Uniform coloring machine of fibers

A uniform and optical fiber technology, applied in the field of optical fiber uniform coloring machine, can solve the problems of damaging the aesthetics and affecting the application of optical fibers, and achieve the effect of avoiding uneven dyeing and improving dyeing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment the present invention is described in further detail, but structure of the present invention is not limited to following embodiment:

[0017] 【Example】

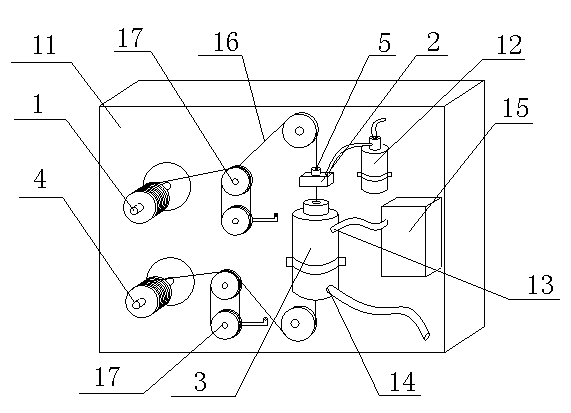

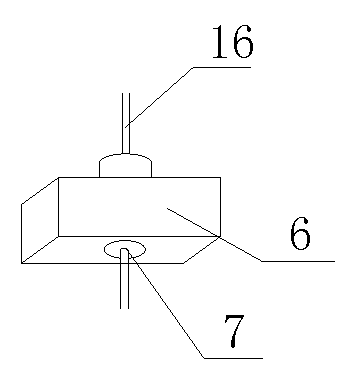

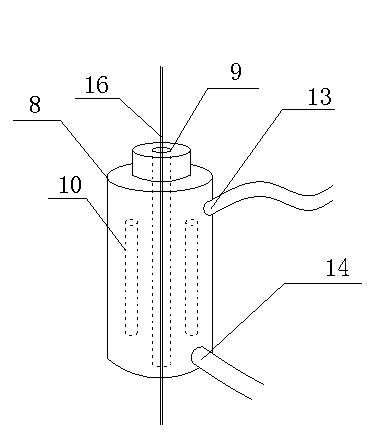

[0018] Such as Figure 1~4 As shown, the optical fiber uniform coloring machine includes a base 11 and a pay-off reel 1 installed on the base 11, a shader 2, a curing furnace 3, a take-up reel 4, and a color tank 12. The pay-off reel 1 , the shader 2, the curing furnace 3 and the take-up reel 4 are arranged in a ring, a tension regulator 17 is arranged between the pay-off reel 1 and the shader 2, and a tension regulator 17 is also arranged between the curing furnace 3 and the take-up reel 4 The tension regulator 17, the pay-off reel 1 and the take-up reel 4 are respectively installed on the support 11 through a motor.

[0019] Further, the above-mentioned tension regulator 17 includes a static turntable 18 and a moving turntable 19, the static turntable 18 is mounted on the machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com