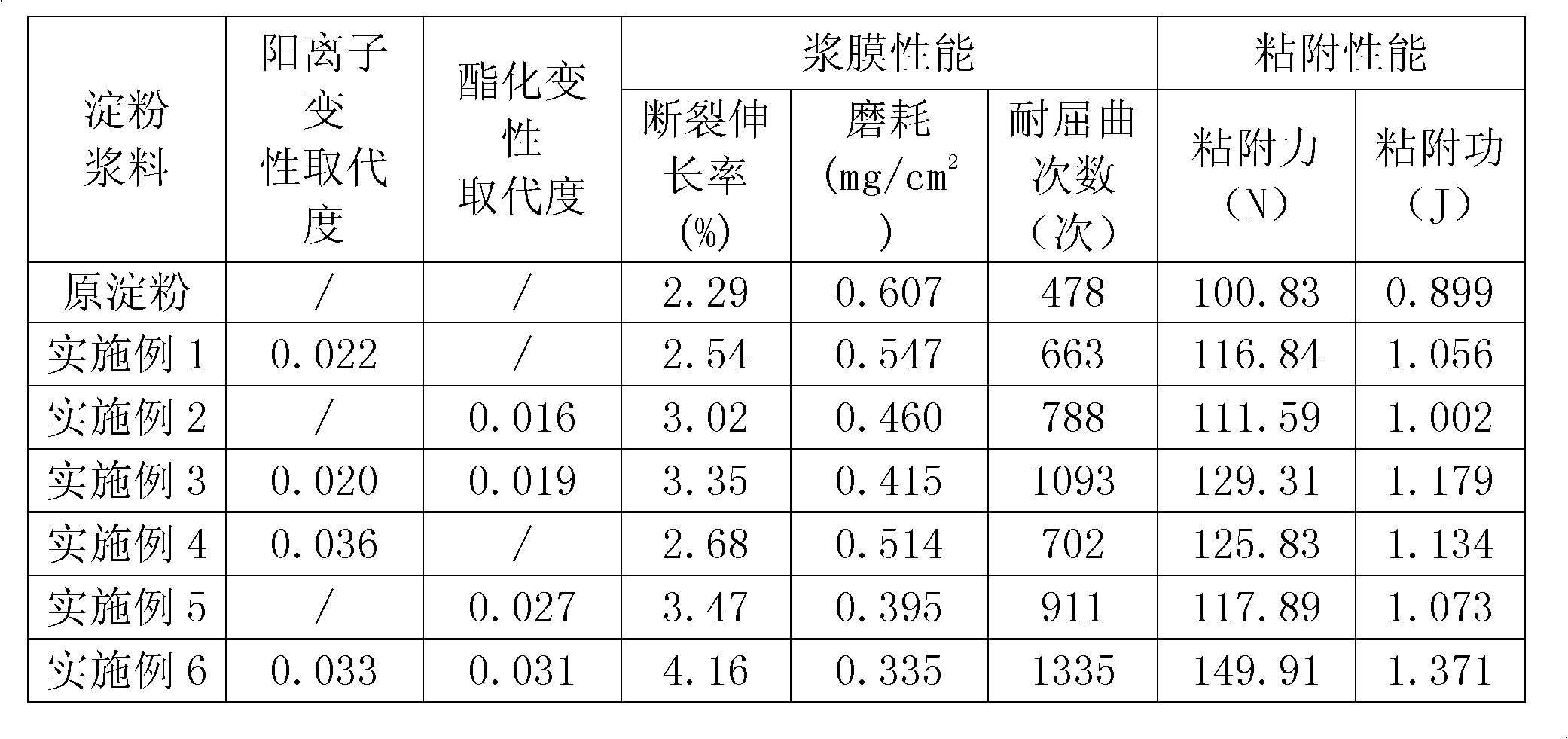

Embodiment 1

[0026] Take by weighing 300 grams of cornstarch (dry weight), add water to make a starch milk with a concentration of 40%, then transfer the starch milk into a 1000mL four-necked flask, install a stirring device, and then place the temperature in a water bath to 50°C. Use 3% sodium hydroxide solution to maintain system pH=11~11.5, slowly add a concentration of 50% aqueous solution containing 12 grams of cationic etherification agent 3-chloro-2-hydroxypropyltrimethylammonium chloride under stirring, and react 6 After one hour, neutralize with 3% hydrochloric acid solution to pH=6.5-7; the product is filtered, washed with water three times, dried at 45°C to constant weight, crushed and sieved to synthesize cationic starch. The cationic denaturation degree of substitution of the product is DS=0.022, and the properties of the size film and the adhesion properties to polyester fibers are shown in Attached Table 1.

Embodiment 2

[0028] Take by weighing 100 grams of cornstarch (dry weight), add water to make concentration of 40% starch milk, then transfer the starch milk into a 500mL four-necked flask, install a stirring device, then place the temperature in a water bath to 35°C, Use 3% sodium hydroxide solution to maintain the pH of the system=8.5~9, slowly add dropwise under stirring an absolute ethanol solution with a volume concentration of 25% containing 4 grams of dodecenyl succinic anhydride, and react with 3% hydrochloric acid after 7 hours The solution is neutralized to pH=6.5-7; the product is filtered, washed three times with 70% ethanol aqueous solution, dried at 45°C to constant weight, crushed and sieved to synthesize starch dodecenyl succinate. The esterification denaturation substitution degree of the product is DS=0.016, and the size film properties and adhesion properties to polyester fibers are shown in Attached Table 1.

Embodiment 3

[0030]Take by weighing 300 grams of cornstarch (dry weight), add water to make a starch milk with a concentration of 40%, then transfer the starch milk into a 1000mL four-necked flask, install a stirring device, and then place the temperature in a water bath to 50°C. Use 3% sodium hydroxide solution to maintain system pH=11~11.5, slowly add a concentration of 50% aqueous solution containing 12 grams of cationic etherification agent 3-chloro-2-hydroxypropyltrimethylammonium chloride under stirring, and react 6 After one hour, neutralize with 3% hydrochloric acid solution to pH=6.5-7; the product is filtered, washed with water three times, dried at 45°C to constant weight, crushed and sieved to synthesize cationic starch. Take by weighing 100 grams (dry weight) of cationic starch synthesized, add water to make concentration of 40% starch milk, then transfer the starch milk into a 500mL four-necked flask, install a stirring device, then place the temperature in a water bath and he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com