Thermal paper manufacturing method capable of preventing mechanical pulp/ chemical mechanical pulp thermal paper from fading

A manufacturing method and technology of thermal paper, applied in paper, papermaking, paper coating, etc., can solve the problems of thermal image fading and acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

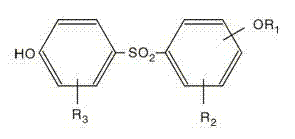

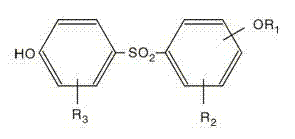

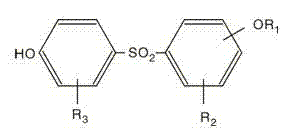

[0016] Example 1 : A manufacturing method of thermal paper capable of preventing thermal paper containing mechanical pulp / chemical mechanical pulp from fading, using 2,4-bis(benzenesulfonyl)phenol as a color developer, and adopting a factory to produce wood pulp containing CTMP 30 %, 50g / ㎡ base paper made of 70% chemical wood pulp.

[0017] The formula and preparation method of pre-coating:

[0018] components number of copies Calcined kaolin 55 Organic hollow pigment 25 Carboxylated styrene-butadiene latex 7 Oxidized starch 7 Auxiliary 6

[0019] Among them, the auxiliary agent is a dispersant, etc., add water to the above components to prepare a coating dispersion with a solid content of 40%, and use a scraper for mixing and stirring to coat the base paper at a coating amount of 5-6g / ㎡, dry it with hot air, press Light spare.

[0020] The preparation of heat-sensitive paint: Amix: Bmix: Cmix=1:2:5.

[0021] Among them, Amix ...

Embodiment 2

[0031] Example 2: A method for manufacturing heat-sensitive paper capable of preventing heat-sensitive paper containing mechanical pulp / chemical-mechanical pulp from fading, using 2,4-bisphenol S as a color developer.

[0032] Except that 2,4-bis(benzenesulfonyl)phenol in Bmix was replaced with 2,4-bisphenol S as the developer, the rest were prepared according to Example 1 to prepare thermal paper for testing.

Embodiment 3

[0033] Example 3: A method for manufacturing heat-sensitive paper capable of preventing fading of heat-sensitive paper containing mechanical pulp / chemical-mechanical pulp, using 3,3-diallyl 4,4'-dihydroxyphenyl sulfone as a color developer.

[0034] Except that the 2,4-bis(benzenesulfonyl)phenol in Bmix was replaced with 3,3-diallyl 4,4`-dihydroxyphenyl sulfone as the color developer, the rest were prepared according to Example 1. Thermal paper, to be tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com