Vinyl-terminated hyperbranched polymer, viscosity-reducing type polycarboxylic acid water reducing agent with hyperbranched structure and preparation methods of vinyl-terminated hyperbranched polymer and viscosity-reducing type polycarboxylic acid water reducing agent

A technology of hyperbranched polymer and vinyl end capping is applied in the field of hyperbranched polymer and concrete admixture, which can solve the problems of high viscosity of concrete and large amount of water reducing agent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

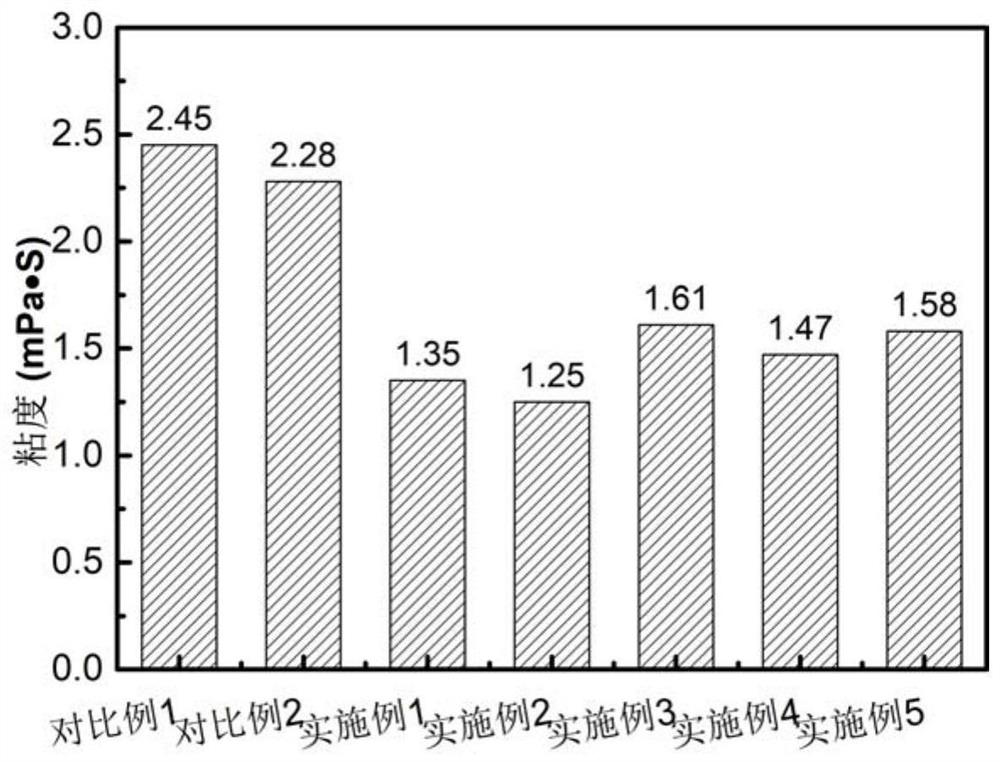

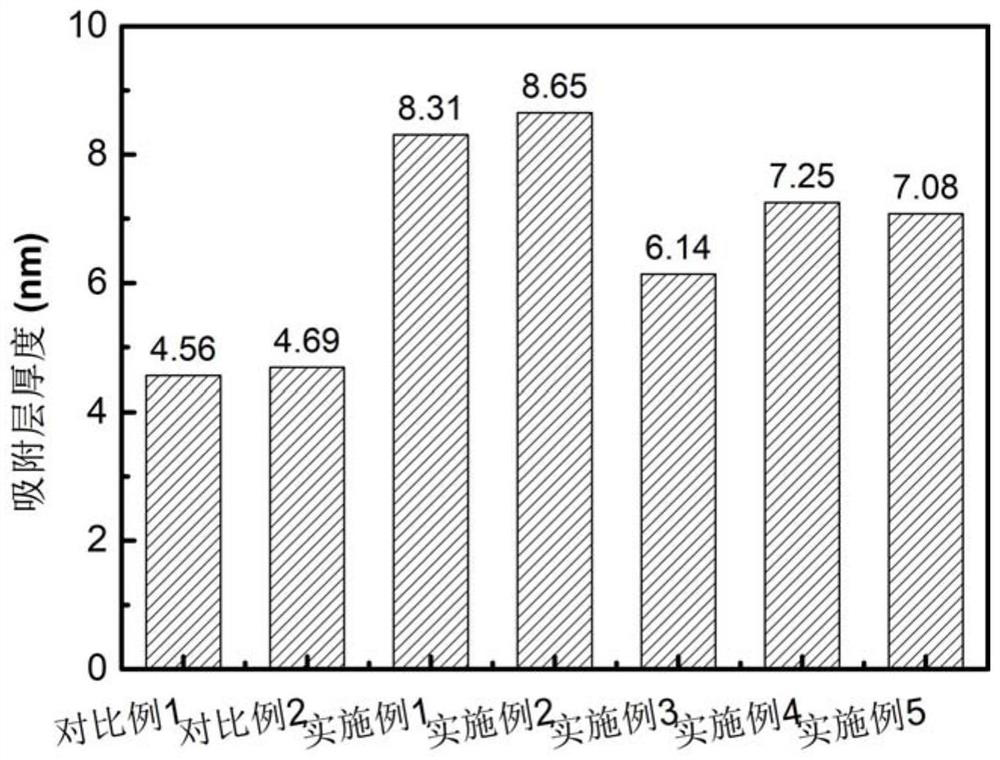

[0055] This example provides a preparation method of a viscosity-reducing polycarboxylate water reducer with a hyperbranched structure, including the following raw materials in mass percentages: 10% unsaturated carboxylic acid, 1.3% unsaturated anhydride, 86.7% unsaturated polyether, 0.4% of unsaturated phosphate ester, 1% of hyperbranched functional monomer, 0.2% of initiator, 0.4% of chain transfer agent, the total is 100%. Specific steps are as follows:

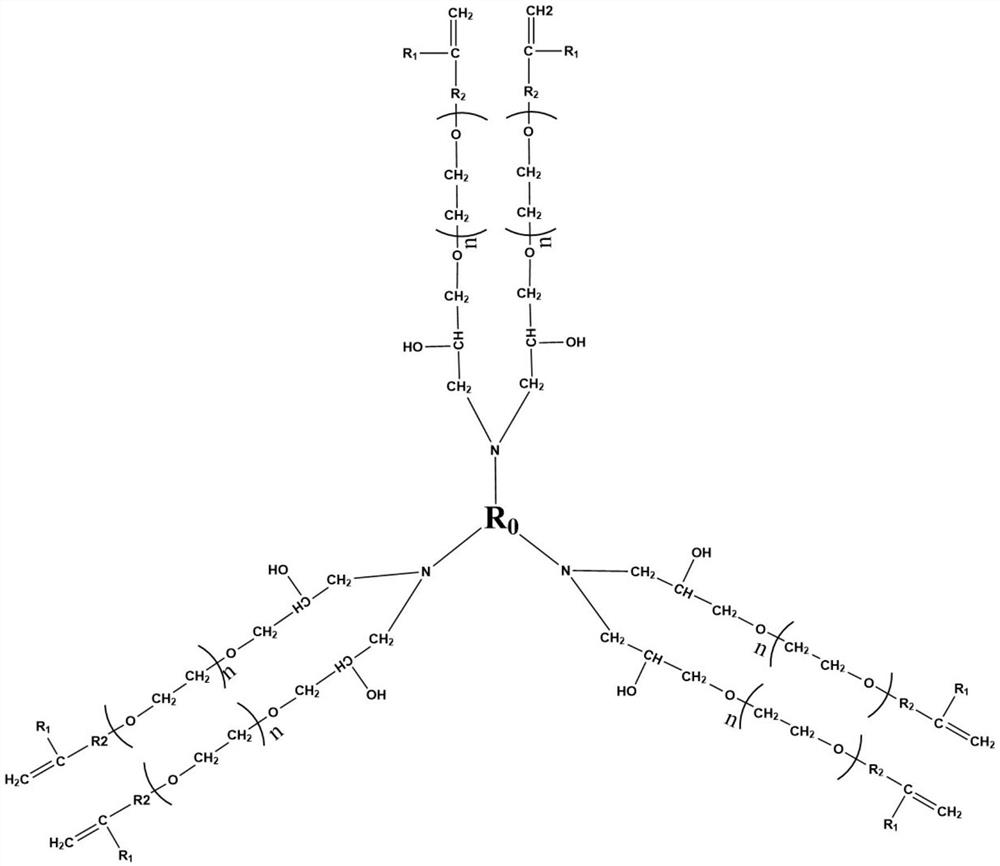

[0056] S1, preparation of vinyl-terminated hyperbranched polymer-functional monomer:

[0057] S1.1, after adding the monomer containing primary amino groups (specifically melamine, 0.5mol), the catalyst (specifically triethylbenzyl ammonium chloride) and the aprotic polar solvent (specifically toluene) into the reactor , heat up to 90°C, add epichlorohydrin dissolved in ethanol dropwise within 1 hour, keep warm for 3 hours after dropwise addition, cool down to room temperature and add solid alkali in four batches in equal...

Embodiment 2

[0069] This example provides a preparation method of a viscosity-reducing polycarboxylate superplasticizer with a hyperbranched structure, including the following raw materials in mass percentages: 7% of unsaturated carboxylic acid, 1% of unsaturated anhydride, 88.5% of unsaturated polyether, 0.5% of unsaturated phosphoric acid ester, 2% of hyperbranched functional monomer, 0.4% of initiator, and 0.6% of chain transfer agent are 100% in total. Specific steps are as follows:

[0070] S1: take by weighing 310g molecular weight 2400 isopentenol polyoxyethylene ether, 3.5g maleic anhydride, 7.0g vinyl-terminated hyperbranched functional monomer (made by S1 in embodiment 1) and 300g deionized water and join in In the reactor, stir and dissolve to obtain the bottom material;

[0071] S2: Take by weighing 21.5g acrylic acid, 3g methacrylic acid, 1.75g methacrylate-2-hydroxyethyl phosphate and 2.1g chain transfer agent mercaptoethanol, dissolve in 30g water to obtain solution A; we...

Embodiment 3

[0076] This example provides a preparation method of a viscosity-reducing polycarboxylate water reducer with a hyperbranched structure, including the following raw materials in mass percentages: 6.0% of unsaturated carboxylic acid, 1.3% of unsaturated anhydride, 89.3% of unsaturated polyether, 0.6% of unsaturated phosphoric acid ester, 1.4% of hyperbranched functional monomer, 0.6% of initiator, and 0.8% of chain transfer agent are 100% in total. Specific steps are as follows:

[0077] S1: Weigh methallyl alcohol polyoxyethylene ether of 313g molecular weight 2400, 4.55g maleic anhydride, 4.9 g vinyl-terminated hyperbranched functional monomer (made by S1 in embodiment 1) and 300g deionized water and add into the reactor, stirring and dissolving to obtain the bottom material;

[0078] S2: Take 21g acrylic acid, 2.1g methacrylic acid-2-hydroxyethyl phosphate and 2.8g chain transfer agent mercaptoethanol, dissolve in 30g water to obtain solution A; weigh 1.6g ammonium persulfat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com