Display assemblies disposed inside mechanical keys in a mechanical keyboard

a technology of mechanical keys and display assemblies, which is applied in the field of mechanical keyboards, can solve the problems of compromising its applicability, affecting the use of mechanical keys, and limited operation life, and achieves the effects of less prone to wear and damage, easy assembly and manufacturing, and long operation li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

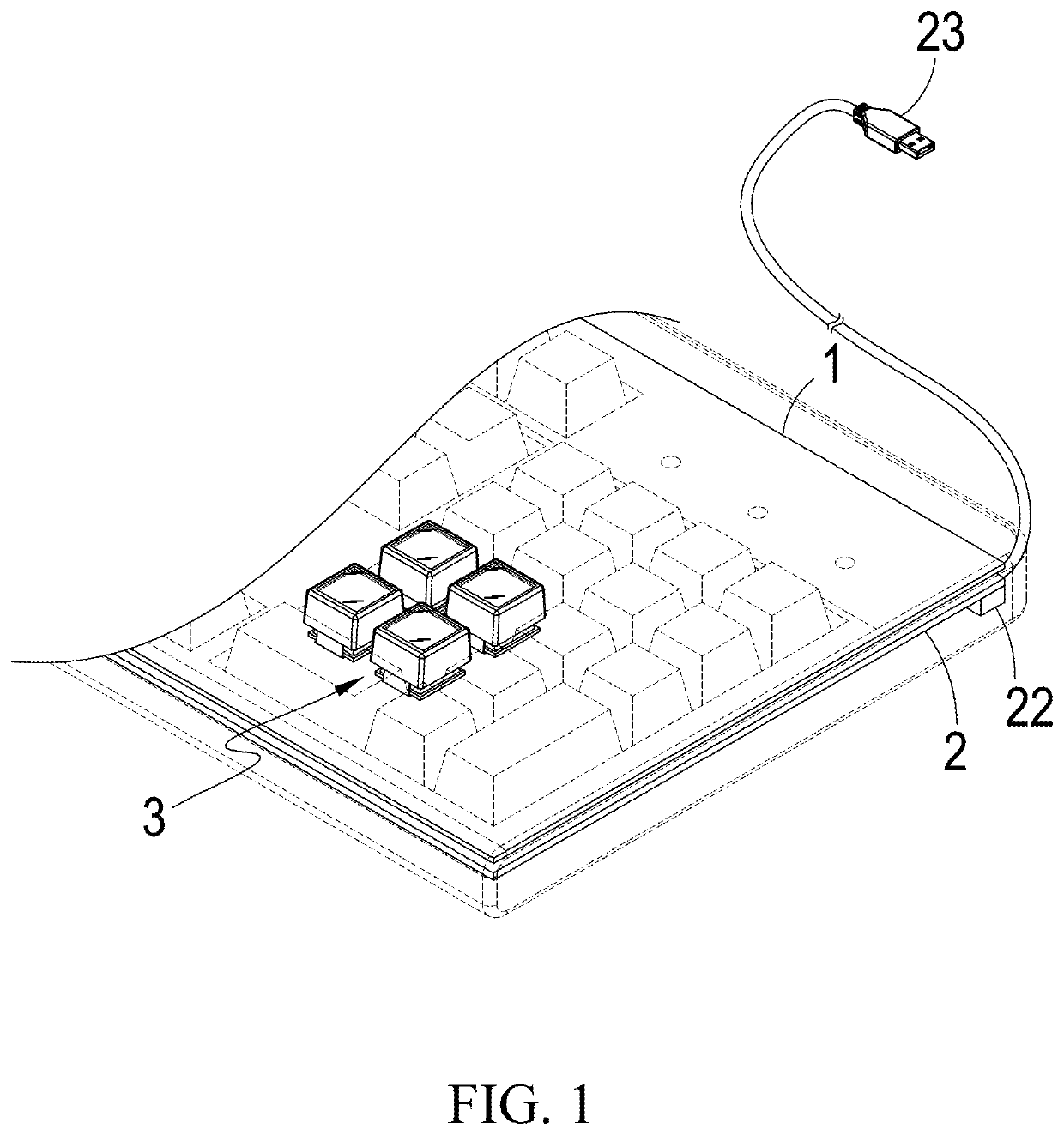

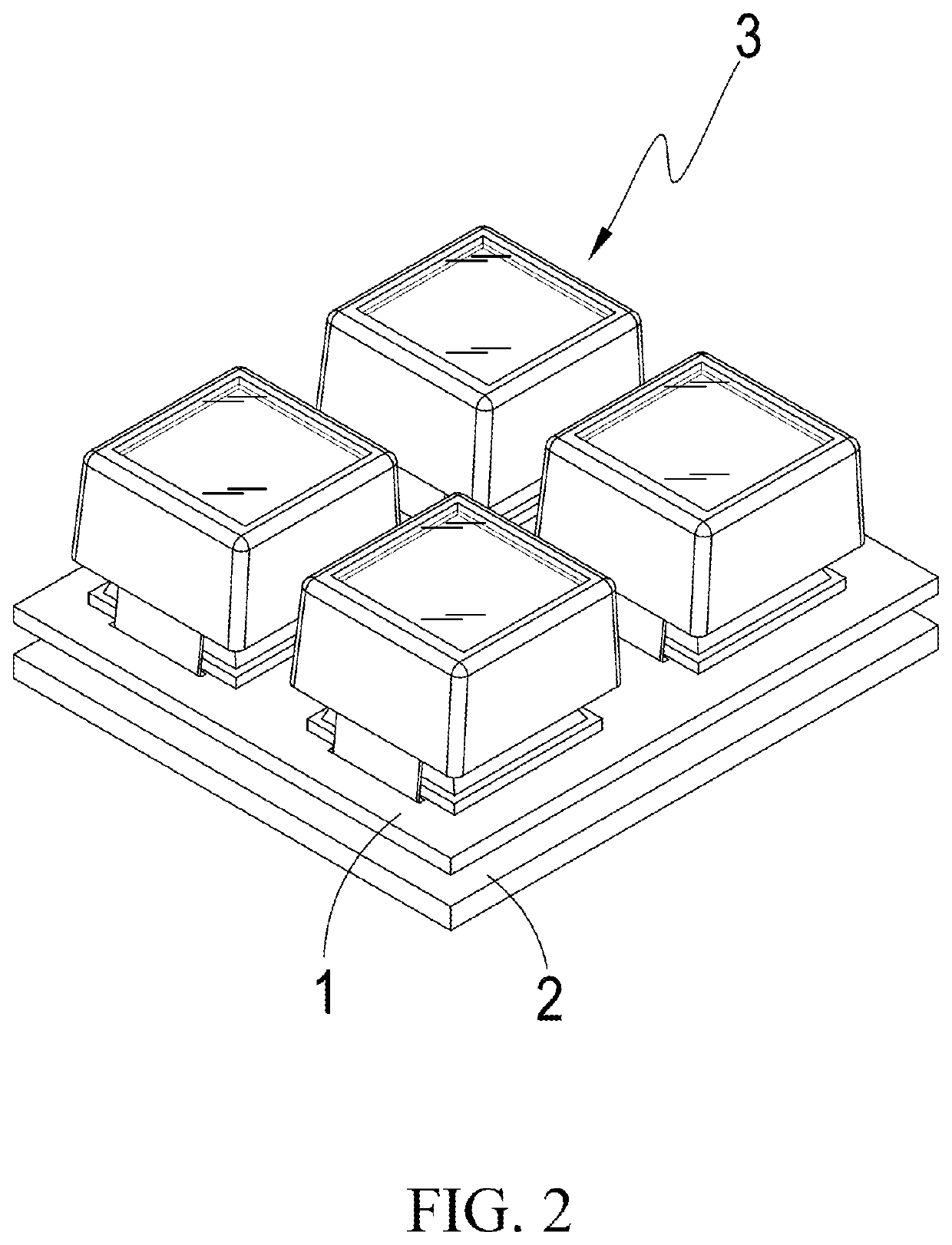

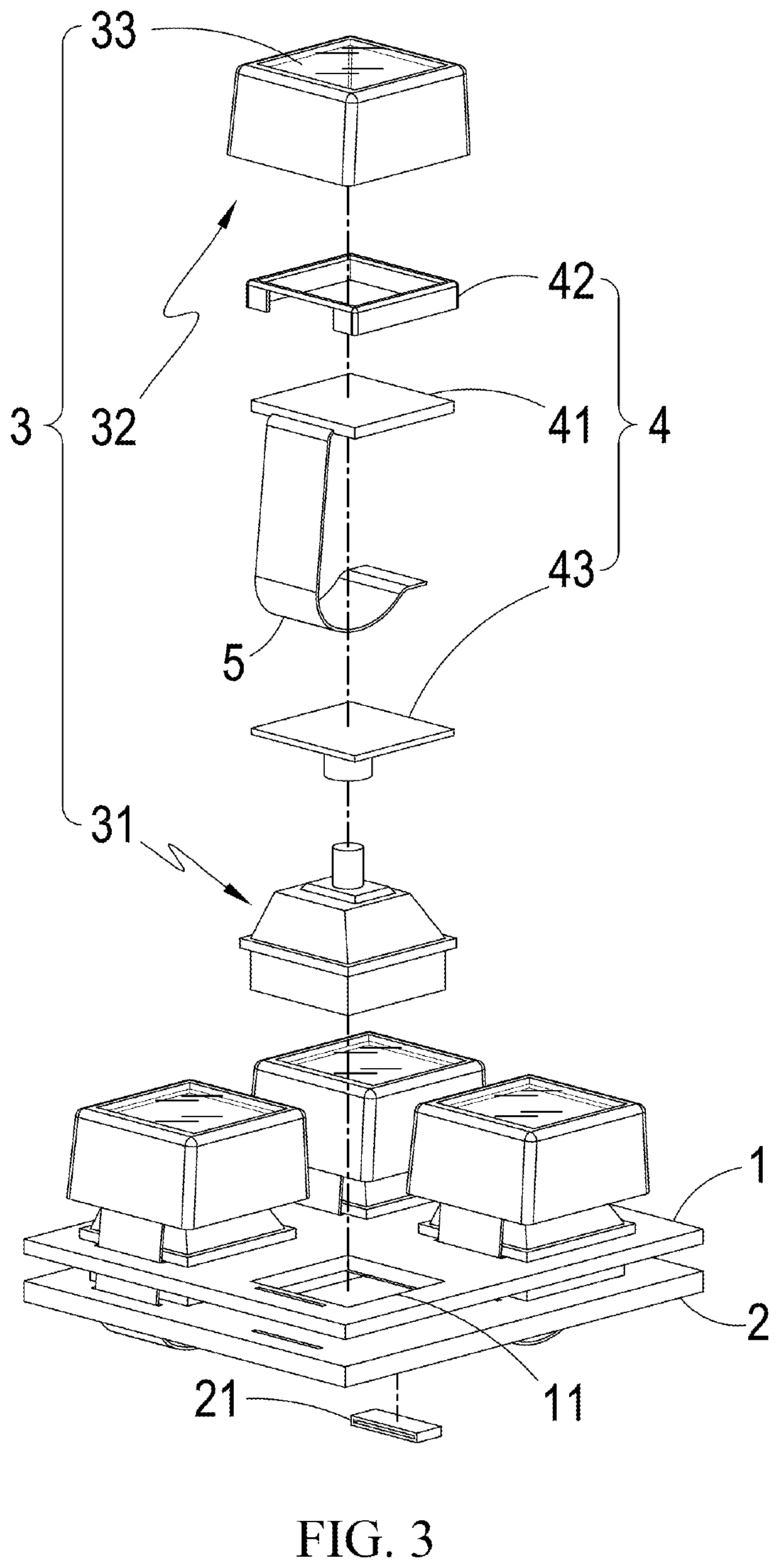

[0023]As shown in FIGS. 1 to 3, a mechanical keyboard according to the present includes a base plate 1, a circuit board 2, multiple mechanical keys 3, multiple display assemblies 4, and multiple signal transmission elements 5. The base plate 1 has multiple through openings 11. The circuit board 2 is disposed to a side of the base plate 1. Each mechanical key 3 is disposed at an opening 11 and connected to the circuit board 2 through the opening 11. Each display assembly 4 is disposed inside a mechanical key 3. Each signal transmission element 5 connects a display assembly 4 to the circuit board 2.

[0024]Each mechanical key 3 includes a keyswitch 31, a keycap 32, and at least a transparent piece 33. The keyswitch 31 is an ordinary mechanical switch connected to the circuit board 2 through an opening 11. The keycap 32 is mounted on the keyswitch 31 through a display assembly 4. The transparent piece 33 is configured to a top side of the keycap 32. It is also possible that the entire ke...

second embodiment

[0030]As shown in FIGS. 8 to 10, the present invention is similar to the previous embodiment except that each frame 42a has a number of notches 421a along bottom edges and a number of slots 422a on circumferential walls of the frame 42a. Each keycap 32a has protrusion 321a on inner walls, each corresponding to a notch 421a. On the other hand, each base 43a has a number of blocks 431a along its circumference, each corresponding to a slot 422a. Through the engagement between the notches 421a and the protrusions 321a, each frame 42a is more reliably positioned in a keycap 32a. Similarly, through the engagement between the slots 422a and the blocks 431a, each base 43a, and therefore each display module 41a, is more reliably coupled to a frame 42a.

third embodiment

[0031]FIG. 11 shows the present invention. As illustrated, the present embodiment is similar to the previous embodiments except that each keycap is the transparent piece 33b itself In other words, the transparent pieces 33b may have various embodiments as long as it may allow a user to view the display modules 41b clearly and conveniently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com