Yarn humidifying machine and humidifying method thereof

A humidity control machine and yarn technology, applied in textiles and papermaking, liquid/gas/steam textile material processing, textile material processing, etc., can solve problems such as re-dyeing, inaccurate dye ratio, poor dyeing quality, etc. Achieve the effect of easy and uniform coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and examples.

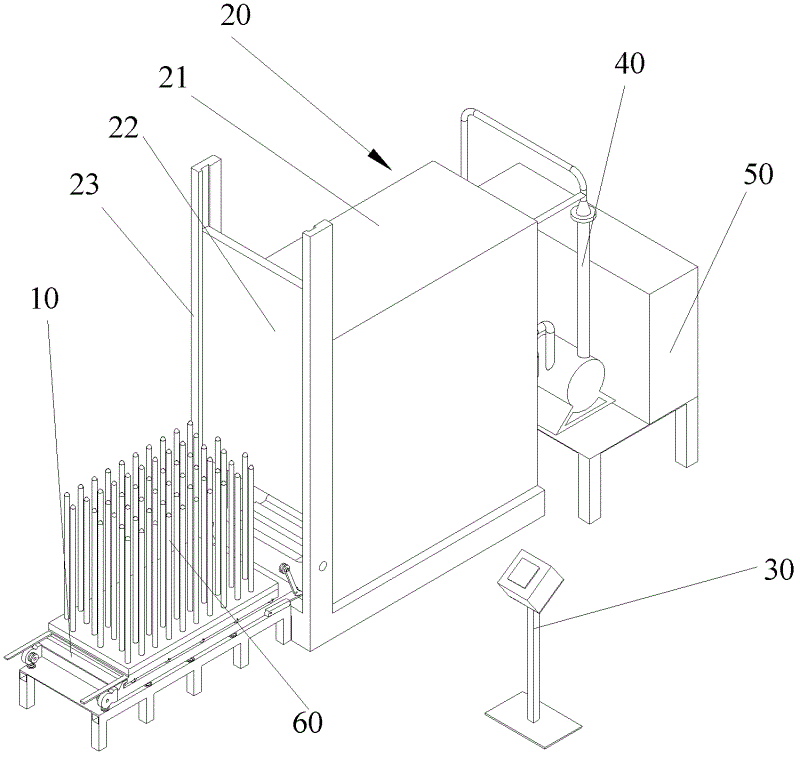

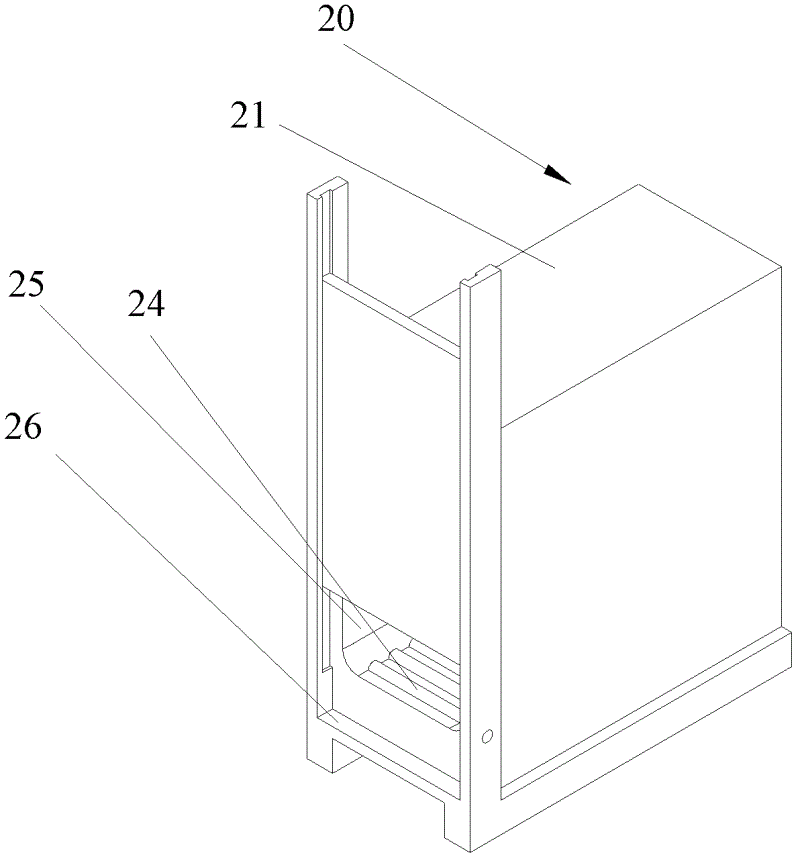

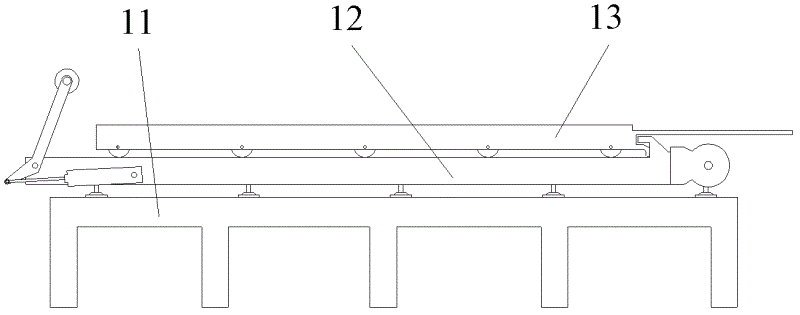

[0027] Such as figure 1 , according to the yarn humidity control machine of the present invention, comprising: a delivery system 10, the yarn 60 to be conditioned is set on the delivery system 10; a humidity control system 20, the yarn 60 is sent into the humidity control system 20 through the delivery system 10 Middle; the steam system 40 communicates with the humidity control system 20 .

[0028] According to an embodiment of the present invention, the yarn humidity conditioner is applied to package yarn dyeing, and the pallet frame filled with yarn rolls is transported to the conveying system 10, and the yarn rolls are sent into the humidity control system 20 through the conveying system 10, and the yarn rolls are sent to the humidity control system 20 after conditioning. The steam generated by the steam system 40 is fed into the wet system 20 to make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com