Lens optical film products

An optical film and product technology, applied in optics, optical components, optical components, etc., can solve the problems of slow discoloration time, high cost, difficult practical operation, etc., and achieve the effect of preventing detachment, preventing shedding, and avoiding uneven dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

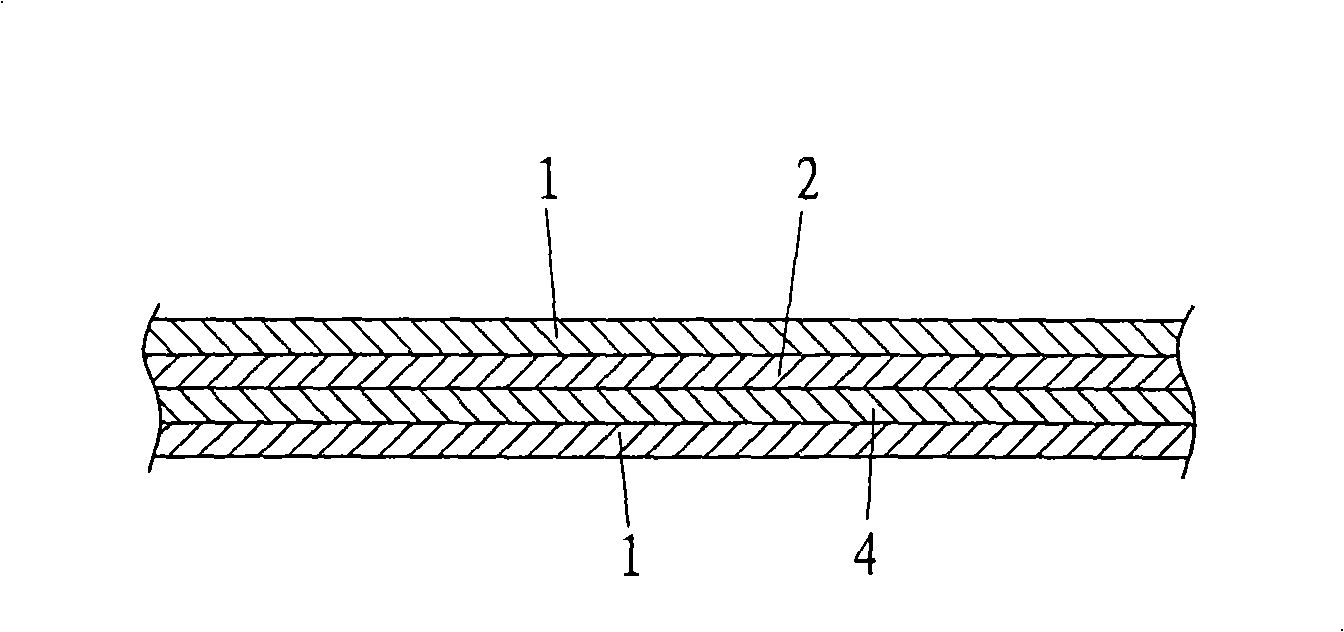

[0016] The first embodiment of the lens optical film product of the present invention is figure 2 As shown, it adopts laminating process, between two layers of TAC (Tri-acetate Cellulose, triacetate cellulose) layer 1, a layer of color-changing layer 2 and a layer of UV-absorbing material layer 4 are bonded, the color-changing layer 2 and The ultraviolet absorbing material layer 4 is a preformed film structure. Because the present invention does not adopt exhaust dyeing technology, it can prevent the phenomenon of uneven dyeing; and because the color-changing layer 2 and the ultraviolet-absorbing material layer 4 are sandwiched between the two TAC layers 1, decolorization can be prevented; moreover, independent The formed color-changing layer can control the color-changing time very well.

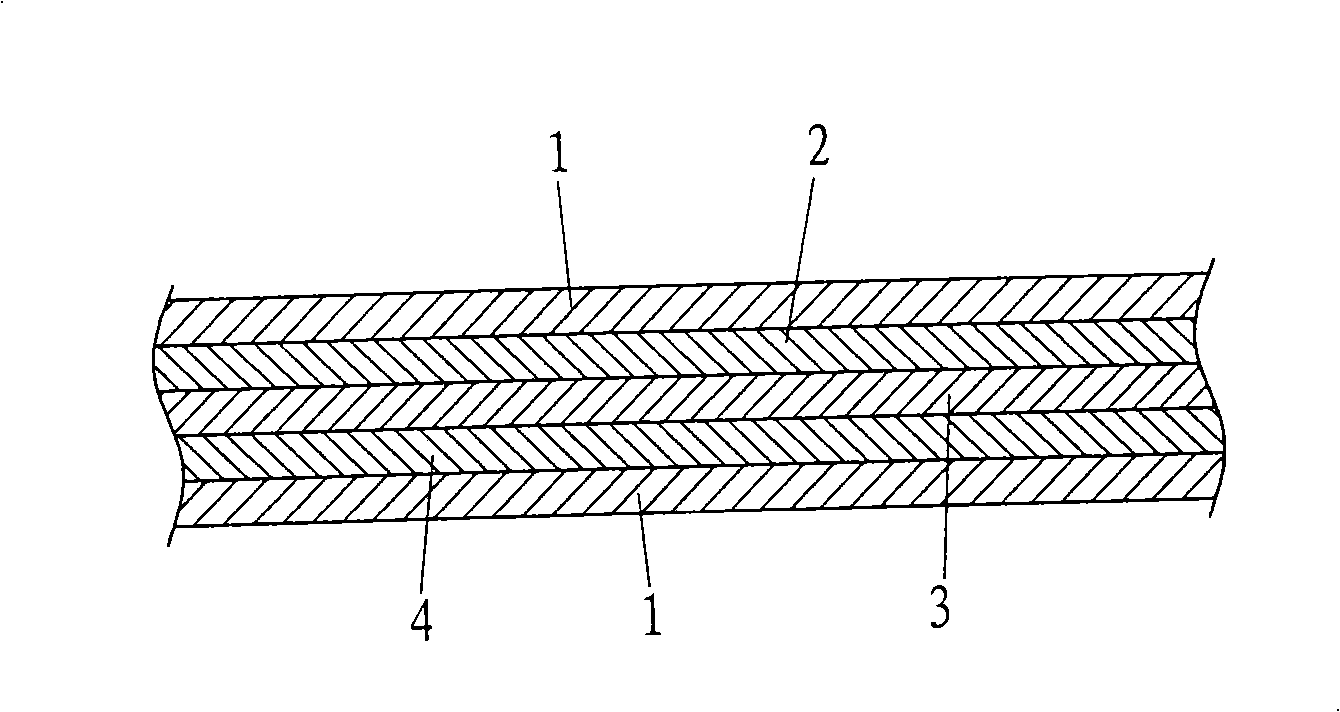

[0017] The second embodiment of the present invention is such as image 3 As shown, it also uses the bonding process to first bond the TAC layer 1 and the color-changing layer 2 together...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com