Single-draw-bar traction device and engine applying same

A traction device and single tie rod technology, applied in transportation and packaging, railway car body parts, bogies, etc., can solve the problems of high manufacturing cost, difficulty in passing curves and ramps, limited length of single tie rod, etc. The effect of maintenance cost, good curve and ramp passing performance, reduction of assembly and disassembly workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The core of the present invention is to provide a single-rod traction device. Through structural optimization design, the single-rod traction device has the characteristics of simple and reliable structure, easy disassembly and assembly, and can effectively control manufacturing and maintenance costs. The present embodiment will be described in detail below in conjunction with the accompanying drawings.

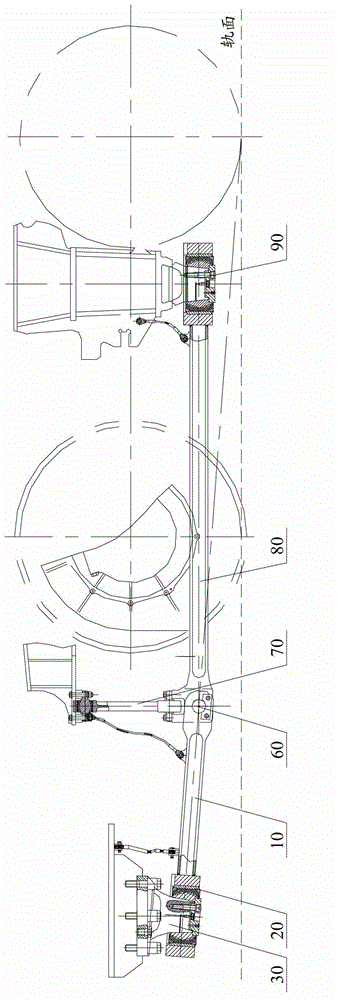

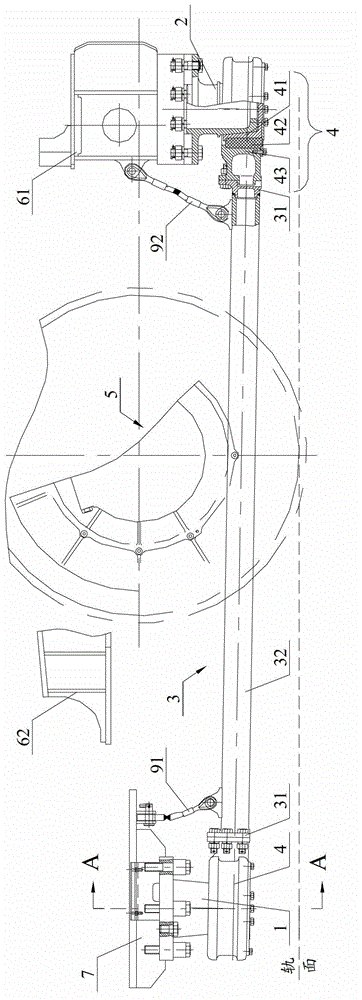

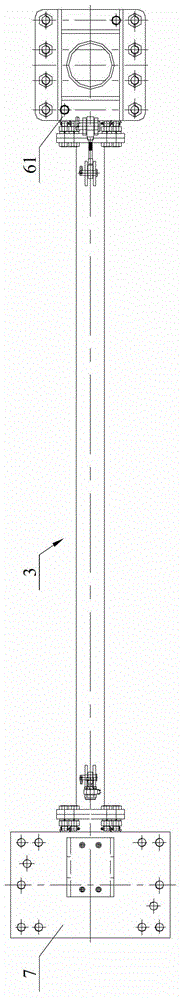

[0034] See figure 2 with image 3 ,in, figure 2 It is a schematic diagram of the overall structure of the single-rod traction device described in this embodiment, image 3 yes figure 2 top view.

[0035] Such as figure 2 with image 3 As shown, the traction device is a single-rod structure, and the rod body is located below the motor 5 and installed between the first beam of the frame (ie, the traction beam 61 of the bogie) and the vehicle body 7 . Among them, the vehicle body fifth wheel 1 is fixed on the car body 7, and the frame fifth wheel 2 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com