Polyurethane caulk compound for high-speed railway and preparation method for polyurethane caulk compound

A high-speed railway and polyurethane technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems that it is difficult to meet the long service life of caulking materials, and avoid water absorption cracking and low temperature embrittlement , high strength, good flexibility and elongation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

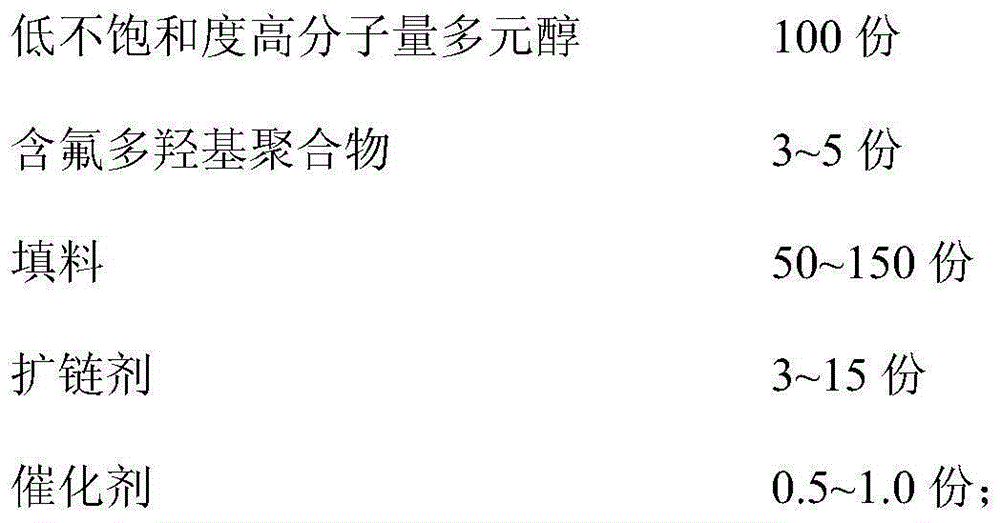

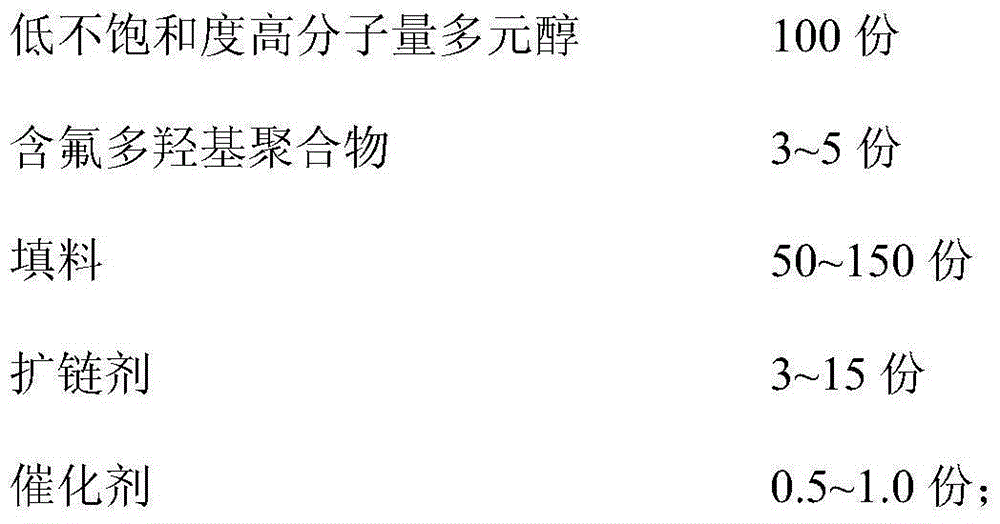

[0032] The polyurethane caulk of the present invention consists of two components, A and B.

[0033] Preparation of Component A: Add 100 parts of low unsaturation and high molecular weight polyether polyol into the reactor, stir, heat up to 110°C, vacuum dehydrate for 2 hours, cool down to below 60°C, add 25 parts of diphenylmethane For diisocyanate (MDI), heat up to 75°C and react for 2-3h. When the NCO content of the measurement system reaches a predetermined value, the reaction is stopped. After the reaction is completed, the temperature is lowered and vacuum defoamed for 30 minutes, and the material is discharged to obtain a polyurethane prepolymer, which is the A component.

[0034] Preparation of component B: 100 parts of low unsaturation and high molecular weight polyether polyol, 3 parts of fluorine-containing polyol, chain extender 3,3'-dichloro-4,4'- 12 parts of diamino-diphenylmethane, filler, stir and disperse evenly, heat to 110°C, and vacuum dehydrate for 1 hou...

Embodiment 2

[0040] The polyurethane caulk of the present invention consists of two components, A and B.

[0041]Preparation of component A: Add 20 parts of polycaprolactone diol and 80 parts of polyether polyol with low unsaturation and high molecular weight into the reaction kettle, stir, raise the temperature to 110°C, vacuum dehydrate for 2 hours, and cool down to below 60°C. Add 30 parts of toluene diisocyanate (TDI), raise the temperature to 80°C, and react for 2-3 hours. When the NCO content of the measurement system reaches a predetermined value, the reaction is stopped. After the reaction is completed, the temperature is lowered and vacuum defoamed for 30 minutes, and the material is discharged to obtain a polyurethane prepolymer, which is the A component.

[0042] Preparation of component B: 100 parts of low unsaturation and high molecular weight polyether polyol, 5 parts of fluorine-containing polyol, chain extender 3,3'-dichloro-4,4'- 8 parts of diamino-diphenylmethane, fille...

Embodiment 3

[0048] The polyurethane caulk of the present invention consists of two components, A and B.

[0049] Preparation of component A: Add 12 parts of polycarbonate diol and 88 parts of polyether polyol with low unsaturation and high molecular weight into the reaction kettle, stir, heat up to 110°C, vacuum dehydrate for 2 hours, cool down to below 60°C, add 30 parts of diphenylmethane diisocyanate (MDI), heated to 75°C, reacted for 2-3 hours. When the NCO content of the measurement system reaches a predetermined value, the reaction is stopped. After the reaction is completed, the temperature is lowered and vacuum defoamed for 30 minutes, and the material is discharged to obtain a polyurethane prepolymer, which is the A component.

[0050] Preparation of component B: Add 100 parts of low unsaturation and high molecular weight polyether polyol, 4 parts of fluorine-containing polyhydroxy polymer, 5 parts of chain extender dimethylthiotoluenediamine, and filler into the reaction kettle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com