Constant flow static pressure working table for gear shaping machine or gear milling machine

A technology of gear milling machine and gear shaping machine, which is applied in the direction of gear cutting machine, gear tooth manufacturing device, gear tooth, etc. problem, to achieve the effect of good vibration absorption performance, reduced power consumption, and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

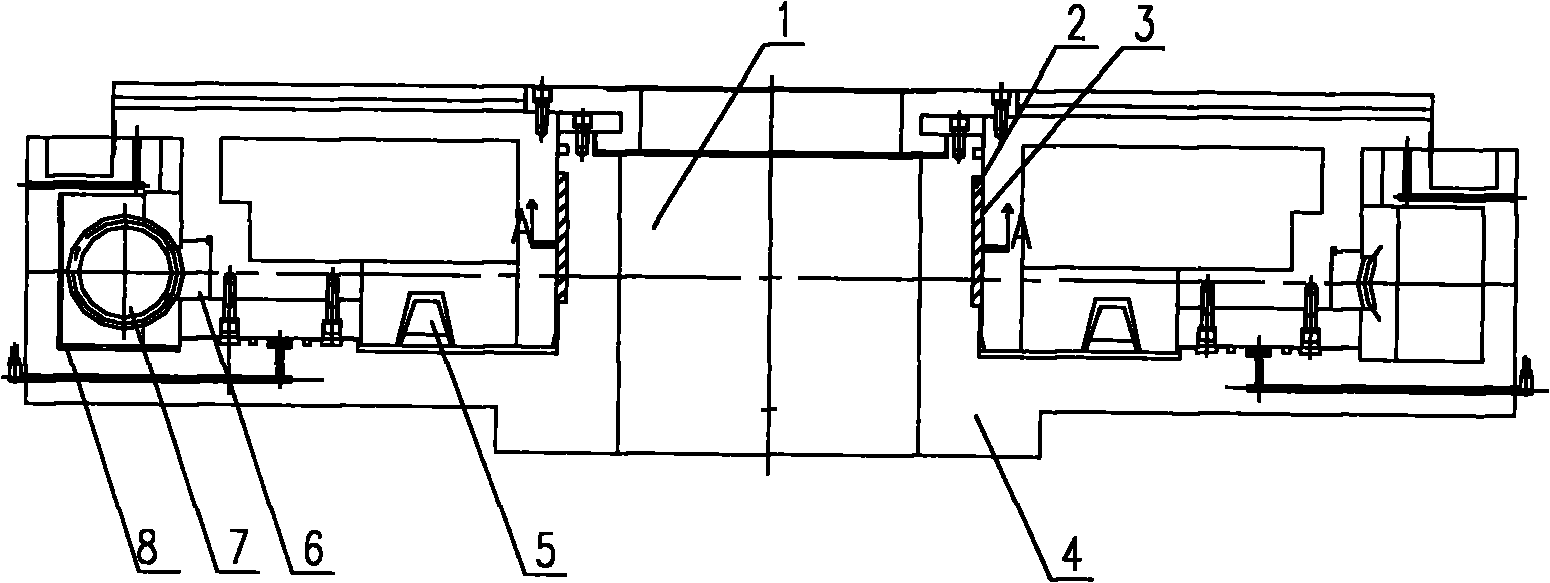

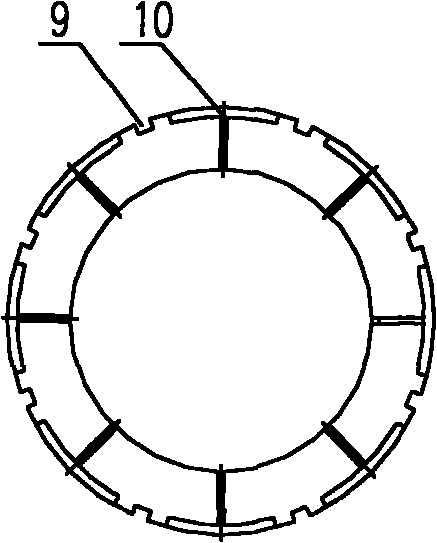

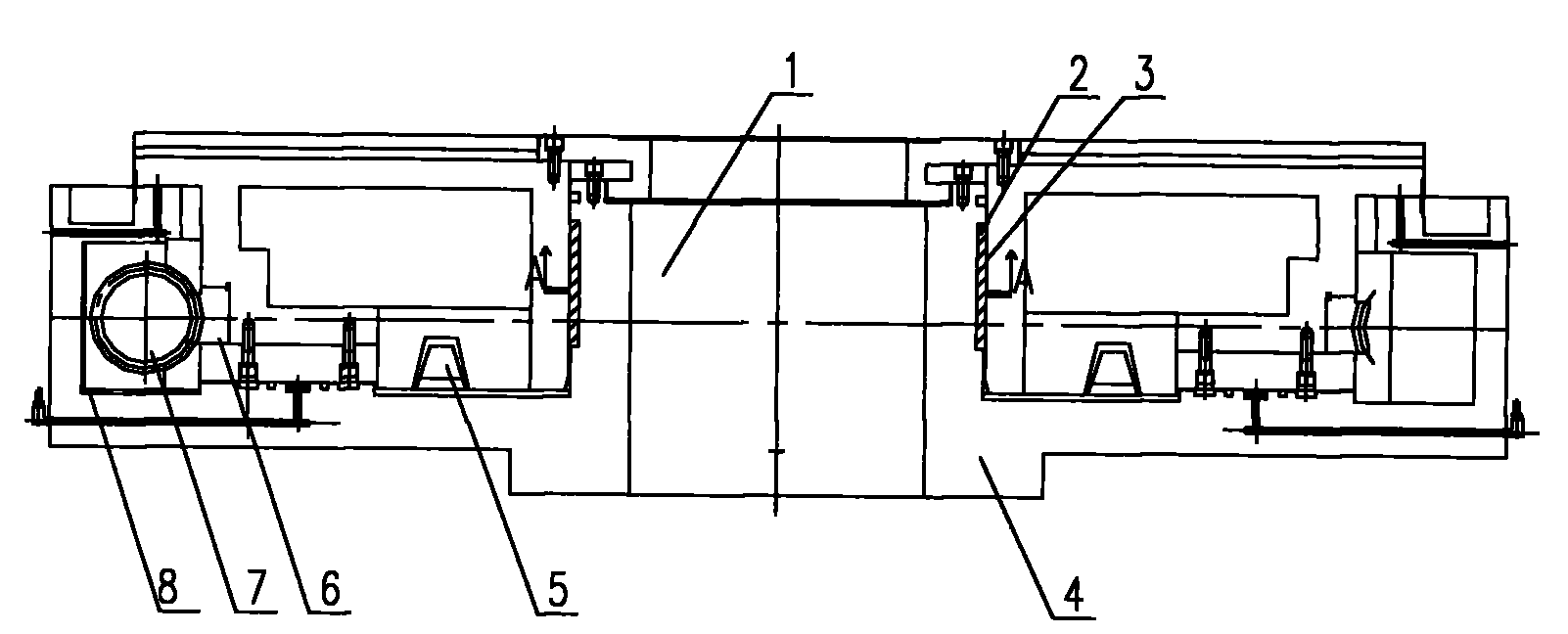

[0019] Such as figure 1 As shown, the constant-current hydrostatic workbench for a gear shaping machine or a gear milling machine includes at least a base 4, a shaft core 1 and a main shaft 3, the main shaft 3 is set outside the shaft core 1, and the main shaft 3 and the shaft core 1 are installed on a hollow base In 4, the shaft core 1 is cylindrical, and the gap between the shaft core 3 and the shaft core 1 is 0.02-0.15mm, that is, the gap between the inner cylindrical surface of the main shaft 3 and the outer cylindrical surface of the shaft core 1 is 0.02-0.15mm, and the shaft core 1 There are more than four rectangular static pressure chambers 2 on the outer surface, and the surroundings of the static pressure chambers 2 are oil-sealed edges, the width of which is 15-45 mm. The static pressure chambers 2 are equal in size and shape, and are evenly distributed on the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com