A gear with a special tooth profile curve

A tooth profile curve and gear technology, which is applied in the design field of special tooth profile curve gears, can solve the problems of sensitive center distance error, difficult processing, limited load capacity of gear pairs, etc., to achieve improved load capacity, less wear and tear, and small slip rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Relevant parameter among the embodiment 1 is:

[0023]

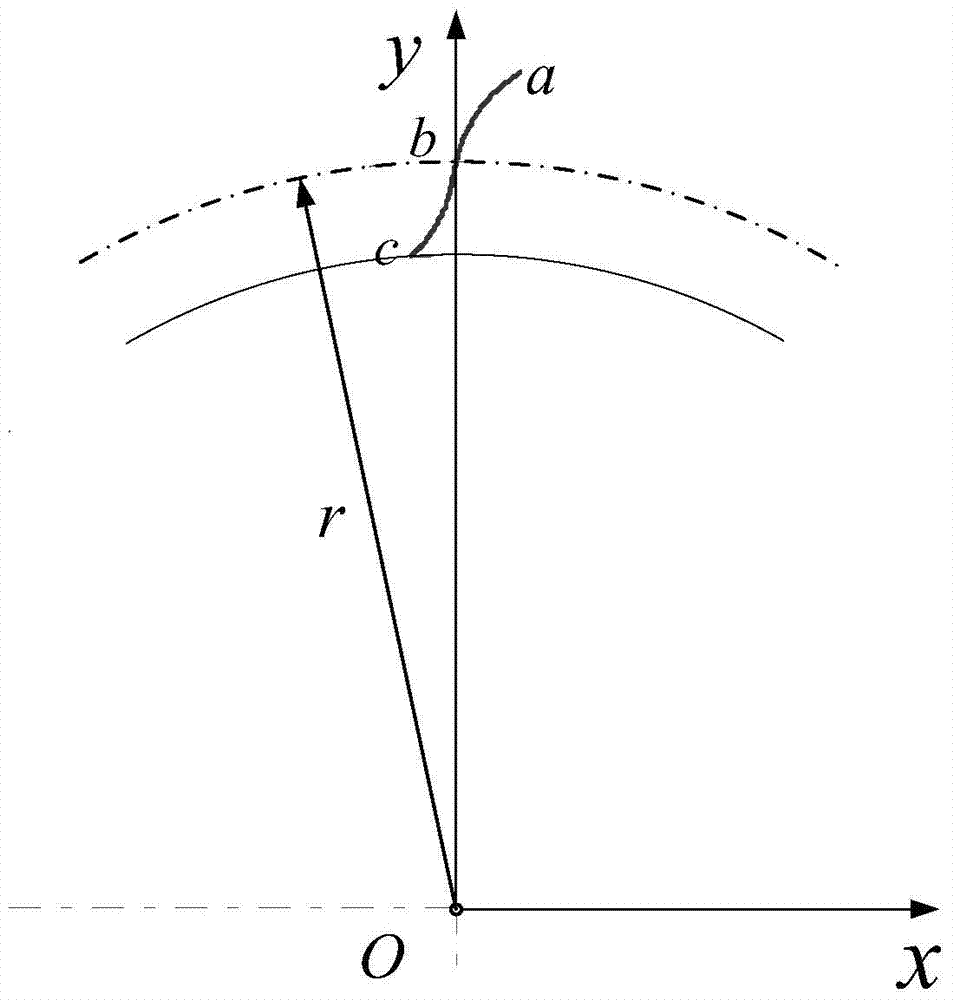

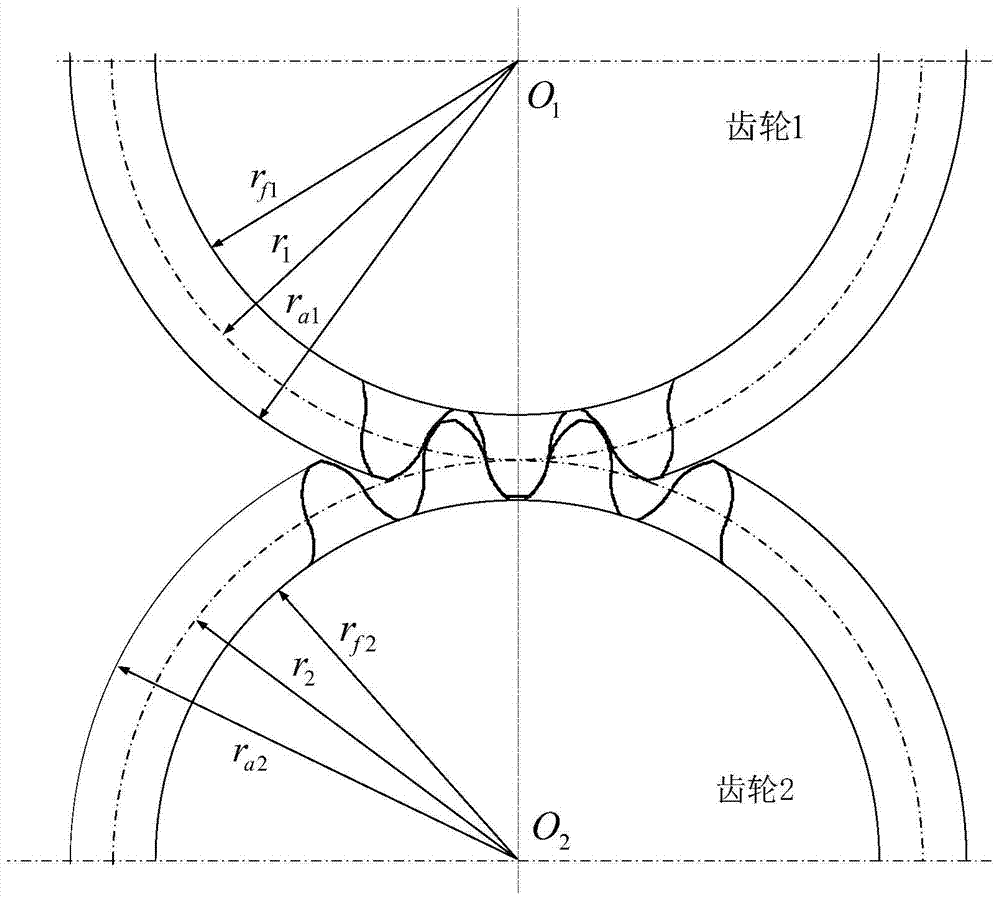

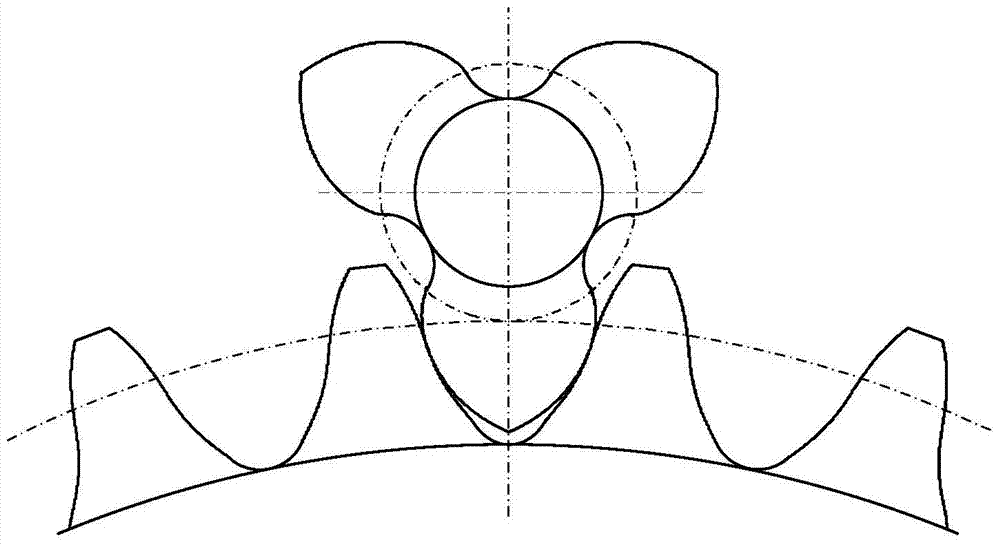

[0024] Substituting the above parameters into the parameter equation of the tooth profile curve can be obtained as follows: figure 1 As shown in the tooth profile curve, after the tooth profile curve undergoes symmetry and rotation transformation, the end face profile of the gear with convex and concave arc characteristics from the tooth top to the dedendum can be obtained. Using the above tooth profile curve parametric equations, it can be designed that can be mutually conjugated and is Gear pairs with convex and concave arc meshing, such as figure 2 shown.

[0025] Using the unique tooth profile curve parameter equation in the present invention, and selecting the corresponding design parameters, the gear with a special tooth profile curve can be obtained by designing the end face tooth profile curve of the gear. It is particularly emphasized that the derivative coefficient λ is introduced in the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com